What's in Your Box?™

Turbocharger Program

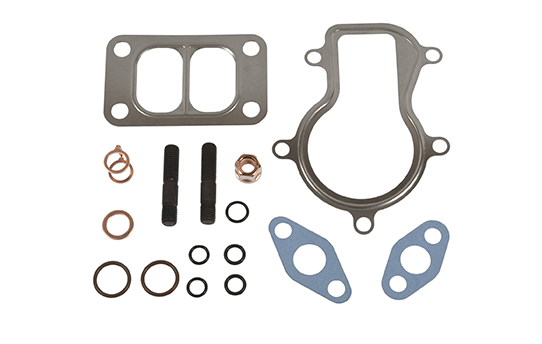

Standard’s all-new Turbocharger Kits include all of the components required for a successful turbocharger installation.

3 Things To Know

140+ Turbo Kits

Standard® offers more than 140 new, no core and remanufactured Turbocharger Kits for gas, diesel, domestic and import applications.

Complete Repair

Standard® Turbocharger Kits include everything needed for a complete, efficient repair.

On-Vehicle Tested

Standard® Turbochargers are tested and validated on actual vehicles at our Testing Center in Texas.

Standard® Has Turbochargers Covered

Coverage

Comprehensive Coverage

The Standard® Turbocharger program includes complete kits and all of the related components needed for turbocharger replacement and servicing. Standard® offers more than 140 Turbocharger Kits for gasoline and diesel applications covering more than 17 million import and domestic vehicles.

Market

Growing Market

In an effort to improve fuel economy, reduce emissions, and improve performance, vehicle manufacturers have added turbocharged vehicles to their lineups at a rapid rate.

- Ford introduced their first turbocharged EcoBoost engine in 2010. They now produce 9 different turbocharged EcoBoost engines for their vehicle lineup and many vehicles are equipped with two turbochargers.

New Vehicles Equipped with Turbochargers

Service Opportunities

Service Opportunities

The GM 1.4L Ecotec engines may develop an oil leak around the PCV valve and plugs on the front engine cover. (GM Service Bulletins PIP5197/PIO957). The loss of oil can starve the turbocharger of lubrication, causing the turbocharger to fail prematurely.

- Standard® Pro Training Tip: Before installing a replacement turbo on a GM 1.4L, carefully check for any oil leaks. It is likely that the original turbo failed due to lack of lubrication.

GM 1.4L Ecotec Engines

Buick Encore (2018-13)

Chevrolet Trax (2018-13)

Chevrolet Cruze (2016-11)

Chevrolet Sonic (2019-12)

Standard® New, No Core Turbocharger Kits for the GM 1.4L Ecotec engine contain everything needed for a complete repair, helping technicians do the job right.

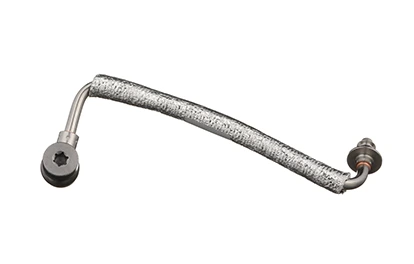

TBC583 includes a premium turbocharger, new gaskets, oil line and required hardware.

Engineering & Design

Engineering

Each Standard® Turbocharger Kit and component is precision-engineered and manufactured to match the original design and performance. This means Standard® turbochargers can be recommended and installed with confidence.

- All Standard® Turbocharger Kits come with a 3-year / 36,000-mile limited warranty.

