What's in Your Box?™

TPMS Program

Standard’s blended Tire Pressure Monitoring System Program includes OE-Matching and Multi-Frequency QWIK-SENSOR® TPMS Sensors for 99% coverage.

3 Things To Know

OE-Match Sensors

Standard® offers a full line of OE-Match pre-programmed TPMS Sensors ready to install right out of the box.

QWIK-SENSOR®

QWIK-SENSOR® Multi-Frequency TPMS Sensors combine 314.9MHz - 434MHz applications into one single Sensor program.

99% Coverage

Our blended program offers 99% coverage plus a full line of service kits and TPMS tools.

Standard® Has TPMS Covered

Coverage

Comprehensive Coverage

The Standard® TPMS program covers 99% of the vehicles on the road. That includes OE-Match TPMS Sensors, QWIK-SENSOR® Multi-Frequency Single Sensor Program, mounting hardware, service kits, and TPMS tools for industry-leading late-model coverage.

- Tire Pressure Monitoring Systems (TPMS) first started appearing on vehicles in 2004, and in 2008 it became mandatory that all new light vehicles sold in the U.S. have this important safety system.

Market

Growing Market

TPMS became mandatory on all new light vehicles sold in the U.S. in 2008, and there are around 1 billion TPMS sensors on roads today.

TPMS sensors are entirely powertrain-neutral, meaning they’re used on all light vehicles regardless of powertrain. Gas, diesel, hybrid or EV, the Standard® TPMS program has you covered.

- TPMS sensors should be relearned any time tire/wheel placement is changed.

Service Opportunities

Service Opportunities

TPMS sensors are sealed units powered by batteries, with the typical lifespan of these batteries being 5-10 years. When one TPMS sensor fails, chances are the others will soon follow. To avoid future problems, experts recommend replacing all 4 TPMS sensors at the same time.

- Canned tire sealants can cause immediate damage to TPMS sensors. If any type of sealant has been used, a new TPMS sensor should be installed.

