What's in Your Box?™

VVT Program

Standard® VVT components offer advanced engineering and manufacturing paired with the most comprehensive coverage in the aftermarket for a VVT program that is second to none.

3 Things To Know

600+ Components

The most comprehensive VVT line in the aftermarket now features more than 600 VVT Solenoids, Sprockets and Kits.

Precision Engineering

Advanced engineering and manufacturing deliver premium-quality VVT components.

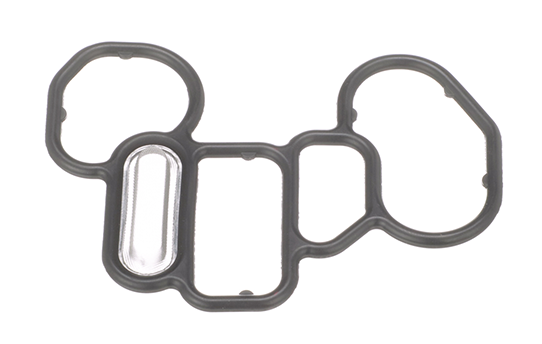

Gaskets Included

Many Standard® and Blue Streak® VVT components include gaskets for an easier installation.

Standard® Has Variable Valve Timing Covered

Coverage

Comprehensive Coverage

With more than 600 SKUs, the Standard® Variable Valve Timing (VVT) program is the most comprehensive in the aftermarket. The Standard® VVT program includes VVT Solenoids, Sprockets, Oil Control Valves, Service Kits, and more.

- Many Standard® and Blue Streak® VVT components include gaskets for easy installation.

Market

Growing Market

In an effort to increase fuel efficiency and elevate performance, nearly every manufacturer has equipped new vehicles powered by internal combustion engines (ICE) with Variable Valve Timing (VVT) technology. Time-in-service and oil quality both affect VVT components and eventually cause the need for replacement. The longer the system is in use, especially on today’s vehicles with longer oil change intervals, the more likely the VVT system is to fail.

- Nearly 100% of vehicles are equipped with VVT.

- In the next 5 years, 76 million more vehicles with Variable Valve Timing will enter the Aftermarket “Sweet Spot” (6-12 years old) during which their VVT sprockets and solenoids may need to be serviced or replaced.

Vehicles Equipped with VVTs

Service Opportunities

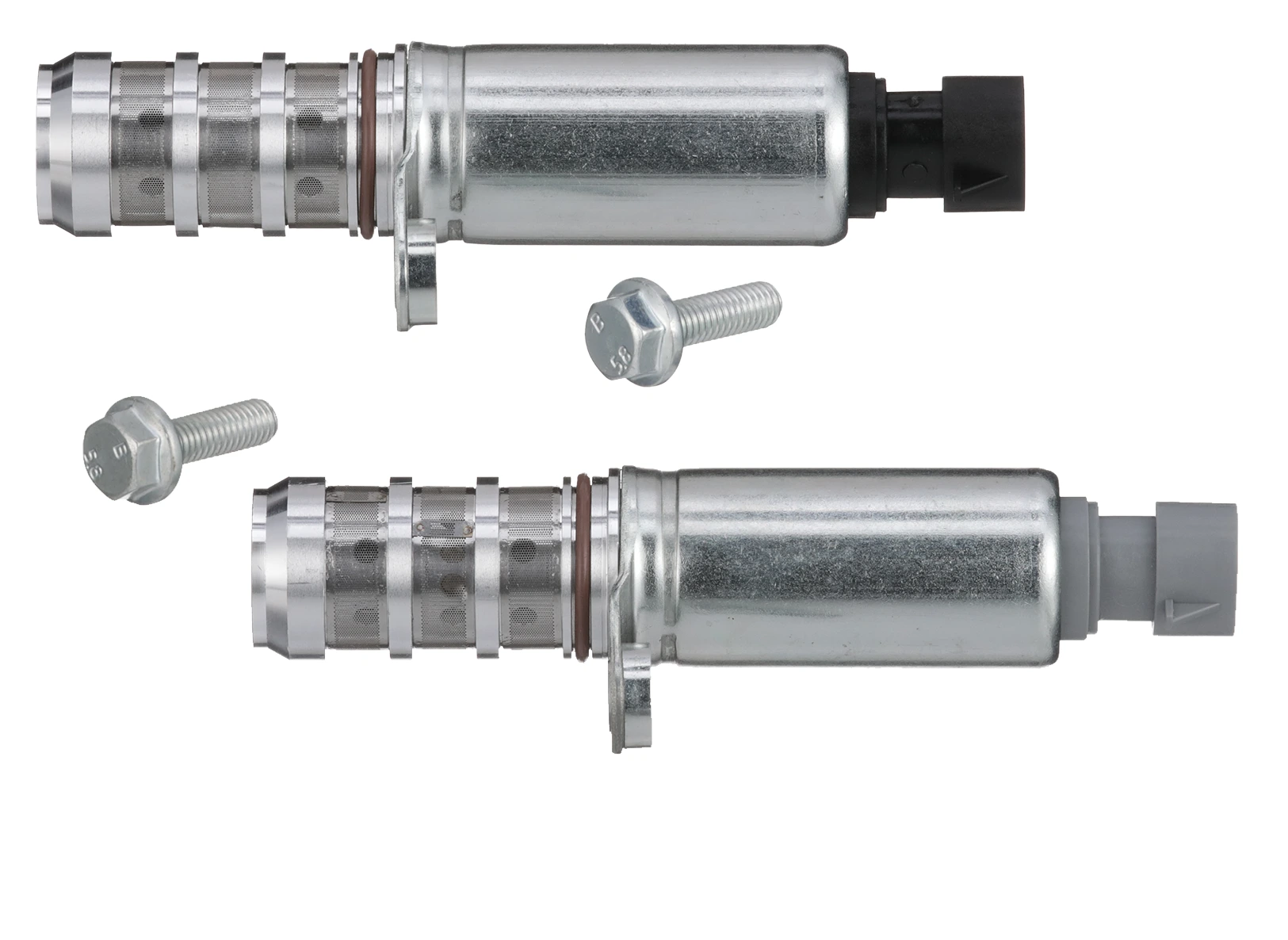

Service Opportunities

The GM 2.4L and Toyota 3.0L / 3.3L engines are known to have high failure rates for VVT solenoids. We have these applications covered with complete solenoid kits that include improvements over the OE design. Blue Streak® VVT solenoid kits include both solenoids for a complete service and are even color-matched to the OE eliminating the chance of installing the VVT in the wrong location.