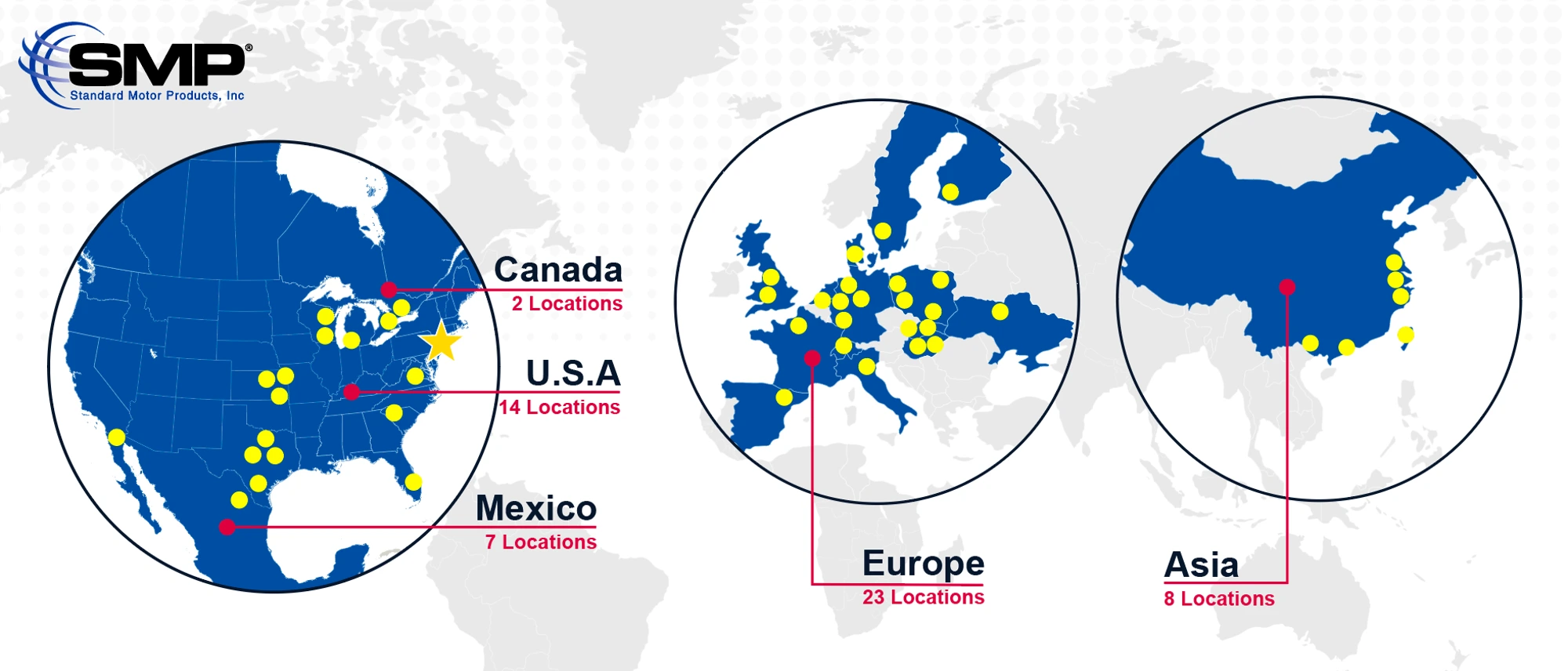

Manufacturing

Precision Manufacturing

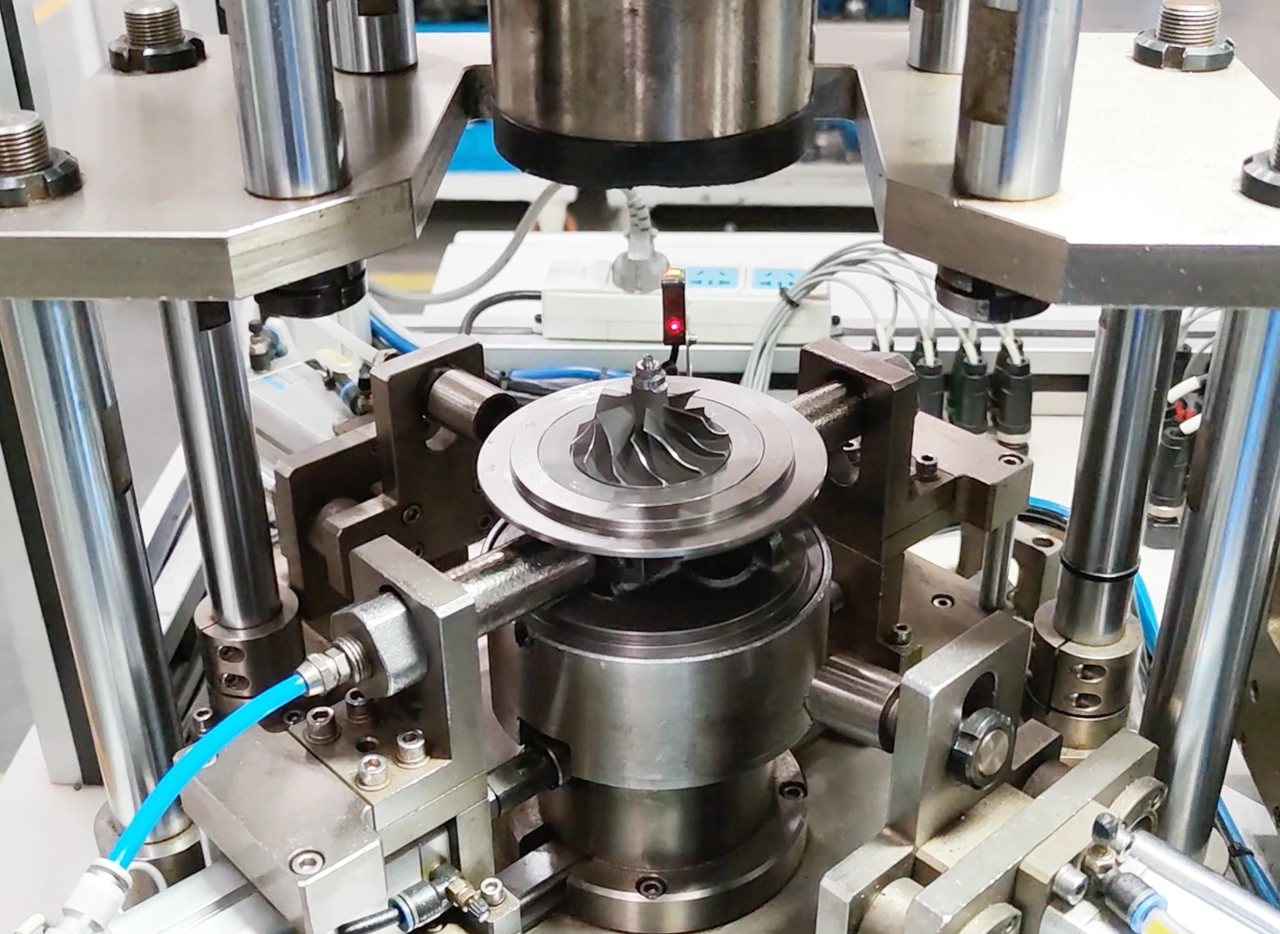

Turbochargers operate at temperatures in excess of 1700°F with the turbine spinning up to 200,000 RPM. Using quality components to manufacture a premium replacement is critical to optimal turbocharger performance and durability.

- SMP facilities hold IATF 16949, ISO 9001, and ISO 14001 certifications. These certifications guarantee a high-quality, reliable component in every box.

