What's in Your Box?™

Blue Streak®

Made to stand the test of time, Blue Streak® by Standard® has always been known for quality and durability. Now, 90 years young, the Blue Streak® brand is still the benchmark against which all other aftermarket brands are measured.

3 Things To Know

Blue Streak® Gives You More

Blue Streak® gives technicians more – more durability over the OE design and more parts in the box to do the job right.

Complete Service Solutions

Blue Streak® delivers complete service solution kits, including Variable Valve Timing Kits, Blower Motor Resistor Kits and Cam Sensor Kits.

Limited Lifetime Warranty

All Blue Streak® parts are backed by our Limited Lifetime Warranty.

Made to Stand the Test of Time™

Coverage

Comprehensive Coverage

Blue Streak® continually releases new high-quality components and kits across numerous categories to help technicians do the job right. Kits include:

-

- Direct Injection High-Pressure Fuel Pump Kits

- Variable Valve Timing Service Kits

- Variable Valve Timing Solenoid Kits

- Blower Motor Resistor Kits

- Camshaft Sensor Kits

- Crankshaft Sensor Kits

- Knock Sensor Kits

- Ignition Coil Kits

- Heavier-Duty Coil Multi-Pack Kits

- Blue Streak® Kits include everything needed for a complete repair.

Market

Brand Preference

The professional automotive technicians’ choice since 1934, today’s technicians still consider Standard® Blue Streak® their top-rated aftermarket brand, unsurpassed for quality, performance and service life.

In a recent survey of shop owners and technicians, Blue Streak had a higher quality score than all other full-line aftermarket competitors*

* 2023 Survey conducted by Babcox Media

Service Opportunities

Service Opportunities

Our engineers discovered that too much energy was passing through each section of the OE coil, creating too much heat, and causing premature coil failure. They designed a Coil with an additional bobbin section, resulting in less heat and a longer service life. The updated Blue Streak® Coils outperform and outlast the OE design. Blue Streak® multi-packs make it easier for technicians to solve a known problem once and for all.

- Blue Streak® Coil Multi-Pack Kits include all of the needed Coils in one box for a complete and easy repair.

30kV needs to pass through only 8 sections, meaning nearly 4kV needs to pass through each section.

30kV passes through 9 sections, meaning only 3.3kV passes through each section, creating less heat, allowing the coil to last longer.

Engineering & Design

Engineering

Blue Streak® engineers evaluate the original part, identify the OE issues, and correct those problems to deliver better-performing and longer-lasting components.

