What's in Your Box?™

Sensor Program

Modern vehicles are equipped with more sensors than ever before. Standard’s line of state-of-the-art Sensors are designed for speed, accuracy and durability to provide today’s vehicles systems with the information they require.

3 Things To Know

9,000+ Sensors

Standard® offers more than 9,000 different Sensors covering over 80 categories.

2,600+ ABS Sensors

Standard® has more than 2,600 ABS Speed Sensors, representing 700 million repair opportunities.

Speed, Accuracy & Durability

Our Sensors are designed specifically for speed, accuracy, and durability, delivering the data that vehicles need in real-time to keep every system operating as designed.

Standard® Has Sensors Covered

Coverage

Comprehensive Coverage

Standard® offers more than 80 different types of Sensors across multiple categories. The Standard® Sensors Program includes Chassis and Drivetrain Sensors, Fluid Level Sensors, Fuel Sensors, Position Sensors, Temperature Sensors, Pressure Sensors, ADAS Sensors, and more. Standard® Sensors are engineered and tested for precision and will integrate correctly with the complex systems on today’s vehicles.

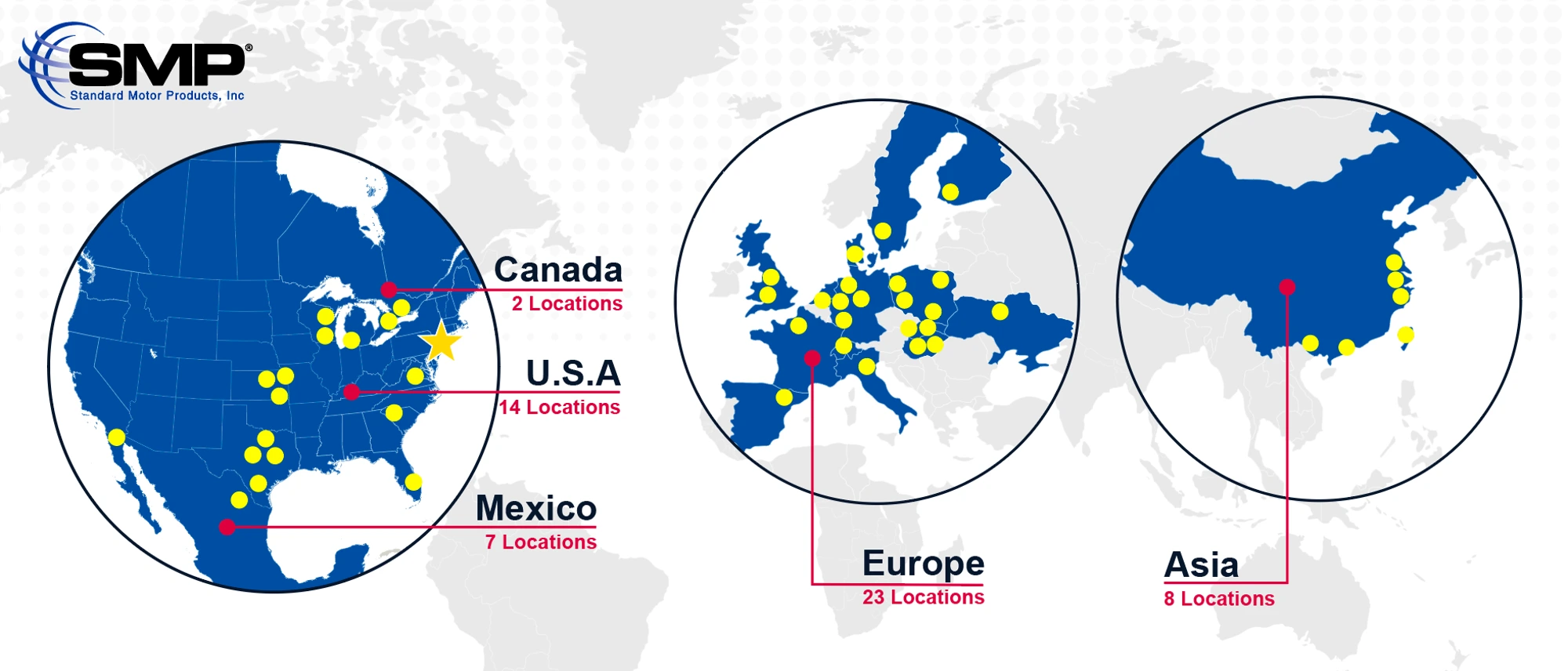

- Standard® manufactures sensors in our own IATF 1649, ISO 9001, and ISO14001-certified facilities.

Market

Growing Market

Modern vehicles are equipped with more sensors than ever. Electronic safety systems and a focus on reducing emissions has created entirely new categories of sensors that were unimaginable 20 years ago. The number of sensors on modern vehicles will continue to grow regardless of powertrain, resulting in more and more service opportunities. As an expert manufacturer of sensors, we have these growing categories covered.

For instance, Standard has nearly two times the Sensors for a 2018 Ford F-150 compared to a 2000 model.

- Many modern turbocharged engines utilize both MAP (Manifold Absolute Pressure) and MAF (Mass Air Flow) sensors to provide the vehicle’s computer with precise information.

