What's in Your Box?™

Fuel Injection Program

Standard’s complete Fuel Injector Program includes over 1,100 precision-engineered Injectors and related fuel injection components with unmatched coverage for import and domestic vehicles.

3 Things To Know

1,100+ New Injectors

& Components

Standard’s complete Fuel Injection program includes more than 1,100 new, not remanufactured GDI, Multi-Port, and TBI Injectors as well as related components.

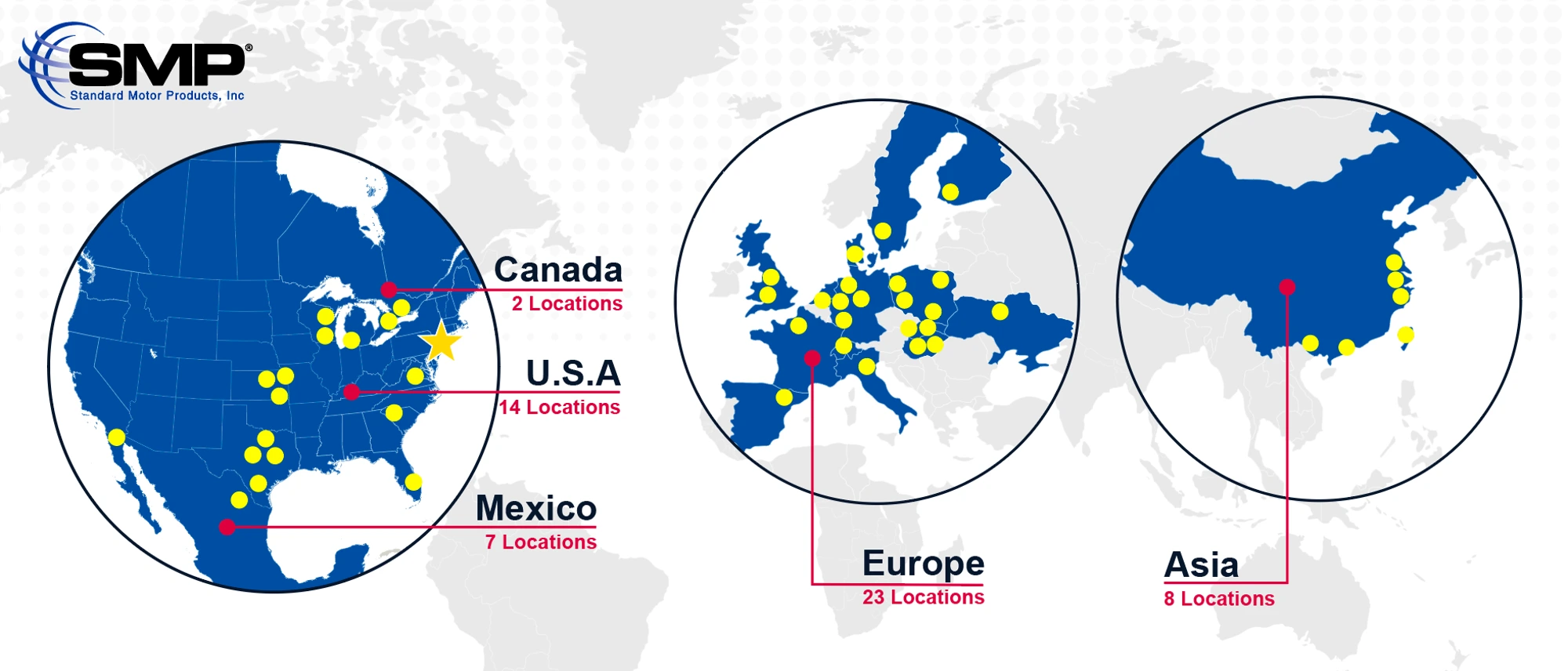

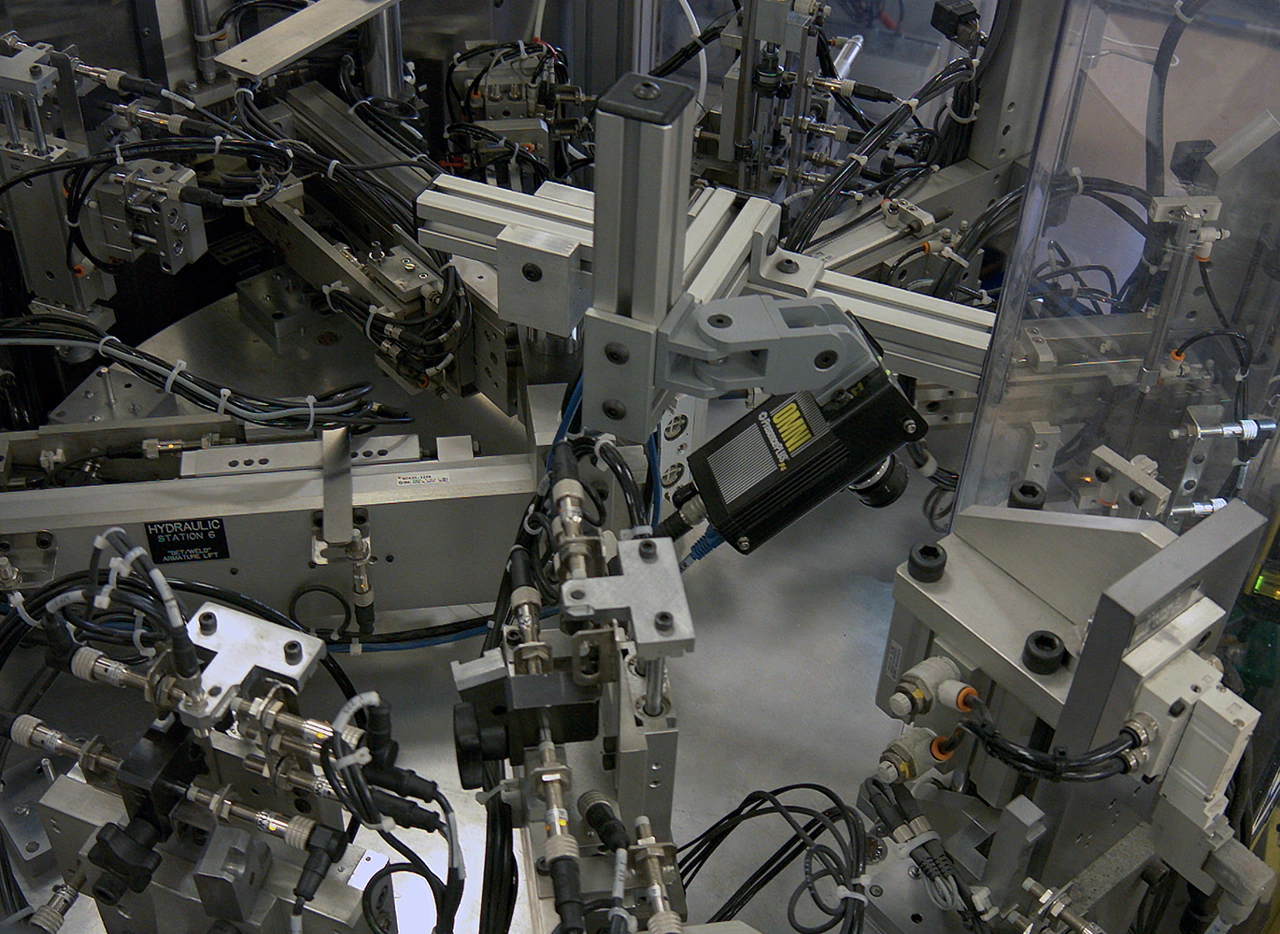

American Manufacturing

Standard®-manufactured Injectors and components are engineered and built in our IATF 16949-certified Greenville, South Carolina facility.

Application-Specific Designs

Application-specific flow and spray patterns match OE specifications and fuel economy.

Standard® Has Fuel Injection Covered

Coverage

Comprehensive Coverage

In coming years, advanced internal combustion engine (ICE) categories like fuel injection are expected to see continued growth. Standard® offers over 1,900 Injectors and related replacement fuel injection components for import and domestic vehicles.

- Standard® offers components for gasoline direct, multi-port, throttle body, and diesel fuel injection.

Market

Growing Market

Fuel injection systems are becoming increasingly complex. In an effort to improve emissions and fuel economy and reduce carbon build-on on the valves, many automakers are equipping new vehicles with both multi-port and direct injection. When performing a fuel injection service, remember that vehicles with dual injection technology might have up to 16 fuel injectors!