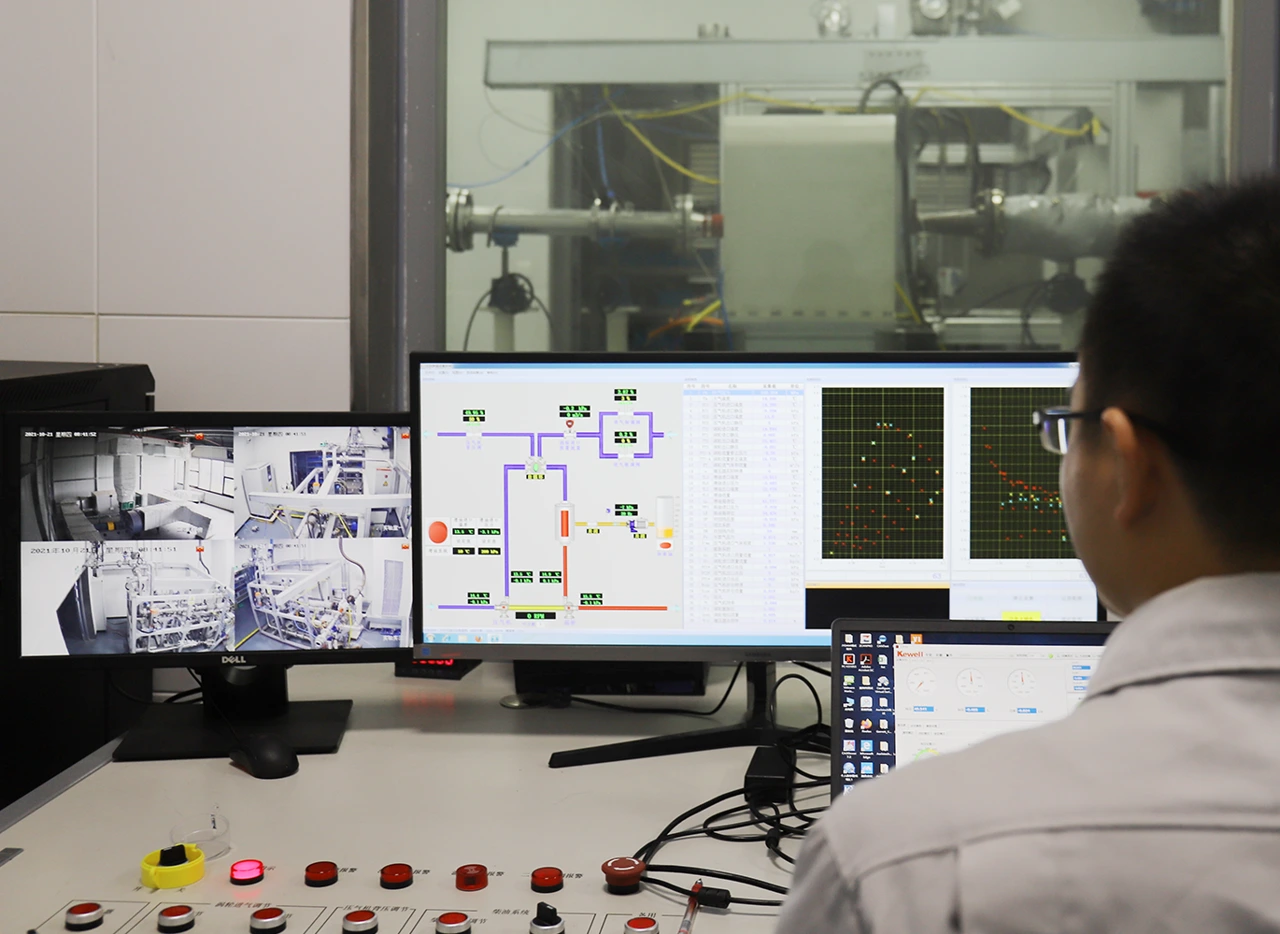

Testing & Validation

Testing & Validation

In the lab and on-vehicles, all Standard® Turbochargers go through a rigorous testing regimen that includes hot gas stand and burst test validation to ensure structural integrity, durability and performance. In fact, Standard® Turbochargers are 100% end-of-line tested through the full RPM range.

