What's in Your Box?™

Collision Repair Program

Today’s collision repair parts don’t just have to fit, they have to function correctly with electronic vehicle safety systems. Precision manufacturing, validation and on-vehicle testing make Standard® the professional’s choice from Active Grille Shutters to Park Assist Sensors and everything in between.

3 Things To Know

8,000+ Components

Standard® offers more than 8,000 parts that may need to be replaced in the event of a collision.

Key Categories

Collision repair categories available include Lighting, ADAS, Door/Body, Cabin, Sensors, Connectors and more.

Correctly Integrate

Standard® parts are designed and tested to correctly integrate with the complex electrical systems of modern vehicles.

Standard® Has Collision Covered

Coverage

Comprehensive Coverage

Standard® offers thousands of the parts that may need to be replaced in the event of a collision. Available collision components include:

-

- Door Lock Actuators

- ABS Sensors

- Parking Brake Actuators

- Park Assist Cameras and Sensors

- Electrical Connectors

- High-Temp Headlight Harnesses

- TPMS Sensors

- Active Grille Shutters and Actuators

- Intercoolers

- Airbag Clock Springs

- Center High Mount Stoplight Assemblies

- and more

- Park assist cameras have become one of the hottest ADAS components. If damage is minor, many motorists may opt NOT to go through an insurance claim and replace only the damaged camera/sensor.

Market

Growing Market

As vehicle manufacturers implement additional electronic safety systems to keep vehicle occupants safer, the number of sensors on vehicles grow to make these systems as accurate as possible. More sensors means more chances for them to be damaged, corroded, or simply wear out over time.

Service Opportunities

Service Opportunities

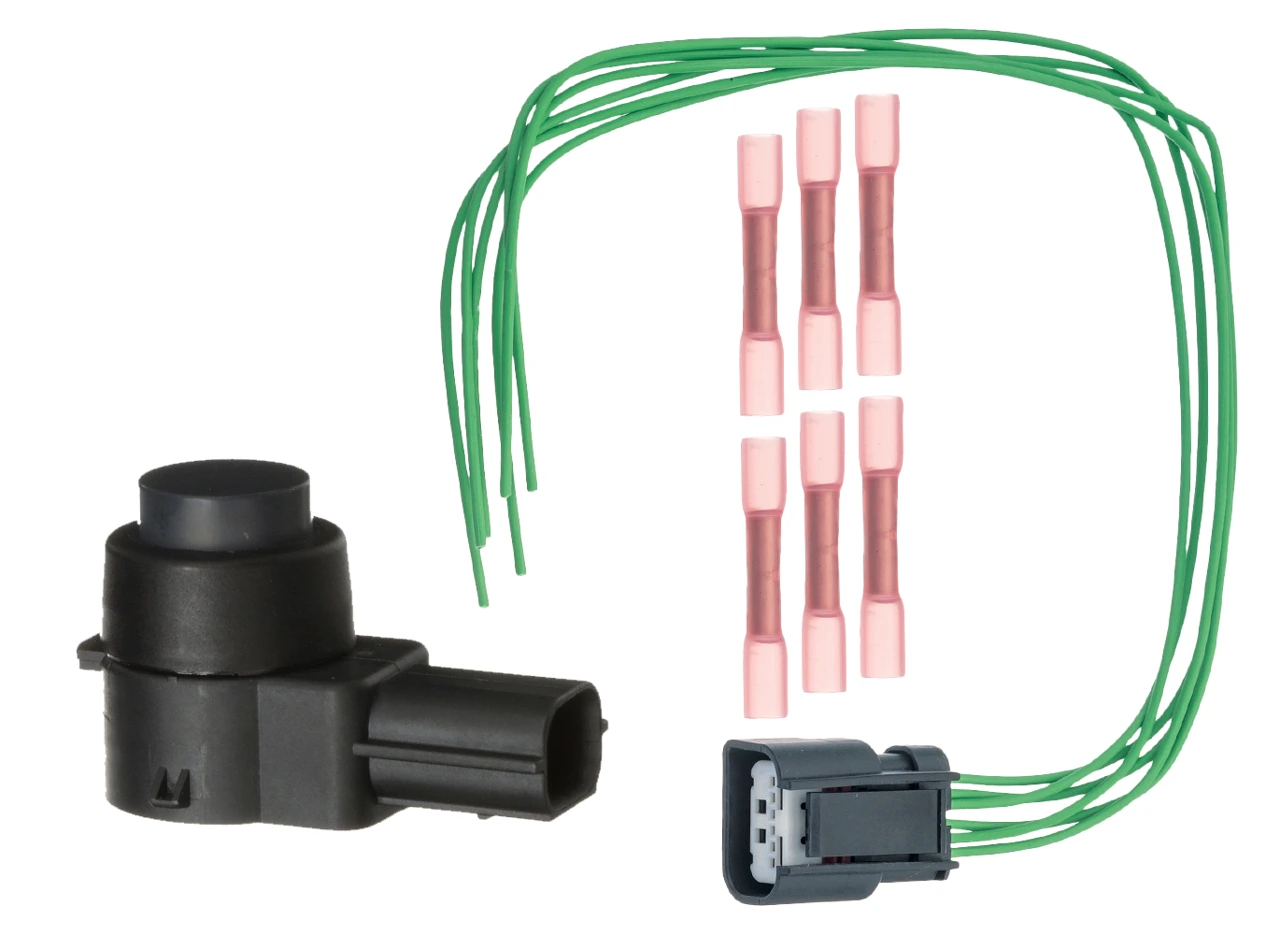

Vehicles use multiple park assist sensors on front and rear bumpers to report distance to an object, utilizing an ultrasonic signal. These sensors are often damaged in front or rear bumper collisions.

When replacing a park assist sensor, it is recommended that you also inspect and replace the park assist connector if it appears bent, damaged or corroded. In addition to a full line of Park Assist Cameras, Standard® also offers the high-temp connectors required to do the job right the first time.