- Blue Streak® VVT Kits include two premium Solenoids with quality O-rings and gaskets to help prevent oil leaks.

Years: 2017-06

Make: GM

Engine: 2.4L

Common DTCs: P0011, P0014, P0016, and P0017

Symptoms: Rattling noise at startup, unstable idle

Solution: Change the engine oil and filter during maintenance intervals and following VVT solenoid replacement

Parts for the job: VVT2000K

Years: 2008-99

Make: Lexus / Toyota

Engines: 3.0L and 3.3L

Common DTC: P1354

Symptoms: Rough idle

Solution: Maintain regular engine oil change intervals. When replacing the solenoids, replace the engine oil and filter

Parts for the job: VVT2001K

Engineering & Design

Engineering

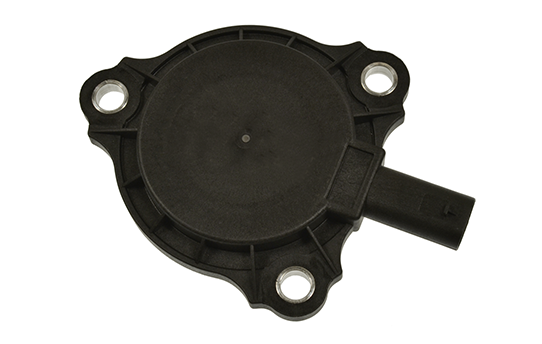

Standard® and Blue Streak® VVT components are direct-fit OE replacements designed to restore engine horsepower and torque curves, reduce emissions, and improve efficiency.

Premium parts start with premium components. Each Blue Streak® VVT component is engineered with design improvements to ensure durability and performance under the most extreme conditions.

- Blue Streak® VVT Solenoids and Sprockets include design improvements for increased durability and gaskets for easy installation.