- While electric vehicles are making headlines, most new car buyers are still choosing gasoline (including hybrid) vehicles. Even by 2035, roughly 94% or more of the cars entering service bays are expected to be powered by internal combustion engines with some type of fuel injection that will require maintenance and repair.

Service Opportunities

Service Opportunities

GDI systems provide many opportunities for repair. In 2020, Honda updated a TSB, alerting techs that the original GDI injectors installed in late-model Odysseys, Pilots and Ridgelines are throwing numerous DTC codes. Standard’s FJ1372 premium New GDI Fuel Injectors include the retaining clip to keep the injectors in position while protecting against vibration.

- Replacing only the worn or failed injector may create a fuel imbalance, as high-mileage injectors have unmatched spray patterns that increase fuel consumption. New Standard® Injectors have evenly matched spray patterns that improve fuel economy.

OE Problem: Check engine light comes on with DTC P0300-P0306 or P219A/B trouble code

Standard® Solution: Replace OE injector with high-quality replacement from Standard®

FJ1372: Honda SUVs, Trucks & Minivans

(2020-16)

Engineering & Design

Engineering

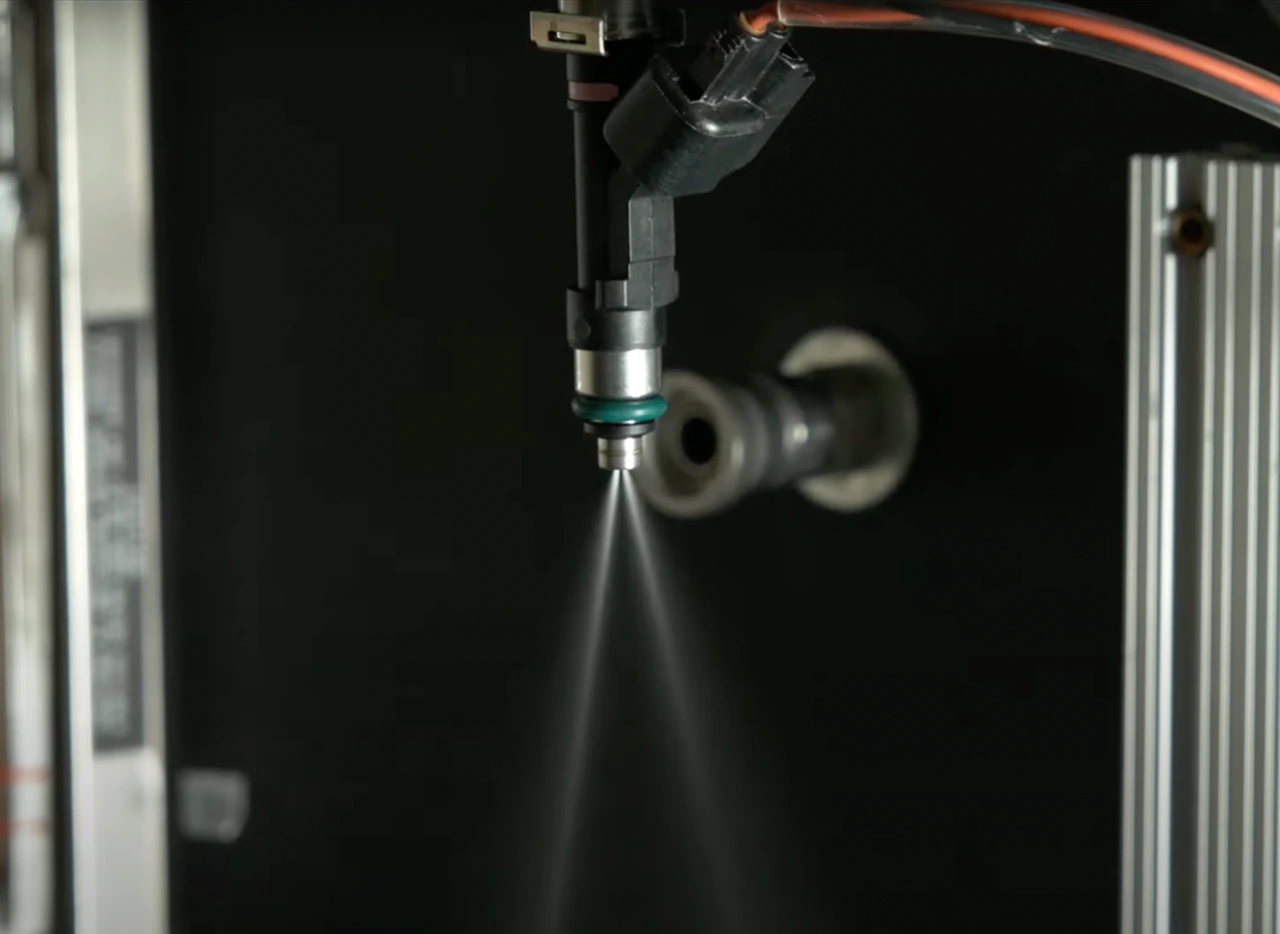

Precision engineering means a commitment to flow and spray pattern matching, and strict requirements for flow rates to deliver better fuel economy and emissions. Standard® Fuel Injectors use metering discs to match OE-style spray patterns. Located at the tip of the injector, the metering disc determines the flow rate and spray pattern of the injector, ensuring positive control of fuel delivery for maximum performance and service life.