Engineering & Design

Engineering

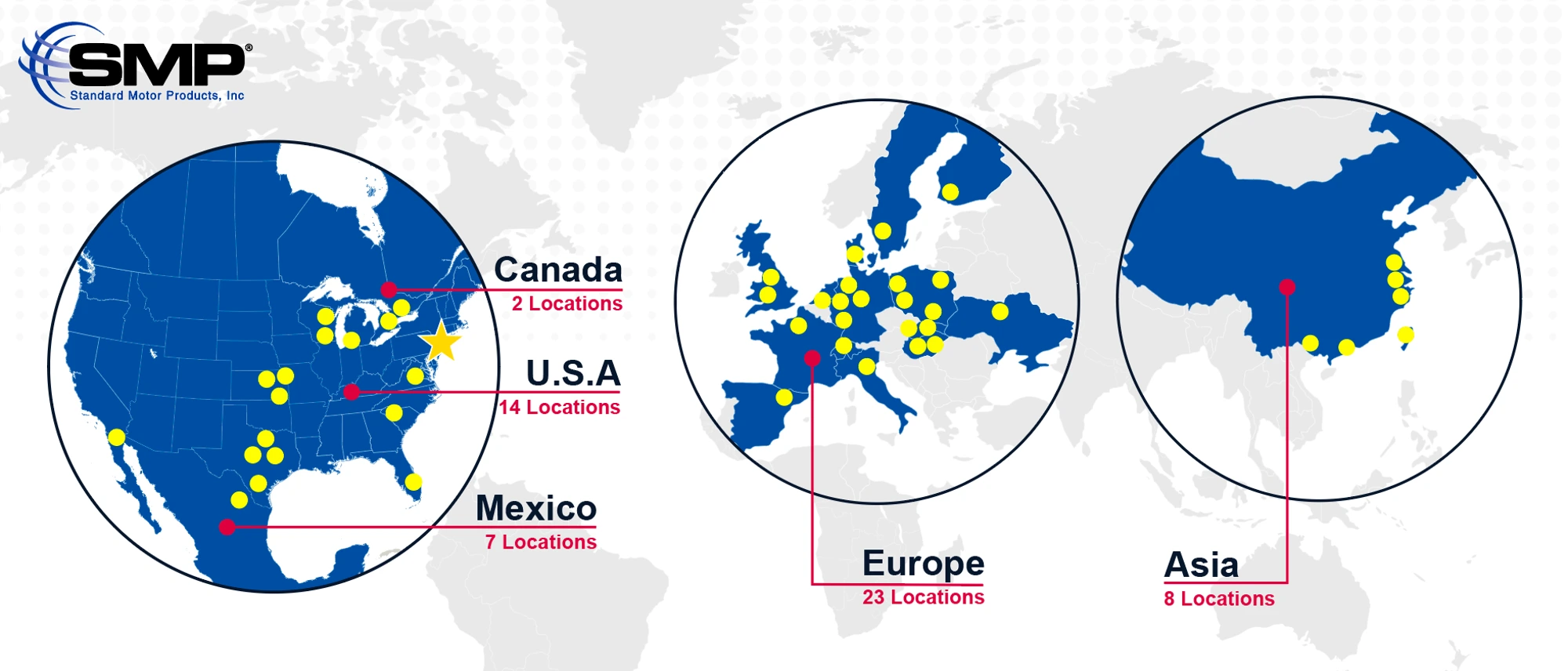

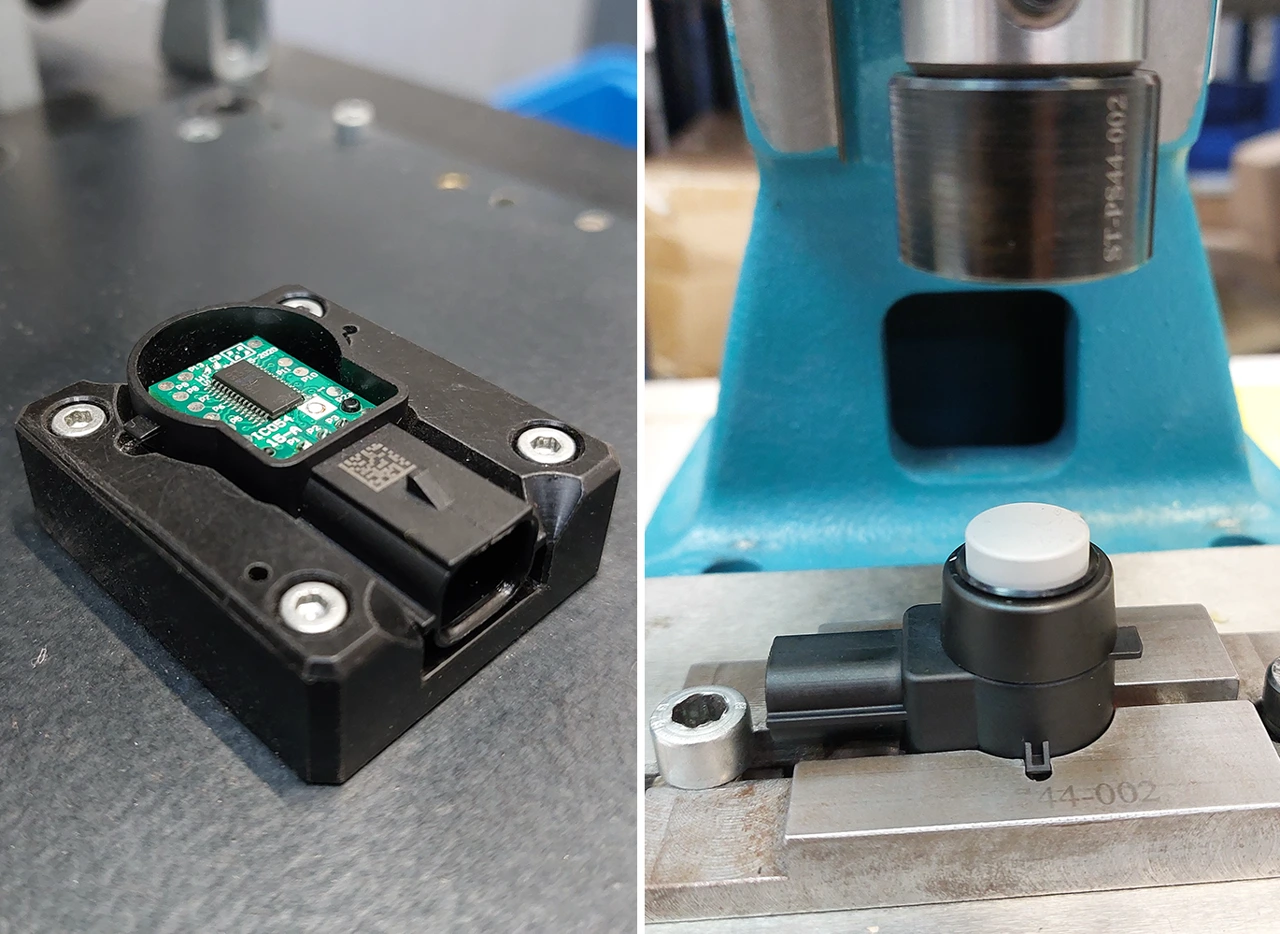

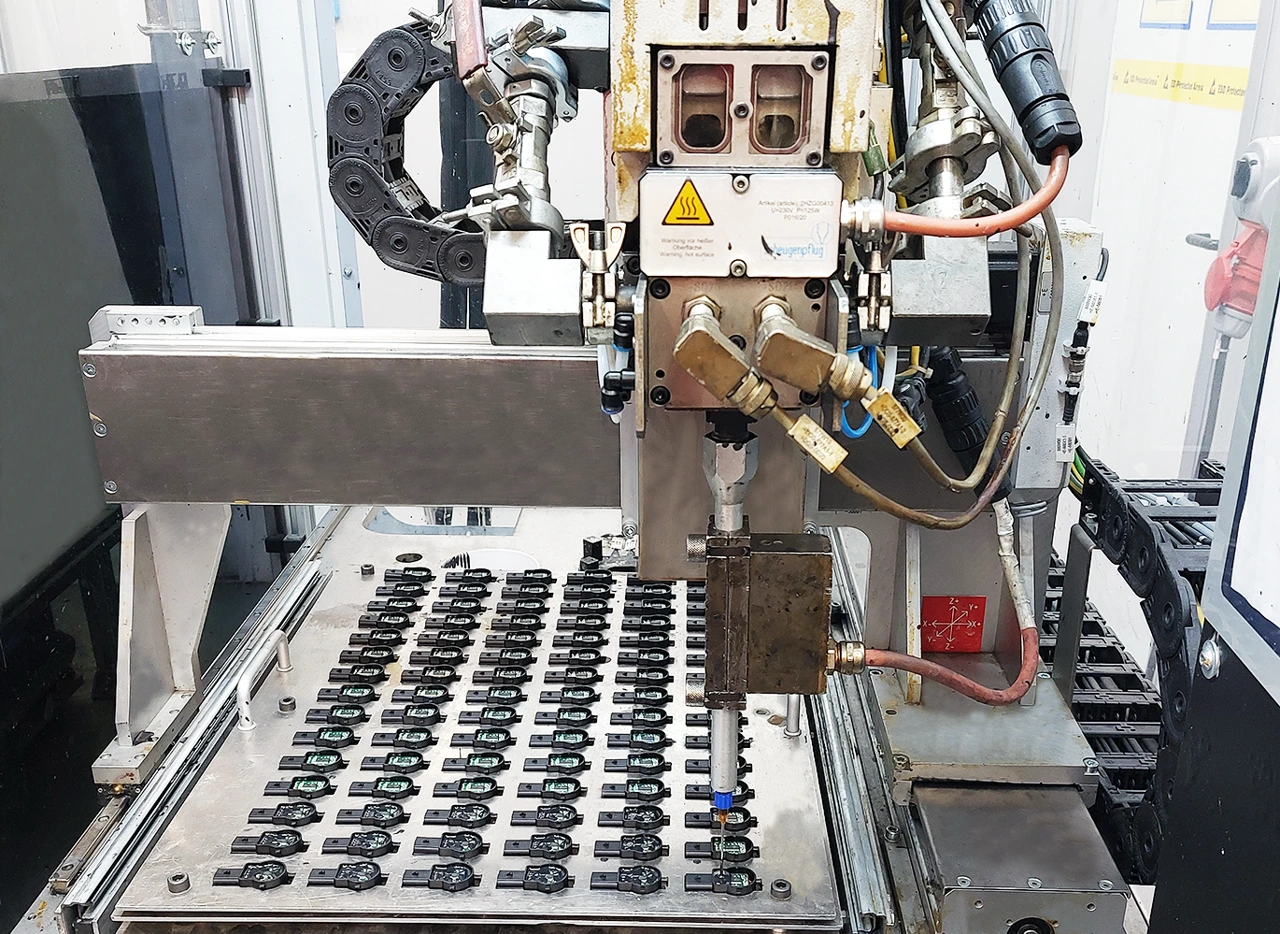

Standard® Park Assist Sensors are engineered and manufactured in our Bialystok, Poland facility, a 145,000 square-foot facility with IATF 16949, ISO 9001 and ISO 14001 certifications.

Each Standard® Park Assist Sensor is engineered to transmit an exact amount of ultrasound energy and receive only echoes that reach the exact level specified by the park assist module, allowing them to precisely detect the location of obstacles for precise operation.

Manufacturing

Precision Manufacturing

As an expert manufacturer, Standard® has complete control over engineering and manufacturing processes, ensuring the highest-quality collision repair components in the industry. We inspect and validate our own raw materials and control the entire manufacturing process at each of our 19 manufacturing facilities around the world to ensure quality. Additionally, our facilities hold IATF 16949, ISO 9001 and ISO 14001 certifications.