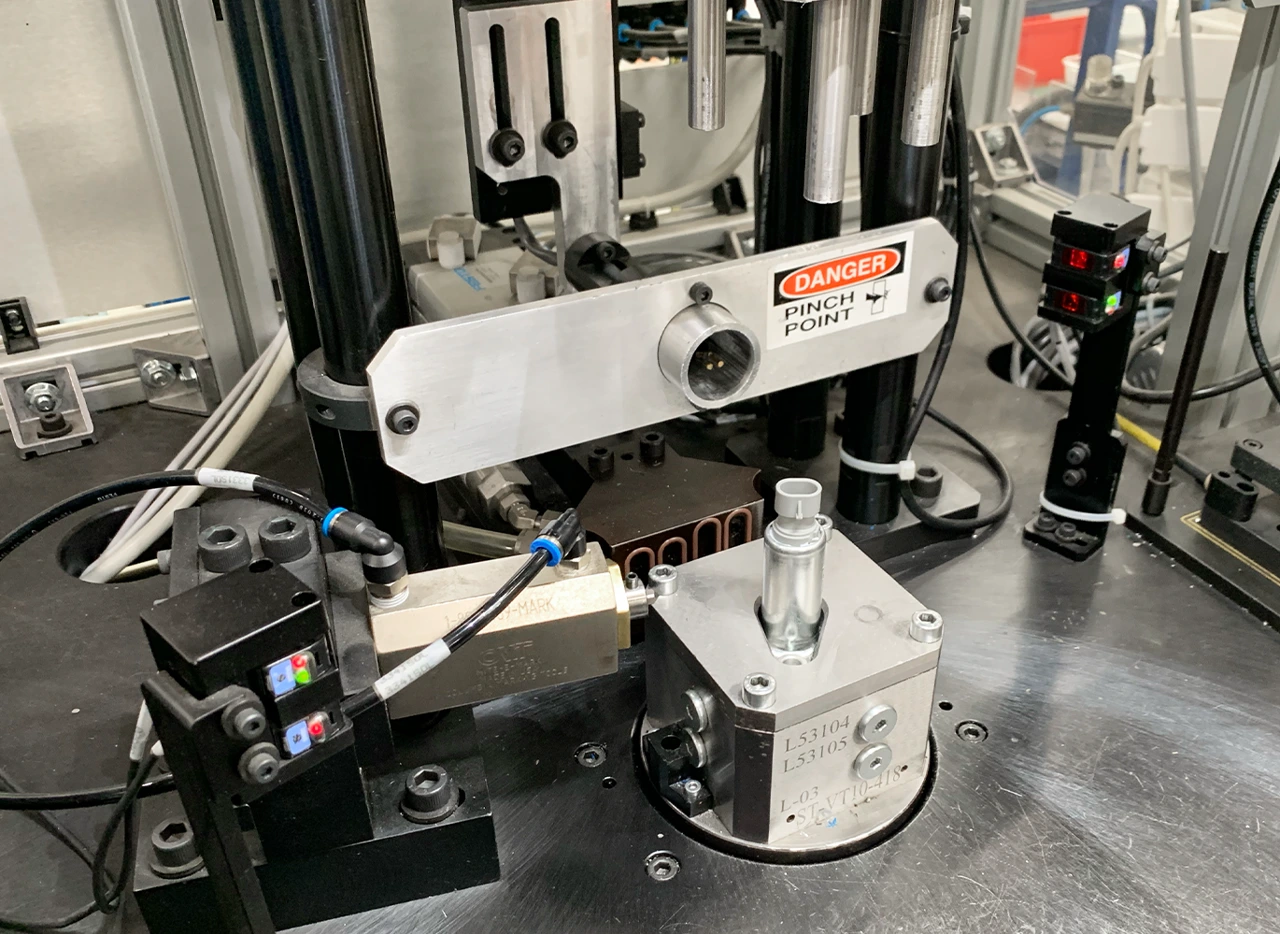

Manufacturing

Precision Manufacturing

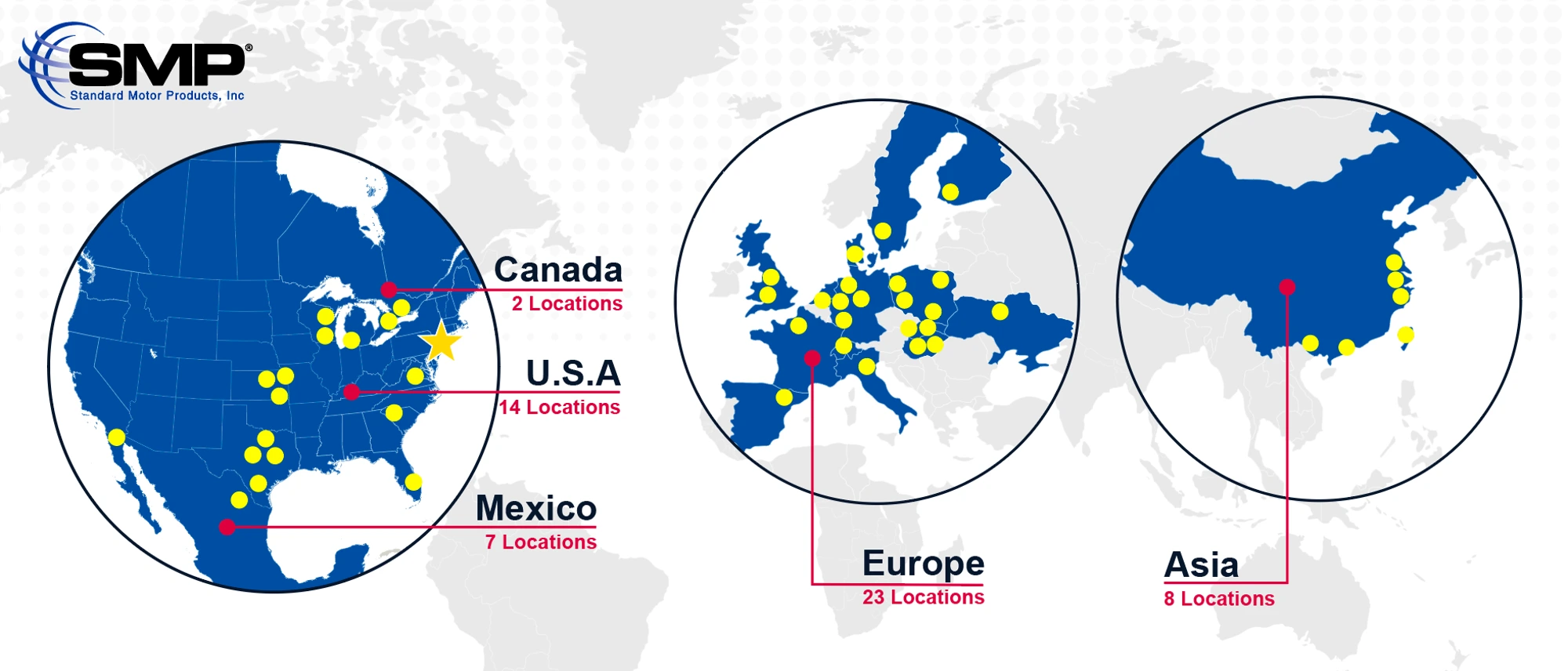

Standard® and Blue Streak® VVT Solenoids and Sprockets are designed and manufactured at our IATF 16949-certified facility in Bialystok, Poland.

Spanning 145,000 square feet, our most advanced facility has more than 750 employees including 60+ resident engineers.

- Our dedication to continuous improvement practices in design, engineering, and manufacturing allows us to make enhancements to the OE design while maintaining complete control over each Blue Streak® VVT component.

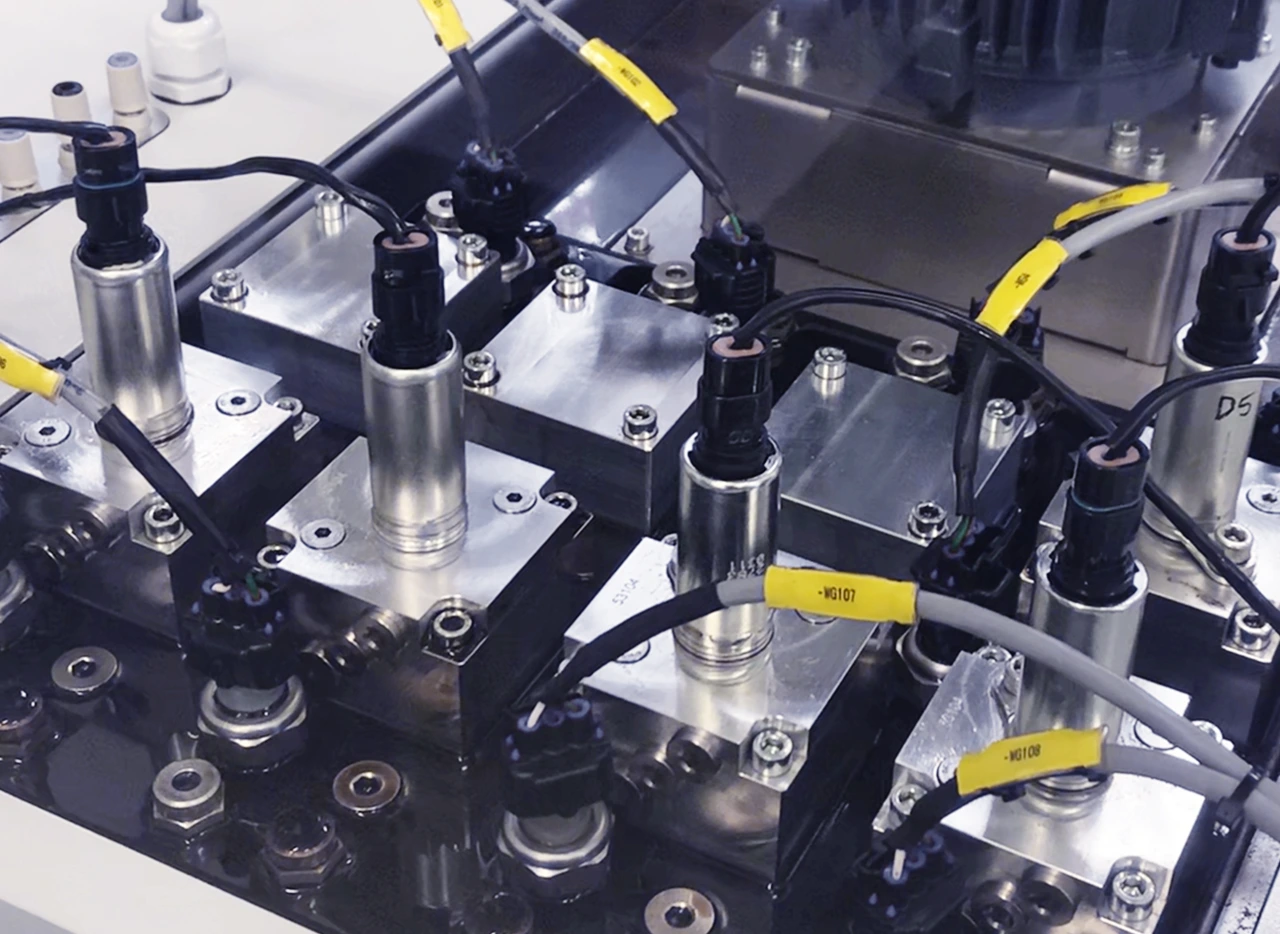

Testing & Validation

Testing & Validation

Standard® and Blue Streak® VVT Solenoids and Sprockets undergo extensive measurement and life testing, plus a full spectrum of environmental analysis. This regimen includes thermal shock, thermal cycling, salt spray, vibration, storage tests, dirty oil tests, and more.