Turbocharger Categories

Technicians look to Standard® for the parts required to do the job right. From Turbocharger Kits to Charge Air Coolers, Standard® has the parts needed to repair turbocharger systems correctly the first time.

Diesel Turbo Kits

New Diesel Turbo Kits

Features & Benefits

Standard® New, No Core Diesel Turbocharger Kits feature 100% new turbochargers so you can install with confidence. Each Turbocharger is a direct-fit replacement for ease of installation and proper performance. All Standard® new Turbochargers are quality tested to meet or exceed OEM quality, and include a 3-year/36,000-mile limited warranty.

100% New, No Core

Can be installed with confidence and no core to return

Premium Cast Housing

For superior durability

Meets OEM Specifications

Rotating journal and thrust bearings are 100% quality tested to meet OEM specifications

Designed and Tested

All Standard® Turbochargers are designed and tested to match OEM quality and performance across the entire RPM range

Complete Kit

Includes all hardware, gaskets, and everything else needed for a complete repair

TBC709 | RAM 2500 (2018-13)

New Diesel Turbocharger Kits Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

2002 Ford F-250 7.3L Powerstroke Turbocharger Replacement

Cummins 6.7 Turbo Actuator Tip | Tech Tip

6.0L Powerstroke Turbocharger Replacement

New Diesel Turbocharger Listings

Reman Diesel Turbo Kits

Features & Benefits

Standard® remanufactured Diesel Turbocharger Kits are remanufactured with components from our selectively curated core inventory to ensure maximum performance and reliability.

Dynamically Balanced

Compressor wheels, turbine shaft/wheel assemblies, and complete center section assemblies to ensure proper operation

Includes New Electrohydraulic Control Valve

Attached to the unit, eliminating the need to buy this part separately

Complete Kit

Includes new rotating, journal and thrust bearings and the required gasket and mounting hardware for easy installation

TBC521 | RAM Trucks (2012-07)

Reman Diesel Turbocharger Kit Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Understanding Turbocharger Operations | Tech Tip