Testing & Validation

Testing & Validation

Standard® Collision Repair components are rigorously tested and validated to match OE vehicle-specific performance. Additionally, our ADAS components are tested on vehicles at our testing center in Texas to ensure that they properly integrate with ADAS systems to keep vehicle occupants safe.

Collision Categories

Technicians look to Standard® for the parts required to do the job right. From Actuators and ADAS components to Underhood and Cabin components, Standard® has the Collision Repair parts needed to service a variety of systems correctly the first time.

Actuators

Door Lock Actuators

Features & Benefits

A door lock actuator, mounted in the door, locks and unlocks that door. Integrated door lock actuators combine electrical actuation with latching mechanization. Standard's growing line of Door Lock Actuators features integrated and nonintegrated actuators. All Standard® DLAs meet Federal Motor Vehicle Safety Standards (FMVSS) requirements for door ejection safety.

Meets FMVSS

No. 206 requirements for door ejection safety

Plug and Play Design

Means no wire splicing for easier installation

Robust Construction

Ensures long, trouble-free service life

Direct-Fit OE Replacement

Designed and tested to OE specifications for a direct-fit replacement

DLA1439 | Honda Pilot (2015-09)

Door Lock Actuator Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

GMC Yukon Denali - Door Lock Actuator Replacement Tips

The Standard® Advantage

When OE Fails...Trust Standard®

Door Lock Actuators

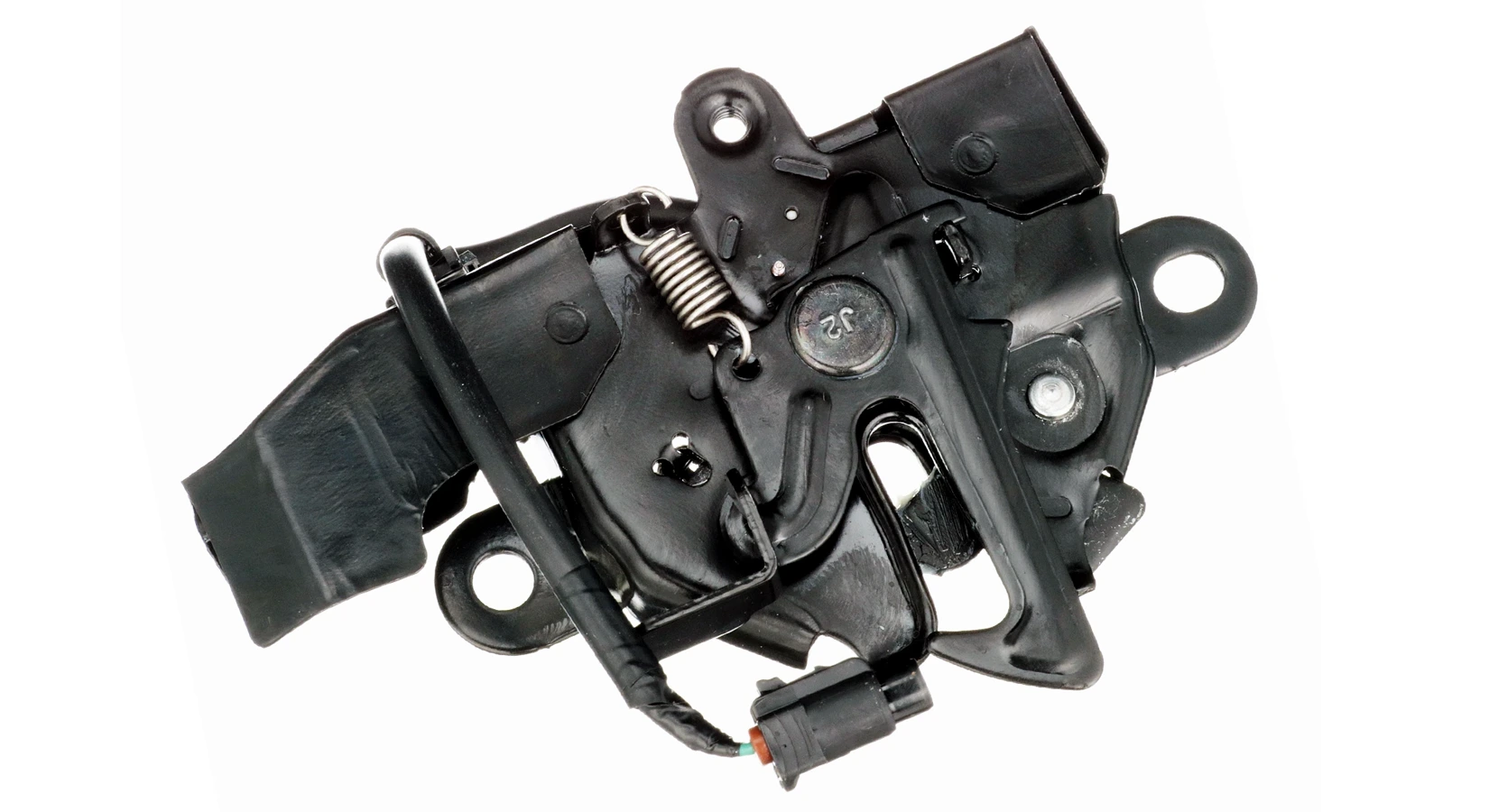

Hood Latches & Actuators

Features & Benefits

A hood latch and actuator are part of the hood latch assembly. They work together to hold the hood shut or allow it to be opened. Standard® Hood Latches and Actuators are direct-fit OE replacements that feature a ”plug & play” design for easy installation. They are designed to meet FMVSS (Federal Motor Vehicle Safety Standards).

Plug and Play Design

Ensures ease of installation

Meets Federal Safety Standards

Direct-Fit OE Replacement

Designed and tested to OE specifications for a direct-fit replacement

DLA1494 | Toyota Sienna (2020-11)

Hood Latch Actuator Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard Brand - Here Is What's In Our Box

