What's in Your Box?™

Electronic Throttle Body Program

Standard® Electronic Throttle Bodies (ETBs) include engineering improvements over the original design for increased durability.

3 Things To Know

Expert Manufacturing

Standard® is an expert manufacturer with over 200 ETBs covering more than 190 million vehicles.

100% New, Never Remanufactured

Every Standard® Electronic Throttle Body is 100% new, never remanufactured, and fully calibrated and tested.

Includes Gaskets

Gaskets are included where required for a complete repair.

Standard® Has Electronic Throttle Bodies Covered

Coverage

Comprehensive Coverage

Electronic Throttle Control (ETC) has been around for decades and can be found on most vehicles. In addition to the highest-quality replacement ETBs, Standard® offers a full line of key components necessary to repair the electronic throttle control system, including Throttle Position Sensors, Accelerator Pedal Sensors, Variable Intake Manifold Actuators, and ETB Connectors — everything needed for a complete repair.

- Adding to its extensive ETB program, Standard® continually releases new numbers to cover import and domestic vehicles.

Market

Growing Market

Vehicle manufacturers began using ETBs to improve fuel economy and reduce emissions. Today, there are more than 250 million vehicles on the road with ETBs. These have very high OE failure rates, especially in the gear train.

- In the next 5 years, 68 million more vehicles with electronic throttle bodies will enter the Aftermarket “sweet spot” of 6-12 years old.

Service Opportunities

Service Opportunities

The Jeep / Chrysler 2.0L and 2.4L often see ETBs fail before 100,000 miles. The main cause is worn or broken gear teeth inside the ETB. Standard’s premium ETB replacement includes improved geometry and high-strength materials for a better-performing and longer-lasting gear train.