Engineering & Design

Engineering

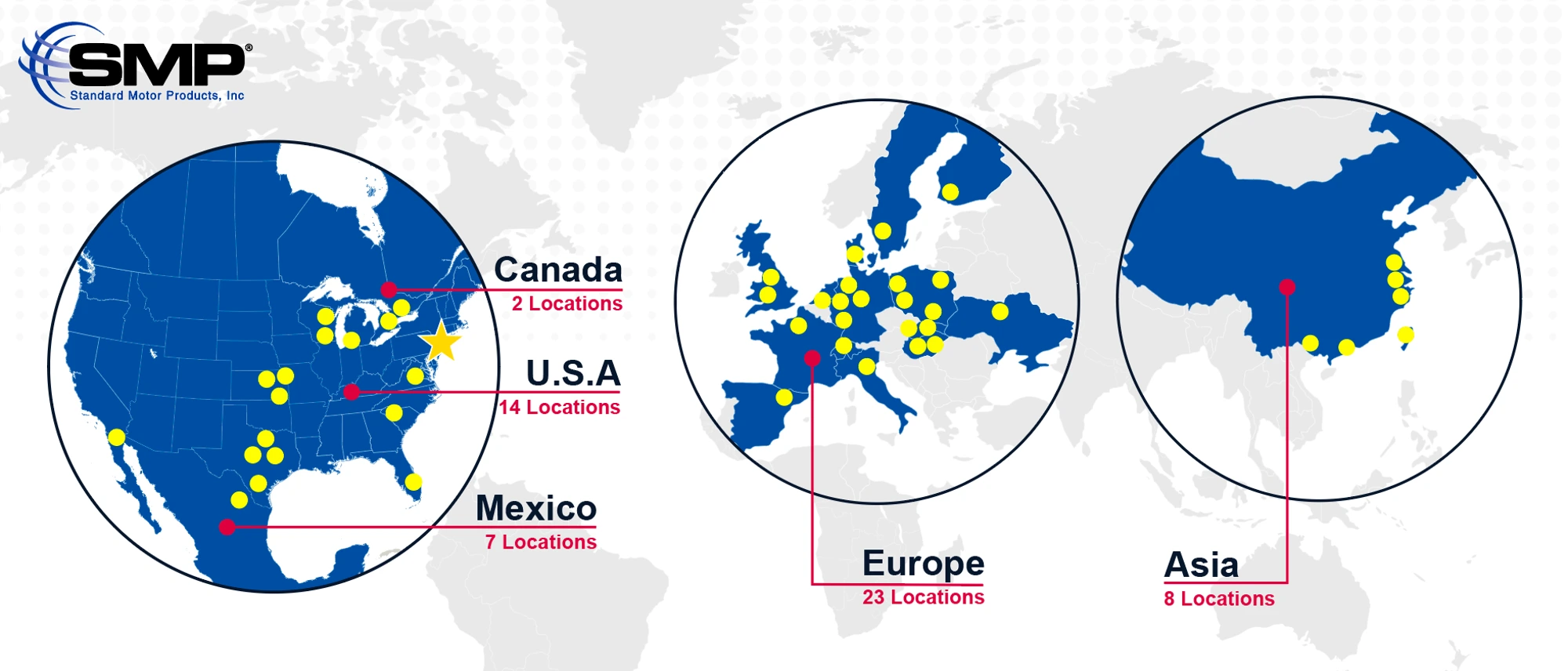

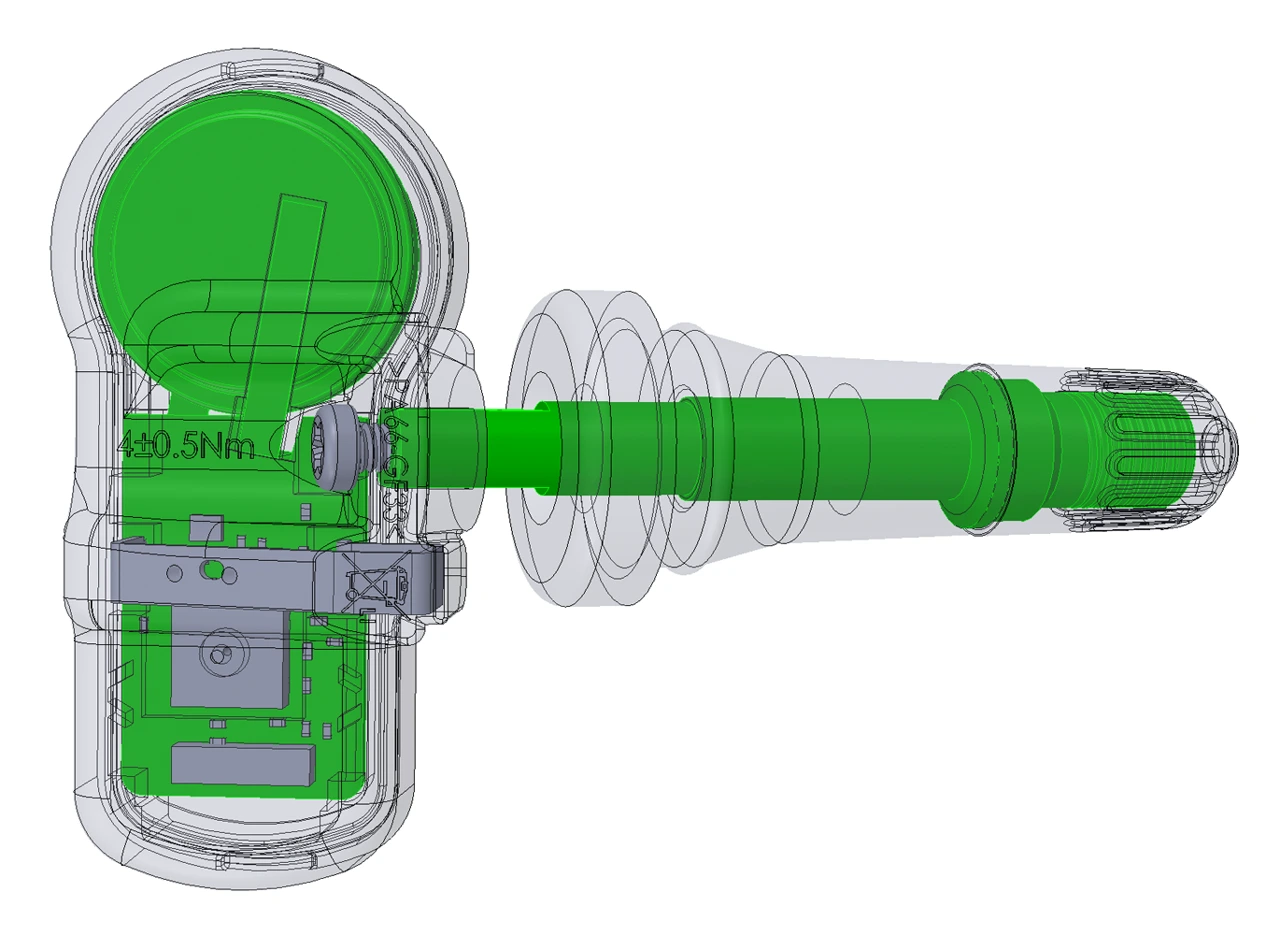

Standard® TPMS Sensors are designed and engineered using the very latest technology.

The QWIK-SENSOR® features faster programming times and a longer battery life, while OE-Match TPMS Sensors are programmed from the factory with exact vehicle-specific application software so they can be directly installed.

- The required sensor programming can be completed before or after installation, and while under pressure.