- Precision Matters; the location and size of the holes must match OE exactly for precise performance. The metering disc must also be indexed correctly onto the injector. Standard® designs metering discs specifically for each application.

Manufacturing

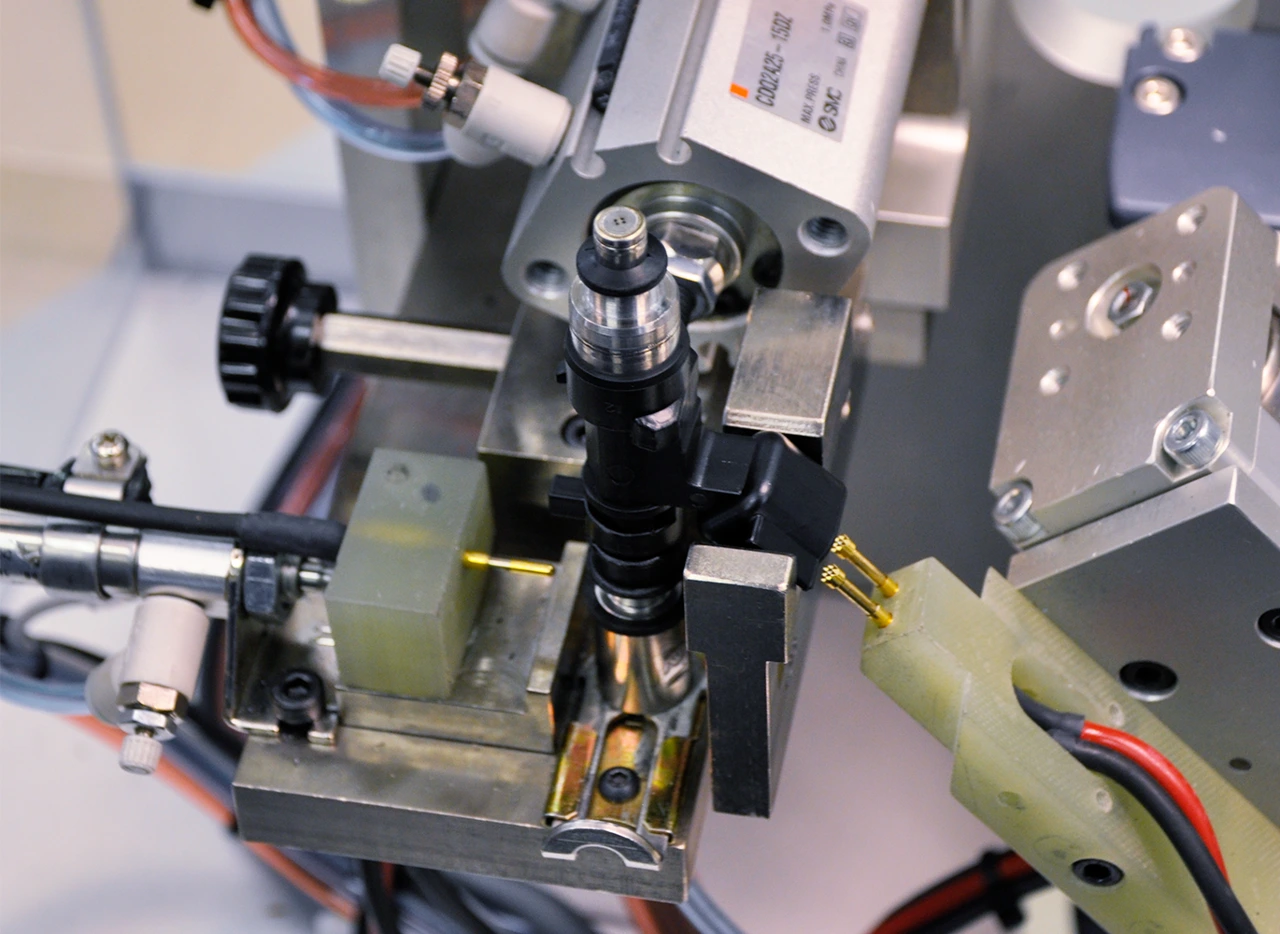

Precision Manufacturing

Standard® Fuel Injectors are expertly manufactured at our vertically integrated facility in Greenville, South Carolina. From raw material to finished product, every Injector is subjected to extensive end-of-line and life-cycle testing, ensuring they meet our strict quality control standards.

- SMP facilities hold IATF 16949, ISO 9001, and ISO 14001 certifications. These certifications guarantee a high-quality, reliable component in every box.

Testing & Validation

Testing & Validation

To make sure every Fuel Injector meets our strict standards for precision quality, enhanced performance, and extra durability, Standard® performs initial life-cycle validation and 100% end-of-line testing. What’s more, we subject our Fuel Injectors to more than 35 different tests and inspections including spray pattern, flow linearity, flow matching, thermal cycle testing and much more.

Fuel Injection Categories

Technicians look to Standard® for the parts required to do the job right. From Injectors to Direct Injection High-Pressure Fuel Pump Kits, Standard® has the parts needed to service fuel injection systems correctly the first time.

Diesel Fuel Injection

New Diesel Fuel Injectors

Features & Benefits

Standard® New Diesel Fuel Injectors are precision manufactured with the latest engineering enhancements to match the OE injector spray and flow patterns. Each Injector undergoes extensive performance and diesel emission testing to ensure proper operation.