Dodge 6.7 Cummins Turbo Replacement

Turbocharged Turbo Diagnostics and Repair Tips | Pro Training PowerHour

Reman Diesel Turbocharger Listings

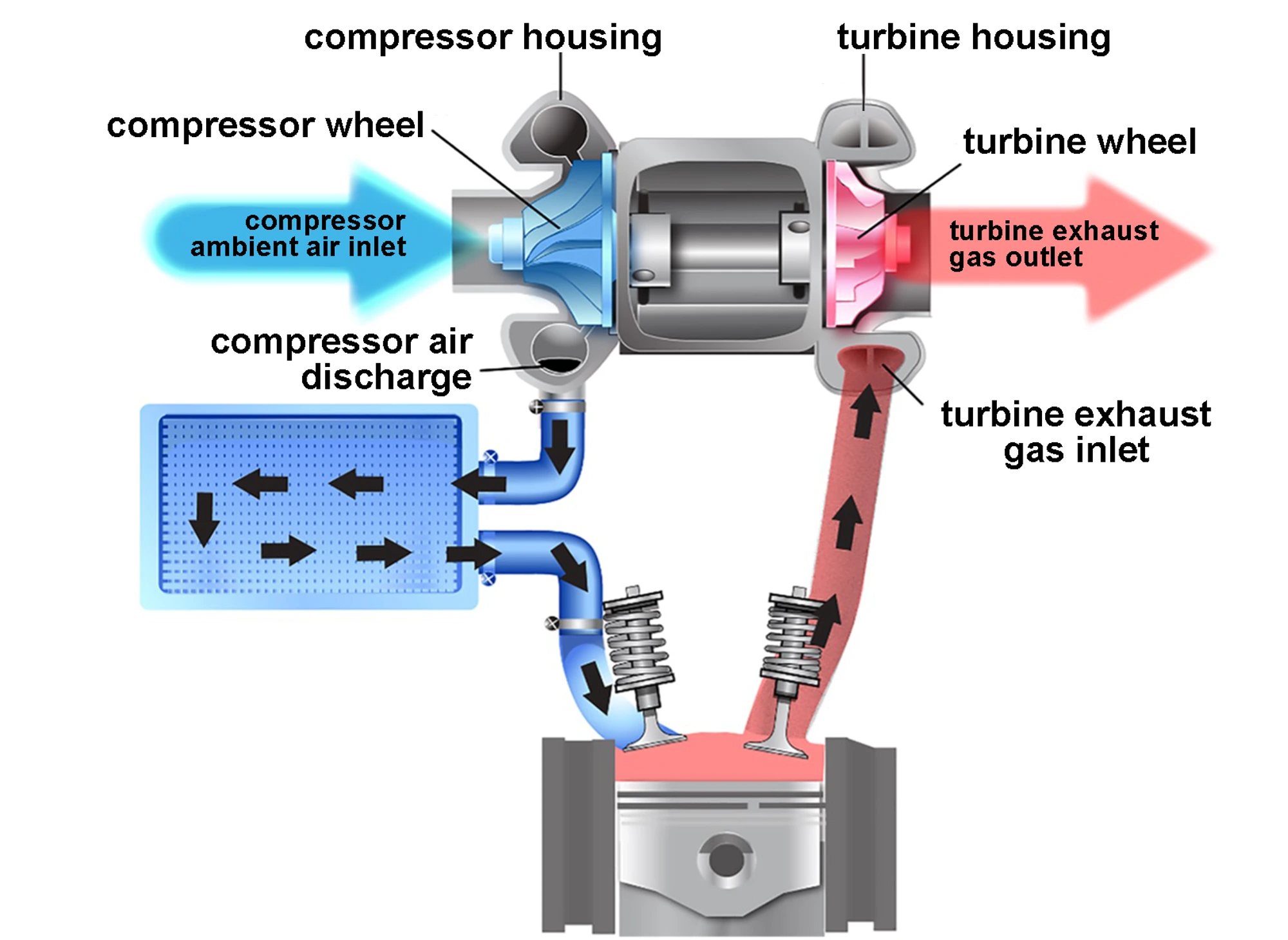

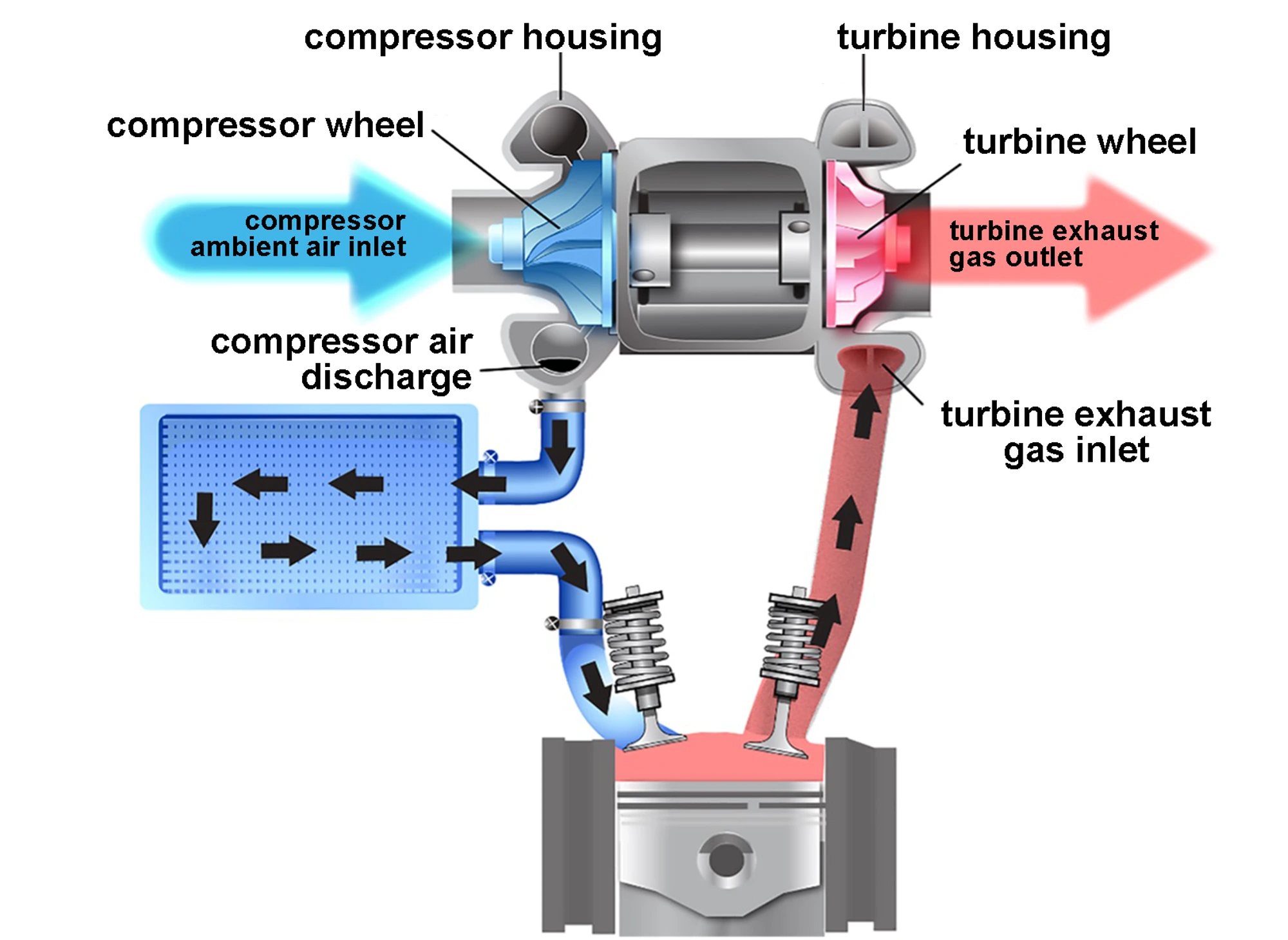

System Overview

System Overview

The turbocharger system converts exhaust gases into centrifugal force by flowing the exhaust through the turbine housing forcing the turbine wheel into motion. As the turbine wheel spins, the compressor wheel on the opposite end of the common shaft draws fresh air into the turbocharger, where it is compressed and forced into the intake system. As the intake air is compressed, it builds heat that must be cooled so the air flows through the intercooler before entering the combustion chamber. The result is more dense air entering the combustion chamber, so more fuel can be added, resulting in better efficiency and more power.