Manufacturing

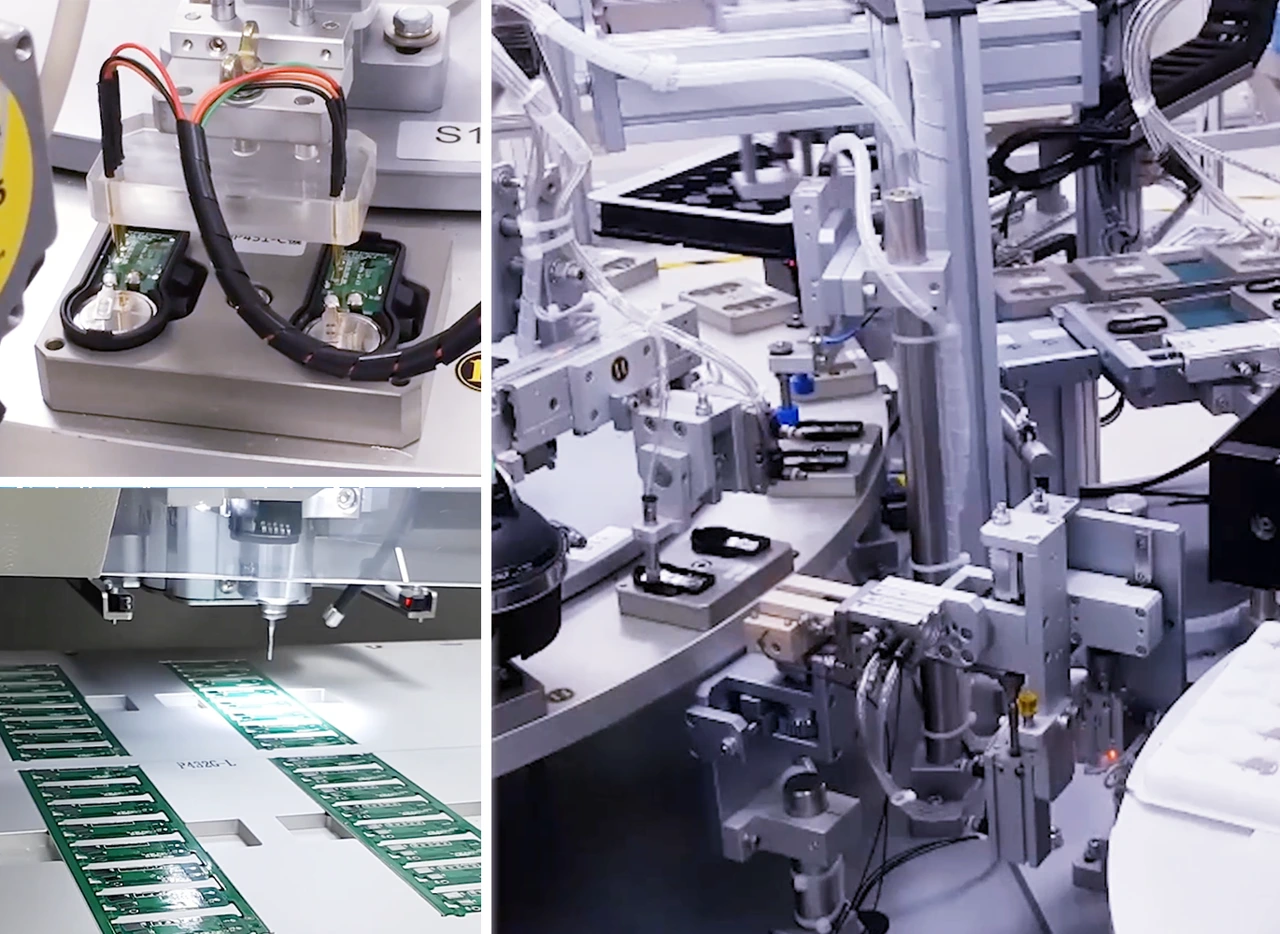

Precision Manufacturing

Standard® TPMS Sensors are designed and manufactured using the latest technology to meet OE performance in compliance with all SAE2657 specifications.

Every Sensor is precision-engineered for application-specific operation and a long service life.

- Our facility produces more than a million Sensors annually, earning international and national certifications including U.S. FCC, European E-Mark, Canada IC, and Taiwan NCC while meeting FMVSS138, SAE J2657, ISO9001, and IATF 16949 quality standards.

Testing & Validation

Testing & Validation

Each Standard® TPMS Sensor undergoes extensive testing to ensure performance and durability. We subject our Sensors to SAEJ2657 certification standards including operational temperature, thermal shock, extreme temperature, humidity, frost, proof pressure, rapid deflation, contamination, salt fog, drop, centrifugal force vehicle speed, and mechanical vibration testing.

- Our results are validated by live 168-hour on-vehicle testing at independent labs.

During normal usage, TPMS sensors are only active for a few hours per day. To make sure our sensor batteries last, we subject them to an Accelerated Life Test.

First, we load the TPMS Sensors in the testing chamber. Next, we run the test 24 hours a day, 7 days a week.

The result is a TPMS sensor battery that lasts, keeping this important safety feature running.

TPMS Categories

Technicians look to Standard® for the parts required to do the job right. From TPMS Sensors to TPMS tools and service kits, Standard® has the parts needed to service TPMS correctly the first time.

TPMS Sensors

OE-Design TPMS Sensors

Features & Benefits

With more than 250 SKUs, Standard® OE-Match TPMS Sensors provide 99% coverage – the best in the industry. Pre-programmed from the factory with exact vehicle-specific OE application software, Standard® TPMS Sensors can be directly installed.

No Programming Required

Pre-programmed and can be installed right out of the box

Maximum Battery Life

Military-grade lithium battery ensures maximum battery life and sensor performance

Direct-Fit Replacement

Matches the original for ease of installation and proper performance

TPM65A | Mazda Cars (2013-04)

OE Design TPMS Sensor Videos

The StandardBrand YouTube TPMS playlist features product and technical information, installation and programming videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Three Things to Know: TPM116RA

Customer TPMS Inspection

Understanding the TPMS Light - Solid or Flashing

OE Design TPMS Sensors

QWIK-SENSOR TPMS Sensors

Features & Benefits

QWIK-SENSOR® Multi-Frequency TPMS Sensors combine all frequencies into a single sensor, eliminating duplication of inventory. The QWIK-SENSOR® is available with a factory-installed rubber or metal valve stem, and works on both domestic and import applications with 314.9MHz to 434MHz TPMS systems. Each Sensor is independently tested to match OE protocols including LOCSYNC, PAL, POD, and WAL advanced TPMS technologies.

ASIC-Equipped

Application-Specific Integrated Circuit features an accelerometer which uses multi-axis positioning allowing the TPMS system to accurately display pressure on demand

Available in Multipacks of 25

For Professionals: Contains 25 individually wrapped QWIK-SENSORS® (available in rubber or metal valve stems)

Metal or Rubber Valve Stem

Factory-installed

Enhanced Signal Integrity

Surface-mounted, dual-band antenna enhances signal integrity and reliability without compromising battery life to ensure data is transmitted accurately

QS106R | Universal

Compatibility

QWIK-SENSOR® Multi-Frequency TPMS Sensors are compatible with most popular TPMS programming tools. For a complete list of compatible tools, including our QWIK-SENSOR® programming tools, view our Just the Facts: QWIK-SENSOR® Tool Compatibility flyer.

