What's in Your Box?™

Oil Filter Housings

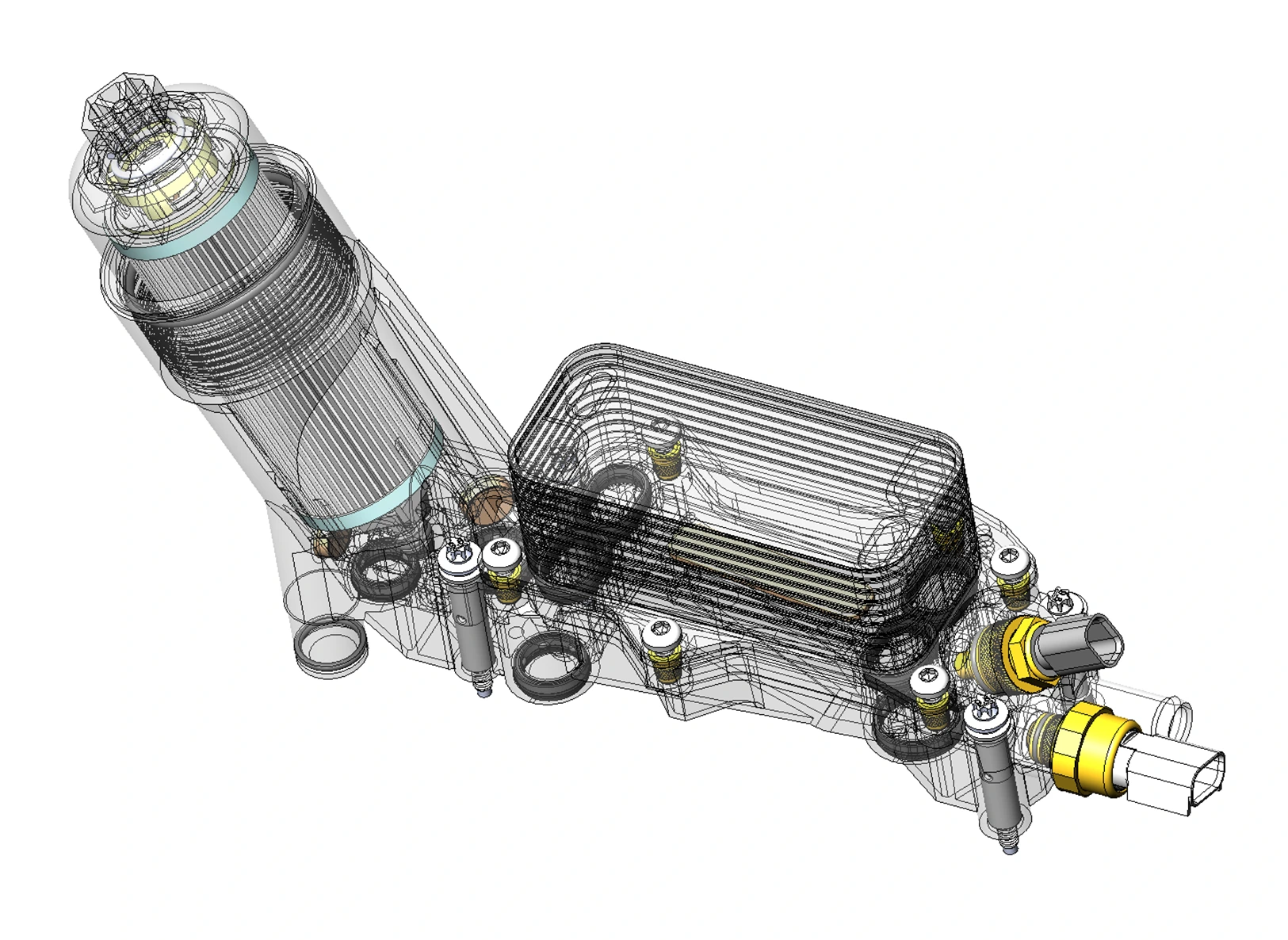

The engineers at Standard® assessed high-failure OE oil filter housings and created completely assembled Oil Filter Housing Kits that address the issues and prevent leaks for a quality, drop-in solution.