Gas Turbo Kits

Features & Benefits

Features & Benefits

Standard® New, No Core Gas Turbocharger Kits feature 100% new turbochargers so you can install with confidence. Each Turbocharger is a direct-fit replacement for ease of installation and proper performance. All Standard® new Turbochargers are quality tested to meet or exceed OEM quality, and include a 3-year/36,000-mile limited warranty.

Premium Cast Housing

For superior durability

100% Tested

Rotating journal and thrust bearings ensure OE-matching performance

100% New, No Core

So you can install with complete confidence with no core to return

Complete Kit

Includes all hardware, gaskets, and everything else needed for a complete repair

TBC599 | Hyundai / Kia Cars & SUVs (2020-15)

Videos

Gas Turbocharger Kits Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

A Closer Look: Turbocharger Kits

Best Practices for Turbocharger Service

Turbocharger Overview And Common Weak Points

System Overview

System Overview

The turbocharger system converts exhaust gases into centrifugal force by flowing the exhaust through the turbine housing forcing the turbine wheel into motion. As the turbine wheel spins, the compressor wheel on the opposite end of the common shaft draws fresh air into the turbocharger, where it is compressed and forced into the intake system. As the intake air is compressed, it builds heat that must be cooled so the air flows through the intercooler before entering the combustion chamber. The result is more dense air entering the combustion chamber, so more fuel can be added, resulting in better efficiency and more power.

Gas Diesel Turbocharger Listings

Turbo Components

Bypass Valves

Features & Benefits

Standard® Turbocharger Bypass Valves are engineered for precise performance, durability and a long service life and are available for import and domestic vehicles.

OE-Matching Connectors

Ensures exact-fit connection to engine wiring harness

Metal Bushing

Drastically reduces risk of cracking the mounting surface during installation

Precision-Manufactured

Utilizing an extensive use of robotics

Tested and Validated

100% product in-line and end-of-line inspection from raw material to packaging

OE-Matching O-Ring

Provides a precise fit and prevents leaks

TBV1009 | Ford / Lincoln Cars & SUVs (2022-14)

Turbocharger Component Videos

The StandardBrand YouTube Turbochargers playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Cummins 6.7 Turbo Actuator Tip | Tech Tip

Turbo Bypass Valve Operation and Testing – Vacuum Controlled | Tech Tip

Turbo Wastegate Testing – Vacuum and Pressure Controlled | Tech Tip

Turbocharger Bypass Valves

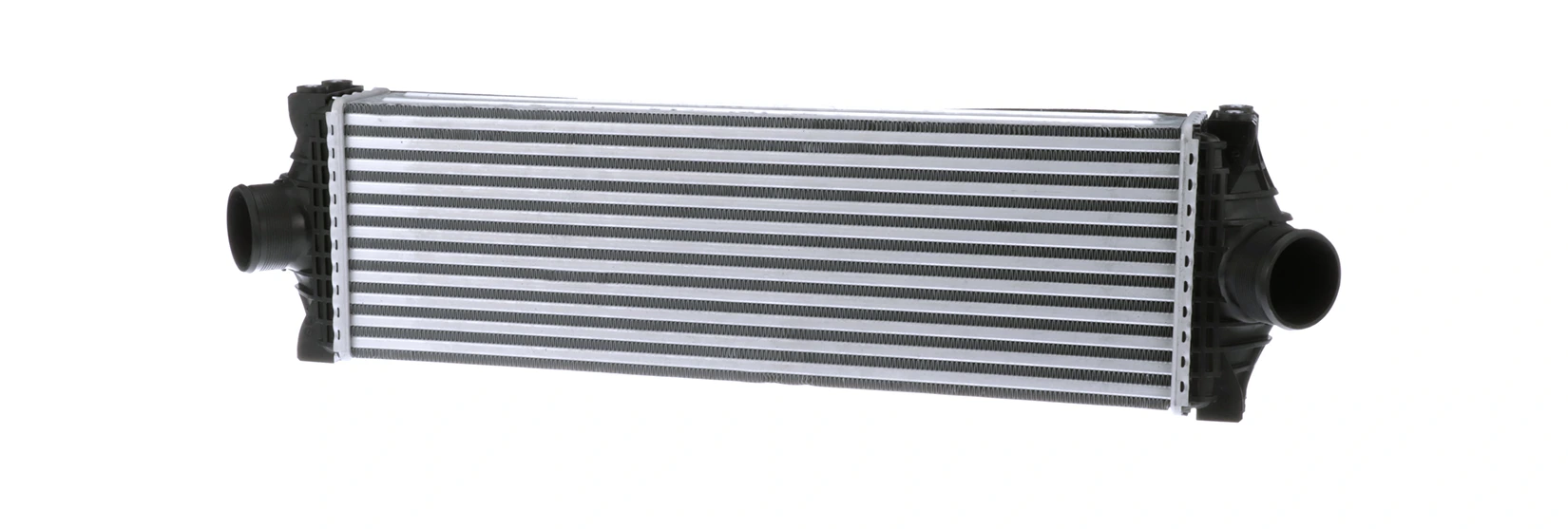

Intercoolers

Features & Benefits

Intercoolers cool the air using heat transfer before it enters the intake manifold. Standard® Charge Air Coolers are direct-fit OE replacements to ensure proper fit, form and function.