Tested and Validated

Undergoes extensive dynamometer and diesel emission testing for proper performance

New, Not Remanufactured

Provides superior quality, emission compliance and fuel economy

Precision Manufactured

Features the latest engineering enhancements to match the OE injector

FJ1380NX | RAM ProMaster 2500 / 3500 (2017-14)

New Diesel Fuel Injection Videos

The StandardBrand YouTube Diesel Fuel Injectors playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

New OE-Production Diesel Fuel Injectors

Ford 6.0 Liter Powerstroke Fuel Injector Installation

6.7L Cummins Fuel Injector Replacement

New Diesel Fuel Injector Listings

Reman Diesel Fuel Injectors

Features & Benefits

Standard® Remanufactured Diesel Fuel Injectors are manufactured at our IS16949, ISO9001, and ISO 14001-certified North American facility where we inspect, disassemble, validate, clean and reassemble each Injector to ensure proper performance.

Calibrated and Validated

Calibrated to OE specification and tested on the flow bench to validate OE fuel flow

Required Components Included

Includes new O-rings, copper seals and instruction sheets for easy installation

New Core Components

Remanufactured using new O-rings, springs, nozzles, delivery valves, shims, gaskets and solenoids to ensure proper sealing and performance

FJ1226 | Chevrolet / GMC HD Trucks (2016-11)

Reman Diesel Fuel Injection Videos

The StandardBrand YouTube Diesel Fuel Injectors playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

A Closer Look: Remanufactured Diesel Injectors

2002 Ford F250 Super Duty 7.3L Powerstroke Diesel Fuel Injector Replacement

6.0L Fuel Injector Installation Tips & Best Practices

Reman Diesel Fuel Injection Listings

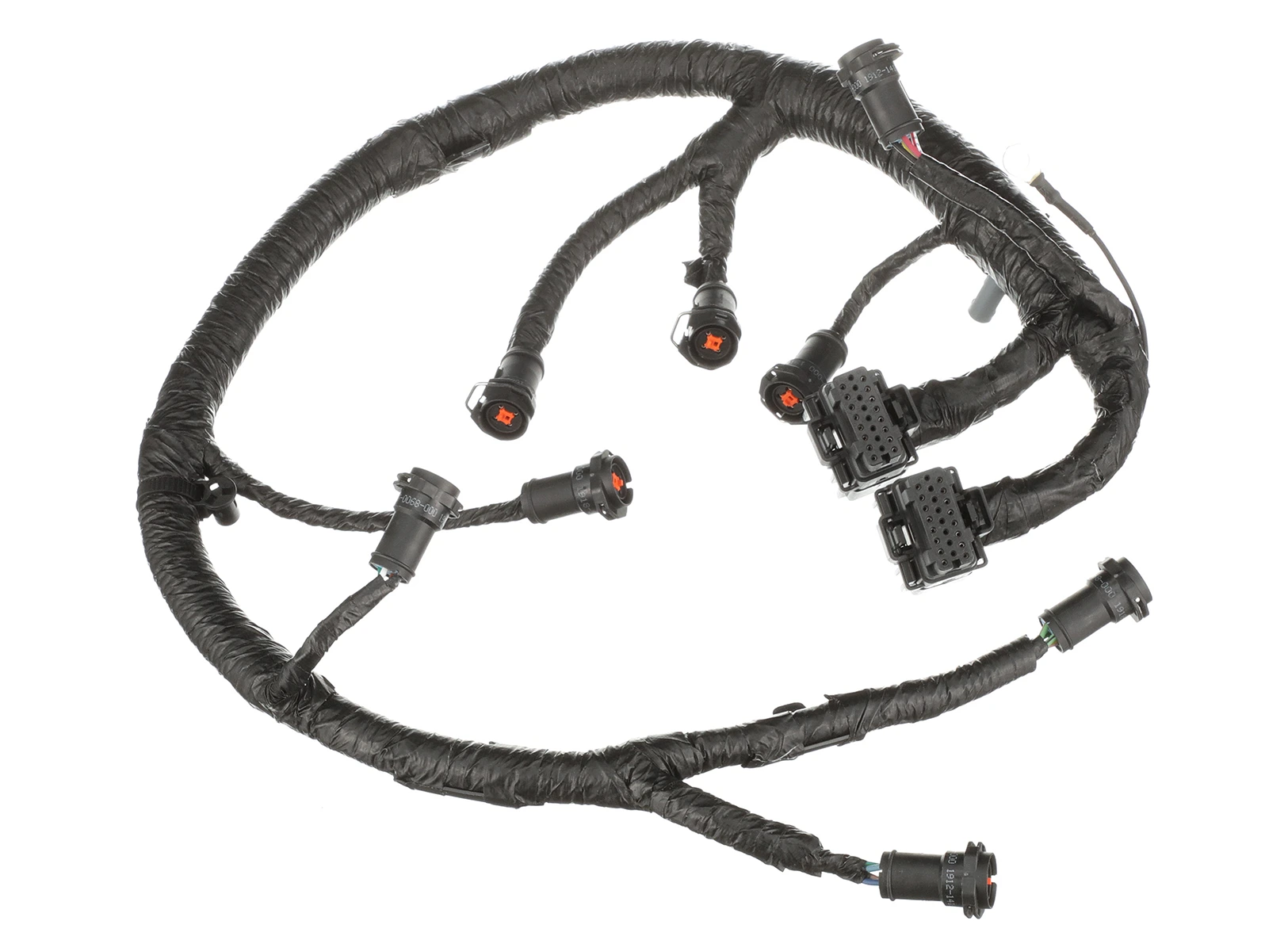

Diesel Fuel Injection Harnesses

Features & Benefits

Standard® Diesel Fuel Injection Harnesses are direct-fit OE replacements to ensure ease of installation, and are designed to withstand extreme under-hood conditions.

Withstands Extreme Conditions

Constructed with high-quality materials that will not become brittle when exposed to extreme engine temperatures

Aluminum Electric Terminals

Are resistant to oxidation ensuring proper signal to injector is maintained

High-Temp Viton® O-Rings

Enable prolonged sealing of electrical connection under extreme conditions

IFH4 | Ford Super Duty Trucks (2007-05)

Diesel Injection Parts

Diesel Fuel Injector Lines

Features & Benefits

Diesel fuel injector lines transport highly pressurized fuel, so it’s important that they are properly engineered to avoid bursting. Standard® Diesel Fuel Injector Lines are quality-tested against bursting to ensure that the high-pressure fuel required to run the vehicle is maintained.