The Standard® Advantage

When OE Fails...Trust Standard®

Hood Latch Actuators

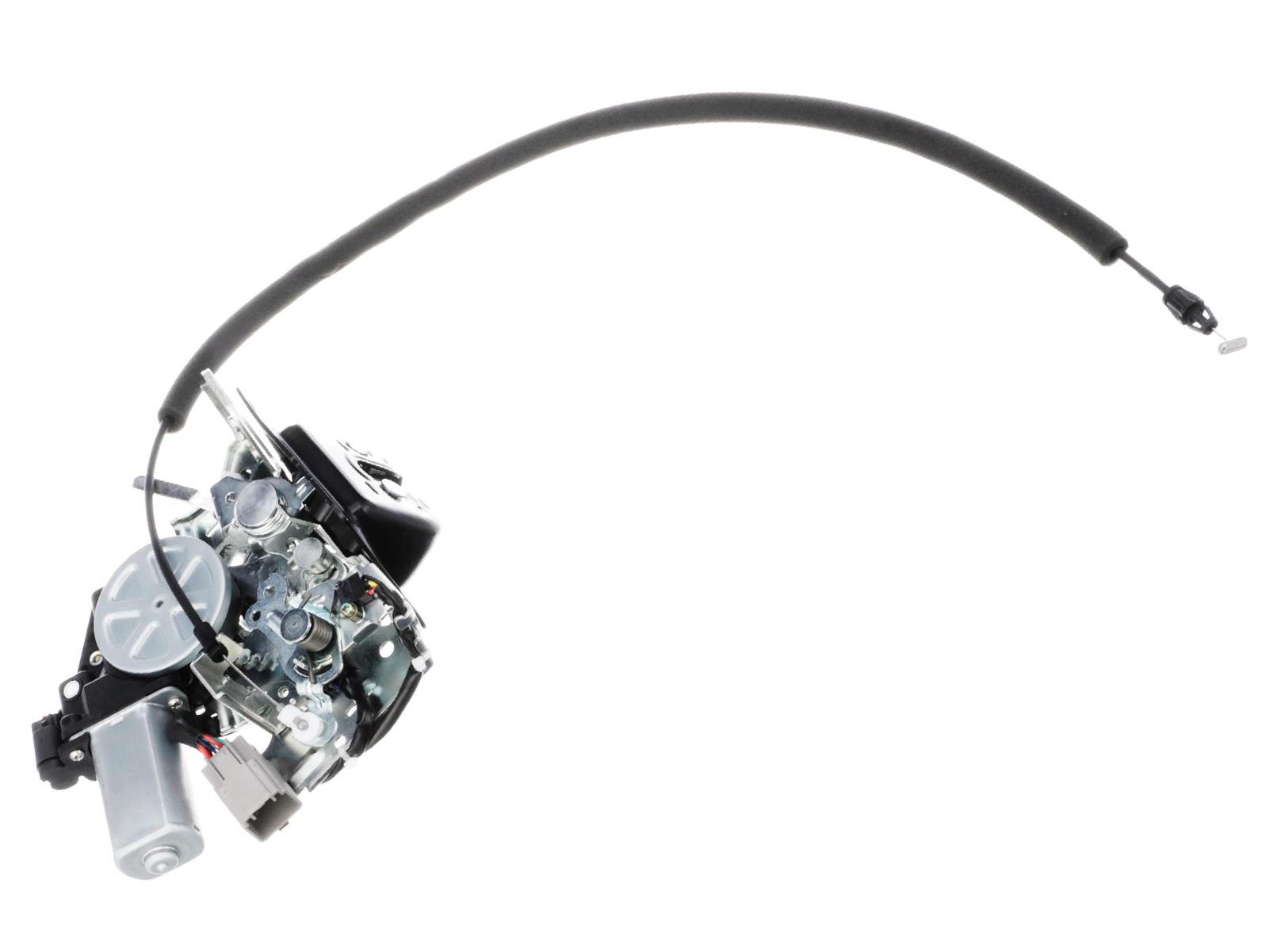

Liftgate Actuators

Features & Benefits

Liftgate actuators are located in the trunk or liftgate area and are easily damaged in a rear-end collision. A liftgate actuator allows the liftgate, rear door or hatchback to be locked and unlocked. It can be manual or powered and operated with a button or by remote. Standard® Liftgate Actuators are direct-fit OE replacements to ensure easy installation, and precise operation.

Precision Engineered

To match the component it is replacing with enhanced durability

Direct-Fit OE Replacement

Designed and tested to OE specifications for a direct-fit replacement

Tested and Validated

To ensure seamless integration and proper operation

DLA1394 | Jeep SUVs (2017-07)

Liftgate Actuator Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

The Standard® Advantage

Standard Brand - Here Is What's In Our Box

When OE Fails...Trust Standard®

Liftgate Actuators

Parking Brake Actuators

Features & Benefits

More and more new vehicles are using electronic parking brakes instead of the older cable design. These newer designs incorporate two separate electronic actuators on the wheels, and are also an integral part of Hill Hold Assist systems. This growing category is entirely powertrain-neutral, meaning parking brake actuators are found on gasoline, diesel, hybrid, and electric vehicles.

Hardware and O-Ring Included

With all Standard® Parking Brake Actuators for proper installation

Plug and Play Design

No additional programming required

Direct-Fit OE Replacement

Designed and tested to OE specifications for a direct-fit replacement

PBA003 | GM Trucks & SUVs (2023-19)

Parking Brake Actuator Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Growing Service Opportunities: Vacuum Pumps and Parking Brake Actuators

The Standard® Advantage

Standard Brand - Here Is What's In Our Box

Parking Brake Actuators

Trunk Lock Actuators

Features & Benefits

A trunk lock actuator allows the trunk to be locked and unlocked. It can be manual or powered and operated with a button or by remote. Standard® offers direct-fit OE replacements that ensure proper fit and form. Our Trunk Lock Actuators match the original for application-specific performance and an easy installation and are designed to meet Federal Safety Standards.

Corrosion-Resistant Design

Durable corrosion-resistant housing enhances latch’s durability

Plug and Play Design

No additional programming required

Direct-Fit OE Replacement

Designed and tested to OE specifications for a direct-fit replacement

DLA1596 | Hyundai Elantra (2020-15)

Trunk Lock Actuator Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

The Standard® Advantage

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

Trunk Lock Actuators

ADAS

Blind Spot Sensors

Features & Benefits

Blind Spot Detection (BSD) Sensors alert drivers to obstacles in their blind spots and are located in the vehicle’s rear quarter area, typically just behind the bumper cover. Standard® BSD Sensors are direct-fit replacements to ensure proper fit and performance.

Tested and Validated

Undergoes extensive testing and validation for correct on-vehicle performance and electronic integration

Direct-Fit OE Replacement

Ensures ease of installation and proper performance

Durable Components

Heavy duty case and new seals help protect against corrosion

BSD16 | Nissan Cars (2017-16)

Blind Spot Detection Videos

The StandardBrand YouTube ADAS playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Advanced Driver Assistance Systems (ADAS) Program by Standard®

Standard® - Advanced Driver Assistance Systems (ADAS) Overview

Standard® - Best Practices for Advanced Driver Assistance Systems (ADAS)

Blind Spot Detection Sensors

Cruise Control Sensors

Features & Benefits

Cruise control distance sensors measure the distance to the leading vehicle, driving the adaptive cruise control and emergency braking systems. These sensors are located behind a vehicle’s front grille opening area. Standard® Cruise Control Distance Sensors are designed and manufactured to stringent quality standards to match the original for an easy installation and to deliver precise performance.

Premium Components

Durable materials withstand harsh conditions to increase lifespan

Direct-Fit OE Replacement

Ensures ease of installation and proper performance

Tested and Validated

Undergoes extensive testing and validation for correct on-vehicle performance and electronic integration

CCD24 | Jeep/Dodge SUVs (2017-16)

Cruise Control Sensor Videos

The StandardBrand YouTube ADAS playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Advanced Driver Assistance Systems (ADAS) Program by Standard®

Standard® - Advanced Driver Assistance Systems (ADAS) Overview

Standard® - Best Practices for Advanced Driver Assistance Systems (ADAS)

Cruise Control Sensors

Lane Departure Cameras

Features & Benefits

Lane departure system cameras notify drivers if their vehicle leaves it lane without the turn signal activated. These cameras have typically been located on the windshield behind the rearview mirror, and are now also in side-view mirrors for additional protection. Standard® LDS Cameras are rigorously tested for proper fit and precise performance to match the original application they are replacing.

Premium Components

Durable materials withstand harsh conditions to increase lifespan

Tested and Validated

Undergoes extensive testing and validation for correct on-vehicle performance and electronic integration

Direct-Fit OE Replacement

For easy installation and proper performance

LDS39 | Toyota Cars (2018-16)

Lane Departure Camera Videos

The StandardBrand YouTube ADAS playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Advanced Driver Assistance Systems (ADAS) Program by Standard®

Standard® - Advanced Driver Assistance Systems (ADAS) Overview

Standard® - Best Practices for Advanced Driver Assistance Systems (ADAS)