New VVT Components are also tested and validated on real cars at our Vehicle Testing Center in Texas. The result is a line of premium VVT components that perform flawlessly and stand up to real-life conditions.

- In addition to a full regimen of testing and analysis, each VVT component undergoes on-vehicle validation to ensure that they integrate correctly and match designed performance in all conditions and across the RPM range.

Better Design, Better Materials, Improved Durability

Design

Design Improvements for Durability

Variable Valve Timing systems in modern engines are increasingly complex, and each component in the system must perform consistently in every condition. Blue Streak® by Standard® components feature design enhancements to optimize lubrication, for faster-responding and longer-lasting Solenoids.

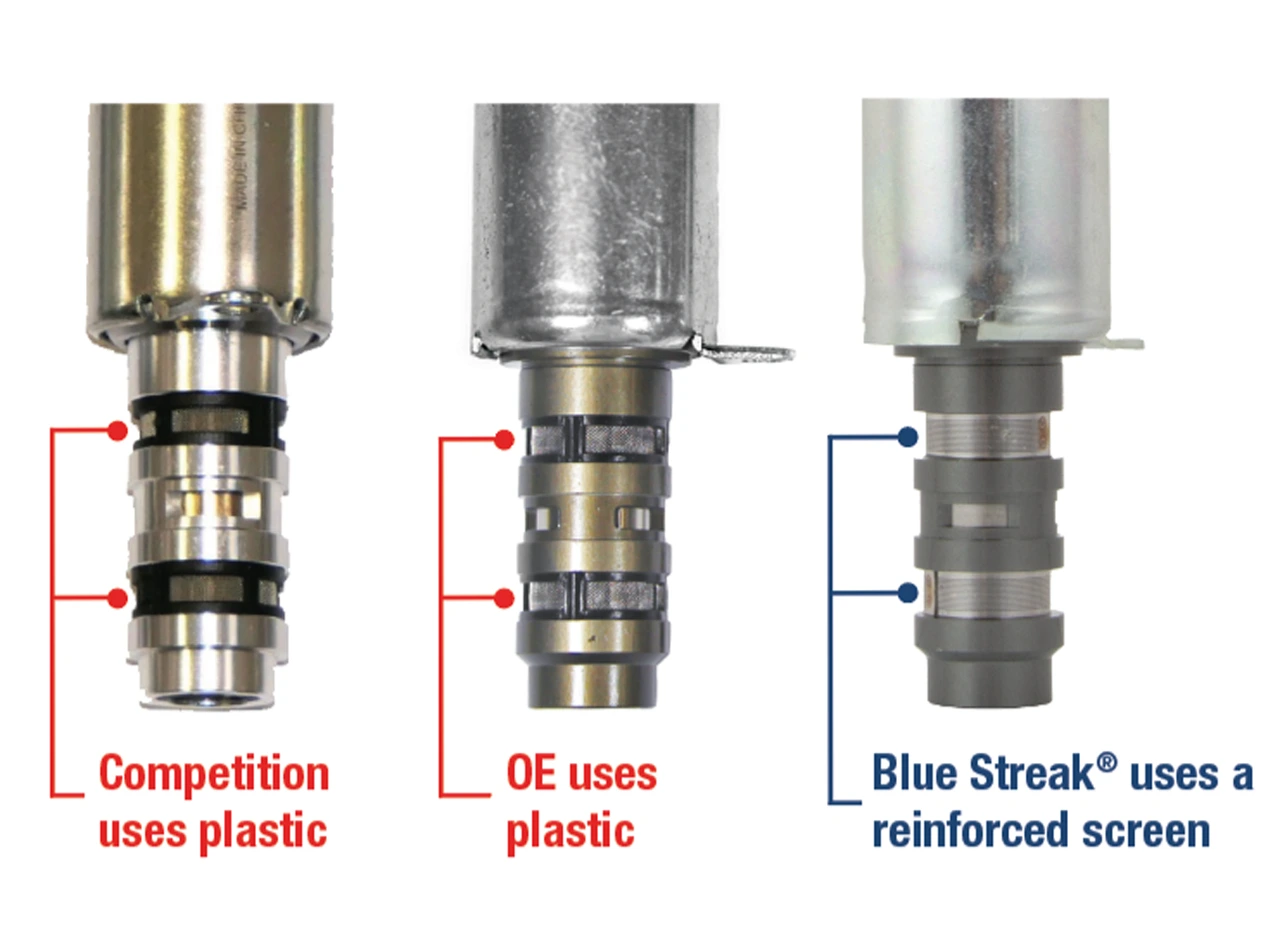

Oil Screen

Improved Screen Stamp

OE and Competitor Problem: The oil screen gets clogged or starts to separate because the plastic on the screens degrades over time.

Blue Streak® Solution: Our VVT Solenoids feature a welded, metal screen which stays intact and is able to correctly filter and manage oil flow.