Tested and Validated

Extensively tested to OE specifications to ensure superior performance and a long service life

Precision Manufacturing

Undergoes extensive design and manufacturing processes to ensure superior durability, longevity and performance, even under extreme conditions

CAC9 | Ford Transit Vans (2021-15)

Turbocharger Component Videos

The StandardBrand YouTube Turbochargers playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Cummins 6.7 Turbo Actuator Tip | Tech Tip

Turbo Bypass Valve Operation and Testing – Vacuum Controlled | Tech Tip

Turbo Wastegate Testing – Vacuum and Pressure Controlled | Tech Tip

Intercoolers (Charge Air Coolers)

MAP Sensors

Features & Benefits

Manifold absolute pressure (MAP) sensors measure the turbo manifold pressure to the ECM and calculates air density and required fuel delivery for optimum combustion. Standard® MAP Sensors are direct-fit OE replacements, ensuring ease of installation and resulting in correct measurements of pressure inside the intake manifold.

Precision Manufacturing

Undergoes extensive design and manufacturing processes to ensure superior durability, longevity and performance, even under extreme conditions

Tested and Proven

Precise automated wire bonding equipment and inspection processes ensure repeatable and reliable electrical connections

Heavy-Duty Case

High-temperature, synthetic case creates hermetically sealed cavity for sensor on one side with port for pressure on the other

OE-Matching

Connectors and terminals ensure exact-fit connection to the engine wiring harness

AS417 | Hyundai / Kia (2022-08)

Turbocharger Component Videos

The StandardBrand YouTube Turbochargers playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Cummins 6.7 Turbo Actuator Tip | Tech Tip

Turbo Bypass Valve Operation and Testing – Vacuum Controlled | Tech Tip

Turbo Wastegate Testing – Vacuum and Pressure Controlled | Tech Tip

MAP Sensors

Turbo Actuator

Features & Benefits

Turbocharger actuators control the flow of exhaust gases through the turbocharger. Standard® Turbocharger Actuators are available for import and domestic vehicles. Each one is a direct-fit replacement for the damaged OE part that fits and performs like the original.

Tested and Proven

Undergoes extensive testing to OE specifications to ensure long-term reliability

Direct-Fit Replacement

To ensure proper fit, form, and function

TBA6 | Hyundai Cars (2014-12)

Turbocharger Component Videos

The StandardBrand YouTube Turbochargers playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Cummins 6.7 Turbo Actuator Tip | Tech Tip

Turbo Bypass Valve Operation and Testing – Vacuum Controlled | Tech Tip

Turbo Wastegate Testing – Vacuum and Pressure Controlled | Tech Tip

Turbocharger Actuators

Turbo Speed Sensors

Features & Benefits

Turbo speed sensors provide the ECM the rotational speed of the turbocharger to help prevent excessive turbo RPMs that can cause turbo and/or engine damage. Standard® Turbo Speed Sensors are engineered to accurately detect turbocharger operating speed and help reduce exhaust temperatures.

Tested and Validated

To OE specifications to ensure superior performance, reliability, and a long service life

Precision Engineered

To accurately detect turbocharger operating speed, clear P0106 trouble codes and reduce exhaust temperatures

Direct-Fit Replacement

To ensure superior performance and a long service life

TSS2 | RAM Trucks (2020-14)

Turbocharger Component Videos

The StandardBrand YouTube Turbochargers playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Cummins 6.7 Turbo Actuator Tip | Tech Tip