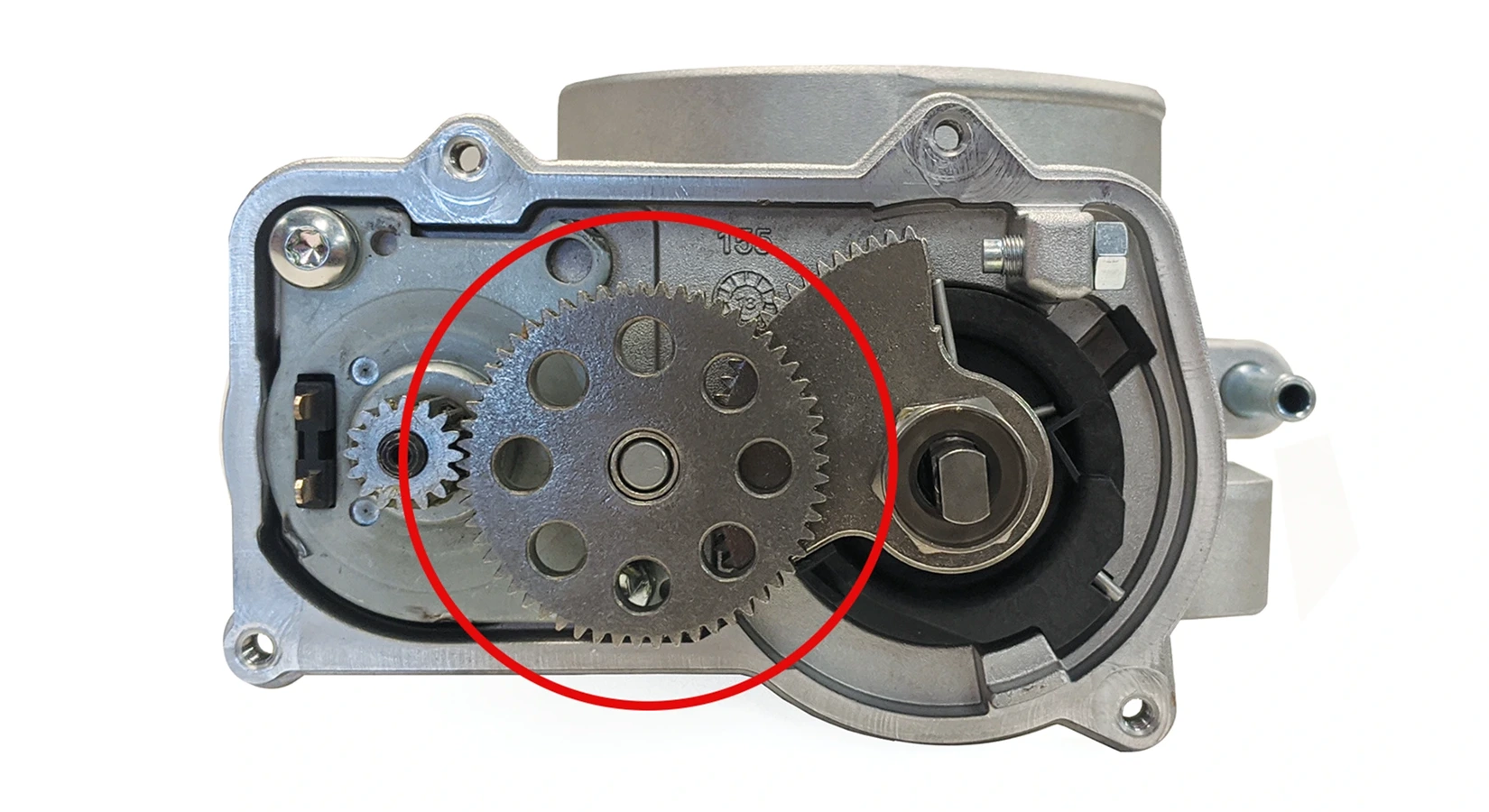

S20176

Chrysler / Jeep / Dodge Cars & SUVs (2020-16)

S20176 features engineering upgrades including a reinforced gear train which outperforms the original design and provides long term reliability.

Engineering & Design

Engineering

After identifying weaknesses in OE electronic throttle bodies, Standard® engineers capitalize on their extensive gear design experience to develop stronger, longer-lasting ETB gears. Our engineers design improvements to outperform the original for durability and service life.

- All Standard®-manufactured ETBs are built in our North American IATF 16949-certified facility.

Stainless Steel Gears

Standard® gearset is made of stainless steel and conforms to the highest standards of precision for a better-performing ETB.

Enclosed Contact Brushes

Totally Enclosed Contact Brushes Our PCB and contact brushes are totally enclosed and separate from the gearset and other moving parts. Motor contacts are plated to minimize contact resistance and resist corrosion. Screw holes include steel compression limiters to help prevent cracking.

Manufacturing

Precision Manufacturing

As an expert Electronic Throttle Body manufacturer, we maintain complete quality control throughout the entire manufacturing process. We assemble and calibrate the components and validate output voltages to ensure they match the OE for fit, form and function. Standard® ETBs are precision engineered and application-specific.

- SMP facilities hold IATF 16949, ISO 900, and ISO 14001 certifications. These certifications guarantee a high-quality, reliable component in every box.

Testing & Validation

Testing & Validation

Standard® ETBs are the result of superior design and the testing proves it. We design and validate our end-of-line testing equipment to make certain that every ETB that leaves our facility performs up to our critical standards.

Each Standard® ETB undergoes testing on a flow bench, in which a blower assembly creates airflow through the ETB while a control system simulates an ECU. Durability testing includes vibration testing in three axes over varying displacements and frequencies while actuating and Standard® ETBs are also subjected to life-cycle testing, which simulates a 10-year life cycle.

Electronic Throttle Body Categories

Technicians look to Standard® for the parts required to do the job right. From Electronic Throttle Bodies to Throttle Position Sensors, Standard® has the high-quality parts needed to repair these complex systems correctly the first time.

Electronic Throttle Bodies

Features & Benefits

Features & Benefits

As an expert ETB manufacturer, Standard® engineers upgrades to failure-prone OE components. Each Standard® Electronic Throttle Body is assembled and calibrated to precisely match OE output voltages, ensuring a smooth relearn process. All Standard®-manufactured ETBs are built in our North American IATF 16949-certified facility, and 100% calibrated and tested to ensure superior performance and durability.