Standard® Ford F-150 Sensor Coverage

Service Opportunities

Service Opportunities

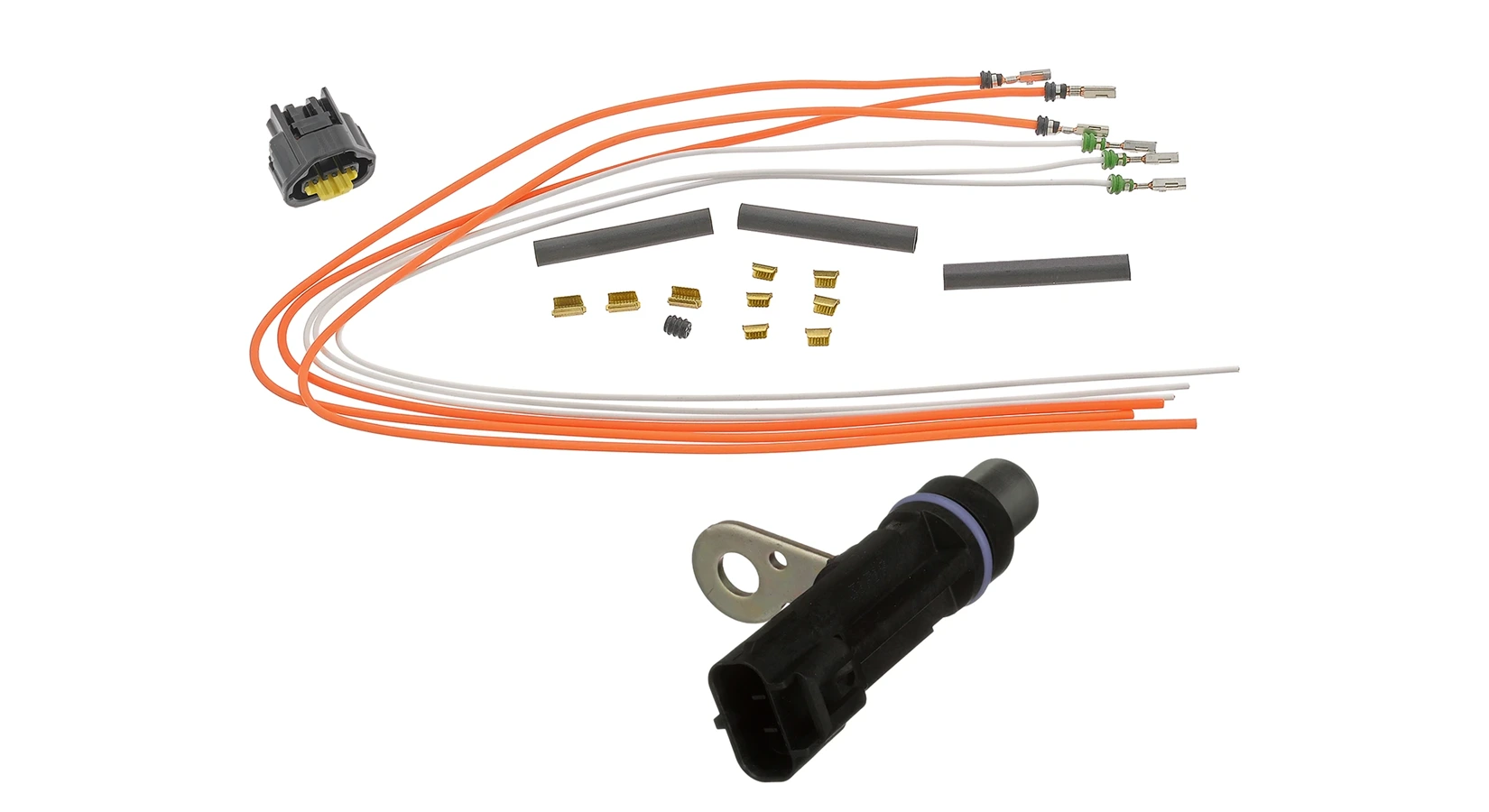

There has already been one recall (2003) and multiple TSBs issued by Nissan and Infiniti regarding issues with camshaft position sensors. These OE issues have been widely reported by technicians in professional forums. Our Blue Streak® Camshaft Sensor Kits address this high-OE-failure opportunity and include both of the required Camshaft Sensors and high-temp connectors for a complete repair solution.

Pictured: PC460K Nissan / Infiniti Cars & SUVs (2018-02)

- Some modern vehicles have up to four camshaft sensors. For optimal ignition timing and fuel injector synchronization, experts recommend replacing them in complete sets.

