What's in Your Box?™

Ignition Program

Standard’s engineering and manufacturing processes use top-of-the-line technology to ensure precise ignition component operation and reliability you can depend on.

3 Things To Know

800+ Ignition Coils

Standard® and Blue Streak® offer more than 800 Coils for 99% aftermarket-leading coverage.

Tested and Validated

Every Ignition Coil is subjected to extensive testing and product validation.

Kits for a Complete Service

Popular Blue Streak® OE Durability Improved Coils are available in multi-packs for a complete Coil service.

Standard® Has Ignition Covered

Coverage

Comprehensive Coverage

Standard’s industry-leading Ignition program offers more than 800 Coils for 99% coverage, as well as a complete line of related components.

In addition to the traditional Coil-On-Plugs, Standard® offers an array of other high-quality Coils and components to help with ignition repairs. From unique coil designs to service kits, Standard® has you covered.

- Exposure to heat, oil intrusion and water intrusion are three of the leading causes of premature failure in OE coils.

Market

Growing Market

There are currently around 283 million vehicles on U.S. roads. In the coming years, U.S. new vehicle sales are forecasted to increase steadily. Combined with the average vehicle age of 12+ years, the car parc is expected to see growth for the foreseeable future — and almost all of them will still be equipped with ignition coils. Ignition coils will remain a strong category for decades to come.

- By 2035, over 262M vehicles on the road (90%) are projected to still use ignition coils.

Vehicles in Operation

Total U.S. Car Parc, Millions of Cars

S&P Global Mobility (LV Sales and Production Forecast July 2023), DOT, Strategy & analysis

Service Opportunities

Service Opportunities

Our engineers discovered that too much energy was passing through each section of the OE coil, creating excess heat and resulting in premature coil failure. They designed a Coil with an additional bobbin section, resulting in less heat and a longer service life. The updated Blue Streak® Coils outperform and outlast the OE design. Blue Streak® multi-packs make it easier for technicians to solve a known problem once and for all.

- When one ignition coil fails, the others are likely not far behind. Save time and money by replacing all ignition coils at one time.

Engineering & Design

Engineering

Premium parts start with premium components. Each Standard® and Blue Streak® Ignition Coil is engineered with features to ensure that our Coils will perform under the most extreme conditions.

Heat is a leading cause of coil failure. The Blue Streak® FD503 features multiple design improvements to improve insulation and reduce operating temperatures. This means better-performing and longer-lasting Ignition Coils.

- In addition to an inability to manage high temperatures, moisture intrusion is another common reason that OE coils fail.