Steel Construction

High-grade, anti-corrosive steel material for durability

Bent at Correct Angles

For precise fit and ease of installation

Ferrule Tip Ends

Designed to match the inlet end of the injector and outlet end of the fuel rail to create a secure seal and reduce the chance of fuel leaks

DIL4 | Chevrolet / GMC Trucks (2004-01)

Diesel Injection Parts

Diesel Fuel Pumps

Features & Benefits

Standard® Diesel Fuel Pumps meet or exceed OE specifications to ensure proper vehicle operation during peak performance. Each Diesel Fuel Pump undergoes end-of-line testing to ensure a quality part right out of the box.

Pressure Regulator Included

To make installation quicker and easier

Quality-Tested

Internal components and seals are 100% quality tested to meet OE specifications

Comprehensive Manufacturing

Manufactured at our IATF 16949, ISO 9001, and ISO 14001-certified facilities

IP57 | Chevrolet / GMC Trucks & Vans (2021-16)

Diesel Injection Parts

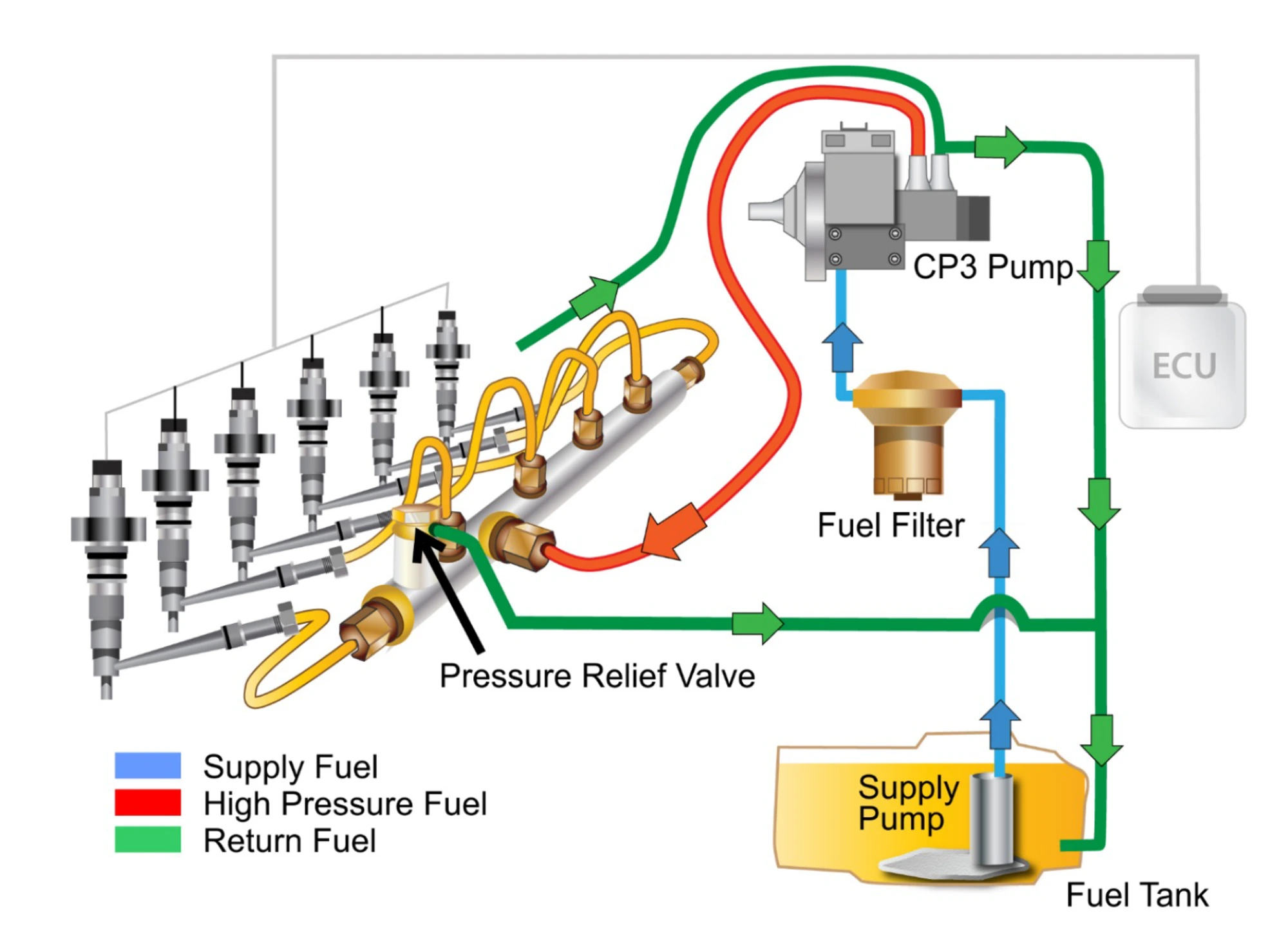

System Overview

System Overview

In diesel fuel injection systems, injectors spray fuel mist into the combustion chamber where it instantly vaporizes and mixes with compressed air. High-temperature conditions cause the mixture to ignite, which must occur at the exact moment that air inside the chamber is at maximum compression. This allows for complete combustion and the production of the maximum amount of energy.

Gasoline Direct Injection

GDI Fuel Injectors

Features & Benefits

GDI systems require special injectors that can inject fuel under the high-pressure requirements of cylinder compression. Standard® GDI Fuel Injectors are always new, never remanufactured. Each Injector is precision engineered and rigorously tested to ensure optimal performance.

Efficient Fuel Delivery

Precision wound and trimmed solenoid windings allow the computer to command efficient delivery of fuel

Stainless Steel Construction

Stainless steel calibration slide and spring assembly prevents corrosion within the fuel control body for a long service life

High-Temp Viton® O-Rings

Enable prolonged sealing of injector under extreme heat conditions

O-Rings and Seals

Additional O-rings and umbrella seals are included for a trouble-free install

Retaining Clip Included

To keep the injector in position while protecting against vibration

FJ1217 | Chevrolet / GMC Trucks & SUVs (2019-14)

Gasoline Direct Injection Videos

The StandardBrand Gasoline Direct Injection playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Gasoline Direct Injection Technology

A Closer Look: Standard® Gasoline Direct Injection (GDI)

GDI Injector Removal and Installation

Gasoline Direct Injection Listings

Fuel Pressure Regulators

Features & Benefits

Standard® Fuel Pressure Regulators are engineered for vehicle-specific fuel delivery. Each unit features a robust housing to reduce the chance of leakage for enhanced durability.