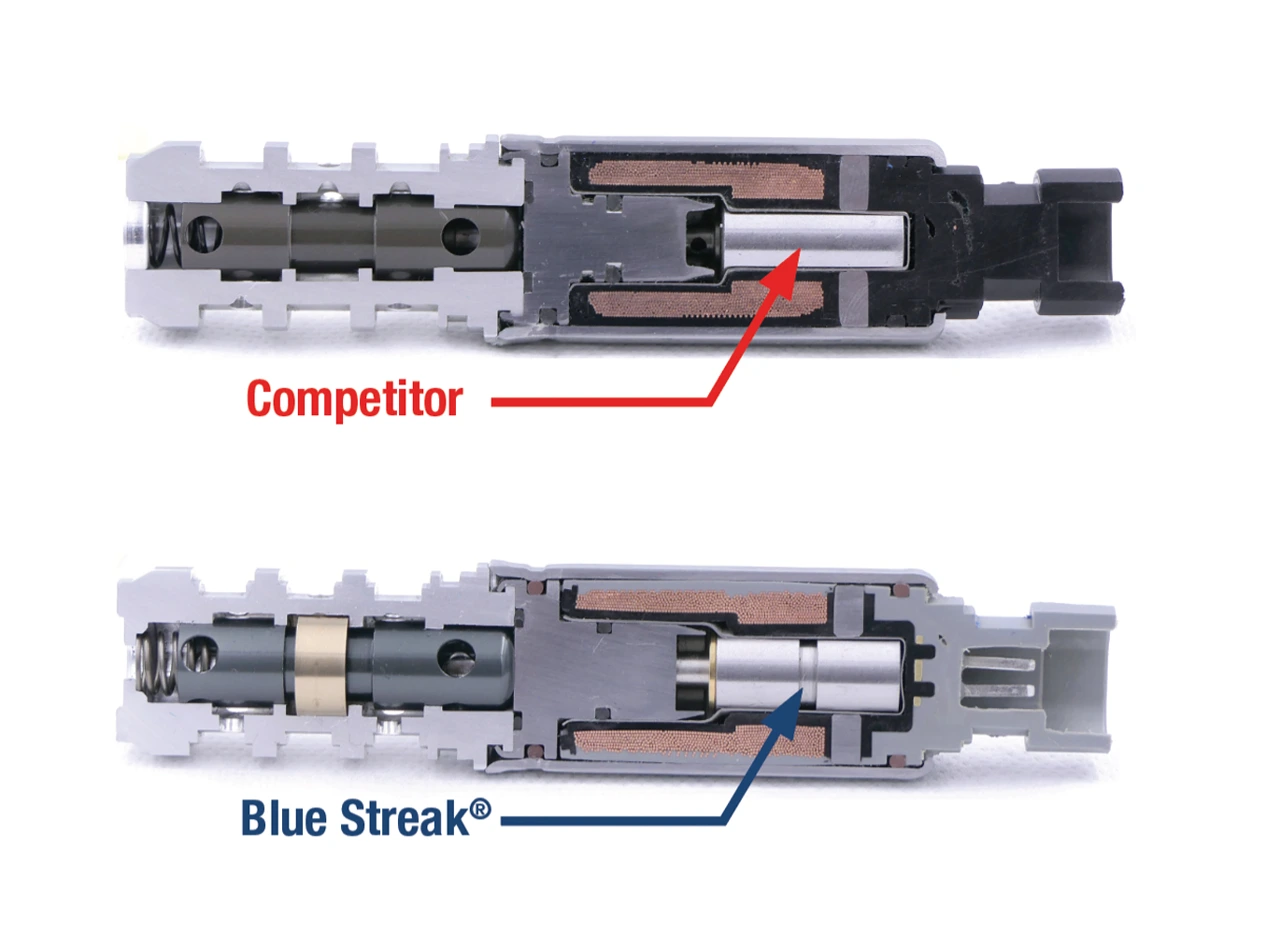

Lubrication

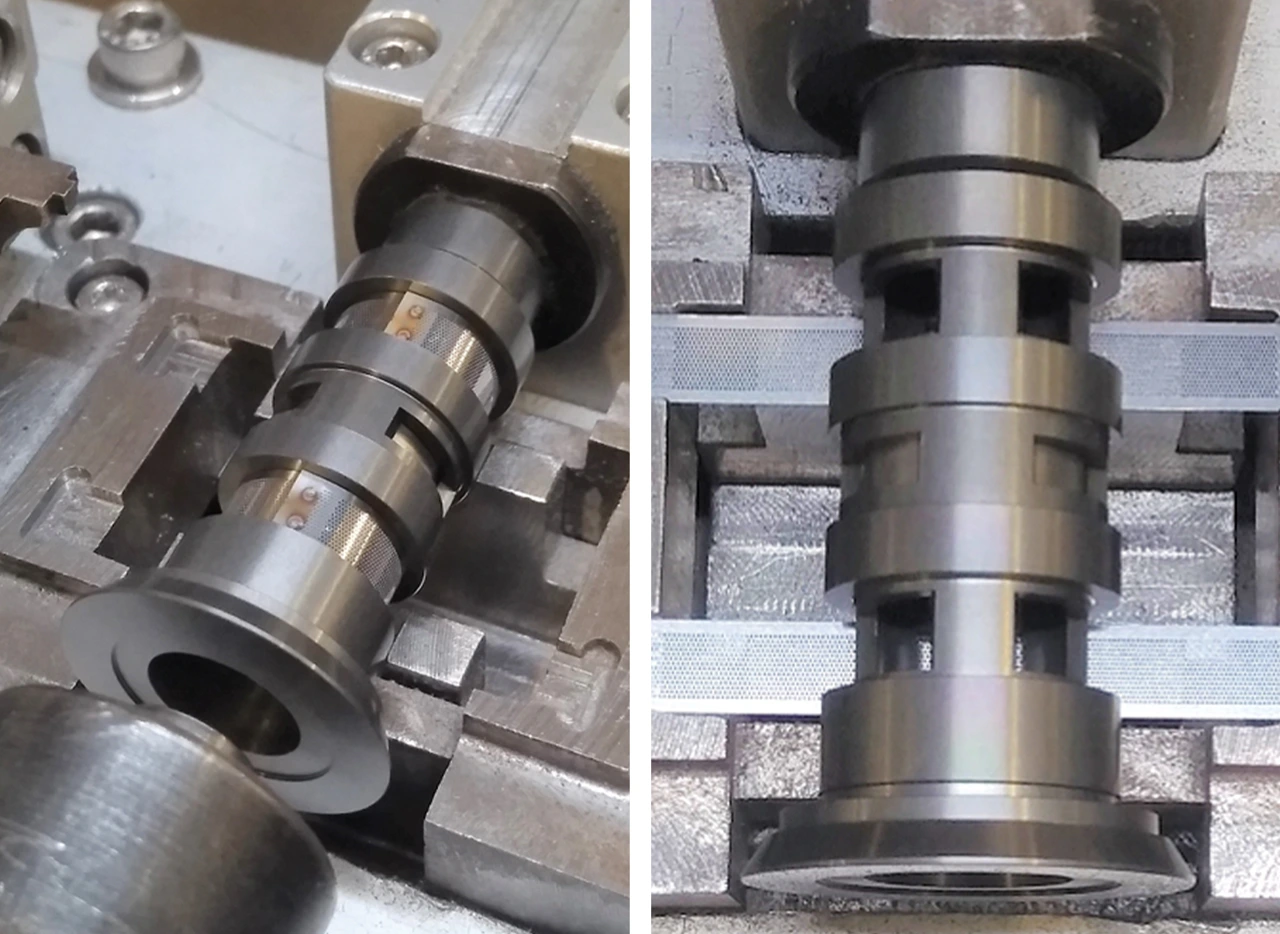

Groove Armature for Lubrication

Competitor Problem: The solenoid responds slower, and eventually internal components fail due to a lack of lubrication.