3 Things To Know

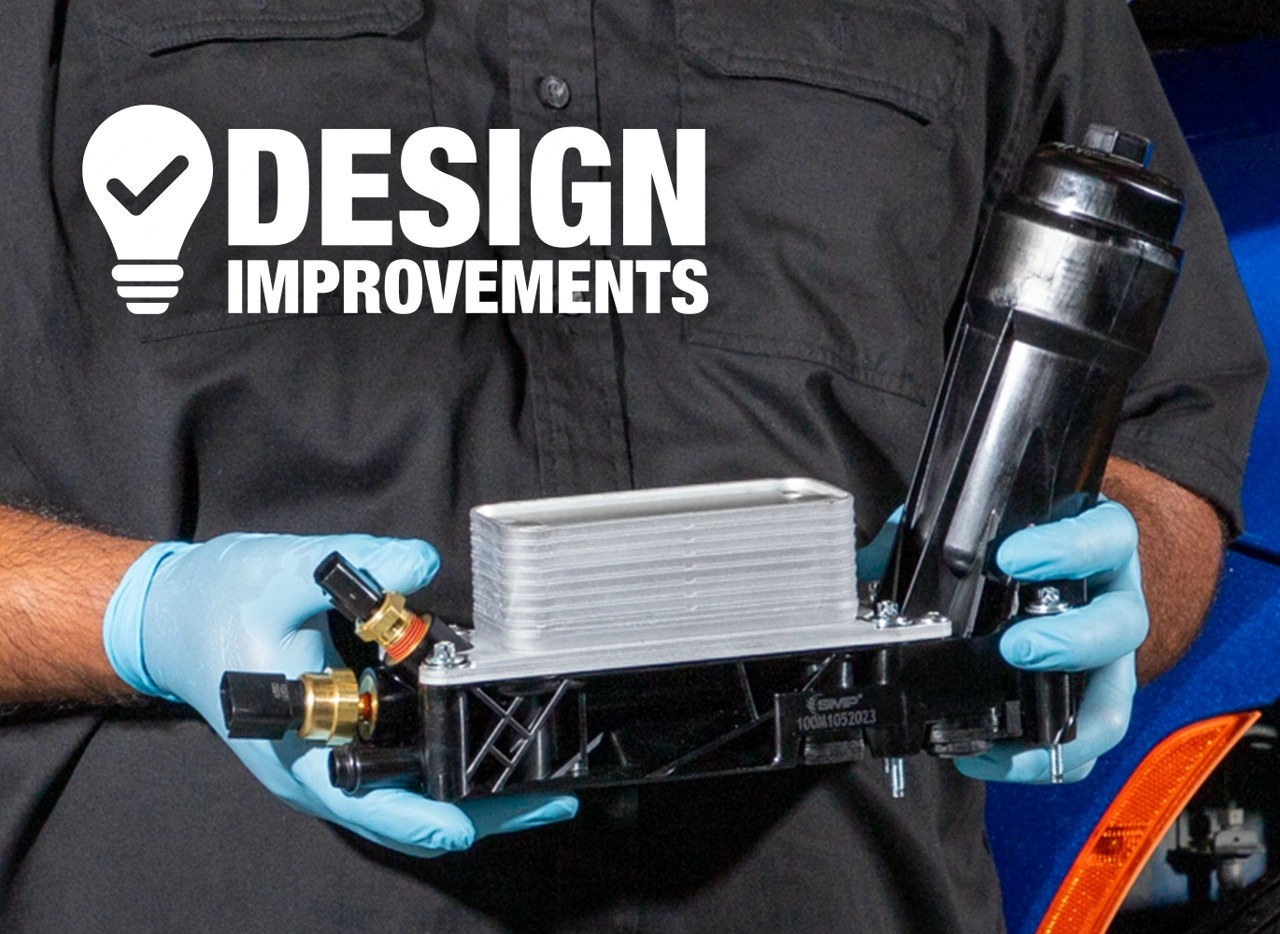

Design Improvements

Standard® Oil Filter Housing Kits feature design improvements over the original to prevent oil leaks.