Precision Engineered

For proper fuel delivery and engine performance

Application-Specific Design

For perfect fit and proper performance

Leak-Resistant

Robust engineering design ensures a greater resistance to leakage

PR460 | VW / Audi Cars (2019-06)

Fuel Pressure Regulator Videos

The StandardBrand Gasoline Direct Injection playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Jeep Cherokee Fuel Pressure Regulator Replacement

Honda 3.5 Liter Fuel Pressure Regulator Replacement

Gasoline Direct Injection Diagnostics and Repair Tips | Pro Training PowerHour

Fuel Pressure Regulator Listings

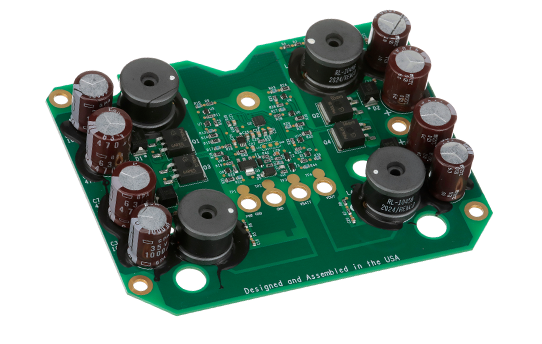

Fuel Pump Driver Modules

Features & Benefits

Standard® Fuel Pump Driver Modules are designed to regulate voltage to the fuel pump to maintain proper fuel pressure over the full operating range of the engine.

Tested and Validated

Undergoes extensive testing and validation to ensure proper performance

Direct-Fit OE Replacement

for ease of installation

Complete Repair

Comes complete with all necessary installation hardware

FPM137 | Toyota Tundra (2019-08)

Fuel Pump Driver Modules

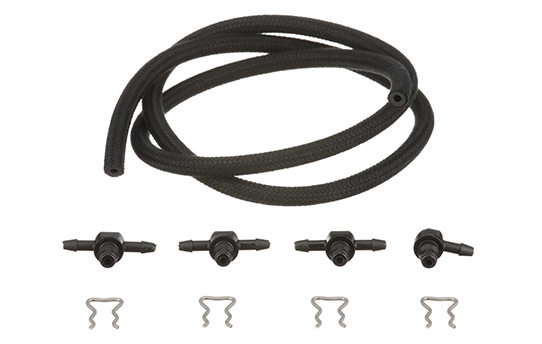

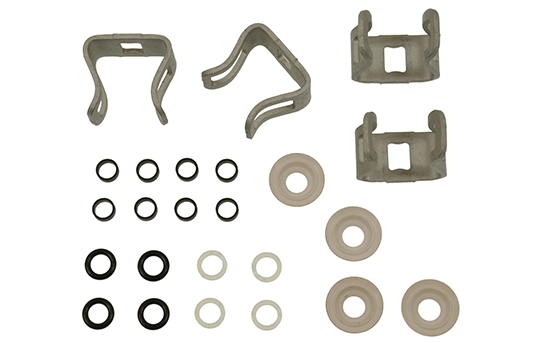

GDI Fuel Injector Seal Kits

Features & Benefits

When servicing GDI injectors, new O-rings and seals are required to ensure a complete repair of the GDI system. Standard® Fuel Injector Seal Kits are tested and inspected in an ISO 9000-compliant facility.

Proven to Last

Undergoes extensive testing to ensure reliability

Direct-Fit OE Replacement

for ease of installation

High-Quality Materials

Constructed from high-quality materials that withstand extreme conditions

SK105 | Audi Cars & SUVs (2012-05)

GDI Fuel Injector Seal Kit Videos

The StandardBrand Gasoline Direct Injection playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

GDI Injector Seal Replacement Tips

Gasoline Direct Injection Technology

Gasoline Direct Injection Diagnostics and Repair Tips | Pro Training PowerHour

GDI Fuel Injector Seal Kits

GDI High-Pressure Fuel Pumps

Features & Benefits

Our all-in-one Direct Injection High-Pressure Fuel Pump Kits simplify fuel pump replacements by including all of the components necessary to do the job right the first time. Each component is a direct-fit OE replacement for proper performance and ease of installation.

Direct-Fit OE Replacement

for ease of installation

Proven to Last

Undergoes extensive testing to ensure reliability

High-Quality Materials

Constructed from high-quality materials that withstand extreme conditions

GDP919 | BMW Cars & SUVs (2020-16)

GDI High-Pressure Fuel Pumps

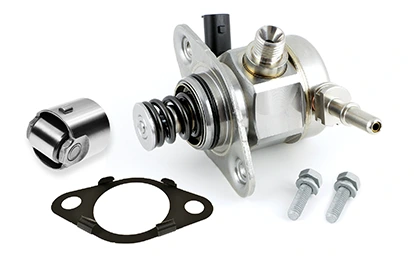

GDI High-Pressure Fuel Pump Kits

Features & Benefits

Our all-in-one Direct Injection High-Pressure Fuel Pump Kits simplify fuel pump replacements by including all of the components necessary to do the job right the first time. Each component is a direct-fit OE replacement for proper performance and ease of installation.

High-Pressure Fuel Pump

Camshaft Follower

Fuel Pump O-Ring

Fuel Pump Mounting Gaskets

GDP102K | General Motors Cars & SUVs (2017-08)

High-Pressure Fuel Pump Kits Videos

The StandardBrand Gasoline Direct Injection playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Blue Streak® GDI High-Pressure Fuel Pump Kits