Blue Streak® Solution: Our VVT Solenoids feature a lubrication groove on the armature, allowing for faster valve switching and decreased wear of internal components.

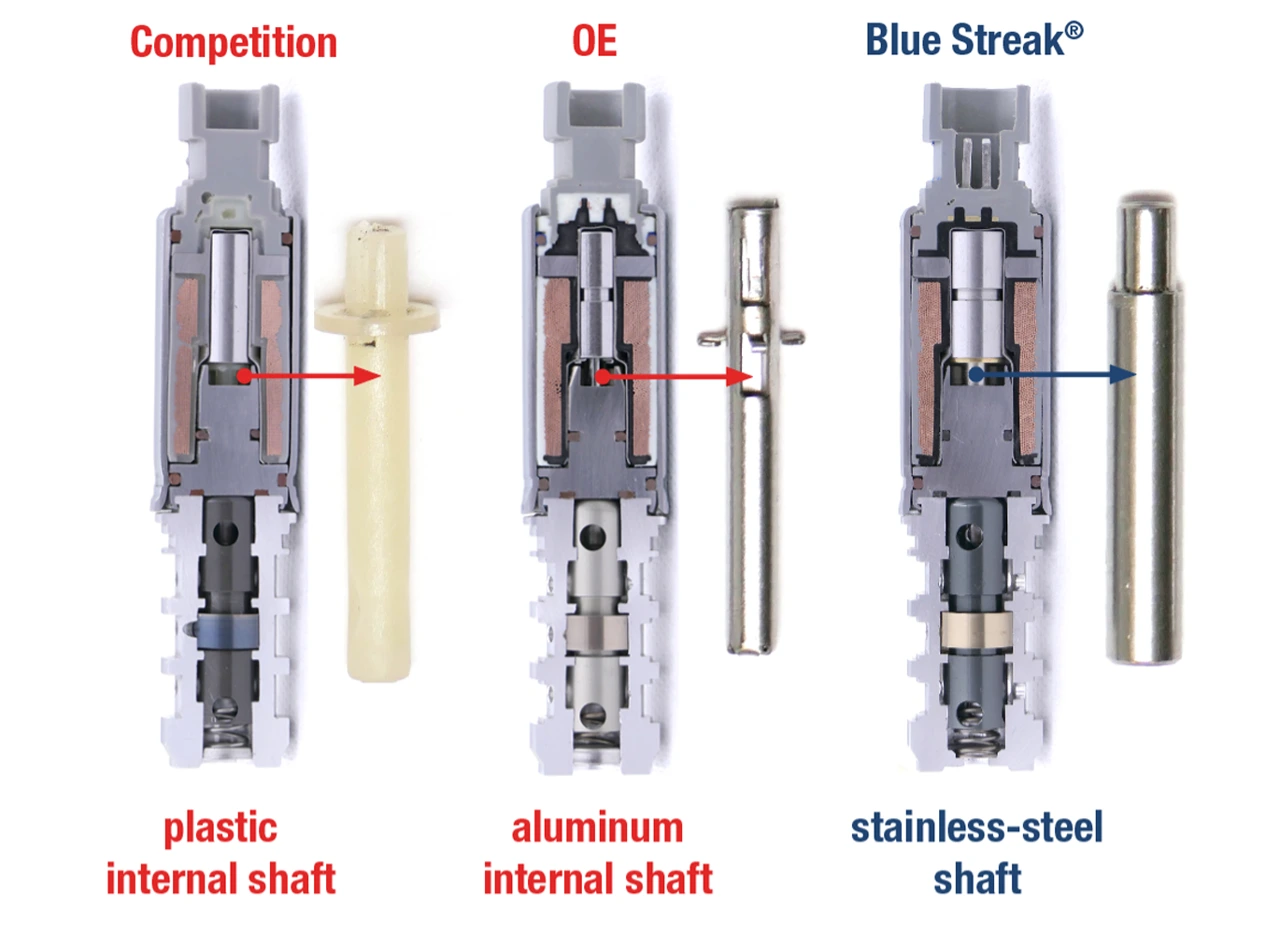

Internal Shaft

Stainless-Steel Shaft

Competitor Problem: The internal shaft cracks, resulting in a failed solenoid, this is because the competitor uses a plastic internal shaft.

OE Problem: Overtime, the response of the solenoid becomes less consistent as the aluminum internal shaft becomes distorted over time.

Blue Streak® Solution: Our VVT101 uses a stronger, stainless-steel shaft for consistent performance and durability.