Engineering & Design

Engineering

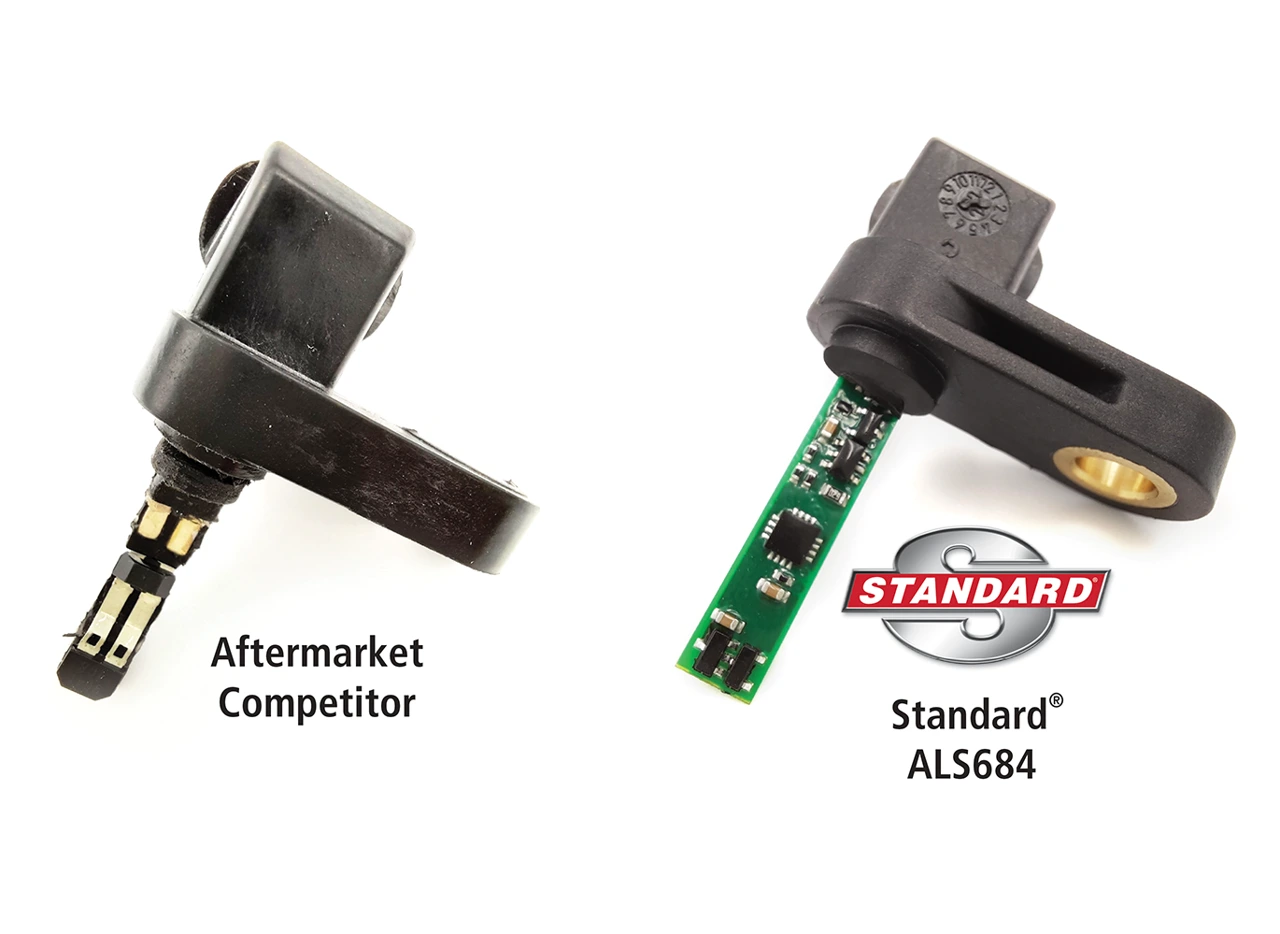

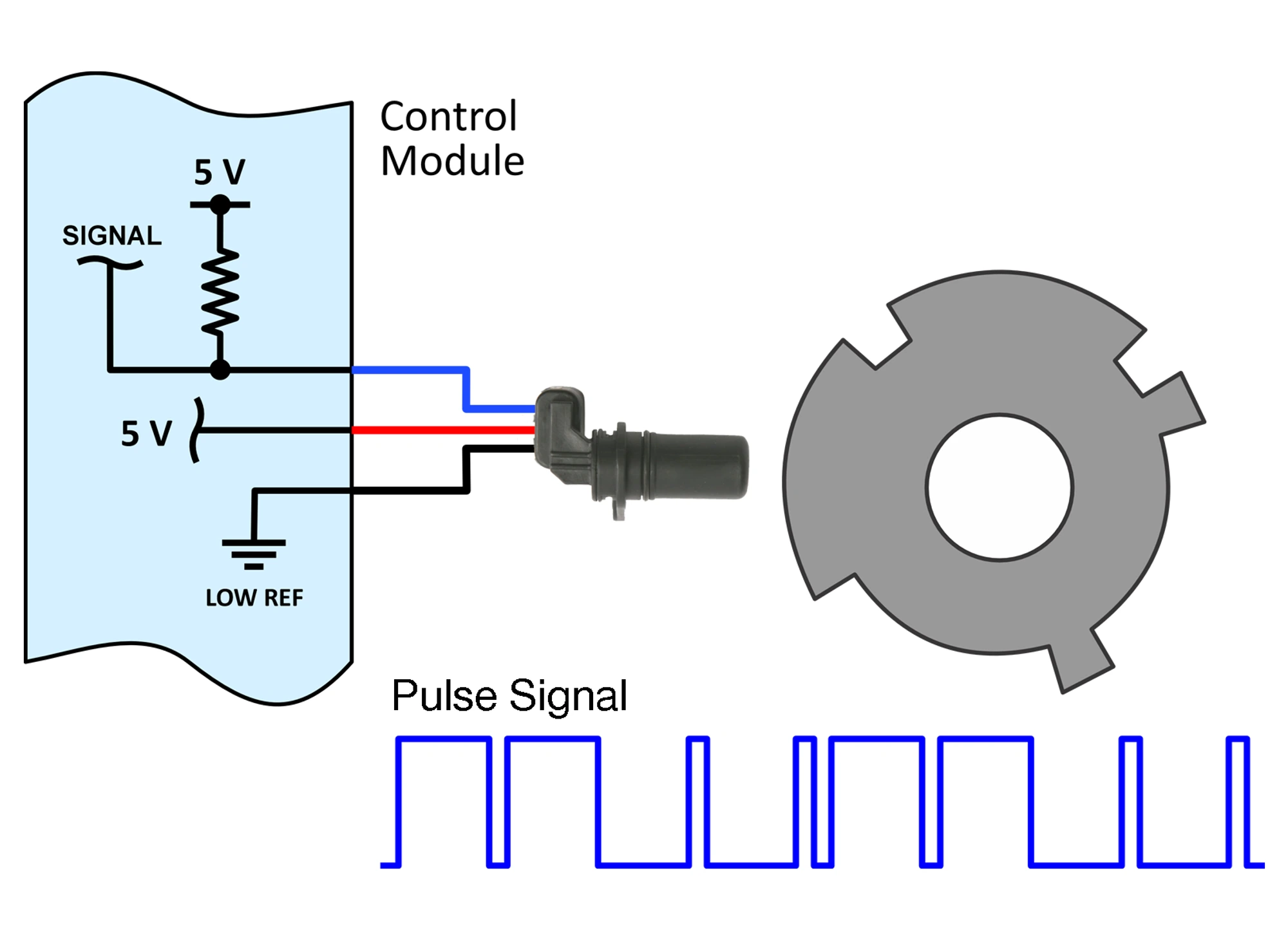

The sensors found on new vehicles are becoming more and more complex. Standard® is committed to engineering sensors that work exactly as the OE intended. For example, in addition to ABS speed sensors on some newer vehicles measuring the speed of each wheel, they also monitor the direction in which the wheel is rotating. A unique signal is sent to the ECU when a wheel is rotating backwards, letting the vehicle know the speed and direction of that wheel. Electronic safety systems utilize this data to help keep vehicle occupants safe. Standard® engineers ABS Sensors that match the performance of the original while many aftermarket alternatives are not capable of measuring the directional rotation of the wheel.

- Standard® has more than 2,600 ABS Speed Sensors, representing 700 million repair opportunities.