Manufacturing

Precision Manufacturing

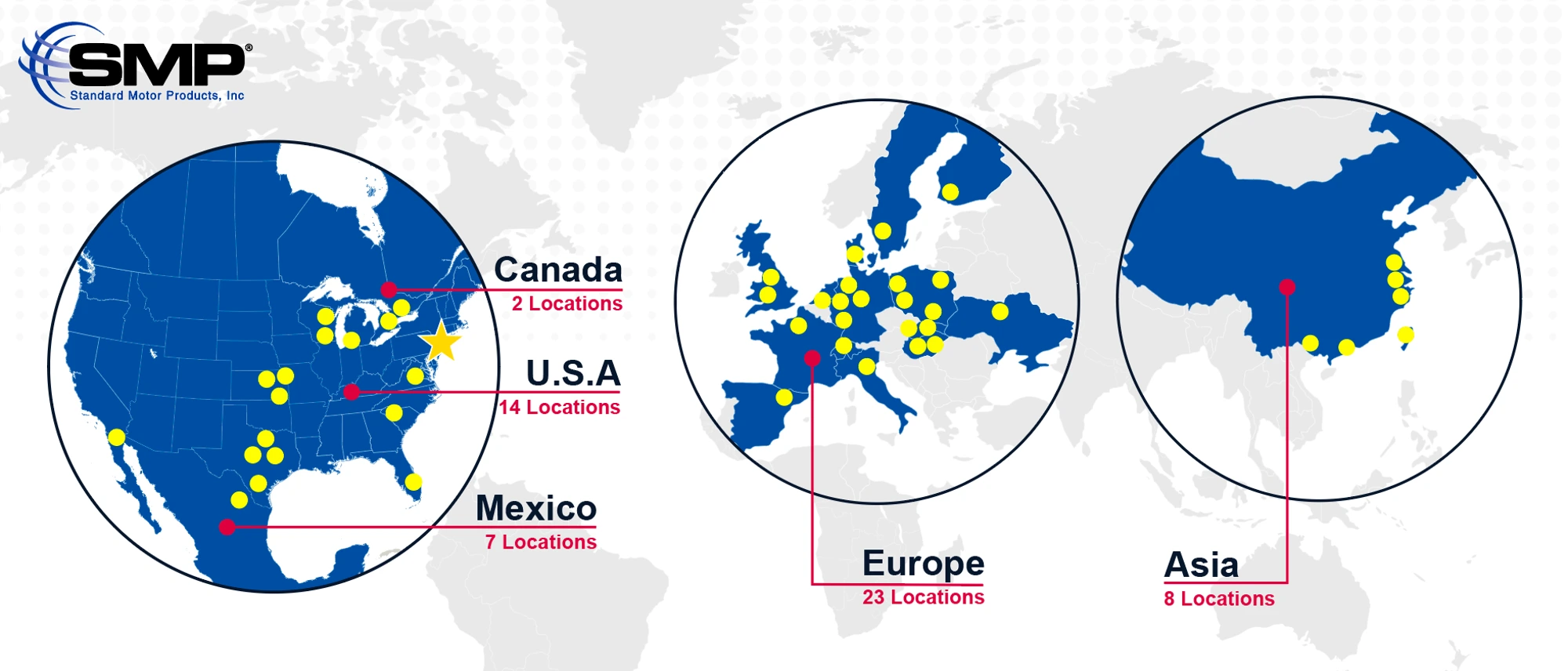

From start to finish, we are an expert manufacturer, validating all components including raw materials. Our manufacturing facilities are IATF 16949, ISO 9001, and ISO 14001 certified.

- SMP operates 19 manufacturing facilities in North America and globally.

Testing & Validation

Testing & Validation

To ensure quality, all products manufactured at the SMP Poland facility undergo a full spectrum of measurement and life testing in addition to a full range of environmental analysis that includes thermal shock, thermal cycling, salt spray, vibration, and storage tests. The result is a line of premium ignition components that perform flawlessly and stand up to real-life conditions.

- Blue Streak® OE Durability Improved Ignition Coils are tested and validated to be the highest-quality Coils available on the market.

Discharge Duration (ms)

Engineering Improvements

Why OE Fails

Why OE Coils Fail

Original Equipment coils are know for their high failure rates. In fact, you are probably here because an original equipment coil has failed. There are several weak points in original designs that lead to premature failure, these can include; allowing water to seep in, not having even spark energy for sustained performance and simply overheating because too much energy is being passed through the internal bobbin sections.

Our engineers identify vehicle specific issues that lead to premature coil failure and design ignition coils with improvements to address these problems.

Why OE Fails

Heat Resistance

Improved Heat Resistance

OE coils often fail because the epoxy gets too hot and cracks, allowing moisture to seep into the coil. This is especially common when the coil is exposed to extreme heat for long periods of time.

Our engineers remedied this problem by improving the insulation on the coil by using a stronger elastomer overmold. This helps prevent the epoxy from cracking, even in high heat conditions, and keeps moisture out.

Higher temperatures cause the epoxy to crack, allowing moisture in and causing the OE coil to fail.

Blue Streak’s epoxy stays intact, keeping moisture out and allowing the Coil to perform as designed.

Operating Temperature

Lower Operating Temperatures

The more energy that has to pass through each internal bobbin section of a coil, the hotter the coil will run. This accelerates wear, eventually leading to a coil failure. Many OE designs do not have enough bobbin sections for a sustained service life and fail.