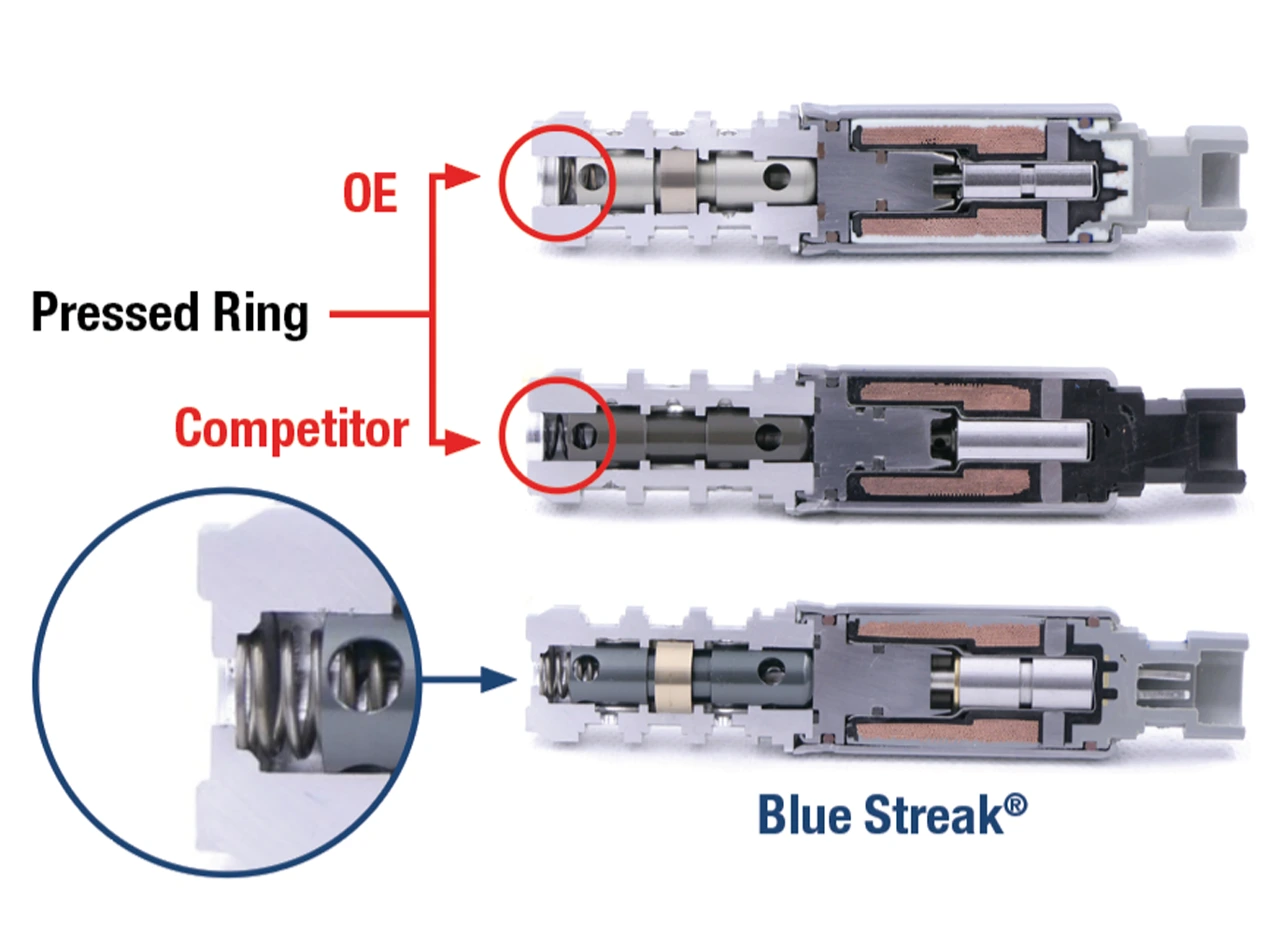

Spring Support

Closed Valve Body for Spring Support

OE and Competitor Problem: The solenoid fails because the internal spring that pressed into place falls apart after thousands of heat-cycles.

Blue Streak® Solution: Our VVT Solenoids feature one-piece closed valve body for spring support, with no chance of falling apart, even after millions of valve switches and heat cycles.

VVT Categories

Technicians look to Standard® for the parts required to do the job right. From VVT Solenoids and Sprockets to Spool Valves and Filters, Standard® has the parts needed to repair VVT systems correctly the first time.

VVT Solenoids

Features & Benefits

Features & Benefits

Generally located on and/or around the cylinder head, VVT solenoids meter the oil flow to control the actuation of the VVT sprocket. Each Standard® and Blue Streak® VVT Solenoid features anodized steel componentry, which limits sludge buildup and protects against sticking, as well as premium O-rings and gaskets to prevent oil leaks, and an OE-matching harness connector.

Welded Reinforcement

Ensures a stronger connection between screen and body

Welded Filters

Have equal overlapping diameters with no gaps to maintain structural integrity

Stainless Steel Shaft

Stronger, stainless steel shaft for consistent performance and durability

Lubrication Groove

Keeps armature lubricated for a longer service life

VVT109 | Ford Cars, Trucks & SUVs (2020-11)

VVT Solenoid Kits

Features & Benefits

The GM 2.4L and Toyota 3.0L / 3.3L applications are known to have high failure rates for VVT solenoids. We have these covered with kits that include improvements over the OE design. Blue Streak® VVT Solenoid Kits include two new premium Solenoids with quality O-rings and gaskets to help prevent oil leaks.

Welded Reinforcement

Ensures a stronger connection between screen and body

Stainless Steel Shaft

Stronger, stainless steel shaft for consistent performance and durability

Two premium VVT Solenoids

Blue Streak® VVT Solenoid Kits include two new premium Solenoids with quality O-rings and gaskets to help prevent oil leaks

Welded Filters

Have equal overlapping diameters with no gaps to maintain structural integrity

Stainless Steel Shaft

Stronger, stainless steel shaft for consistent performance and durability

Hardened Steel Componentry

Limits sludge buildup

VVT2000K | GM 4 Cyl. (2017-06)

Videos

VVT Solenoid Videos

The StandardBrand YouTube Variable Valve Timing (VVT) playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Variable Valve Timing (VVT) Overview

Standard® VVT Components

Diagnosing Variable Valve Timing (VVT) Systems

VVT Solenoids

VVT Sprockets

Features & Benefits

Features & Benefits

Located on the camshaft, sprockets help maximize horsepower and torque curves, reducing emissions and improving vehicle efficiency. Standard® engineers have designed numerous improvements to our most popular VVT Sprocket for enhanced performance and long-lasting durability. Standard® and Blue Streak® VVT Sprockets are direct-fit OE replacements and meet tight dimensional tolerances to improve internal sealing, minimize oil drain back, and reduce frequency of PCM correction.

Bolt Included

OE-style installation bolt included for ease of installation

Larger Contact Area

Means no friction between the sprocket and rotor

Advanced Componentry

Advanced coil spring and locking pin for durability

Enhanced Performance

In timing phase response

Design Improvements

Virtually eliminate component wear for less oil loss

VVT500 | Ford Cars, Trucks & SUVs (2014-04)

Videos

VVT Sprocket Videos

The StandardBrand YouTube Variable Valve Timing (VVT) playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Variable Valve Timing (VVT) Overview

Standard® VVT Components

Ford 5.4L Cam Phaser and VVT Control Solenoid Replacement

VVT Sprockets

VVT Service Kits

Features & Benefits

Features & Benefits

Ford 5.4L engines feature highly technical VVT systems that are susceptible to failure. They typically fail due to low engine oil levels, poor oil circulation, or oil and filter change irregularities. Blue Streak® offers a Complete Timing Repair Kit to solve this OE problem. Everything for a complete repair – solenoids, sprockets, timing chain, guide, tensioner, arm, seals, crankshaft wheel, and gaskets.