Manufacturing

Precision Manufacturing

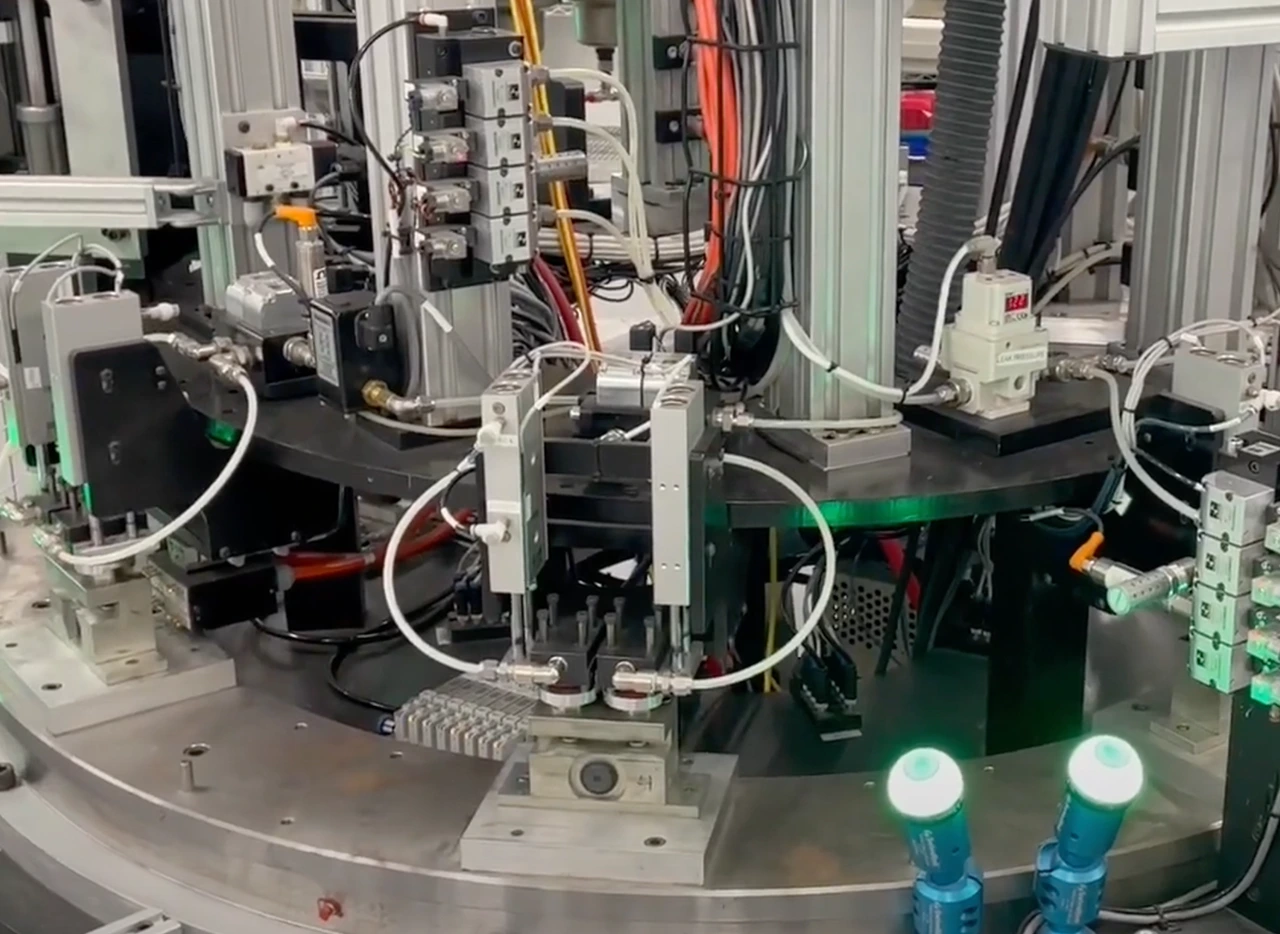

Our TPMS facility produces more than a million Sensors each year and has earned multiple certifications, including US FCC, European E-Mark, and Canada IC while meeting FMVSS 138, SAE J2657, ISO 9001 and IATF 16949 quality standards.

- To make sure our TPMS Sensors last, we subject them to a high-speed Accelerated Life Test.

Testing & Validation

Testing & Validation

Standard® Camshaft and Crankshaft Position Sensors are rigorously tested for pulse width and signal amplitude. Standard® Cam Sensors are subjected to 48-68 hour vibration tests across multiple planes to ensure correct and accurate performance in any situation. Standard® Crank Sensors undergo intense chamber testing from -40 to 257 degrees. This extensive testing helps protect against incorrect voltage output and short circuits to maintain accuracy in all conditions.

Sensor Categories

Technicians look to Standard® for the parts required to do the job right. From Chassis and Drivetrain Sensors to Temperature Sensors, Standard® has the parts needed to keep the complex, sensor-dependent systems of modern vehicles operating correctly.

Chassis & Drivetrain Sensors

ABS Sensors

Features & Benefits

The ABS speed sensors on some newer vehicles measure more than just the speed of each wheel. They also monitor the direction in which the wheel is rotating. A wheel that is rotating backwards will send a unique signal to the ECU that lets the vehicle know the speed and direction of that wheel. This data is used by electronic safety systems. While aftermarket competitors’ ABS sensors cannot determine which direction the wheels are rotating, the Standard® ALS684 uses microsensors to produce the unique forward and reverse signals that modern vehicles require to keep electronic safety systems working as designed.

Brass Insert

Prevents cracking during installation

Includes Multiple Micro Sensors

Which measure the directional rotation of the wheel as an integral part of electronic safety systems

OE-Style Sealed Connector

For protection in harsh conditions

ALS684 | Toyota / Lexus Cars, Trucks & SUVs (2022-03)

ABS Speed Sensor Videos

The StandardBrand YouTube ABS Speed Sensors playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Recommending Replacement ABS Sensors

What's In Your Box: Standard Anti-lock Brake (ABS) Sensor Program

Standard® ABS Sensors Overview

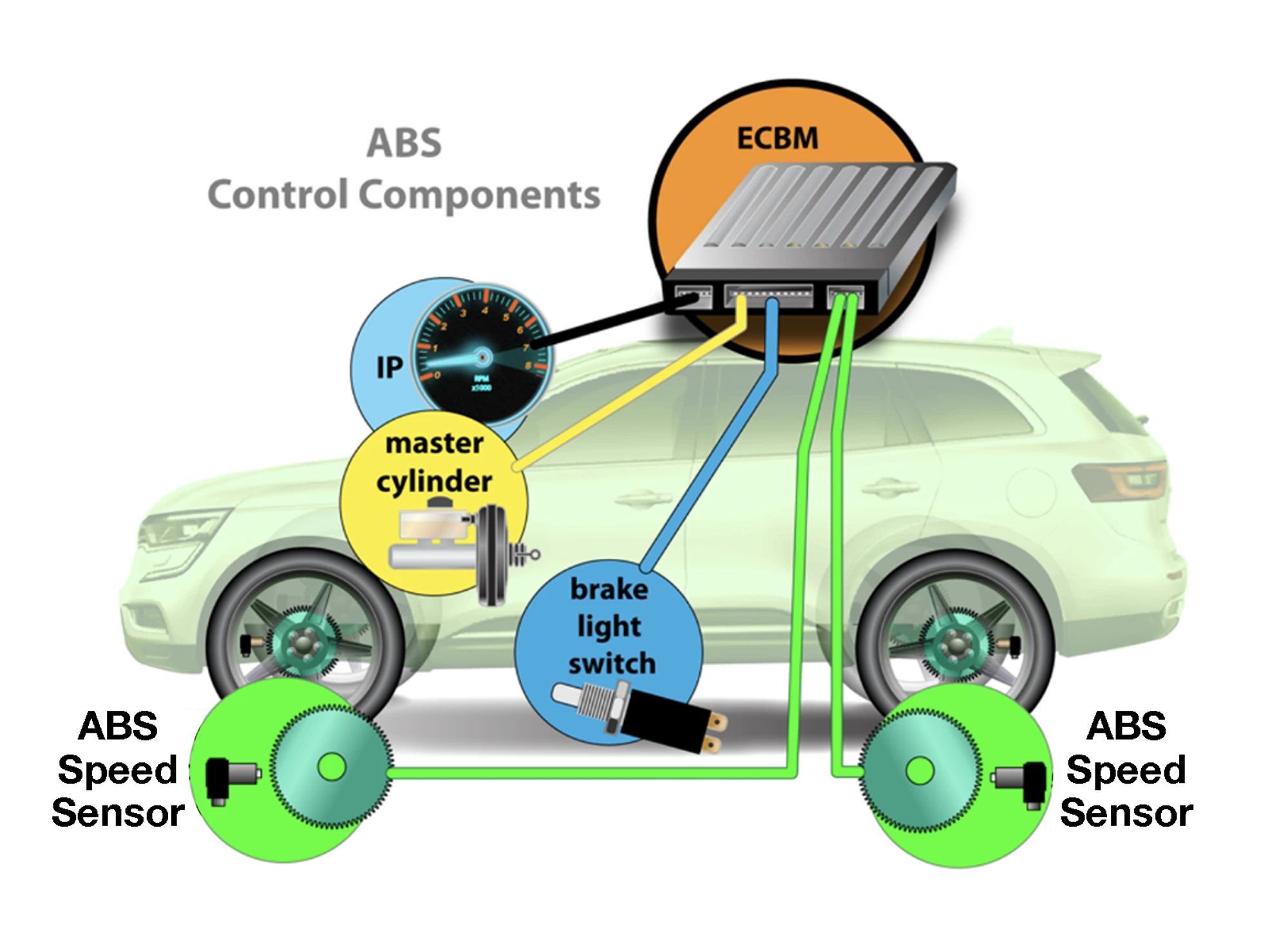

System Overview

Anti-lock Braking Systems are intended to do exactly as the name portrays – prevent a vehicle’s wheels from locking up during a braking event. If any of the wheels lock up, the driver has less control of the vehicle and is more prone to an accident. By releasing some brake pressure to the locked-up wheel, the stopping distance will be increased, but the driver will be able to maintain control to hopefully avoid a collision.