QWIK-SENSOR® TPMS Sensor Videos

The StandardBrand YouTube TPMS playlist features product and technical information, installation and programming videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® Single Sensor TPMS Program

T47000 TPMS Tool Copy/Clone Set of QWIK-SENSORs DEMO

T47000 TPMS Tool Retrieve-ID For Copy Clone Set of QWIK Sensors Demo

QWIK-SENSOR® TPMS Sensors

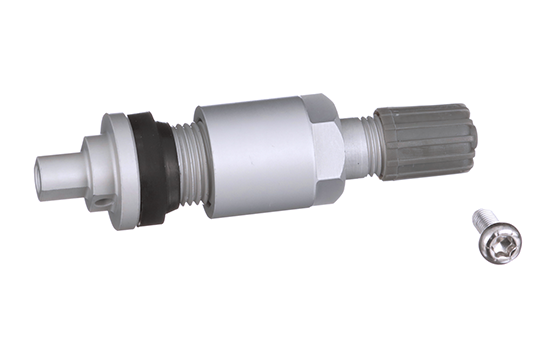

TPMS Service Kits

Features & Benefits

Standard® offers a full line of complete TPMS Service Kits including valve cores, valve nuts, seals, washers and valve caps. Each component in our TPMS Service Kits is precision-engineered with high-grade materials for peak operation, enhanced performance and a long service life.

Precision-Engineered

With high-grade materials for peak operation and reliability

OE-Matching

A full line of complete TPMS coverage, matching the OE for perfect fit and proper performance

TPM1050K | Jaguar / Land Rover Cars & SUVs (2016-04)