Custom Elastomeric Seal

Protects sensor from environmental under-hood elements such as dust, vapor and liquids

New, Never Remanufactured

To maximize performance and extend service life

Gasket Included

Where required

Magnet Molded

In high-performance polymer to ensure consistent location and low friction with bearing surfaces

S20203 | Chrysler Cars, Trucks & SUVs (2024-11)

Videos

Electronic Throttle Body Videos

The StandardBrand YouTube Electronic Throttle Bodies (ETB) playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

A Closer Look: Electronic Throttle Bodies

Electronic Throttle Body Diagnostic and Replacement Tips

GM 3.5 Liter Electronic Throttle Body Replacement | Installation Spotlight

System Overview

System Overview

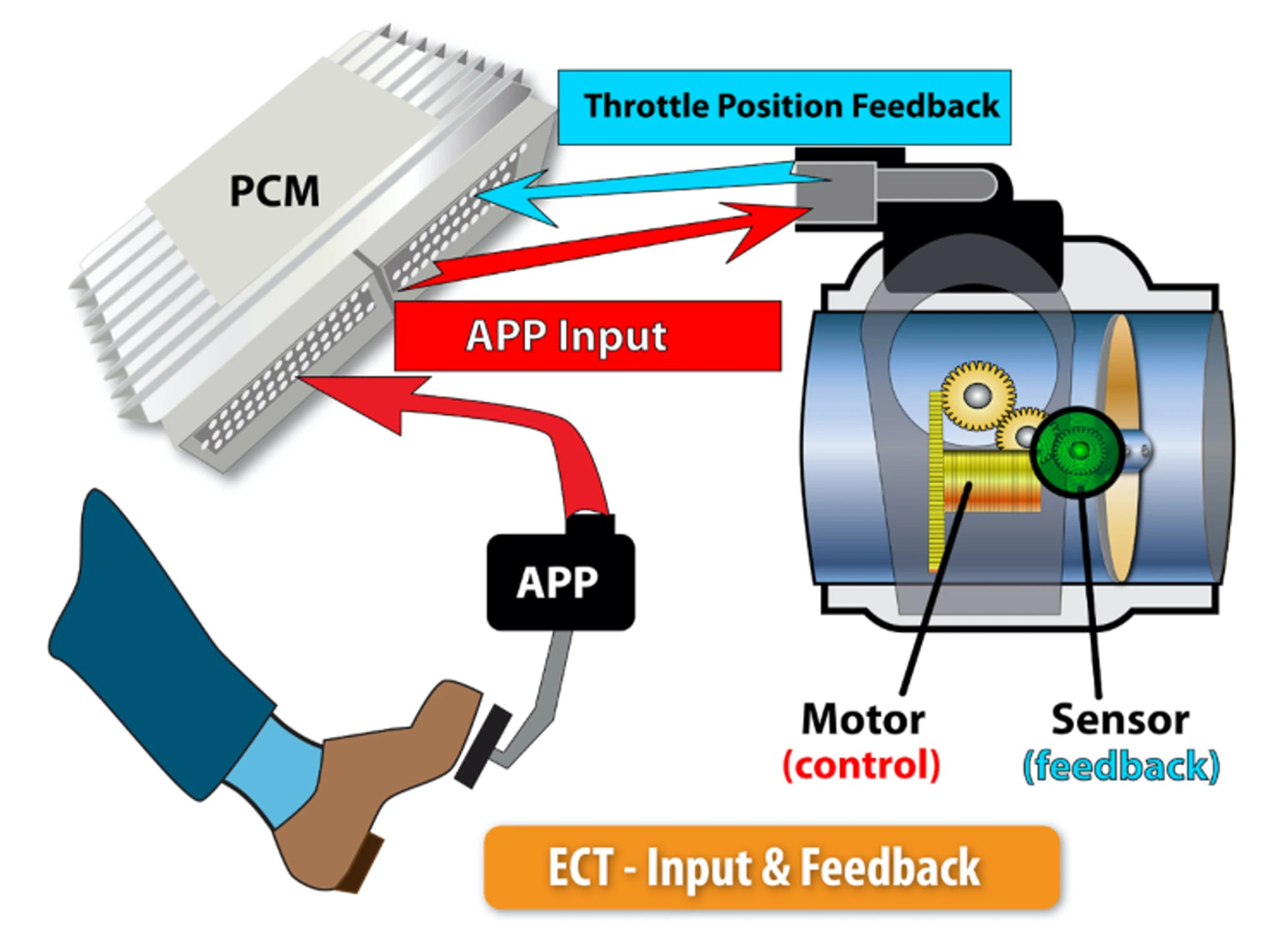

The ETB opens and closes based on input from the accelerator pedal position sensor or throttle cable in older vehicles. Most ETBs use two wires that control throttle body motor function. To drive the throttle blade open, power is supplied on one wire, while the other wire is supplied ground. To close the throttle blade, the polarities are reversed.