ABS Speed Sensors

Brake Pad Wear Sensors

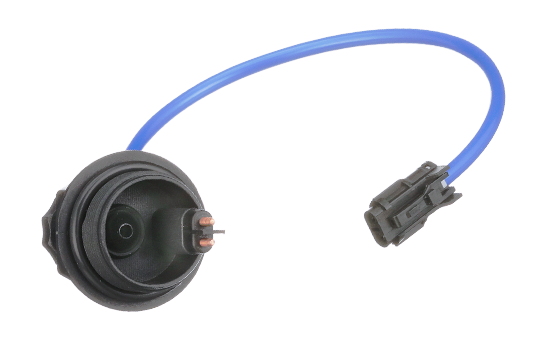

Features & Benefits

The Brake Pad Wear sensor, or brake wear indicator, is an added safety feature on many vehicles used to warn a vehicle’s driver if their brake pad’s life becomes too low. Standard® Brake Pad Wear Sensors are direct OE replacements for ease of installation and seamless operation.

Protective Sleeve

Prevents wire chafing and short-circuiting

High-Quality Materials

High-quality synthetic resin construction resists extreme temperatures and environmental conditions

OE-Style Connectors and Terminals

Ensure water-tight connection to the engine wiring harness

PWS304 | VW SUVs (2015-11)

Brake Pad Wear Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

The Standard® Advantage

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

Brake Pad Wear Sensors

Transmission I/O Sensors

Features & Benefits

Transmission input/output sensors calculate the transmission’s actual gear ratio during usage. Typically, two sensors communicate the transmission data to the vehicle's powertrain control module. The first sensor, referred to as the input sensor, monitors the speed of the transmission’s input shaft. The second sensor is the output sensor, which monitors the output shaft speed. Standard® Transmission Input / Output Sensors are precision-engineered to ensure optimization of engine performance and gas and exhaust regulation.

OE-Exact Output Signal

Ensures accurate readings and peak performance

100% Tested

Environmental, endurance, and end-of-line tested for signal amplitude and polarity to ensure consistent product reliability and performance

OE-Exact Connectors and Terminals

Ensure proper fit

SC495 | Honda Cars & SUVs (2020-13)

Transmission I/O Sensors Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Three Things to Know: SC501 - Transmission Input Sensor

Transmission Input/Output Speed Sensor Installation - Dodge, Chrysler, Plymouth 2.7L

When OE Fails...Trust Standard®

Transmission I/O Sensors

Vehicle Speed Sensors

Features & Benefits

The vehicle speed sensor (VSS) measures transmission/transaxle output or wheel speed. The ECM uses this information to modify engine functions such as ignition timing, air/fuel ratio, transmission shift points, and to initiate diagnostic routines. Standard® Vehicle Speed Sensors undergo environmental, endurance, and 100% end-of-line testing for signal amplitude and polarity to ensure consistent product reliability and performance.

Brass Insert

Prevents cracking during installation and resists corrosion

OE-Style Connectors and Terminals

Ensure water-tight connection and proper fit

OE-Matching Output Signal

Provides accurate readings and peak performance

SC655 | Honda Cars & SUVs (2020-13)

Vehicle Speed Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Three Things to know: SC634 – Vehicle Speed Sensor

The Standard® Advantage

Standard Brand - Here Is What's In Our Box

Vehicle Speed Sensors

Fuel & Pressure Sensors

EGR Valve Pressure Sensors

Features & Benefits

Exhaust gas recirculation (EGR) pressure sensors detect exhaust gas flow through the EGR passage. Standard® EGR Pressure Sensors pass meticulous quality control to assure accurate voltage output for proper performance.

High-Quality Materials

Including multiple precious metal contacts and polymer thick film resistors for extended service life

Tested and Validated

Rigorous end-of-line testing validates output voltages to exacting specifications for reliable, trouble-free operation

VP32 | Ford Super Duty Trucks (2019-11)

EGR Pressure Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard Brand - Here Is What's In Our Box