Factory-Assembled

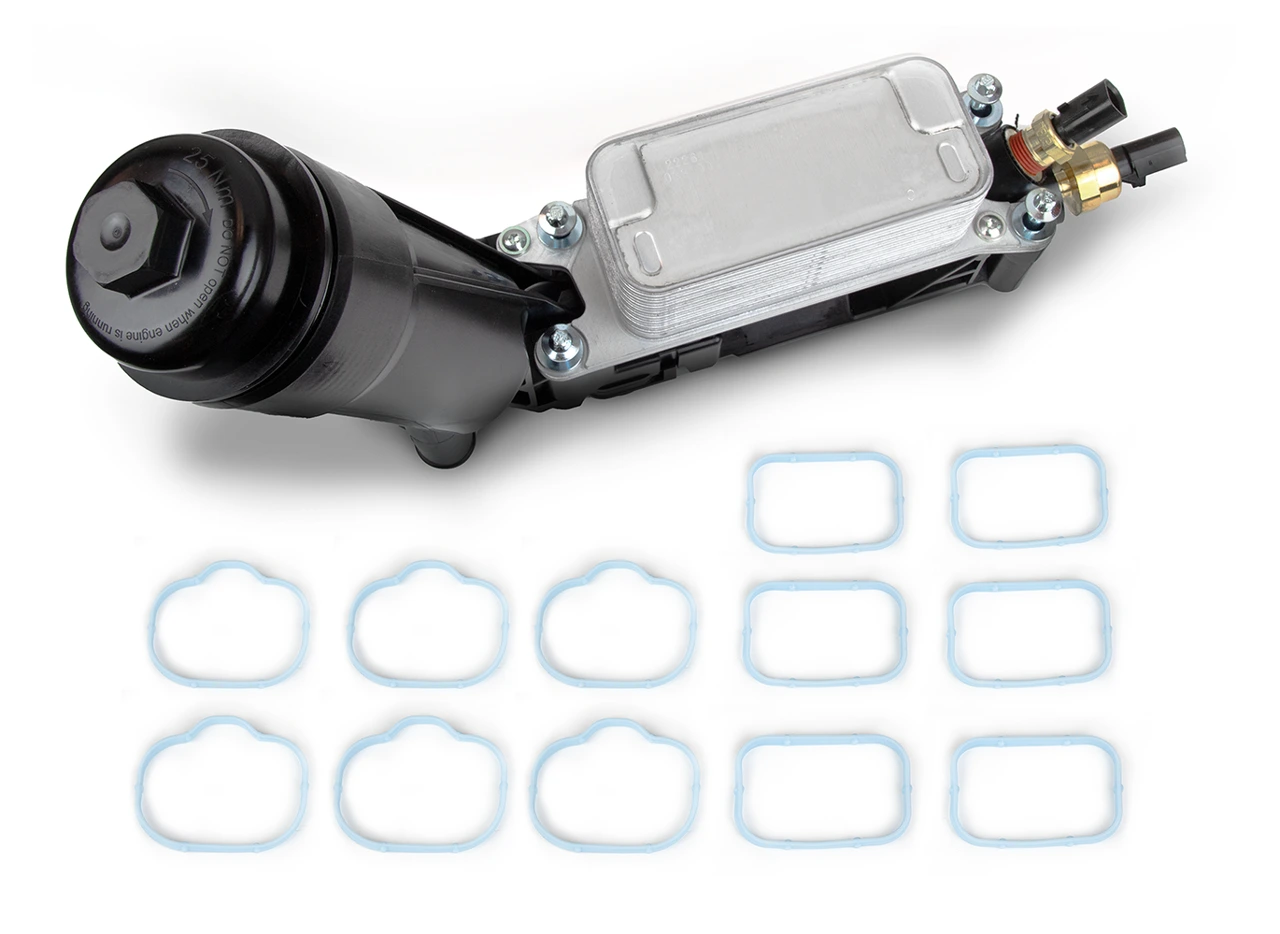

Comes assembled from the factory with both sensors and heat exchanger already installed, and includes new gaskets.

Correct Cooling

Designed to match the thermal characteristics of the original for correct cooling.

Standard® Has Oil Filter Housings Covered

Market

Growing Market

Original oil filter housings are high-OE-failure components. In addition to offering multiple year-specific housings for the popular 3.6L Chrysler Pentastar V6, Standard® also offers oil filter housing and oil coolers for import and domestic nameplates including BMW, Mercedes-Benz, Volvo, and General Motors.

In service since 2011, the 3.6L Chrysler Pentastar has powered more than 10 million (and counting) of the most recognizable vehicles on the road, including the Dodge Challenger, Jeep Wrangler, and RAM 1500. The oil filter housings on these vehicles are know to fail and leak.

- Contrary to popular belief, the original high-temp housings do not warp. Instead, leaks develop at several locations.