Electronic Throttle Body Listings

Throttle Position Sensors

Features & Benefits

Features & Benefits

The throttle position sensor moves with the throttle and sends a voltage signal to the computer indicating throttle angle and speed of movement data, which measures engine load and adjusts timing, fuel delivery, converter clutch operation, and clears flood mode. Our Throttle Position Sensors are designed, manufactured, and tested to maintain specific installed outputs to match OE designed performance across the entire RPM range.

Magnet Molded

In high-performance polymer to ensure consistent location and low friction with bearing surfaces

Integrated Circuit (IC)

Effectively measures rotation of small magnet attached to throttle shaft and is calibrated to provide accurate, linear output characteristics

Custom Elastomeric Seal

Protects sensor from environmental under-hood elements such as dust, vapor, and liquids

TH381 | Ford Cars, Trucks & SUVs (2019-03)

Videos

Throttle Position Sensor Videos

The StandardBrand YouTube Throttle Position Sensors playlist features product and technical information and installation videos. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Electronic Throttle Body P2135 TPS Correlation Diagnostic Tip

Ford Throttle Position Sensor Installation Tips

Nissan / Infiniti Throttle Relearns

Throttle Position Sensor Listings

Competitive Analysis

Standard S20006 vs the Competition

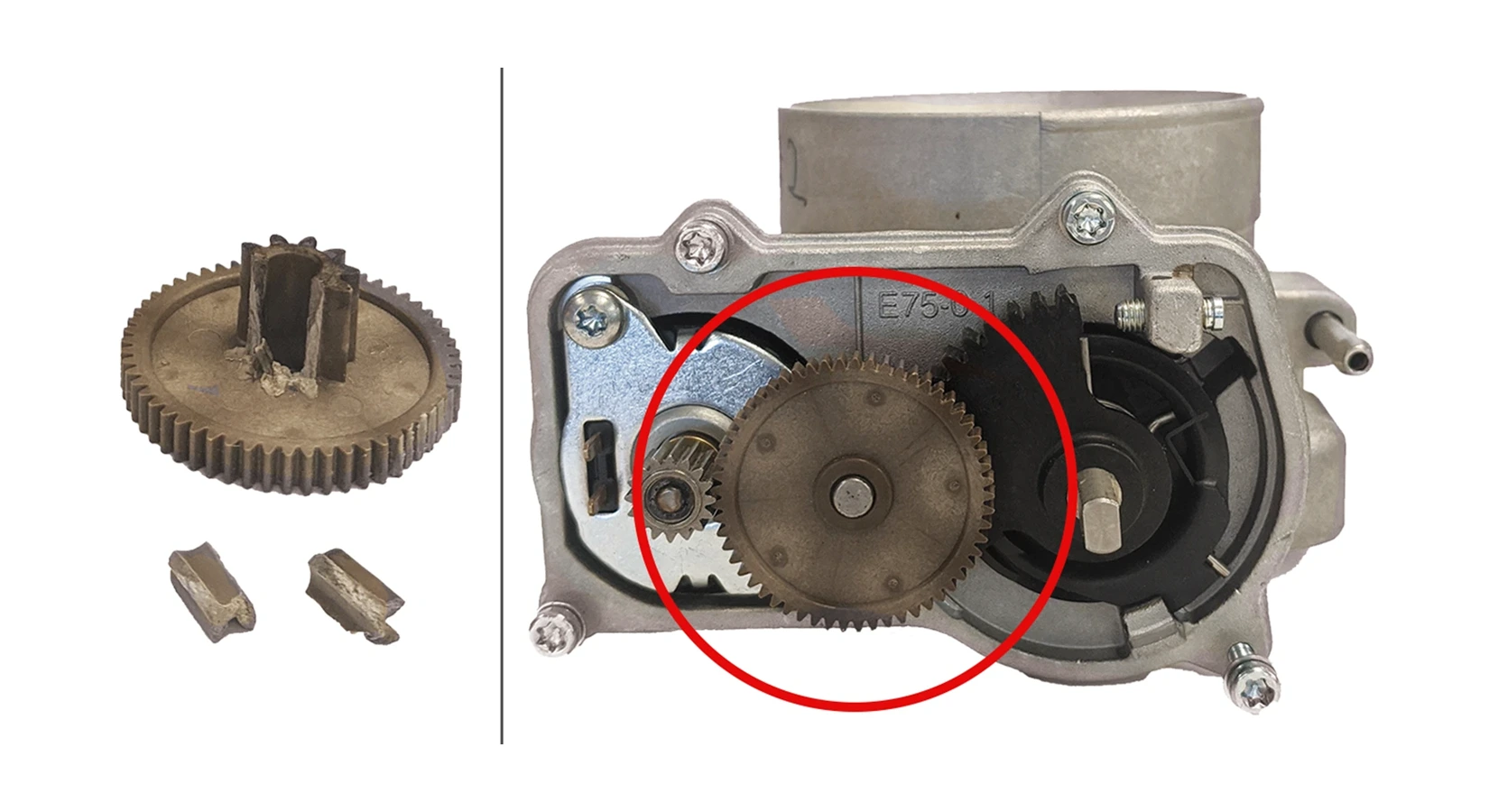

In order to ensure the highest level of quality and durability, Standard® subjected its S20006 Electronic Throttle Body and a competitive ETB to a range of extensive testing in a competitive analysis. Standard’s superior quality was proven to stand up to the most severe under-hood conditions and strenuous demands of today’s engines. The competition did not.

Standard S20006 PASSED

Even after 45 days of endurance testing, our ETB was intact and fully operational. Standard® delivers a premium-quality ETB that performs under the toughest conditions.

The Competition FAILED

After only 10 days of testing, the competitor’s ETB failed with a cracked compound gear. Inherent design flaws caused the unit to fail prematurely.

Competitive Analysis - Standard S20006

Competitive Analysis - The Competition

Competitive Analysis - Standard S20006

Competitive Analysis - The Competition

Standard