We engineer and manufacture coils with more internal bobbins compared to the OE, meaning that less energy has to pass through each section. The result is a coil; that runs cooler and lasts longer.

30kV needs to pass through only 8 sections, meaning nearly 4kV needs to pass through each section.

30kV passes through 9 sections, meaning only 3.3kV passes through each section, creating less heat.

One-Piece Housing

Improved Boot Design

Moisture intrusion is another reason that ignition coils fail. Many original designs use a simple O-ring try to prevent moisture intrusion, but over time the O-ring degrades, allowing water to seep in and damage the coil.

Blue Streak coils feature and improved, one-piece design that doesn’t require an O-ring, eliminating the chance of moisture damaging the coil.

Moisture intrusion causes the OE coil to prematurely fail when the O-ring breaks down.

We engineered an improved, one-piece design that eliminates the need for an O-ring and removes the chance of moisture intrusion.

Higher Spark

More Spark Energy

The harder a coil has to work, the sooner it will fail. This is why Blue Streak® coils are engineered with a higher spark energy compared to the original coil. By giving the coil more capabilities, it doesn’t have operate close to it’s maximum capacity, allowing it to last longer.

- Blue Streak® UF406 has 7% higher spark energy than OE.

Ignition Categories

Technicians look to Standard® for the parts required to do the job right. From Ignition Coils to Distributor components, Standard® has the parts needed to repair these systems correctly the first time.

Ignition Coils

Blue Streak Ignition Coils

Features & Benefits

Each Blue Streak® Ignition Coil is engineered with features to ensure that they perform under the most extreme conditions. Standard® engineers identify OE weak points and design Coils that last. Blue Streak® Coils are manufactured in Poland and tested in the lab and on vehicles to ensure precise performance.

Advanced Thermoplastic Coil Connector

Ensures proper connection and resists fractures caused by heat and thermal cycling

100% Pure Copper Windings

In the primary and secondary bobbins improve durability and provide higher resistance to prevent internal shorts and dielectric breakdown

High-Grade Copper Wires

Ensure heat resistance and prevent high voltage breakdown

Stainless Steel Spring

With internal ferrite noise suppressor prevents radio frequency interference (RFI)

High-Temp Boot

Prevents high-voltage leaks

UF303 | GM Cars, Trucks, and SUVs (2008-02)

Blue Streak Ignition Coil Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® and Blue Streak® Ignition Coil Overview

A Closer Look: Blue Streak Ignition Coils

A Closer Look - Blue Streak Ignition Coils for Import Vehicles

Blue Streak® Ignition Coils

Blue Streak Ignition Coil Multipacks

Features & Benefits

Blue Streak® Ignition Coil Multipacks offer a complete replacement of old or worn ignition coils for a total repair. Each Blue Streak® Coil is engineered with features to ensure that they perform under the most extreme conditions. Blue Streak® Ignition Coils are manufactured in Poland and tested in the lab and on vehicles to ensure precise performance.

Updated Internal Design

Addresses OE flaws and helps to extend service life

100% Pure Copper Windings

In the primary and secondary bobbins improve durability and provide higher resistance to prevent internal shorts and dielectric breakdown

High-Temp Boot

Prevents high-voltage leaks

Advanced Thermoplastic Coil Connector

Ensures proper connection and resists fractures caused by heat and thermal cycling

UF349K6 | Nissan / Infiniti Cars, SUVs & Vans (2019-02)

Blue Streak Coil Multipack Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® and Blue Streak® Ignition Coil Overview

A Closer Look: Blue Streak Ignition Coils

A Closer Look - Blue Streak Ignition Coils for Import Vehicles

Blue Streak® Ignition Coils

Standard Ignition Coils

Features & Benefits

Standard® Ignition Coils are engineered and tested to meet OE spark energy output, impedance, and durability in all operating conditions.