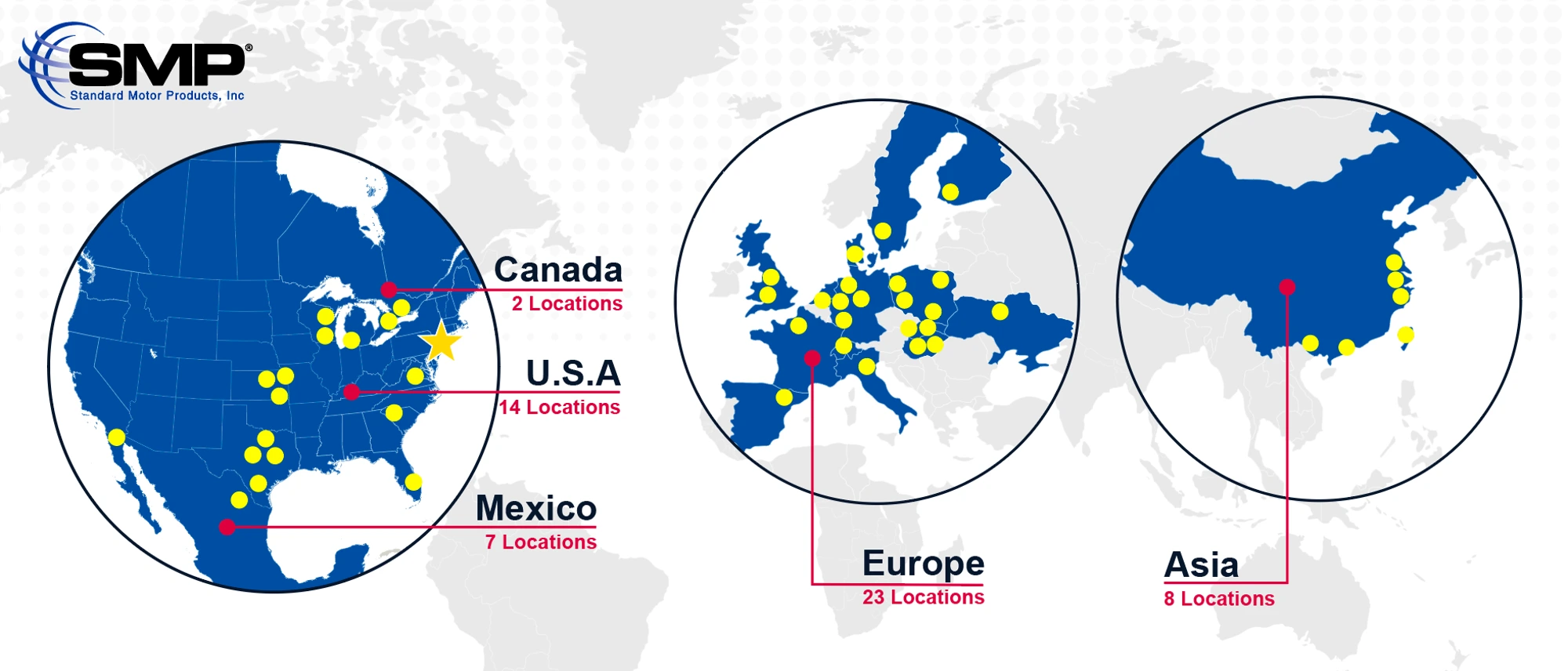

- We operate 19 manufacturing facilities in the U.S., North America and globally.

Moisture intrusion causes the OE coil to prematurely fail when the O-ring breaks down.

We engineered an improved, one-piece design that eliminates the need for an O-ring and removes the chance of moisture intrusion.