Lane Departure Cameras

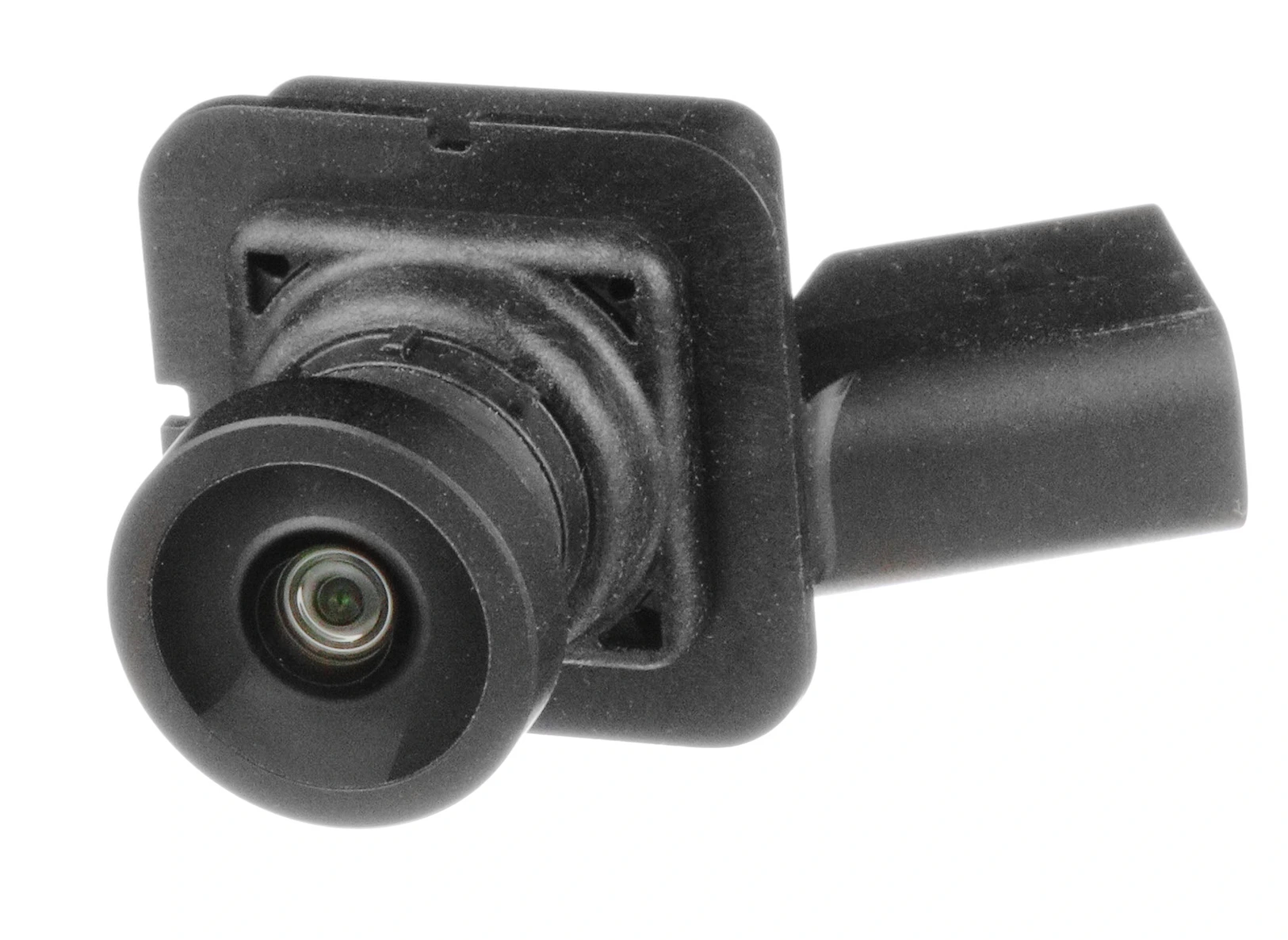

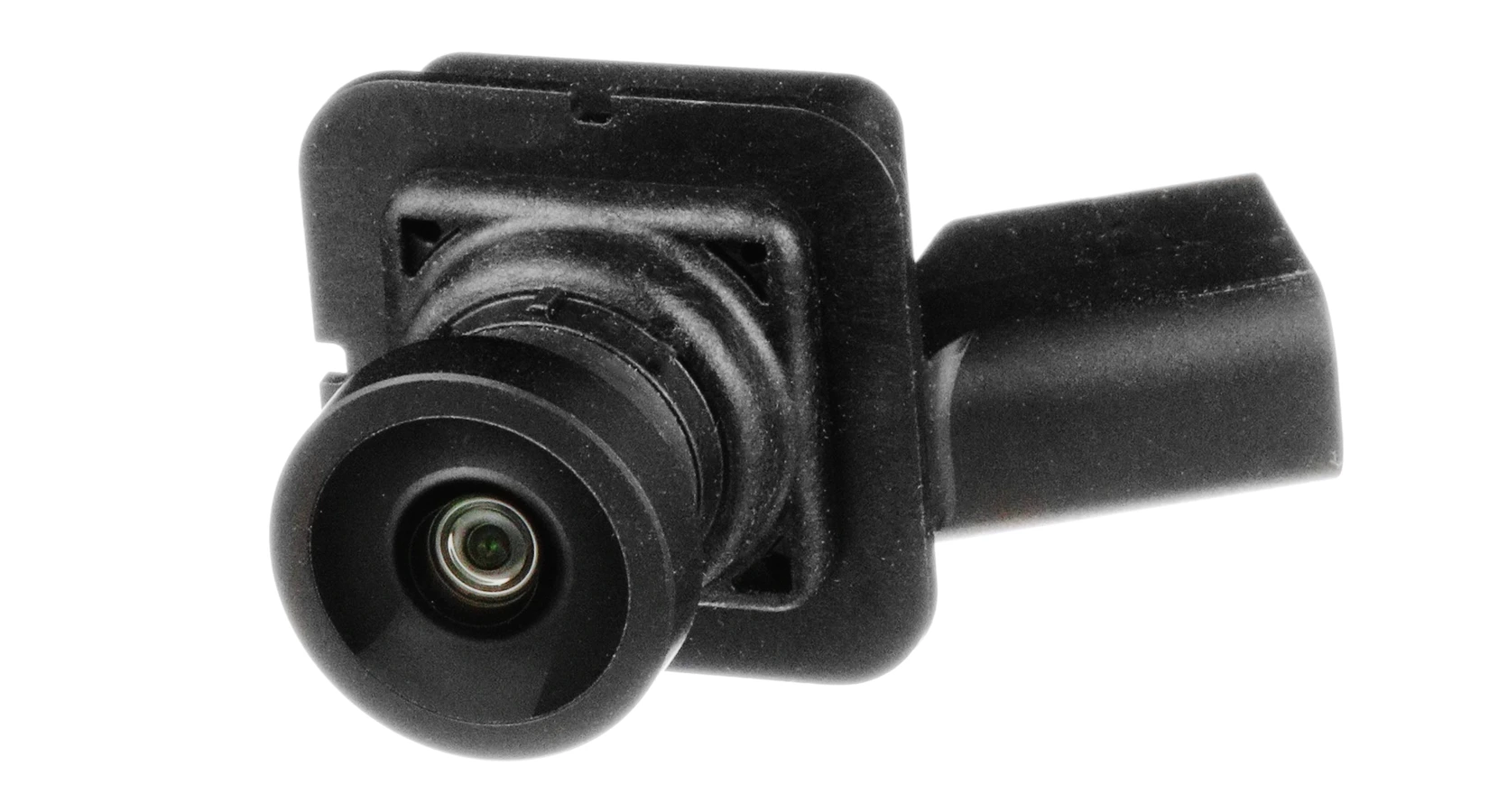

Park Assist Cameras

Features & Benefits

Park assist (or back-up) cameras alert the driver of people and objects in the vehicle’s path while in reverse. These cameras have been mandatory on all vehicles sold in the U.S. since 2018. A premium replacement for the failed OE unit, many Standard® cameras are ‘plug & play’ — no programming required. Each Camera is rigorously tested to match OEM vehicle-specific performance.

Direct-Fit OE Replacement

For easy installation and proper performance

Plug & Play Design

No programming required

Tested and Validated

Undergoes extensive testing and validation for correct on-vehicle performance and electronic integration

PAC252 | Ford Trucks (2022-17)

Park Assist Camera Videos

The StandardBrand YouTube ADAS playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Advanced Driver Assistance Systems (ADAS) Program by Standard®

Standard® - Advanced Driver Assistance Systems (ADAS) Overview

Standard® - Best Practices for Advanced Driver Assistance Systems (ADAS)

Park Assist Cameras

Park Assist Sensors

Features & Benefits

Park assist sensors, also known as backup sensors, alert drivers to approaching objects while parking or backing up. These sensors report the distance to an object using an ultrasonic signal in real-time. Standard® Park Assist Sensors are direct-fit replacements utilizing advanced ultrasonic technology that exactly matches the detection capabilities of the original sensors.

Advanced Ultrasonic Technology

Matches the object detection range of OE ensuring the driver is alerted of objects within the vehicle’s path

Manufactured in Poland

Engineered and manufactured in SMP’s state-of-the-art Poland facility

New Seal Included

To help keep moisture out for a long service life

OE-Matching Performance

To integrate seamlessly with electronic safety systems

PPS45 | Chrysler, Dodge, Jeep, RAM (2022-09)

Park Assist Sensor Videos

The StandardBrand YouTube ADAS playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® - Advanced Driver Assistance Systems (ADAS) Overview

GMC Yukon Rear Park Assist Sensor Installation | Installation Spotlight

Ford Truck Park Assist Sensor Installation | Installation Spotlight

Park Assist Sensors

Steering Angle Sensors

Features & Benefits

The steering angle sensor gives the vehicle’s computer the steering wheel’s rate of turn, wheel angle and other important data. The performance of modern safety systems like Electronic Stability Control are dependent on the data from these components Standard® Steering Angle Sensors are rigorously tested and validated to ensure precise performance.