GM 4 Cylinder GDI Pump and Injector Removal

Gasoline Direct Injection Diagnostics and Repair Tips | Pro Training PowerHour

GDI High-Pressure Fuel Pump Listings

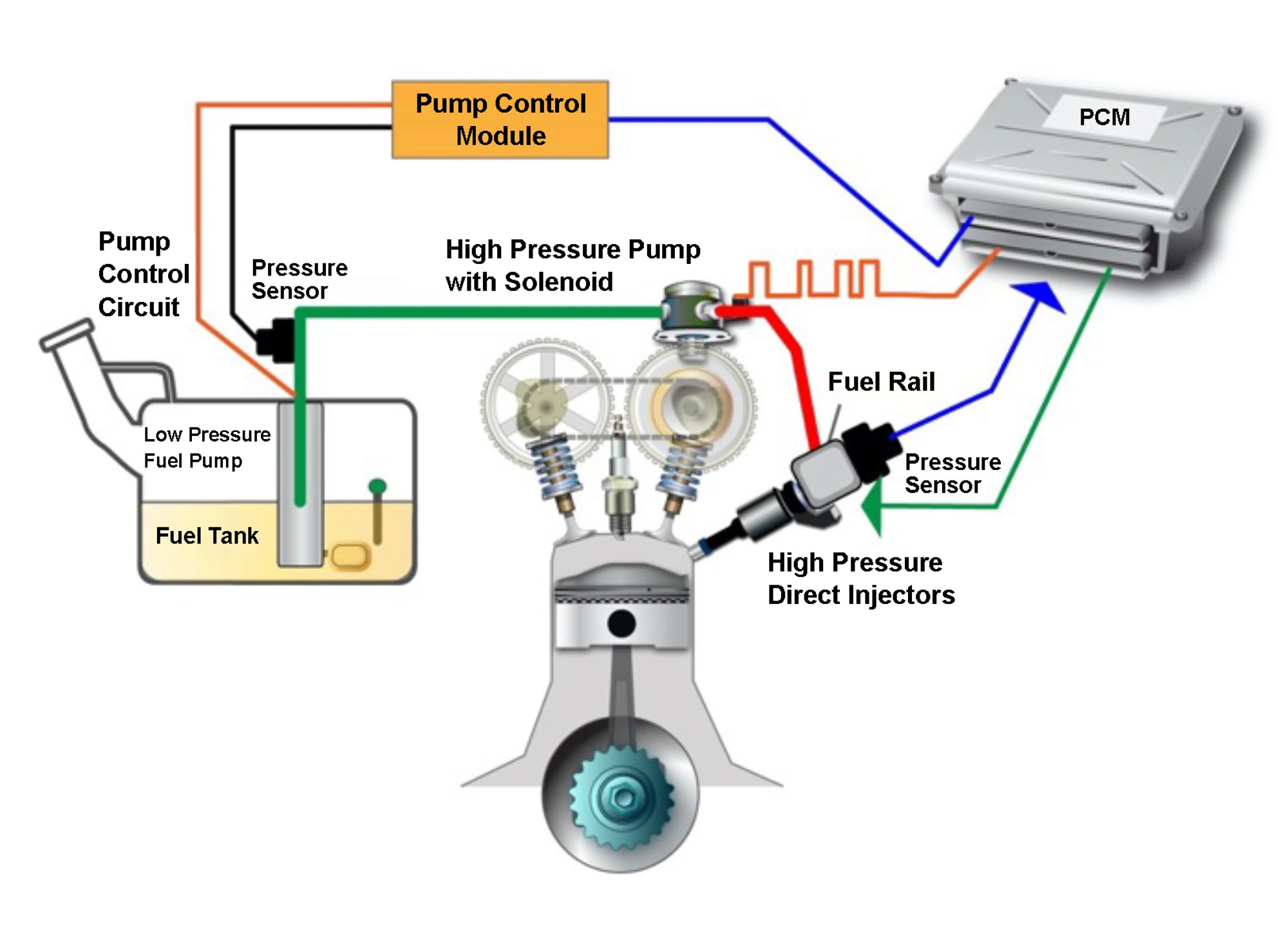

System Overview

System Overview

The fuel injectors on a GDI engine inject fuel directly into the combustion chamber primarily on the intake stroke and, in some cases, on the compression stroke as well. As engine speed increases, fuel pressure is increased to help increase fuel delivery in a shorter amount of time, producing more power.

Multi-Port Fuel Injection

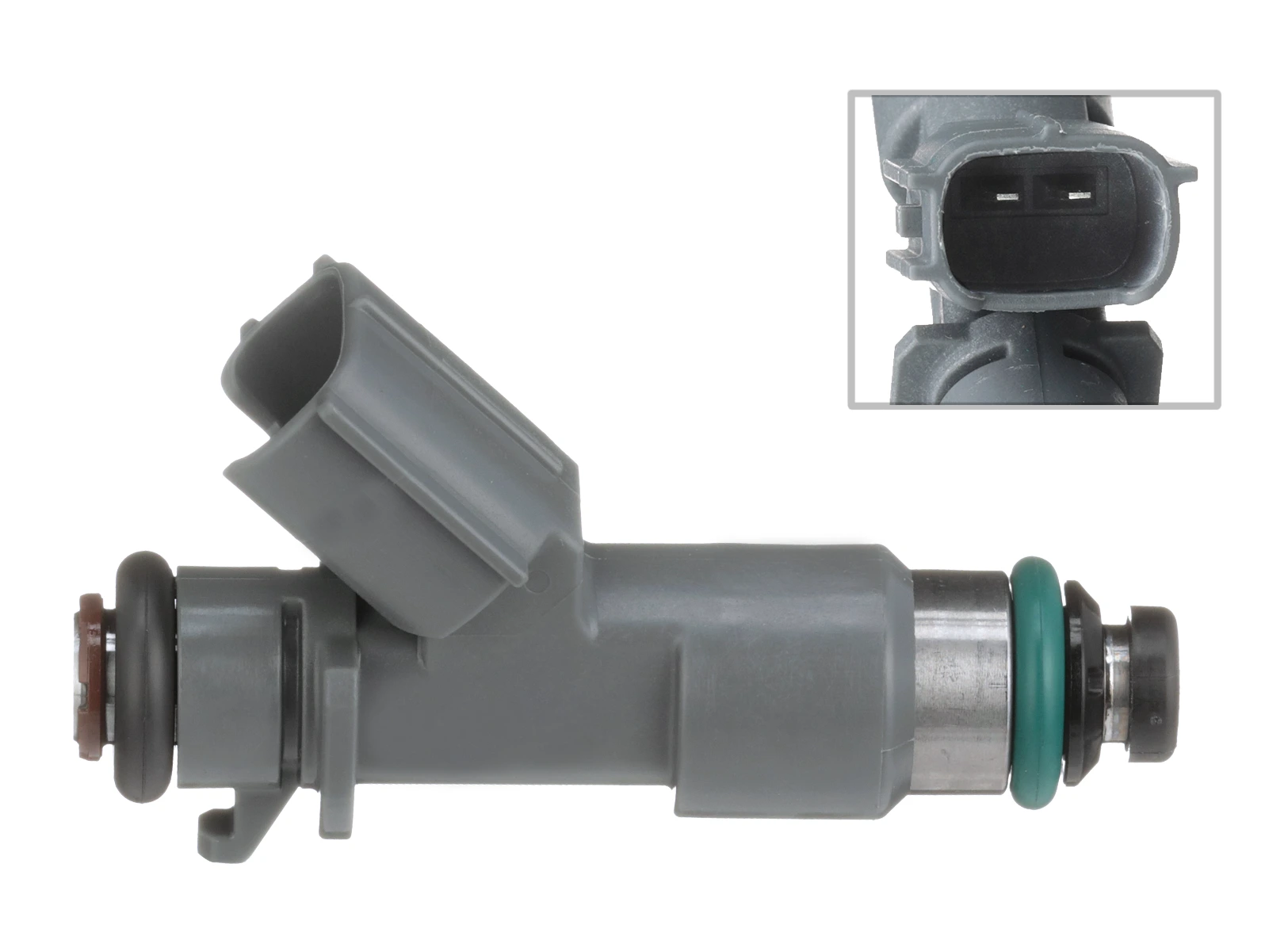

MFI Fuel Injectors

Features & Benefits

Standard® Multi-Port Fuel Injectors are always 100% new, never remanufactured. Each Injector is a direct-fit OE replacement and is meticulously designed, manufactured and tested to exceed the quality of the failed original injector it is replacing.