Engineering & Design

Engineering

While oil filter housings on Pentastar V6 engines may all look similar, there are distinct differences from year to year, like oil pressure sensors, oil filters, flow rates, and lack of a temperature sensor on late-model applications. Universal designs may not be correct for every application, which is why we offer five different housings for these vehicles.

- Standard® has designed and manufactured five different oil filter housing kits for these engines, with each one including OE-matching sensors and an oil filter with the correct flow rate.

Manufacturing

Precision Manufacturing

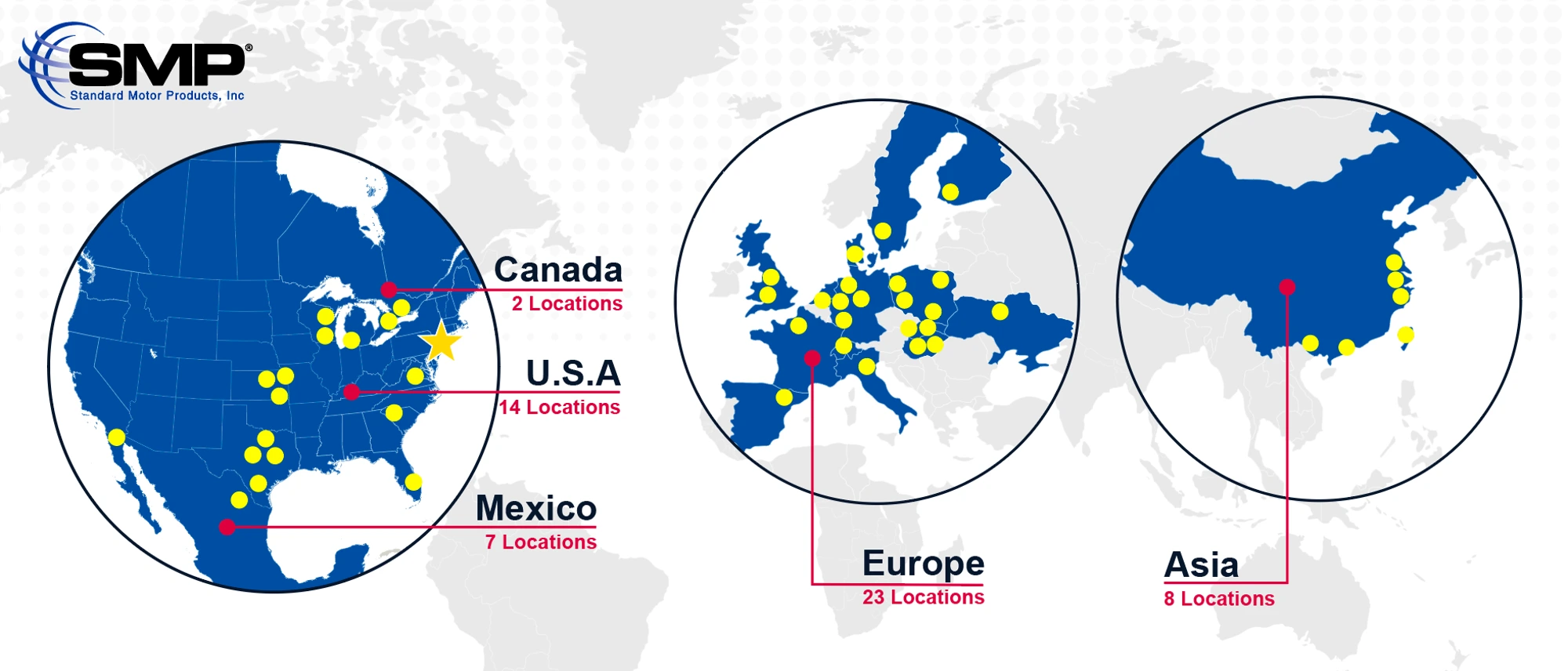

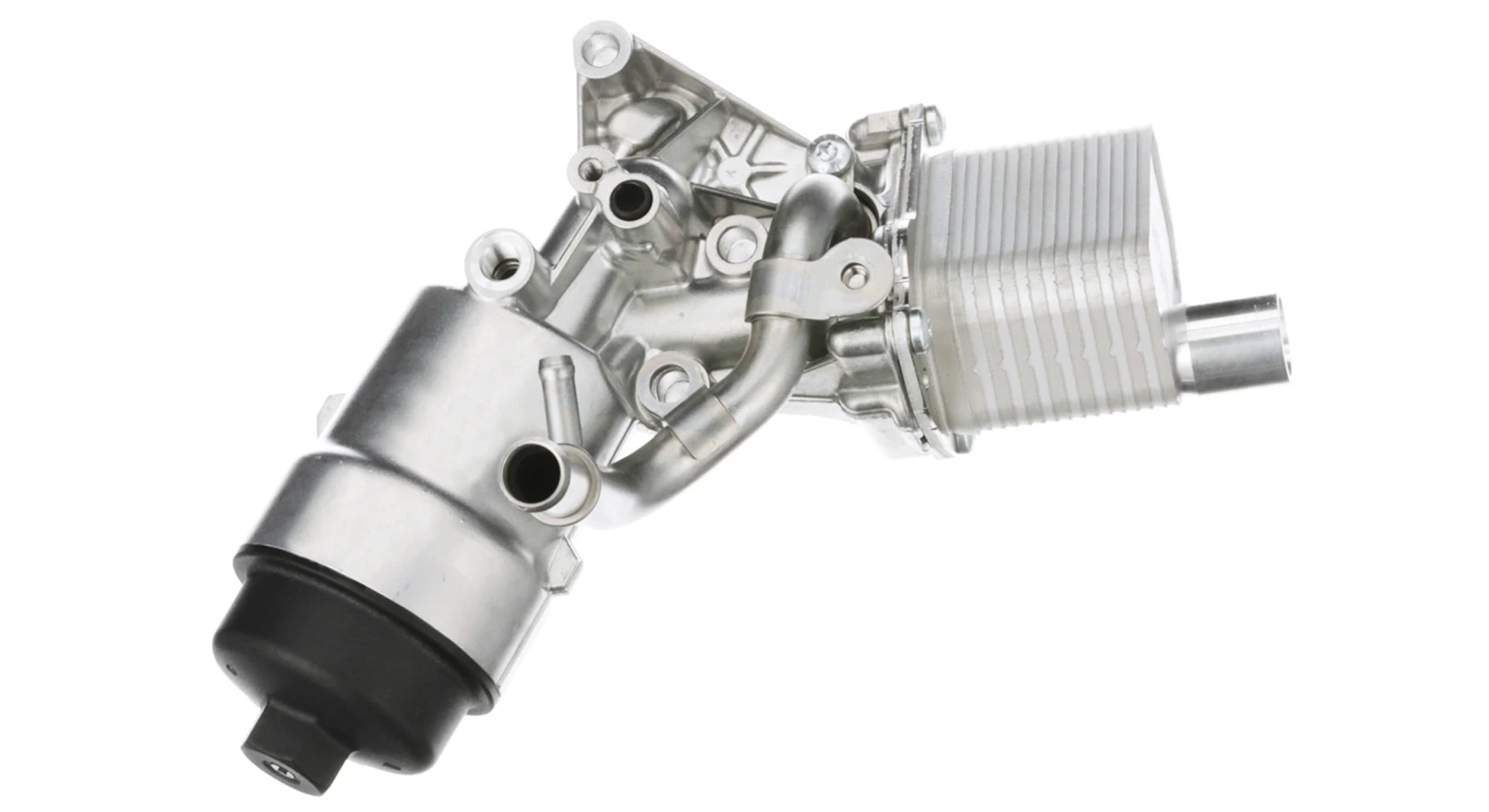

Inside the Standard® box, you’ll find an Oil Filter Housing Kit that is factory-assembled. Each housing includes a new oil pressure sensor, oil temperature sensor, oil cooler, the correct year/make/model-specific oil filter, and new gaskets and seals already installed. Our Oil Filter Housing Kits also include the intake manifold gaskets needed for a complete repair. Standard® Oil Filter Housing Kits for the Pentastar V6 are manufactured and assembled in North America.

- SMP facilities hold IATF 16949, ISO 9001, and ISO 14001 certifications. These certifications guarantee a high-quality, reliable component in every box.

Testing & Validation

Testing & Validation

Standard® Oil Filter Housings and their installed components undergo extensive testing so that you can install them with confidence. Housings are pressure-tested for leaks, and oil pressure sensors and oil temperature sensors are tested for accuracy in our lab and road-tested on actual vehicles for performance and durability.