Accurate High-Energy Output

Provided by advanced bobbin technology, highly specialized silicone magnetic steel core and optimized winding to restore engine performance

100% Pure Copper Windings

In the primary and secondary bobbins improve durability and provide higher resistance to prevent internal shorts and dielectric breakdown

High-Temp Boot

Prevents high-voltage leaks

UF710 | Subaru Cars (2016-13)

Standard Ignition Coil Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard Ignition Coils: When OE Fails… Trust Standard®

Standard® and Blue Streak® Ignition Coil Overview

A Closer Look: Blue Streak Ignition Coils

Standard® Ignition Coils

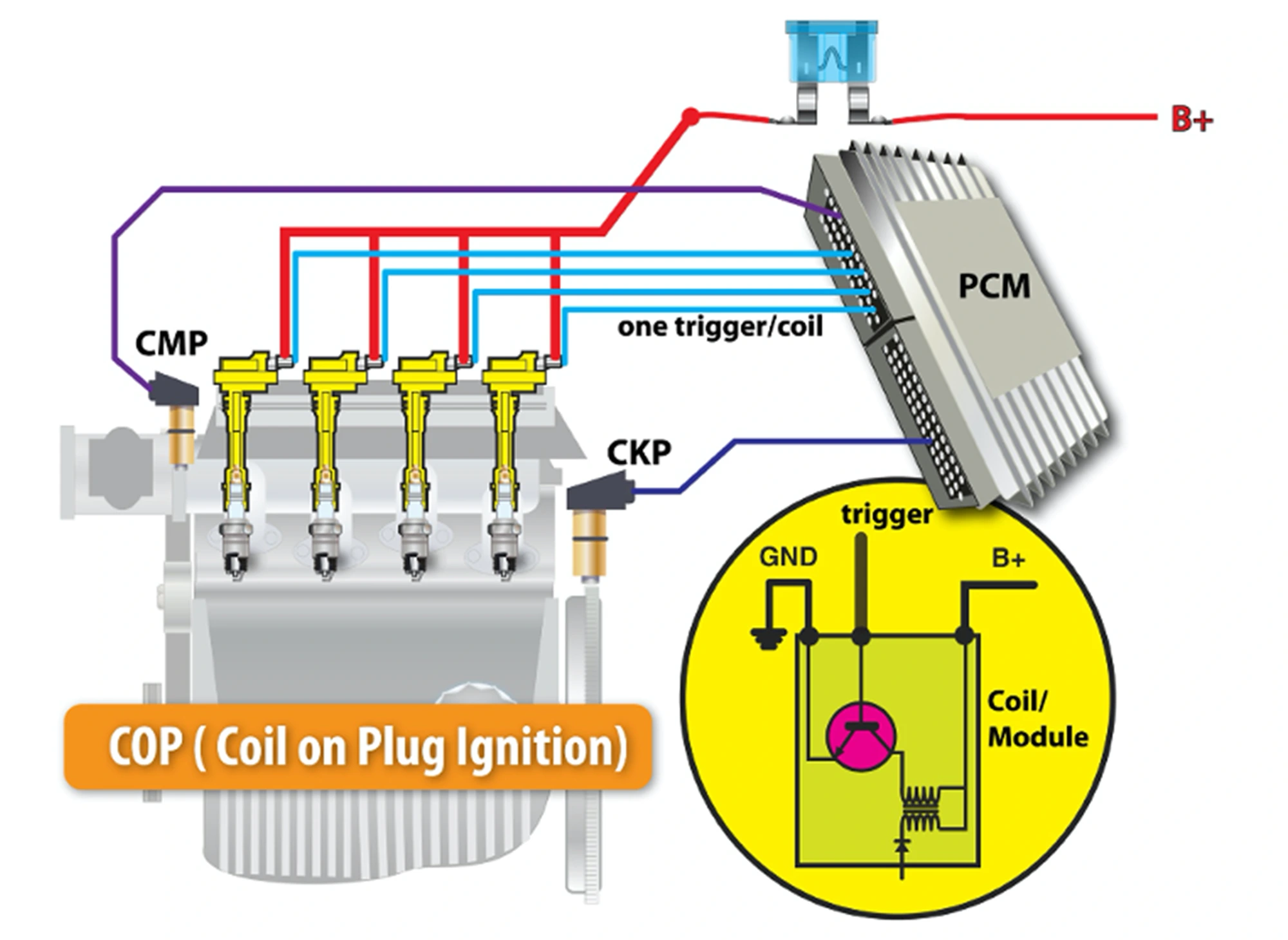

System Overview

System Overview

The Coil-On-Plug (COP) system has gained popularity because of its universal application, control precision, and increased capabilities. The coil is provided a B+ source to one end of the primary winding, and the other end is connected to a low-side driver in the PCM. With this configuration, the PCM internally handles very high current, and also allows for technician access to the primary circuit for various tests.