Robust Design and High-Grade Materials

Meet the stringent demands of today’s vehicles

Direct-Fit Replacement

Electrically-operated sensor replaces damaged OE units, restoring power steering functionality

Copper Alloy Conductors

Ensure superior electrical conductivity with low resistive losses

SWS75 | Toyota Cars (2016-13)

Steering Angle Sensor Videos

The StandardBrand YouTube ADAS playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Advanced Driver Assistance Systems (ADAS) Program by Standard®

Standard® - Advanced Driver Assistance Systems (ADAS) Overview

GM Steering Angle Sensor Tip

Steering Angle Sensors

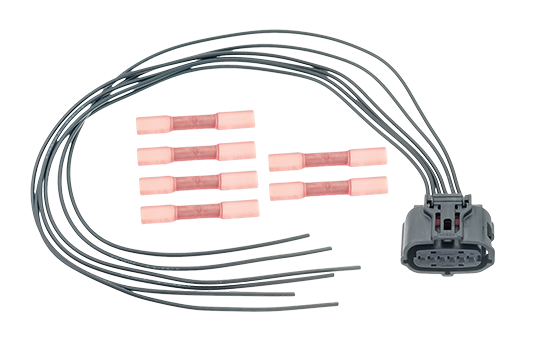

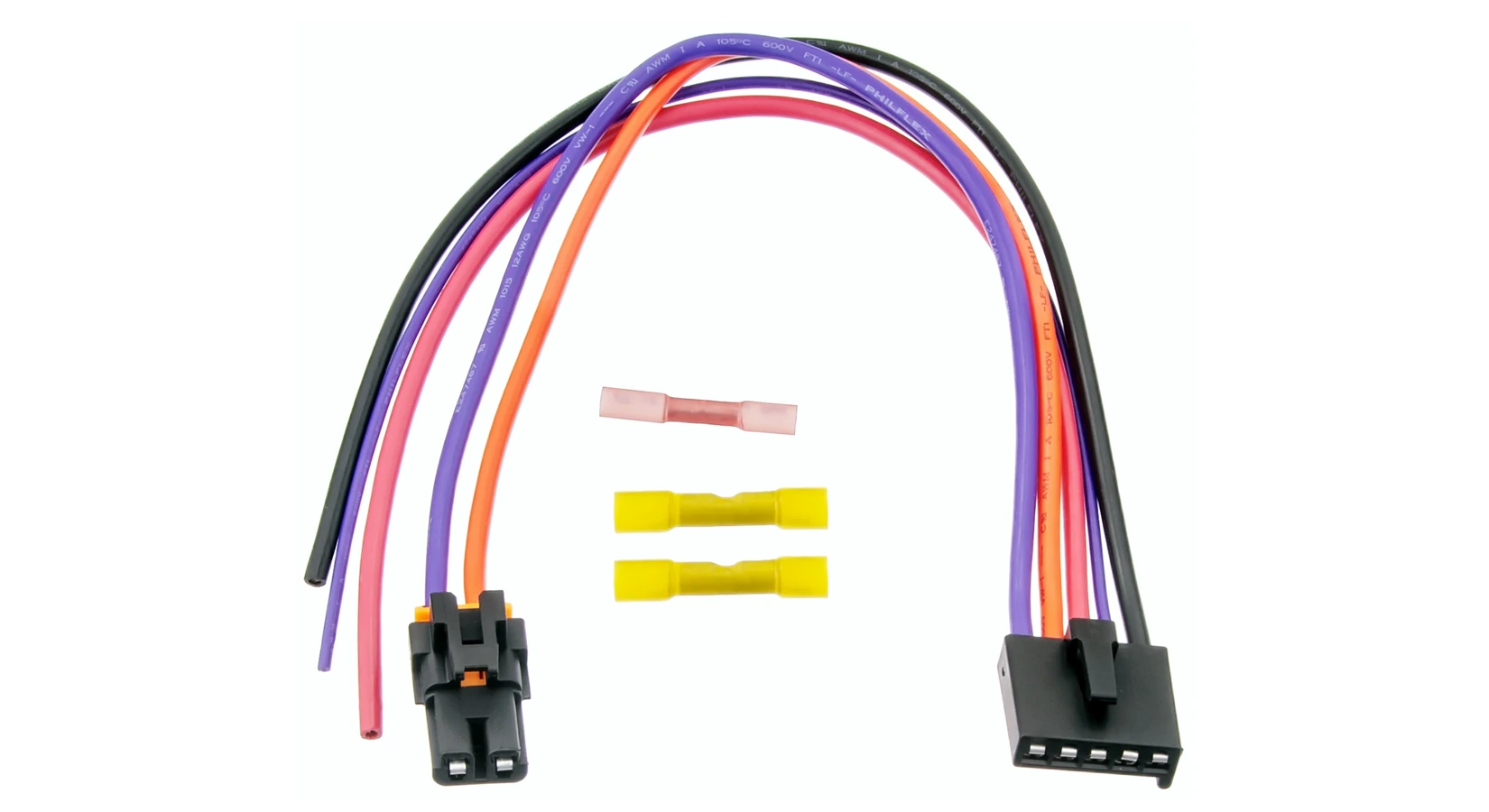

Connectors & Pigtails

Blower Motor Resistor Harnesses

Features & Benefits

Standard® Blower Motor Resistor Harnesses are designed to reduce amperage draw and harness melting. Each Harness has been re-engineered with TXL copper wiring to withstand high electrical current and prevent burning out and melting, and can be used as a pigtail if the original harness is damaged. High-temp plastic harness and heavy-duty mating connections withstand extreme temperatures, which is validated during our thermal cycling processes ranging from -22° to 257°F.

High-Grade Materials

Terminals are manufactured with high-grade materials such as copper alloy, brass and phosphor bronze

Polyamide Resin Housing

To provide the connectors with prolonged life and superior performance in harsh environments

100% Tested

For proper mechanical and electrical operation

S2920 | GM Cars, Trucks & SUVs (2016-99)

Blower Motor Resistor Harness Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® and Blue Streak® BMR Overview

Blower Motor Resistor Replacement Tips

Successful Blower Motor & Resistor Diagnosis & Replacement

Blower Motor Resistor Parts

Electrical Connectors

Features & Benefits

Standard® offers an ever-expanding line of Connectors in more than 300 categories. All of our Connectors are manufactured with high-quality materials and tested to perform in harsh conditions.

High-Grade Materials

To ensure peak conductivity

100% Tested

For proper mechanical and electrical operation

S-567 | Ford / Lincoln / Mazda / Mercury (2005-80)

Electrical Connector Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

The Standard® Advantage

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

Electrical Connectors

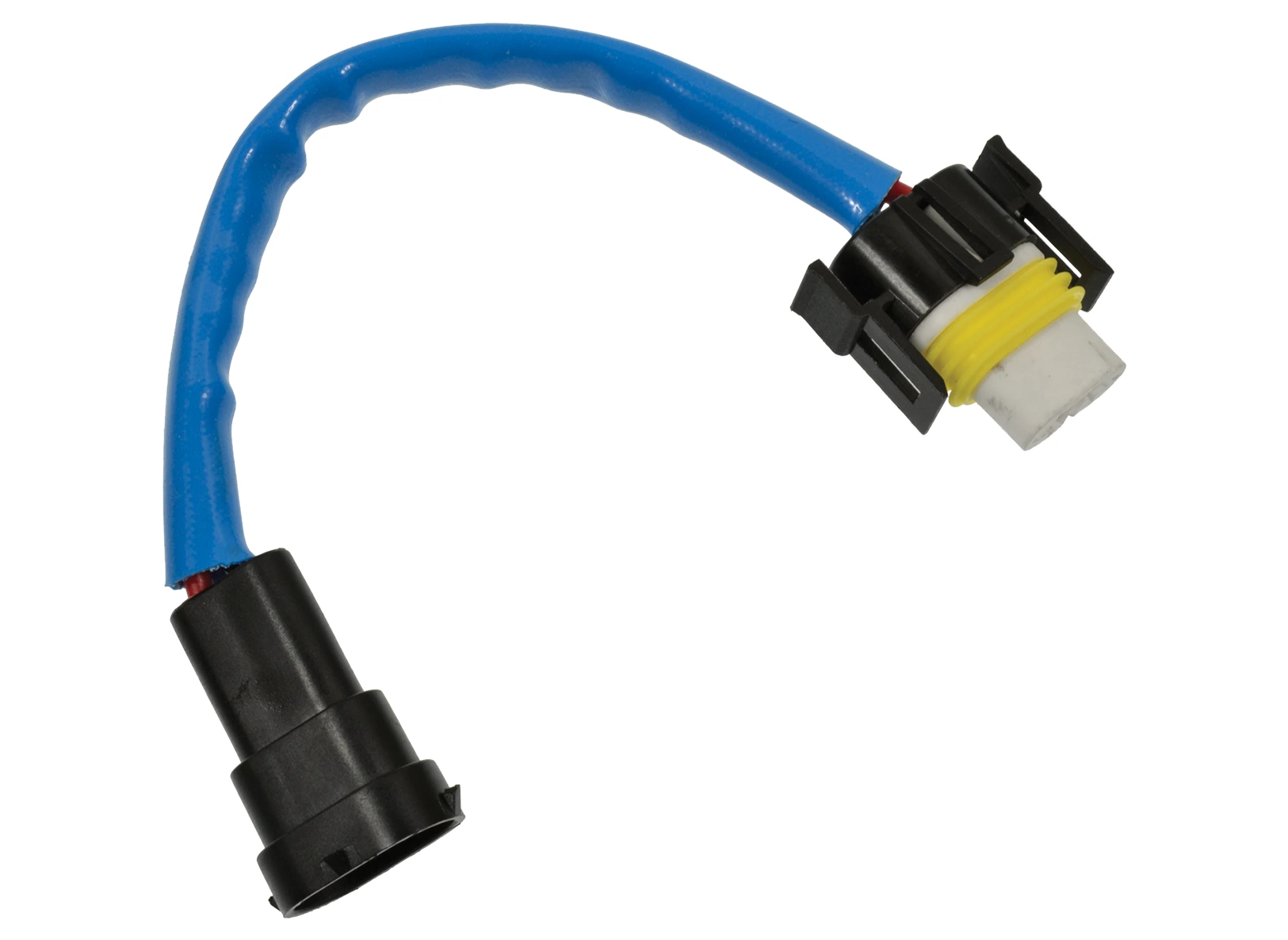

High-Temp Headlight Harnesses

Features & Benefits

The headlight wiring harness supplies consistent power from a vehicle’s battery to its lighting system. To prevent melting, Blue Streak® Headlight Wiring Harnesses have high-temp connectors that can withstand extreme heat. The wiring harnesses also have 14-gauge wire for better conductivity and a “plug & play” feature that lets you plug the wiring harness right between the factory harness and new bulb.