The Standard® Advantage

When OE Fails...Trust Standard®

EGR Pressure Sensors

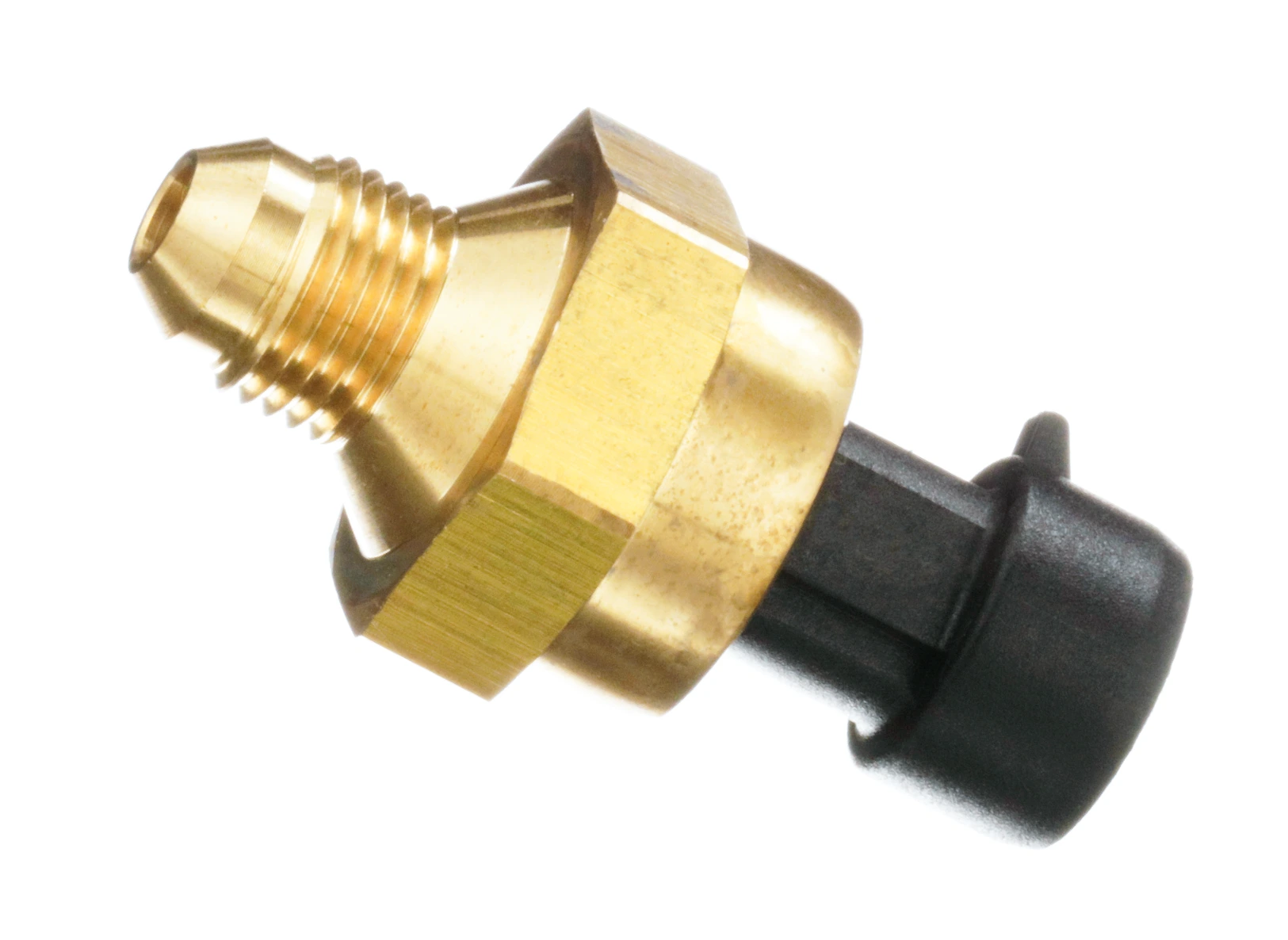

Fuel Pressure Sensors

Features & Benefits

Fuel pressure sensors monitor fuel flow to deliver designed fuel injection performance. They also detect evaporative leaks such as faulty gas caps. Standard® offers a line of fuel pressure sensors to provide coverage and quality for this important EVAP category.

Direct-Fit OE Replacement

Ensures ease of installation and proper performance, resulting in correct pressure measurements

Extensive Design Process

Undergoes extensive design and manufacturing processes to ensure superior durability, longevity and performance, even under extreme conditions

Tested and Validated

Stringent testing and validation processes ensure correct performance and durability

FPS142 | Ford / Lincoln Trucks & SUVs (2024-21)

Fuel Pressure Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

The Standard® Advantage

Fuel Pressure Sensors

Knock Sensors

Features & Benefits

Knock sensors create a voltage signal based on the vibrations caused by detonation. The computer uses this signal to retard timing when spark knock occurs. Standard® Knock Sensors are designed to respond to knock frequencies up to 1000 Hz, accommodating shifts in engine knock frequency and making for a more flexible sensor.

Precision Manufacturing

Sensor body is precision-machined to tune the resonant frequency to the engine knock frequency

Tested and Validated

All units are 100% tested using an accelerometer vibration test to ensure trouble-free operation

Automated Data Acquisition System

Continuously monitors sensor output to ensure that it responds with appropriate voltage output at the specified frequency range

KS225 | Toyota / Lexus / Scion (2024-02)

Knock Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

LS Engine Knock Misdiagnosis | Tech Tip

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

Knock Sensors

MAF Sensors

Features & Benefits

Mass air flow (MAF) sensors are precision components that measure the amount of airflow entering the intake manifold and must communicate clearly with the engine control module. Remanufactured MAF sensors with debris from prior use can hinder this communication and cause the vehicle to experience drivability issues. To ensure accurate airflow, precise performance, and longer service life, Standard® MAF Sensors are 100% NEW, and never remanufactured.

100% New, Never Remanufactured

To avoid leftover debris that can cause sensor failure

Proprietary Sensing Elements

Provide accurate airflow output to ECU over a wide range of ambient temperatures

100% Tested

To ensure that the ECU receives accurate airflow readings under hard engine conditions, which are required to balance and deliver the correct air/fuel ratio to the engine to achieve clean burns

MAS0407 | Nissan / Infiniti Cars, Trucks & SUVs (2024-03)

MAF Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

A Closer Look: Standard Mass Air Flow (MAF) Sensors

Full Housing Style MAF Sensors

Drop In Style MAF Sensors

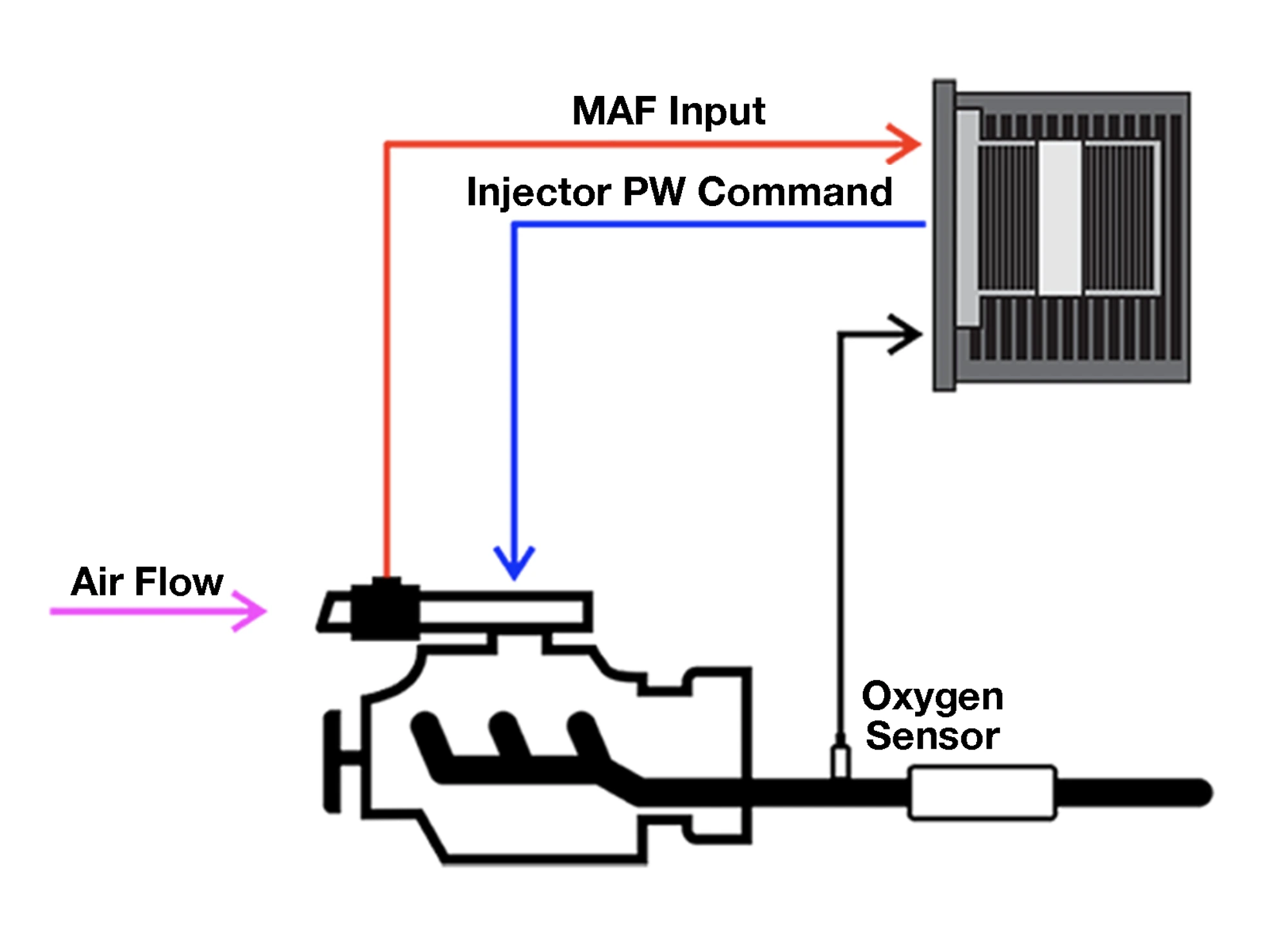

System Overview

In a mass air flow system, the base fuel calculation is very simple. The ECM receives the air mass value from the mass airflow sensor and then calculates the required injector pulse width to deliver the amount of fuel needed for the desired air/fuel ratio.