Ignition Components

Distributor Caps

Features & Benefits

Capitalizing on decades of research and development, Standard® Distributor Caps contain unmatched quality yielding superior performance.

Solid Brass Terminals

Make better connections with greater resistance to electrical pitting and corrosion

High-Grade Materials

Made of high-dielectric-strength reinforced polyester resin for less carbon tracking, greater resistance to electrical breakdown and superior performance

RFI Resistors

Eliminate radio static and potential ECU-damaging spikes

JH231 | Nissan / Infiniti Cars (2000-1994)

Distributor Cap Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Jeep Cherokee Distributor Cap Replacement

Ignition System Diagnosis | Pro Training PowerHour

Jeep Cherokee Ignition Rotor Replacement

Distributor Caps

Distributor Cap & Rotor Kits

Features & Benefits

Standard® Distributor Cap and Rotor Kits include all of the needed components for a complete and easy repair solution.

High-Grade Materials

Cap made of high-dielectric-strength reinforced polyester resin for less carbon tracking, greater resistance to electrical breakdown and superior performance

Solid Brass Terminals

Make better connections with greater resistance to electrical pitting and corrosion

Precision Engineering

Engineered and manufactured to exacting standards for performance and durability

DR473 | GM Cars (1997-94)

Distributor Cap and Rotor Kit Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Jeep Cherokee Distributor Cap Replacement

Jeep Cherokee Ignition Rotor Replacement

Ignition System Diagnosis | Pro Training PowerHour

Distributor Cap & Rotor Kits

Ignition Control Modules

Features & Benefits

Ignition control modules fail when they overheat, commonly causing a no-start, engine stuttering or stalling. Standard® Ignition Control Modules resist failure and are extensively tested to ensure performance and durability.

Double Wire Bond Interconnect System

For improved durability

Electro Static Discharge Protection

High battery over-voltage shutdown protection

Nickel-Plated Steel Lead Frame

To minimize connector oxidation and maximize electrical contacts

LX381 | GM Cars, Trucks & SUVs (2007-96)

Distributor Cap and Rotor Kit Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Ignition System Diagnosis | Pro Training PowerHour

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

Ignition Control Modules

Ignition Wire & Cable

Battery Cables

Features & Benefits

Standard® is your source for quality-engineered battery cables and related components. Each cable features advanced technology that delivers superior power, efficient performance, and ease of installation to outlast and outperform the competition.

Proper Wire Gauge for Performance

Gauge meets or exceeds OE performance for voltage flow

Protective Loom

Loom is applied where applicable to help keep outside elements from the outer jacket

High-quality Terminals

100% copper, brass, or stainless steel terminal maximizes voltage transfer

OE-style Terminals

OE-style terminals ensure proper fit

Protective Rubber Jacket

Cross-linked synthetic rubber jacket protects against abrasions, melting, and corrosion while remaining flexible in all conditions, including cold weather

A76-0F | RAM 2500/3500

Battery Cable Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Honda Accord Negative Battery Cable Replacement

Battery Bolt Replacement Tip

Battery Terminal Repair Bolt

Battery Cables

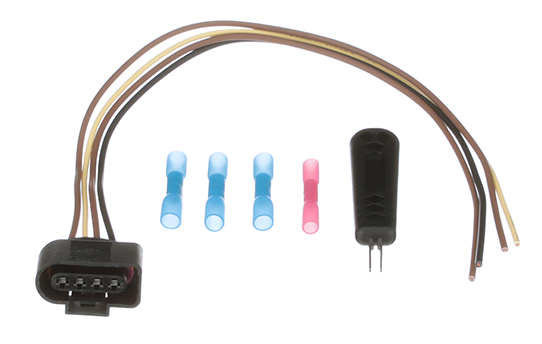

Coil on Plug Boot Kits

Features & Benefits

Standard® Coil on Plug Boot Kits are specifically designed for vehicles that have spark plug wires and direct ignition coils.