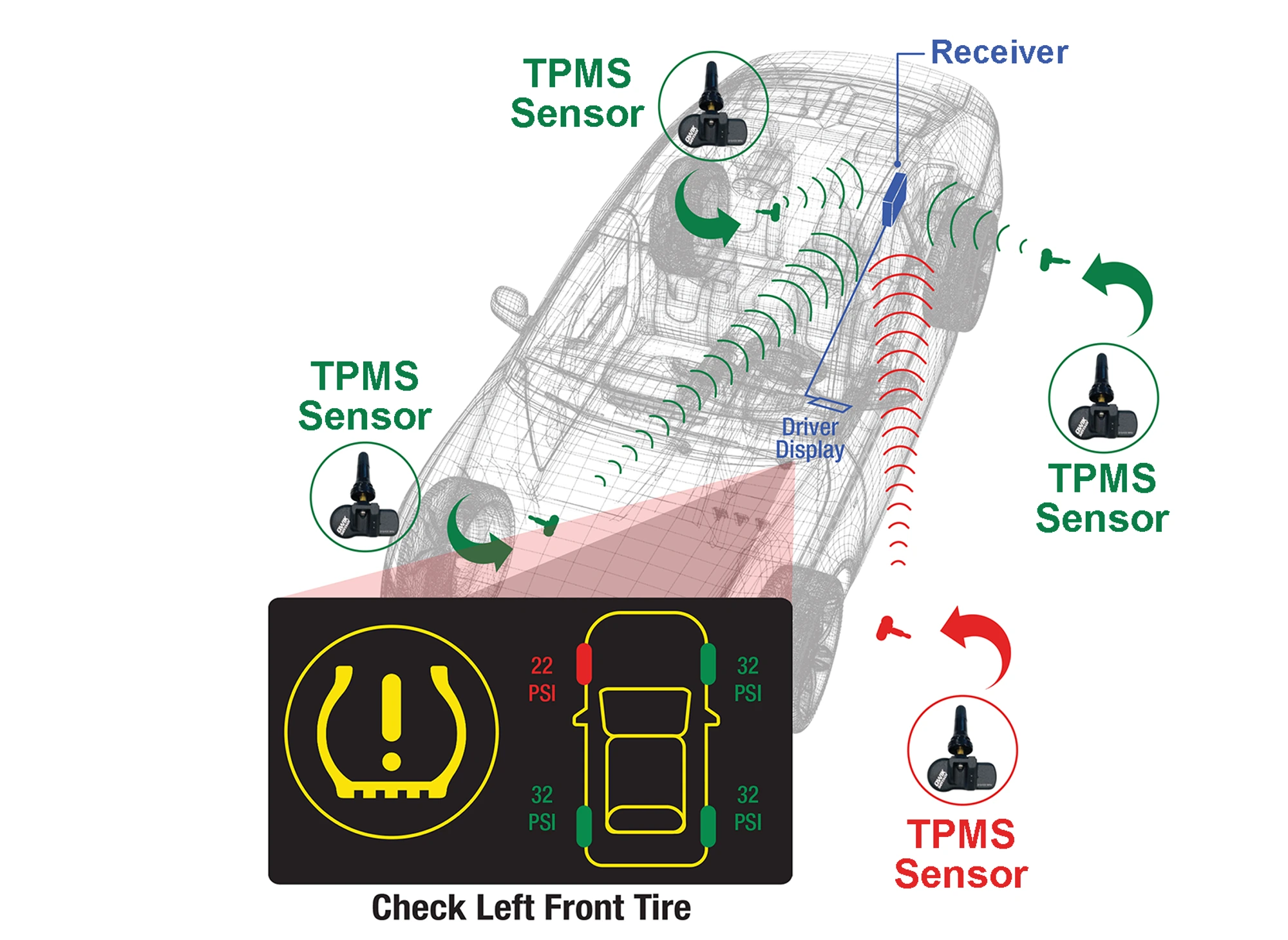

System Overview

System Overview

The TPMS sensor is typically located as a valve-mounted stem in the tire. There are also band-mounted sensors that are attached to the wheels themselves. TPMS sensors can fail due to road hazard damage, overtightening, using an improper valve core, electronic failure and sensor battery discharge.

TPMS Programming Tools

T47000

Features & Benefits

Standard’s T47000 TPMS Service Tool Kit is a TPMS diagnostic tool that provides comprehensive make, model and year-specific relearn procedures built into the tool, speeding up the repair process and saving technicians money.

Direct & Indirect Relearns

Provides both direct (OBD, auto, manual) and indirect TPMS relearn procedures

Limited Lifetime Updates

Included for the original purchaser

QWIK-SENSOR®-Compatible

Programs QWIK-SENSOR® TPMS Sensors by create, copy, copy by ODBII, copy by set of sensors or TPMS ID input

Built-In OBD Module

With a quick connect cable, allowing simple and easy OBDII transfers without the need for an additional accessory

T47000 | Universal

T47000 Tool Videos

The StandardBrand YouTube TPMS playlist features product and technical information, installation and programming videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

T47000 TPMS Tool RKE Key Fob test Demo

T47000 TPMS Tool - Create New QWIK-SENSOR® Demo

T47000 TPMS Tool Tire Pressure Placard Adjustment Demo

T48000

Features & Benefits

The Standard® T48000 TPMS Service Tool Kit is a comprehensive TPMS diagnostic tool that allows technicians to efficiently service universal and OE TPMS sensors. This tool programs Standard® OE-Match Sensors, QWIK-SENSOR® Multi-Frequency Sensors, and other popular universal and multi-coverage sensors.

Integrated OBDII Module

Eliminates the need for a separate dongle

Application-Specific Relearns

Comprehensive make, model, and year-specific relearn procedures speed up the repair process

Wi-Fi-Capability

Allows for software updates without the need to plug into a PC

Bluetooth Technology

Allows for connection to peripherals and accessories wirelessly

T48000 | Universal

T48000 Tool Videos

The StandardBrand YouTube TPMS playlist features product and technical information, installation and programming videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

TPMS Tech Tip: Tool Update

Standard® Single Sensor TPMS Program

TPMS Tech Tip: Signal Interference From Hoist

T57000

Features & Benefits

The Standard® T57000 advanced TPMS Service Tool provides comprehensive coverage for domestic, European, and Asian vehicles, allowing for complete TPMS service management. Built-in relearn procedures speed up the repair process. This tool programs universal multi-coverage sensors.

Bluetooth Technology

Allows for connection to peripherals and accessories wirelessly

Onboard History

Saves TPMS history onboard and in PC so professional repair work order information can be provided to customers

Integrated VIN Scanner

Ensures accurate selection of make/model/year

High-Resolution Touch Screen

4.3-inch color display allows for easy navigation

T57000 | Universal

T57000 Tool Videos

The StandardBrand YouTube TPMS playlist features product and technical information, installation and programming videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

TPMS Tech Tip: Tool Update

Standard® Single Sensor TPMS Program

TPMS Tech Tip: Signal Interference From Hoist

TPM5020

Features & Benefits

Standard’s complete TPM5020 TPMS Tool Kit includes all of the tools needed to complete a TPMS service neatly packed and protected in a molded tool case.