- New applications are also tested for fit, performance and durability on real vehicles at our testing center in Irving, Texas.

Design Improvements to Prevent Leaks

Design

Improvements Over the OE

Pentastar oil filter housings are known for their high failure rates. Contrary to popular belief, these high-temp synthetic housings do not warp. There are actually multiple weak points in the original design where oil can leak. Our engineers evaluated the original units and designed housings with multiple improvements over the original to address the OE weak points.

- Standard® Oil Filter Housings are manufactured utilizing Zytel®, a high-strength material, that matches the cooling characteristics of the OE design.

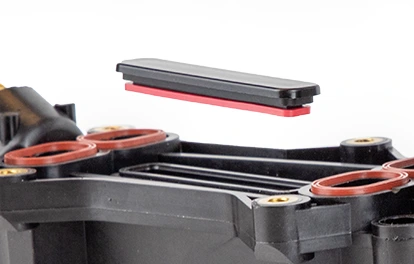

Housing Plugs

O-rings and Ultrasonically Welded Plugs

OE Problem: Oil leaks from the back of the housing around the core plugs that are installed without any seals or O-rings.

Standard® Solution: We install an O-ring on each core plug before ultrasonically welding them into the housing, creating a positive, long-lasting seal.

Internal Seals

Additional Seal Added to Core Plug

OE Problem: Oil contaminates the coolant causing cooling system problems, which can result in overheating and premature radiator failure. This happens because there is no seal on the core plug that separates the oil and coolant passages.

Standard® Solution: We added a robust seal to the core plug which separates these two passages to prevent an internal failure and cross-contamination.

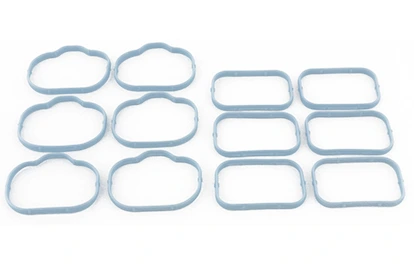

Base Seals

Distortion-resistant Seals

OE Problem: The OE seals often become distorted or crushed resulting in an oil leak around the base of the housing.

Standard® Solution: We install new, distortion-resistant seals made from a synthetic material that is less prone to failure than the original.

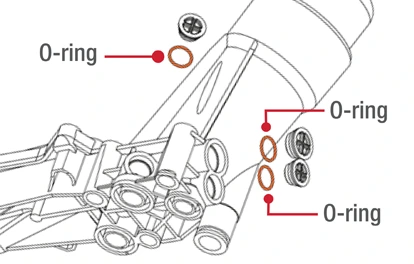

High-Temp O-Rings

High-temp O-rings on Brass Inserts

OE Problem: Oil leaks from the brass sensor inserts because there is not an effective seal between the brass and the synthetic housing material.

Standard® Solution: Additional O-rings are installed on our knurled brass inserts to prevent oil leaks before the sensors are installed and torqued to specification in a controlled, contaminant-free environment.

Oil Filter Housing Categories

Technicians look to Standard® for the parts required to do the job right. From Oil Filter Housing Kits to Oil Coolers, Standard® has the parts needed to repair these systems correctly the first time.

Oil Filter Housing Kits

Features & Benefits

Features & Benefits

Standard® Oil Filter Housing Kits are designed with improvements over the original to prevent oil leaks. Each Oil Filter Housing Kit comes already assembled from the factory and includes new temperature and oil pressure sensors (where required), new OE-matching oil filter and cap, and gaskets and hardware for a clean installation.

Includes Gaskets & Hardware

O-rings and gaskets included for a complete repair

Synthetic Housing

High-strength, high-temp synthetic housing matches OE heat-dissipating characteristics

Includes Oil Filter

The correct year/make/model oil filter is already installed

100% New and Assembled

All components are entirely new and come assembled from the factory

Pre-Installed Sensors

Oil temperature and oil pressure sensors included and already installed

OFH101 | Chrysler Cars, SUVs, Trucks & Vans (2016-11)

Videos

Oil Filter Housing Kit Videos

The StandardBrand YouTube Oil Filter Housings Kits playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Oil Filter Housing Weak Points & Standard® Solutions

A Closer Look: Oil Filter Housing Kits

Oil Filter Housing Assembly Installation

System Overview

System Overview

Modular oil filter housings are becoming more common on today’s vehicles. One modular unit contains the oil filter, multiple sensors and serves as an oil cooler.