VVT Sprockets

Timing Chains

VVT Solenoids

Crankshaft Seal

Crankshaft Position Wheel

Drive Gear Sprocket

Gaskets

Timing Chain Guides & Tensioner Arms

Timing Chain Tensioners

VVT420K | Ford 5.4L (2014-04)

Videos

VVT Service Kit Videos

The StandardBrand YouTube Variable Valve Timing (VVT) playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Variable Valve Timing (VVT) Overview

Standard® VVT Components

Diagnosing Variable Valve Timing (VVT) Systems

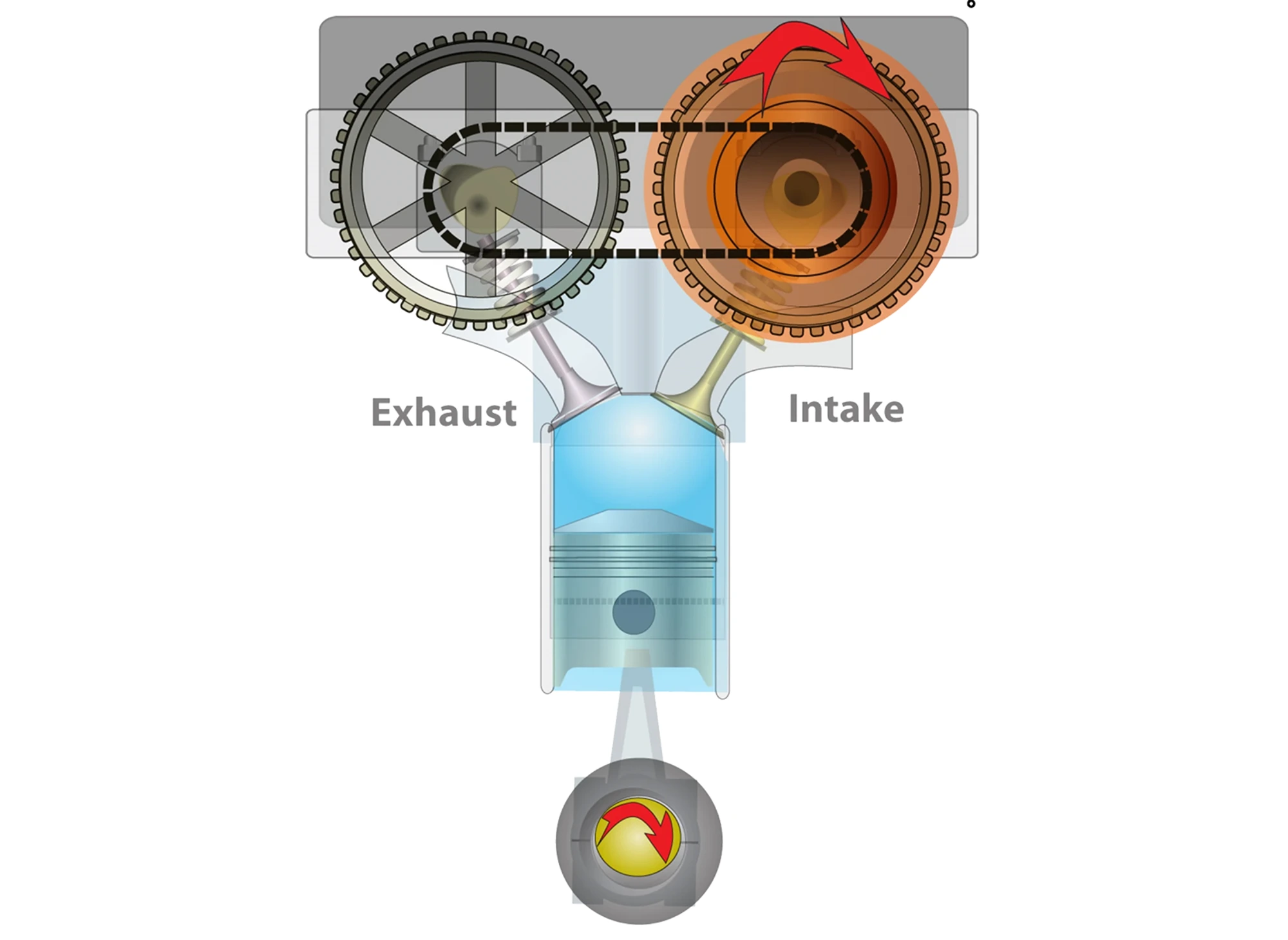

VVT System Overview

System Overview

The primary components in VVT systems are control solenoids and sprockets. Most VVT systems are oil-activated, and some newer systems operate off rotational torque from the engine. In VVT systems, the timing of a valve lift event in an internal combustion engine is altered to increase efficiency. The control solenoid receives a signal from the PCM and meters the flow of engine oil through a series of passages. This moves the sprocket to the advance or retard position. For increased performance, the exhaust cam is retarded a small amount to promote engine breathing. Higher engine speeds mean shorter valve open times and increased air velocity. The increased velocity pushes more exhaust out of the cylinder. The retarded exhaust valve timing increases volumetric efficiency. The exhaust valve is still open when the intake opens. Outgoing exhaust pulse creates a low-pressure zone behind the valve, which increases the pressure differential between the intake port and the combustion chamber for better cylinder filling.

VVT Program

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in VVT system technology. Here’s what they say to look out for during a VVT component installation.

Rough idle, stalling, lack of power, decreased fuel economy, engine noise or a check engine light may be signs of an issue with the VVT system.

Using the correct oil weight is critical to the health of any variable valve timing system.

When a VVT solenoid fails or is blocked, the lack of proper lubrication can cause the timing chain and gear to prematurely wear or break entirely.

Using a lab scope and referencing a “known good” cam/crank pattern is a very accurate method for diagnosing failed timing components.

Always change the engine oil and filter when replacing a VVT solenoid or sprocket.

If one solenoid or sprocket fails, it’s likely the other VVT components are nearing the end of their service life too. It’s suggested to replace both solenoids and sprockets at the same time and inspect/replace all related timing chain components in the system.

Rough idle, stalling, lack of power, decreased fuel economy, engine noise or a check engine light may be signs of an issue with the VVT system.

Using the correct oil weight is critical to the health of any variable valve timing system.

When a VVT solenoid fails or is blocked, the lack of proper lubrication can cause the timing chain and gear to prematurely wear or break entirely.

Using a lab scope and referencing a “known good” cam/crank pattern is a very accurate method for diagnosing failed timing components.

Always change the engine oil and filter when replacing a VVT solenoid or sprocket.

If one solenoid or sprocket fails, it’s likely the other VVT components are nearing the end of their service life too. It’s suggested to replace both solenoids and sprockets at the same time and inspect/replace all related timing chain components in the system.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-4 of 4

No results found