Manufactured with steel gears for long-lasting performance and reliability

Competition

Uses inferior plastic gears that break down under normal operating conditions

Electronic Throttle Body Program

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in electronic throttle control systems. Here’s what they say to look out for during an ETB service.

A worn or malfunctioning ETB may not be able to control the blade as designed. This will lead to decreased fuel mileage and acceleration problems.

A rough idle, stalling or surging are all signs that the throttle position sensor may not be functioning properly.

ETBS usually fail because of wear on the gear train and bearings from age and mileage. Contamination can also cause an ETB to fail.

Many ETB problems are caused by a loose pin fit at the electrical connector. Do your customer a favor and replace the pigtail connector when you’re replacing the ETB.

For some vehicles, relearning procedures are simple. Operate the engine for two minutes in park with AC off, two minutes in park with AC on, two minutes in drive with AC off, and two minutes in drive with AC on.

High idle or intermittent stalling are common concerns after replacing an ETB if the proper relearn procedure isn’t followed. Refer to service information to verify if and how to perform a relearn for the vehicle you’re working on.

A worn or malfunctioning ETB may not be able to control the blade as designed. This will lead to decreased fuel mileage and acceleration problems.

A rough idle, stalling or surging are all signs that the throttle position sensor may not be functioning properly.

ETBS usually fail because of wear on the gear train and bearings from age and mileage. Contamination can also cause an ETB to fail.

Many ETB problems are caused by a loose pin fit at the electrical connector. Do your customer a favor and replace the pigtail connector when you’re replacing the ETB.

For some vehicles, relearning procedures are simple. Operate the engine for two minutes in park with AC off, two minutes in park with AC on, two minutes in drive with AC off, and two minutes in drive with AC on.

High idle or intermittent stalling are common concerns after replacing an ETB if the proper relearn procedure isn’t followed. Refer to service information to verify if and how to perform a relearn for the vehicle you’re working on.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-7 of 7

No results found