High-temp Viton® O-Rings

Enable proper sealing under extreme conditions

Application-Specific Resistance

Precision-wound and trimmed solenoid coil windings allow application-specific resistance values

Corrosion-Resistant

Tin-plated brass terminals increase corrosion resistance

Leak-Proof Seal

Valve seats machined to a one-micron finish for a leak-proof seal

FJ982 | Honda / Acura Cars & SUVs (2018-08)

Multi-Port Direct Injection Videos

The StandardBrand YouTube Gas Fuel Injection playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

A Closer Look: Standard Fuel Injectors

Gas Fuel Injection | Standard WIYB Training Series

GM V6 and V8 Central Port Fuel Injection Replacement

Gas Fuel Injector Listings

Fuel Pressure Regulators

Features & Benefits

Standard® Fuel Pressure Regulators are engineered for vehicle-specific fuel delivery. Each unit features a robust housing to reduce the chance of leakage for enhanced durability.

Precision Engineered

For proper fuel delivery and engine performance

Leak-Resistant

Robust engineering design ensures a greater resistance to leakage

Application-Specific Design

For perfect fit and proper performance

PR496 | Nissan Cars (2023-09)

Fuel Pressure Regulator Videos

The StandardBrand Gasoline Direct Injection playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Jeep Cherokee Fuel Pressure Regulator Replacement

Honda 3.5 Liter Fuel Pressure Regulator Replacement

Gasoline Direct Injection Technology

Fuel Pressure Regulator Listings

Fuel Pump Driver Modules

Features & Benefits

Standard® Fuel Pump Driver Modules are designed to regulate voltage to the fuel pump to maintain proper fuel pressure over the full operating range of the engine.

Tested and Validated

Undergoes extensive testing and validation to ensure proper performance

Direct-Fit OE Replacement

for ease of installation

Complete Repair

Comes complete with all necessary installation hardware

FPM137 | Toyota Tundra (2019-08)

Fuel Pump Driver Modules

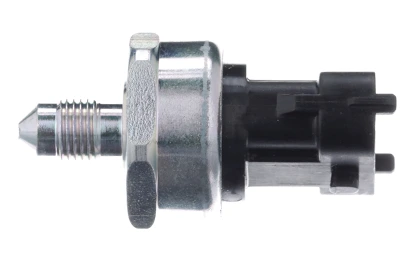

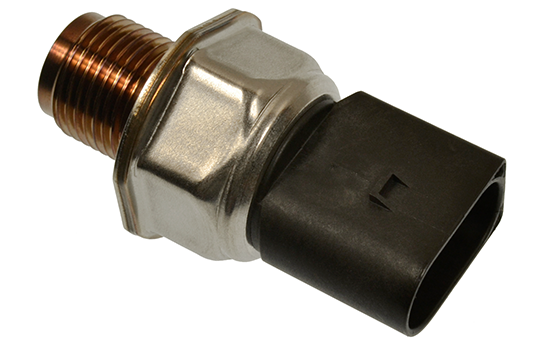

Fuel Pressure Sensors

Features & Benefits

Fuel pressure sensors monitor fuel flow to deliver designed fuel injection performance. They also detect evaporative leaks such as faulty gas caps. Standard® offers a line of fuel pressure sensors to provide coverage and quality for this important EVAP category.

Direct-Fit OE Replacement

Ensures ease of installation and proper performance, resulting in correct pressure measurements

Extensive Design Process

Undergoes extensive design and manufacturing processes to ensure superior durability, longevity and performance, even under extreme conditions

Tested and Validated

Stringent testing and validation processes ensure correct performance and durability

FPS142 | Ford / Lincoln Trucks & SUVs (2024-21)

Fuel Pressure Sensor Videos

The StandardBrand Gasoline Direct Injection playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

GM Flex Fuel Sensor Replacement | Installation Spotlight

Fuel Rail Pressure Sensor Replacement - Ford Taurus/Mercury Montego

Gas Fuel Injection | Standard WIYB Training Series

Fuel Injection Program

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in fuel injection systems. Here’s what they say to look out for during a fuel injection service.

When replacing or servicing GDI injectors, new O-rings and seals are required. You should never reuse O-rings and seals from an injector you are replacing.

If an injector is “stuck on” it may flood the cylinder(s), flood the crankcase, and fill the exhaust with raw fuel. This could result in engine failure and damage additional exhaust components.

Faulty injectors will typically trigger the check engine light and set a variety of trouble codes, such as P0171 or P0174, which indicate an incorrect air/fuel ratio.

Fuel deposits are a common problem in GDI engines. Left unchecked, they can foul injectors and actually alter engine timing, causing drivability problems.

Any fuel line with a yellow tag is for one-time use only and must be replaced if it is removed.

When an injector is being replaced, it is also recommended that a new fuel filter and new injector seals are also installed to help reduce comebacks.

When replacing or servicing GDI injectors, new O-rings and seals are required. You should never reuse O-rings and seals from an injector you are replacing.

If an injector is “stuck on” it may flood the cylinder(s), flood the crankcase, and fill the exhaust with raw fuel. This could result in engine failure and damage additional exhaust components.

Faulty injectors will typically trigger the check engine light and set a variety of trouble codes, such as P0171 or P0174, which indicate an incorrect air/fuel ratio.

Fuel deposits are a common problem in GDI engines. Left unchecked, they can foul injectors and actually alter engine timing, causing drivability problems.

Any fuel line with a yellow tag is for one-time use only and must be replaced if it is removed.

When an injector is being replaced, it is also recommended that a new fuel filter and new injector seals are also installed to help reduce comebacks.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-35 of 35

No results found