Mass Air Flow (MAF) Sensors

MAP Sensors

Features & Benefits

MAP (manifold absolute pressure) sensors convert vacuum/manifold pressure to an electric signal. The real-time information is used for both fuel delivery and ignition. Standard® MAP Sensors are 100% tested to make sure variations in pressure generate the correct output to match OE performance in all conditions.

High-Quality Materials

High-temperature, glass-reinforced plastic case creates hermetically sealed cavity for sensor on one side with port for pressure on the other

Tested and Validated

Undergoes precise automated wire bonding equipment and inspection processes to ensure repeatable and reliable electrical connections

AS417 | Hyundai / Kia Cars & SUVs (2022-08)

MAP Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Honda 3.5 Liter MAP Sensor Replacement

MAP Sensor Tech Tips

Dodge Ram Cummins 5.9 MAP/Boost Sensor Replacement

MAP Sensors

Position Sensors

Accelerator Pedal Sensors

Features & Benefits

The performance and accuracy of accelerator pedal sensors is critical to vehicle performance, fuel economy and safety. Standard® Accelerator Pedal Sensors undergo intense testing to make sure the output matches the slope and linearity of the original in all pedal positions.

High-Quality Materials

High-impact ABS plastic provides the best solution to pedal support and spring guide components

Dual Return Springs

Provide redundancy and comfortable, familiar pedal force profile

Multi-Finger Wiper Design

Accurately controls sensor contact to within a few grams of force

APS162 | Honda Odyssey (2010-05)

Accelerator Pedal Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Honda Accord Accelerator Pedal Replacement | Installation Spotlight

Honda Accord Accelerator Pedal Replacement

Three Things to Know: APS504 - Accelerator Pedal Sensor

Accelerator Pedal Sensors (APS)

Camshaft Sensors

Features & Benefits

The performance of variable valve timing on modern engines is dependent on real-time data from the camshaft position sensors. This is why every Standard® Camshaft Sensor is designed for accurate performance, fast processing and long-term durability. We put each unit through end-of-line timing, pulse width, and signal amplitude testing.

Sealed Metal Casing

Prevents oil intrusion

Advanced Circuitry

Provides immunity from electromagnetic interference that meets ISO standards

Fluorocarbon Rubber Oil Seal

Ensures secure fit

Rotated Mounting Ear

Matches the OE design

Integrated Waterproof Connector

Ensures lasting performance

Sealed Construction

Withstands extreme underhood conditions to ensure durability

PC464 | Nissan Cars, Trucks & Vans (2018-01)

Features & Benefits

Blue Streak® developed high-quality Camshaft Sensor Kits to provide technicians with what they need to do the complete job. Our Kits include two Blue Streak® Camshaft Sensors along with the needed high-quality connectors to replace the melted or damaged originals.

Integrated Analog to Digital Converter

Sends a digital signal to the ECM for precise timing to optimize fuel economy and performance

Advanced Circuitry

Provides immunity from electromagnetic interference that meets ISO standards

Complete Kit

Includes two new precision sensors and high-temp connectors for a complete repair

Sealed Construction

Withstands extreme underhood conditions to ensure durability

Fluorocarbon Rubber Oil Seal

Ensures secure fit

PC460K | Nissan Cars & SUVs (2018-02)

Camshaft Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® Cam and Crank Sensors

Cam and Crank Sensors | Standard® WIYB Training Series

Engine Operation – Keeping It In Time | Pro Training Power Hour

System Overview

Camshaft position sensors take readings off the camshaft and in real time send a signal to the vehicle’s control module. That information is used to adjust both fuel and timing for optimal fuel economy, performance and emissions. For the system to perform correctly, the camshaft position sensors much be accurate, fast and be durable enough to perform in high-heat conditions for thousands of miles.

Camshaft Sensors

Crankshaft Sensors

Features & Benefits

Correct ignition timing depends on quick and accurate data from the crankshaft position sensors. All Standard® Crankshaft Position Sensors are precision engineered and manufactured for accuracy, speed and durability. To ensure durability under extreme conditions, our Crankshaft Position Sensors are subjected to extensive testing including a 48- to 64-hour-long vibration test across three different planes.

Matching Connectors

Tin-plated brass terminals ensure accurate, watertight connection to harness

Protective Sleeve

Prevents wires from chafing and creating short circuits

Factory-Installed Grommets and Wire Clips

Ensure proper mounting during installation

High-Strength Neodymium Magnets

Ensure proper signal voltage to the ECM

Integrated Analog to Digital Converter

Digital signal processing with a dynamically adaptive switch point improves accuracy and operation

PC1021 | Hyundai / Kia Cars & SUVs (2018-01)

Features & Benefits

Blue Streak® developed high-quality Crankshaft Sensor Kits to provide technicians with what they need to do the complete job. Blue Streak® Kits include a high-quality Crankshaft Sensor and a direct-replacement high-temp connector for a complete repair solution.

High-Grade Terminals

Copper alloy, brass, and phosphor bronze terminals for durability

Integrated Analog to Digital Converter

And digital signal processing with a dynamically adaptive switch point improves accuracy and operation

High-Quality Materials

Constructed with an insert-molded rare earth magnet and surface mount electronics in a sealed housing suitable for harsh underhood conditions

Complete Kit

Includes a crankshaft sensor and high-quality connector for a complete repair

PC284K | Chrysler / Dodge / Jeep / RAM (2013-99)

Crankshaft Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Cam and Crank Sensors | Standard® WIYB Training Series

Standard® Cam and Crank Sensors

Engine Operation – Keeping It In Time | Pro Training Power Hour

Crankshaft Sensors

Throttle Position Sensor

Features & Benefits

The throttle position sensor moves with the throttle and sends a voltage signal to the computer indicating throttle angle and speed of movement data, which measures engine load and adjusts timing, fuel delivery, converter clutch operation, and clears flood mode. Standard® Throttle Position Sensors are designed, manufactured, and tested to maintain specific installed outputs to match OE designed performance across the entire RPM range.