Plug and Play Design

Plugs between the factory harness and new bulb for ease of installation

Fiberglass Wrapping

Prevents chafing

14 Gauge Wire

For better conductivity

Hi-Temp Connector

Prevents melting caused by high-intensity bulbs

Flexible Design

Can be used as a pigtail if the original connector is melted

LWH104 | Multiple Applications

High-Temp Headlight Harness Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

The Standard® Advantage

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

High-Temp Headlight Harnesses

Sensors

ABS Sensors

Features & Benefits

The ABS speed sensors on some newer vehicles measure more than just the speed of each wheel. They also monitor the direction in which the wheel is rotating. A wheel that is rotating backwards will send a unique signal to the ECU that lets the vehicle know the speed and direction of that wheel. This data is used by electronic safety systems. While aftermarket competitors’ ABS sensors cannot determine which direction the wheels are rotating, the Standard® ALS684 uses microsensors to produce the unique forward and reverse signals that modern vehicles require to keep electronic safety systems working as designed.

Includes Multiple Micro Sensors

Which measure the directional rotation of the wheel as an integral part of electronic safety systems

Brass Insert

Prevents cracking during installation

Manufactured in Poland

OE-Style Sealed Connector

For protection in harsh conditions

ALS684 | Toyota / Lexus Trucks & SUVs (2022-03)

ABS Sensor Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Recommending Replacement ABS Sensors

What's In Your Box: Standard Anti-lock Brake (ABS) Sensor Program

Standard® ABS Sensors Overview

ABS Sensors

Headlight Level Sensors

Features & Benefits

Headlight level sensors work with the vehicle’s self-leveling headlight system to adjust the beams to the right height. They can even make up for headlights that have shifted because of a loaded trunk. These sensors are essential to proper performance of an HID lighting system. Standard's direct-fit Headlight Level Sensor replacements restore headlight self-leveling system function for improved visibility.

Precision-Engineered

Accurately communicates with the vehicle’s self-leveling headlight system and adjusts headlight height in relation to vehicle height

Direct-Fit Replacement

Restores proper headlight self-leveling system function for improved visibility

Compensates for Vehicle Weight

Once installed, the sensor compensates for headlights that have shifted because the vehicle is carrying additional cargo

LSH100 | BMW / MINI Cars & SUVs (2014-96)

Headlight Sensor Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard Brand - Here Is What's In Our Box

The Standard® Advantage

When OE Fails...Trust Standard®

Headlight Level Sensors

Ride Height Sensors

Features & Benefits

A ride height sensor electronically tracks the distance between the vehicle's underside and the road. That information is used by the engine control unit to help the suspension system keep the vehicle level and riding smoothly. Standard® Ride Height Sensors come complete with sensor, linkage and mounting bracket for a complete assembly and easy installation.

Comes Complete

With sensor, linkage, and mounting bracket – everything needed for a complete repair

Direct-Fit Replacement

For a unit that is commonly damaged in collisions

Precision-Engineered

To properly restore suspension self-leveling system for improved ride comfort

LSH136 | Lexus Cars (2013-06)

Ride Height Sensor Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

The Standard® Advantage

Ride Height Sensors

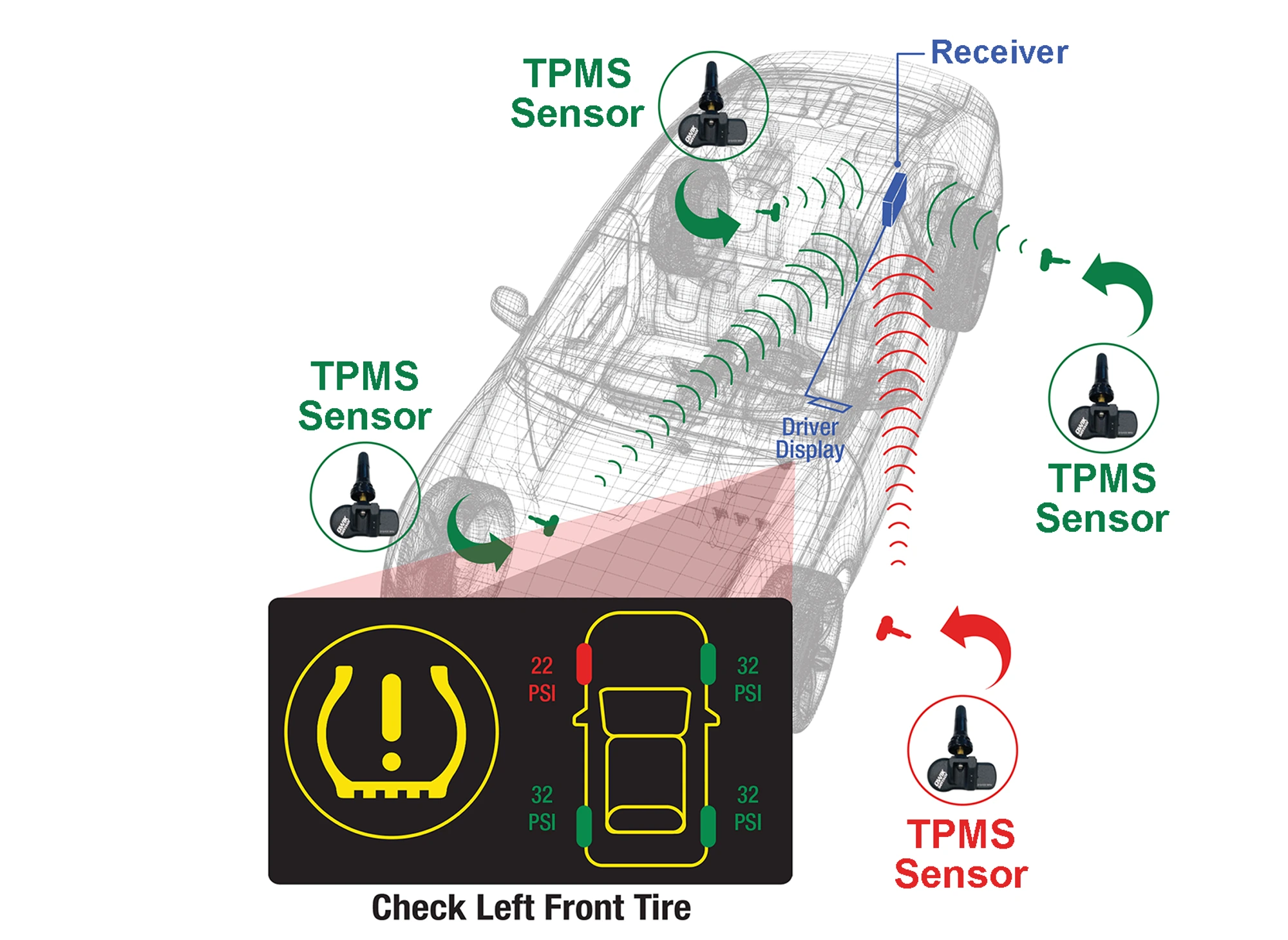

TPMS Sensors

Features & Benefits

QWIK-SENSOR® Multi-Frequency TPMS Sensors combine all frequencies into a single sensor, eliminating duplication of inventory. The QWIK-SENSOR® is available with a factory-installed rubber or metal valve stem, and works on both domestic and import applications with 314.9MHz to 434MHz TPMS systems. Each Sensor is independently tested to match OE protocols including LOCSYNC, PAL, POD, and WAL advanced TPMS technologies.