Sockets and Tools

Includes T-10, T-15, T-20 and 7mm sockets, as well as pre-torqued T-20 and T-10 tools

Torque Wrench

¼-inch torque wrench (20-200 in/lb) complete with 11mm and 12mm deep sockets, offering wider torque range and ensuring accurate TPMS nut installation

Additional Tools

Includes Beru valve stem holding tool, grommet pick, grommet slide and valve core tool

TPM5020 | Universal

TPM5020 Tool Videos

The StandardBrand YouTube TPMS playlist features product and technical information, installation and programming videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Customer TPMS Inspection

Understanding the TPMS Light - Solid or Flashing

Standard® Single Sensor TPMS Program

Tire Tread Depth Gauge

Features & Benefits

The Standard® TPMSSDTG TPMS Programming Tool connects to our T56000 and T57000 diagnostic tool kits allowing for a complete tire and TPMS sensor check during routine maintenance.

Color-Coded

Green, yellow and red color coding effectively illustrates wear against safety thresholds, helping to promote customer service and tire sales

Easy Results

Connects to T56000 and T57000 where results can be displayed or transferred to a PC to share with customers

Detects Worn/Damaged Tires

Professional-grade tool allows for the quick detection of worn tires, tire damage and even poor alignment resulting in additional service and tire sales opportunities

TPMSSDTG | Universal

Tire Tread Depth Gauge Videos

The StandardBrand YouTube TPMS playlist features product and technical information, installation and programming videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Tire Tread Depth Gauge VT56000 SMP TPMS Tool Accessory

Tire Tread Depth with the T56000 TPMS Tool

Standard® Single Sensor TPMS Program

TPMS Tool Updates

Features & Benefits

Standard® uses Live Sensor technology in our TPMS tools. The Live Sensor function allows Standard® to update database files for programmable tools without waiting for a whole new software update. Live Sensor allows the release of make-model-year coverage and updates as soon as they are available, in as little as a few hours. In addition, any mistakes or errors found in the data can be immediately fixed for all users in real-time.

TPMS Tool Updates

Updating Your TPMS Tools Is Easy

Download the update for the T47000, T48000, and T57000 tools. (PC only)

Once downloaded, simply follow the steps to keep your tool up to date with the latest software. Updates will continually be released, so check back for updates.

TPMS Tool Update Videos

The StandardBrand YouTube TPMS playlist features product and technical information, installation and programming videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

TPMS Tools (T46000, T47000, T56000) Software Update Instructions Video

TPMS Tech Tip: Tool Update

Standard® Single Sensor TPMS Program

TPMS Programming Tools

TPMS Program

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in tire pressure monitoring systems. Here’s what they say to look out for during a TPMS service.

Low air in a tire can lead to safety issues like the risk of hydroplaning, diminished brake performance, delayed steering response, and a chance of a blowout.

Underinflated tires can cost a motorist more than $200 more in fuel per year.

A sensor relearn procedure should be performed on any vehicle with TPMS after every tire rotation or replacement.

Every time a tire is removed from the wheel, the TPMS service parts (valve stems, seals, nuts, washers, valve cores and caps) should be replaced, as these parts are all exposed to extreme weather, corrosion and aging.

Canned tire sealants can cause immediate damage to TPMS sensors. If any type of sealant has been used, a new TPMS sensor should be installed.

It is wise to update your TPMS tool regularly. Not only will this keep your tool up-to-date with the most recent vehicle coverage, but it will ensure your tool is equipped with any additional software fixes that may have been released since your previous update.

Low air in a tire can lead to safety issues like the risk of hydroplaning, diminished brake performance, delayed steering response, and a chance of a blowout.

Underinflated tires can cost a motorist more than $200 more in fuel per year.

A sensor relearn procedure should be performed on any vehicle with TPMS after every tire rotation or replacement.

Every time a tire is removed from the wheel, the TPMS service parts (valve stems, seals, nuts, washers, valve cores and caps) should be replaced, as these parts are all exposed to extreme weather, corrosion and aging.

Canned tire sealants can cause immediate damage to TPMS sensors. If any type of sealant has been used, a new TPMS sensor should be installed.

It is wise to update your TPMS tool regularly. Not only will this keep your tool up-to-date with the most recent vehicle coverage, but it will ensure your tool is equipped with any additional software fixes that may have been released since your previous update.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-14 of 14

No results found