Magnet Molded

In high-performance polymer to ensure consistent location and low friction with bearing surfaces

Integrated Circuit (IC)

Effectively measures rotation of small magnet attached to throttle shaft and is calibrated to provide accurate, linear output characteristics

Custom Elastomeric Seal

Protects sensor from environmental under-hood elements such as dust, vapor, and liquids

TH381 | Ford Cars, Trucks & SUVs (2019-03)

Throttle Position Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Dodge RAM & Cummins Throttle Position Sensor Installation

Ford Throttle Position Sensor Installation Tips

Throttle Position Sensor (TPS) Installation - Dodge, Chrysler, Plymouth 2.7L

Throttle Position Sensors (TPS)

Temperature Sensors

Air Intake Temp Sensors

Features & Benefits

The air intake temperature sensor is used by the computer to measure air density for fuel mixture control. The computer uses this information to trim the air/fuel ratio according to the air density. Each Standard® Air Intake Temperature Sensor is 100% tested to ensure trouble-free performance and durability.

High-Quality Materials

Withstand extreme underhood conditions

Direct-Fit OE Replacement

For ease of installation

Design Ensures Accuracy

Design specifies tight tolerance thermistor response values to ensure accuracy of temperature measurement and proper operation

AX129 | Mercedes-Benz Cars, SUVs & Vans (2020-96)

Air Intake Temp Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Honda 3.5 Liter Intake Air Temperature Sensor Replacement | Installation Spotlight

Jeep Cherokee Intake Air Temperature Sensor Replacement

Intake Air Temp Sensor Replacement

Air Intake Temperature Sensors

Ambient Air Temp Sensor

Features & Benefits

Ambient Air Temp Sensors change resistance with temperature, information the computer then uses to the trim the air/fuel ratio according to air density. Each Standard® Ambient Air Temp Sensor is a direct-fit OE replacement, manufactured from the highest-quality materials.

Direct-Fit OE Replacement

For ease of installation

High-Quality Materials

Withstand extreme underhood conditions

Extensive Design Process

Undergoes extensive design and manufacturing processes to ensure superior durability, longevity and performance, even under extreme conditions

AX203 | BMW Cars & SUVs (2022-95)

Ambient Air Temp Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard Brand - Here Is What's In Our Box

When OE Fails...Trust Standard®

The Standard® Advantage

Ambient Air Temperature Sensors

Coolant Temp Sensors

Features & Benefits

The coolant temperature sensor monitors coolant temperature and is critical to many PCM functions such as fuel injection, ignition timing, variable valve timing and transmission shifting. The engine can be in danger of damage if it operates at too high of a temperature. Each Standard® Coolant Temperature Sensor is environmental and 100% functional tested to ensure optimum performance and durability out of the box.

Precision-Machined Brass Housing

Maximizes thermal conductivity between sensor body and coolant

Design Ensures Accuracy

Design specifies tight tolerance thermistor response values to ensure accuracy of temperature measurement and proper operation

Durable Connector

Glass fiber-reinforced plastic polymer connector ensures dimensional stability and proper mating connector fit across temperature extremes

AX54 | GM Cars, SUVs, Trucks & Vans (2022-97)

Coolant Temp Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

The Standard® Advantage

Standard Brand - Here Is What's In Our Box

When OE Fails...Trust Standard®

Coolant Temperature Sensors

Cylinder Head Temp Sensors

Features & Benefits

Cylinder head temperature sensors monitor the temperature of the cylinder head to ensure that the engine is within safe operating parameters. Standard® Cylinder Head Temperature Sensors are 100% factory tested to ensure proper performance you can trust.

Design Ensures Accuracy

Design specifies tight tolerance thermistor response values to ensure accuracy of temperature measurement and proper operation

100% Tested

To ensure trouble-free performance

Direct-Fit OE Replacement

For ease of installation

TX91 | Ford / Lincoln Cars, SUVs, Trucks & Vans (2019-97)

Cylinder Head Temp Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

SMP Evolving Capabilities

Standard Brand - Here Is What's In Our Box

When OE Fails...Trust Standard®

Cylinder Head Temp Sensors

Exhaust Gas Temp Sensors

Features & Benefits

Standard® Exhaust Gas Recirculation (EGR) Temperature Sensors are designed to specify tight tolerance thermistor response values to ensure the accuracy of temperature measurement and proper operation.

Design Ensures Accuracy

Design specifies tight tolerance thermistor response values to ensure accuracy of temperature measurement and proper operation

High-Quality Materials

Withstand extreme underhood conditions

Direct-Fit OE Replacement

For ease of installation

TX350 | General Motors Trucks (2022-17)

EGR Temp Sensor Videos

The StandardBrand YouTube channel features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

The Standard® Advantage

Standard Brand - Here Is What's In Our Box

When OE Fails...Trust Standard®

EGR Temperature Sensors

Additional Sensors

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in engine and sensor technology. Here’s what they say to look out for when replacing a sensor.

An inaccurate wheel speed sensor will make the control module think that a wheel is slipping, and reduce engine torque by limiting the throttle opening. Replacing the throttle body will not fix this problem.

Many sensors share the same supply voltage source, and in many cases, a shorted sensor will make all the sensors on that power supply shut down. Typically the quickest solution is to unplug one sensor at a time and cycle the ignition key to see if the reference voltage returns.

A faulty cam sensor can cause an extended crank situation. When the vehicle is being started, the engine may just continue rotating as the computer is looking for enough information.

When replacing a crankshaft position sensor, make sure the appropriate relearn is performed. Failing to do this may cause the vehicle to misfire and run poorly.

When an engine coolant temp sensor is suspected to be faulty, wait for the vehicle to cool so that the coolant temperature and ambient air temp should match. With the vehicle off, if the temps do not match, then the coolant temp sensor may not be reading correctly.

Due to the location of the accelerator pedal sensor and the amount of moisture or condensation that comes from wet floor mats and/or drivers’ wet feet, it is advisable to use dielectric grease on the electrical connector.

An inaccurate wheel speed sensor will make the control module think that a wheel is slipping, and reduce engine torque by limiting the throttle opening. Replacing the throttle body will not fix this problem.

Many sensors share the same supply voltage source, and in many cases, a shorted sensor will make all the sensors on that power supply shut down. Typically the quickest solution is to unplug one sensor at a time and cycle the ignition key to see if the reference voltage returns.

A faulty cam sensor can cause an extended crank situation. When the vehicle is being started, the engine may just continue rotating as the computer is looking for enough information.

When replacing a crankshaft position sensor, make sure the appropriate relearn is performed. Failing to do this may cause the vehicle to misfire and run poorly.

When an engine coolant temp sensor is suspected to be faulty, wait for the vehicle to cool so that the coolant temperature and ambient air temp should match. With the vehicle off, if the temps do not match, then the coolant temp sensor may not be reading correctly.

Due to the location of the accelerator pedal sensor and the amount of moisture or condensation that comes from wet floor mats and/or drivers’ wet feet, it is advisable to use dielectric grease on the electrical connector.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-29 of 29

No results found