Stainless Steel Construction

Prevents corrosion

Resistor Included

For an easy repair solution

High-Temp Rubber Boot

Keeps spark from arching

CPBK177 | GM Cars & SUVs (2017-05)

Coil on Plug Boot Kit Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Trailblazer Coil On Plug Boot Kit Installation

Coil-On-Plug Boot Replacement

When OE Fails...Trust Standard®

Coil on Plug Boot Kits

Coil on Plug Boots

Features & Benefits

Engine environment, heat, water contamination, fuel and lubricant contamination and abrasion damage can all shorten the life of coil-on-plug boots significantly. Standard® Coil-on-Plug Boots are manufactured from the best materials for top performance and endurance.

High-Temp Rubber Boot

Keeps spark from arching

Spring Included

For a complete repair solution

SPP178E | Nissan Cars, Trucks & SUVs (2023-12)

Coil on Plug Boot Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Trailblazer Coil On Plug Boot Kit Installation

Coil-On-Plug Boot Replacement

When OE Fails...Trust Standard®

Coil on Plug Boot

Spark Plug Wires

Features & Benefits

Standard® Spark Plug Wires channel maximum voltage to the spark plugs and feature enhanced RFI protection for better overall performance. They are designed, built, and tested to meet or exceed tough international IATF 16949 quality standards, and are available in sets for a complete repair solution.

High-Grade Components

Patented high-gloss clear coat formulation with high-temperature silicone jacket for durability

Enhanced Wire Core Design

Matched to the OE type: low ohm, ferrite mag, wire wound, silicone or metallic

Abrasion Resistant

Construction enhances abrasion resistance while providing greater protection against severe temperatures

Complete Set

Features matching boots, a wire core and jacket, and extras like clips, trays, looms and numbered leads

55801 | Hyundai / Kia Cars & SUVs (2012-96)

Spark Plug Wire Set Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

GM 3.5 Liter Spark Plug Wire Replacement

Spark Plug Wire Replacement - Dodge Neon

Spark Plug Wire Tech Tips

Spark Plug Wire Sets

Ignition Program

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in ignition systems. Here’s what they say to look out for during an ignition system service.

Exposure to heat, oil intrusion, and water intrusion are three of the leading causes of premature failure in OE coils.

Incorrect spark plug gaps can cause coils to work harder and fail prematurely.

An ignition-related misfire can damage the catalytic converter in a few miles or several minutes of driving if a vehicle doesn’t register the faulty coil and continues to feed fuel to the cylinder.

When replacing a faulty ignition coil, make sure that the driver in the PCM has not been damaged by a shorted coil. This is especially prevalent in Ford 2-wire coils.

If an intake plenum needs to be removed to access an ignition coil, do your customer a favor and replace all the ignition coils on that bank at the same time.

When replacing an ignition coil, replace all the secondary ignition components (plugs, boots, wires) as well.

Exposure to heat, oil intrusion, and water intrusion are three of the leading causes of premature failure in OE coils.

Incorrect spark plug gaps can cause coils to work harder and fail prematurely.

An ignition-related misfire can damage the catalytic converter in a few miles or several minutes of driving if a vehicle doesn’t register the faulty coil and continues to feed fuel to the cylinder.

When replacing a faulty ignition coil, make sure that the driver in the PCM has not been damaged by a shorted coil. This is especially prevalent in Ford 2-wire coils.

If an intake plenum needs to be removed to access an ignition coil, do your customer a favor and replace all the ignition coils on that bank at the same time.

When replacing an ignition coil, replace all the secondary ignition components (plugs, boots, wires) as well.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-18 of 18

No results found