ASIC-Equipped

Application-Specific Integrated Circuit features an accelerometer which uses multi-axis positioning allowing the TPMS system to accurately display pressure on demand

Available in Multipacks of 25

For Professionals: Contains 25 individually wrapped QWIK-SENSORS® (available in rubber or metal valve stems)

Metal or Rubber Valve Stem

Factory-installed

Enhanced Signal Integrity

Surface-mounted, dual-band antenna enhances signal integrity and reliability without compromising battery life to ensure data is transmitted accurately

QS106R | Universal

TPMS Sensor Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® Single Sensor TPMS Program

TPMS Tech Tip: Tool Update

Understanding the TPMS Light - Solid or Flashing

System Overview

The TPMS sensor is typically located as a valve-mounted stem in the tire. There are also band-mounted sensors that are attached to the wheels themselves. TPMS sensors can fail due to road hazard damage, overtightening, using an improper valve core, electronic failure and sensor battery discharge.

TPMS Sensors

Underhood & Cabin Components

Active Grille Shutter Actuators

Features & Benefits

Active grille shutter actuators control a vehicle’s active grille shutter, opening and closing them to direct airflow. This reduces aerodynamic drag, offering improved fuel mileage, and increased range on electric vehicles. They are the first point of contact in a front-end collision, and are easily damaged. Standard® Active Grille Shutter Actuators are a direct-fit OE replacement that works with OEM and aftermarket active grille shutters.

Improves Fuel Mileage

Designed to regulate vehicle’s frontal airflow to reduce aerodynamic drag and offer improved fuel mileage

Direct-Fit Replacement

For a unit that is commonly damaged in collisions

High-Grade Materials

Resist corrosion and withstand extreme engine temperatures for durability

100% Tested

Undergoes 100% end-of-line testing to meet or exceed OE performance

AGA1008 | Ford / Lincoln Trucks & SUVs (2021-18)

Active Grille Shutter Actuator Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Active Grille Shutters | Pro Training PowerHour

Standard Brand - Here Is What's In Our Box

The Standard® Advantage

Active Grille Shutter Actuators

Active Grille Shutters

Features & Benefits

Active Grille Shutters (AGS) offer the latest technology to improve fuel economy. AGS regulate frontal airflow in the vehicle to reduce aerodynamic drag, offering improved fuel mileage, and increased range on electric vehicles. Open shutters allow air to flow through the radiator and into the engine compartment to promote cooling. When cooling air is not needed, the shutters close, rerouting air around the vehicle to reduce aerodynamic drag and fuel consumption. When fully closed, the reduction in drag can reduce CO2 emissions by close to 2%. AGS are the first point of contact in a front-end collision and are damaged easily. Failure can also be mechanical or the result of calibration errors. An obstruction can cause the shutters to bind together, blowing the grille shutter system's dedicated fuse. All Standard® AGS are built from high-grade industrial plastic to resist corrosion and withstand extreme engine temperatures, and undergo 100% end-of-line testing.

High-Grade Materials

Resist corrosion and withstand extreme engine temperatures for durability

Improves Fuel Mileage

Designed to regulate vehicle’s frontal airflow to reduce aerodynamic drag and offer improved fuel mileage

Direct-Fit Replacement

For a unit that is commonly damaged in collisions

100% Tested

Undergoes 100% end-of-line testing to meet or exceed OE performance

AGS1002 | Ford F-150 (2017-15)

Active Grille Shutter Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Active Grille Shutters | Pro Training PowerHour

Standard Brand - Here Is What's In Our Box

The Standard® Advantage

Active Grille Shutters

Airbag Clock Springs

Features & Benefits

An airbag clock spring is an assembly that contains a flat ribbon spirally wound so the steering wheel can be turned and maintain a constant electrical connection to the driver airbag, horn and other electrical controls mounted on the steering wheel. When airbags are deployed, the high heat generated melts the connector behind the airbag. The clock spring must be replaced. Standard® Clock Springs are direct-fit replacements featuring premium components to ensure superior application-specific performance.

Robust Design

With high-grade materials meet the stringent demands of today’s service professional

Direct-Fit Replacement

Electrically-operated switch that replaces damaged OE units, increasing road safety and restoring steering wheel airbag function

Copper Alloy Conductors

Ensure superior electrical conductivity with low resistive losses

CSP122 | Dodge / Chrysler Vans (2013-08)

Airbag Clock Spring Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Clock Spring Replacement Tips

Airbag Clockspring Tip | Tech Tip

Standard Brand - Here Is What's In Our Box

Airbag Clock Springs

DRL Components

Features & Benefits

Daytime running lights switch on when a vehicle is started and are on at all times that the headlights aren’t on. Standard® offers Daytime Running Light components including DRL Modules and DRL Sockets so that this system can be easily repaired.

Direct-Fit Replacement

For a unit that is commonly damaged in collisions

High-Grade Materials

Ensure peak conductivity and superior connections

S1022 | GM Cars & Trucks (2007-99)

DRL Component Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

The Standard® Advantage

DRL Components

HID Headlight Ballasts

Features & Benefits

High-intensity discharge (HID) headlights use high-voltage current to produce stronger light than halogen headlights. The ballast controls the headlights' intensity. Ballasts can be damaged by collisions, overheating, moisture intrusion or burn out from repeated duty cycles. Nonworking headlights reduce visibility and create safety concerns for drivers and motorists. Standard® HID Modules feature OE-match internal circuitry with heavy-duty casings surrounding the electronics for durability. DOT-certified to comply with Federal Motor Vehicle Safety Standards, our HID Headlight Ballasts are a direct replacement.

Heavy-Duty Casing

Around electronics ensures durability

Internal Circuitry

Matches OE design to ensure performance

Plug and Play Design

No additional programming required

HID110 | GM / BMW / VW / Hyundai / Mercedes-Benz (2019-00)

HID Headlight Ballast Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

A Closer Look: HID Headlight Ballast

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

HID Headlight Ballasts

High Mount Stoplight Assemblies

Features & Benefits

High mount stoplight assemblies are located to maximize visibility, but that also leaves them susceptible to collision, with lenses and interior components that often break on impact. Quality-designed to prevent water intrusion, which can lead to brake light failure, Standard’s OE-matching replacements ensure proper fit, form, and function for an easy installation.

Direct-Fit OE Replacement

For proper fit and easy installation

Watertight Construction

Quality-designed to prevent water intrusion, which can lead to brake light failure

Vehicle-Specific Connector

Matches OE for proper connectivity and easy installation

Helps Prevent Rear-end Collisions

Restores the ability to warn drivers of following vehicles when brakes are applied

BTL123 | Dodge / RAM Trucks (2024-09)

High Mount Stoplight Assembly Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

When OE Fails...Trust Standard®

Standard Brand - Here Is What's In Our Box

The Standard® Advantage

High Mount Stoplight Assemblies

Intercoolers

Features & Benefits

Intercoolers, also called “Charge Air Coolers,” cool the air using heat transfer before it enters the intake manifold. Standard® Intercoolers are direct-fit OE replacements to ensure a seamless installation process and proper performance. Each Standard® Intercooler is designed, manufactured and tested to stringent quality standards to deliver precise vehicle-specific performance, and are 100% new, not remanufactured. They are built from the highest-quality materials to withstand harsh underhood conditions for a long service life, and are 100% factory tested for air/water leaks.

Tested and Validated

Extensively tested to OE specifications to ensure superior performance and a long service life

Precision Manufacturing

Undergoes extensive design and manufacturing processes to ensure superior durability, longevity and performance, even under extreme conditions

Direct-fit Replacement

For a unit that is commonly damaged in collisions

CAC9 | Ford Transit Vans (2021-15)

Intercooler Videos

The StandardBrand YouTube Collision playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Ford 6.0 Powerstroke Charge Air Cooler (Intercooler) Replacem

The Standard® Advantage

When OE Fails...Trust Standard®

Intercoolers

Switches and Relays Program

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in collision components. Here’s what they say to look out for during collision repair.

In addition to being damaged in collisions, blind spot detection sensors are prone to failure due to corrosion from salt spray entering the casing and destroying the circuit board inside.

Electric and hybrid vehicles also use active grille shutters to improve aerodynamics and assist with cooling the battery and drive motor.

The door lock actuator on the driver’s door is the most replaced as it experiences more wear than the others.

During a collision repair, before replacing an ADAS Component, always refer to specific service information for the procedures required for that component.

Before installing any replacement part after a collision, make certain that the mounting surface is true to the original location.

To prevent broken headlight level sensor linkage, check the mounting bracket for corrosion and rust. If you notice any, clean it with rust penetrant.

In addition to being damaged in collisions, blind spot detection sensors are prone to failure due to corrosion from salt spray entering the casing and destroying the circuit board inside.

Electric and hybrid vehicles also use active grille shutters to improve aerodynamics and assist with cooling the battery and drive motor.

The door lock actuator on the driver’s door is the most replaced as it experiences more wear than the others.

During a collision repair, before replacing an ADAS Component, always refer to specific service information for the procedures required for that component.

Before installing any replacement part after a collision, make certain that the mounting surface is true to the original location.

To prevent broken headlight level sensor linkage, check the mounting bracket for corrosion and rust. If you notice any, clean it with rust penetrant.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-25 of 25

No results found