Turbo Bypass Valve Operation and Testing – Vacuum Controlled | Tech Tip

Turbo Wastegate Testing – Vacuum and Pressure Controlled | Tech Tip

Turbocharger Speed Sensors

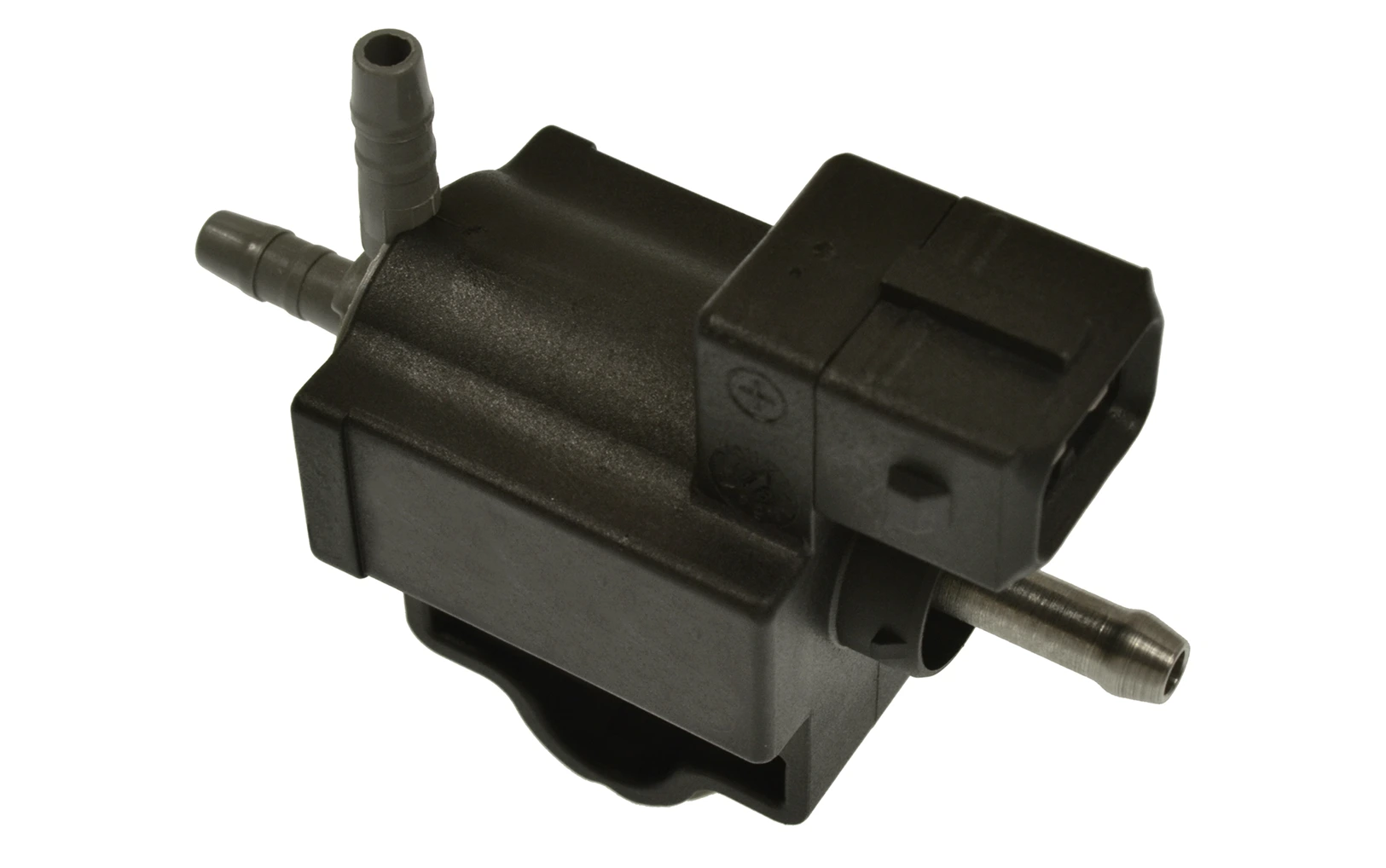

Wastegate Solenoids

Features & Benefits

Turbocharger wastegate solenoids regulate the amount of boost on turbocharged engines. Standard® Wastegate Solenoids are extensively tested to OE specifications to ensure superior performance and a long service life.

Direct-Fit Replacement

For ease of installation

Extensively Tested

In the lab to ensure correct performance and a long service life

TBV1004 | GM Cars & SUVs (2021-11)

Turbocharger Component Videos

The StandardBrand YouTube Turbochargers playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Cummins 6.7 Turbo Actuator Tip | Tech Tip

Turbo Bypass Valve Operation and Testing – Vacuum Controlled | Tech Tip

Turbo Wastegate Testing – Vacuum and Pressure Controlled | Tech Tip

Turbocharger Wastegate Solenoids

Turbocharger Program

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in turbochargers. Here’s what they say to look out for during a turbocharger service or installation.

When a turbocharger fails, the motorist will likely experience a lack of power and reduced fuel mileage. The engine may also begin to operate at higher temperatures.

A turbo failure can send oil and metal debris through the intake. The entire intake system, including the intercooler, should be thoroughly inspected.

Turbos usually don’t fail on their own. The primary causes of turbo failure are contamination and lack of oil.

Air ductwork must be sealed and perfectly clean.

Ensure there is proper lubrication and cooling at the turbo. Bleed fresh engine oil through the new turbo before starting the engine.

Install a new air filter along with an oil change and replace all applicable breathers.

When a turbocharger fails, the motorist will likely experience a lack of power and reduced fuel mileage. The engine may also begin to operate at higher temperatures.

A turbo failure can send oil and metal debris through the intake. The entire intake system, including the intercooler, should be thoroughly inspected.

Turbos usually don’t fail on their own. The primary causes of turbo failure are contamination and lack of oil.

Air ductwork must be sealed and perfectly clean.

Ensure there is proper lubrication and cooling at the turbo. Bleed fresh engine oil through the new turbo before starting the engine.

Install a new air filter along with an oil change and replace all applicable breathers.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-11 of 11

No results found