Cap and O-Ring

New cap and O-Ring to help prevent future oil leaks

Oil Filter

Vehicle-specific oil filter for proper flow rate specified by the vehicle manufacturer

O-rings and Ultrasonically Welded Plugs

O-rings installed on core plugs before being ultrasonically welding into the housing, creating a long-lasting seal.

Hardware

O-Rings and Gaskets included for a complete repair

Gasket Set

Complete gasket set for a smooth installation

Internal Seal

Robust seal added to core plug prevents internal failure and cross-contamination oil and coolant

Oil Cooler

Matches OE-designated operating and cooling characteristics

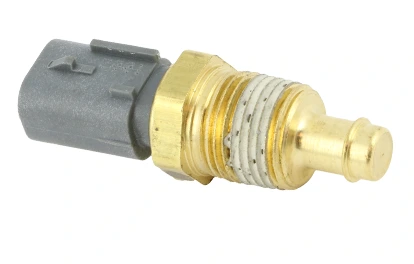

Oil Temperature Sensor

Made to withstand extreme conditions and tested for performance and durability

O-Rings on Brass Insert

Improved design over the original to prevent oil leaks

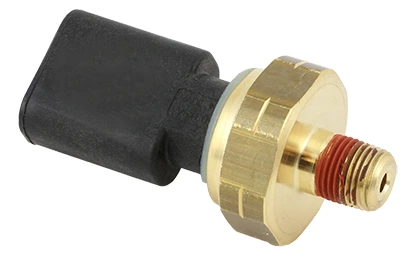

Oil Pressure Sensor

Computer calibrated to ensure accurate oil pressure readings

Oil Filter Housing Kits

Oil Coolers

Features & Benefits

Standard® Engine Oil Coolers undergo extensive in-lab and on-vehicle testing to ensure that they match OE cooling characteristics.

Vehicle-Specific Design

Direct-fit replacement ensures proper fit for ease of installation and correct performance

Precision Manufactured

Using the highest-quality materials for durability and longevity

Gasket Included

For a complete repair

OCK98 | VW Cars & SUVs (2022-14)

Oil Filter Housing Assemblies

Features & Benefits

Standard® Oil Filter Housing Assemblies are designed with improvements over the original to prevent oil leaks, and are manufactured using high-quality materials for durability and longevity.

100% New and Assembled

All components are entirely new and come assembled from the factory

Vehicle-Specific Components

Oil filter included with new cap and O-ring

Correct Cooling

Housing matches OE heat-dissipating characteristics

OFH109 | GM Cars (2021-11)

Oil Filter Housing Program

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in oil filter housings. Here’s what they say to look out for during an oil filter housing replacement.

A failed oil filter housing assembly can leak oil, causing severe unrepairable damage, resulting in complete engine replacement.

OE units can also fail internally, which can cause the engine oil and coolant inside of them to mix, resulting in a potential engine failure.

Over-torquing during installation can damage the housing, resulting in an oil leak.

It is important to follow the correct torque specs when installing a new housing. Slowly tighten each bolt, alternating corners to make sure all of the seals seat correctly.

Before removing the intake manifold to access the oil filter housing, ensure that any dirt and debris are removed from the area, and cover the intake ports with tape to prevent dirt, coolant, or oil from getting into the intake ports. Remove the tape upon reassembly.

It is common for the seals to be damaged during installation, especially the front seal directly under the filter. It is recommended to use automotive lubricant/ grease on this seal and take extra care when installing the housing.

A failed oil filter housing assembly can leak oil, causing severe unrepairable damage, resulting in complete engine replacement.

OE units can also fail internally, which can cause the engine oil and coolant inside of them to mix, resulting in a potential engine failure.

Over-torquing during installation can damage the housing, resulting in an oil leak.

It is important to follow the correct torque specs when installing a new housing. Slowly tighten each bolt, alternating corners to make sure all of the seals seat correctly.

Before removing the intake manifold to access the oil filter housing, ensure that any dirt and debris are removed from the area, and cover the intake ports with tape to prevent dirt, coolant, or oil from getting into the intake ports. Remove the tape upon reassembly.

It is common for the seals to be damaged during installation, especially the front seal directly under the filter. It is recommended to use automotive lubricant/ grease on this seal and take extra care when installing the housing.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-3 of 3

No results found