Manufacturing

Precision Manufacturing

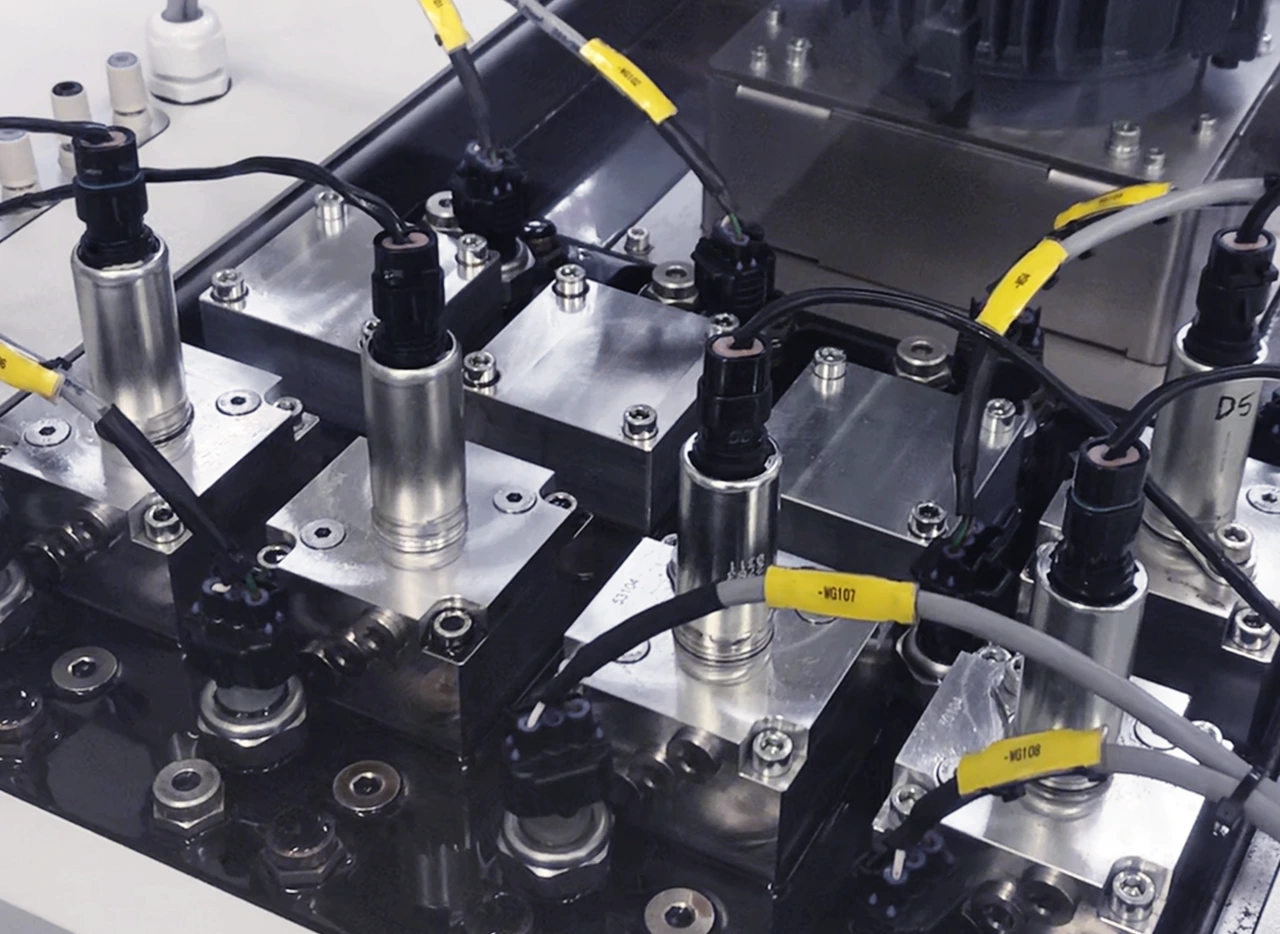

Blue Streak® components are the result of over 90 years of precision manufacturing. For instance, Blue Streak® Ignition Coils are designed and manufactured at our IATF 16949-certified facility in Bialystok, Poland. Spanning 145,000 square feet, our most advanced facility has nearly 1,000 employees and teams of design and production engineers.

- SMP facilities hold IATF 16949, ISO 9001, and ISO 14001 certifications. These certifications guarantee a high-quality, reliable component in every box.

Testing & Validation

Testing & Validation

All Blue Streak® parts undergo rigorous examination and product validation, including extensive measurement, end-of-line and product cycle life testing, plus a full range of environmental analysis. We go to these lengths to ensure 100% product reliability, so you can install every Blue Streak® part with confidence.

- All Blue Streak® components are backed by a Limited Lifetime Warranty.

Blue Streak Categories

Technicians look to Blue Streak® for the parts required to do the job right. Made to stand the test of time, Blue Streak® by Standard® has always been known for superior quality and durability.

Blower Motor Resistor Kits

Features & Benefits

Features & Benefits

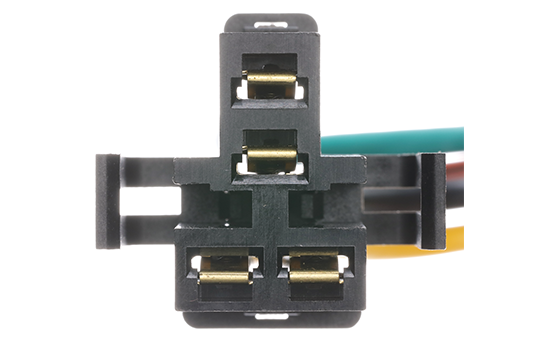

Blue Streak® Blower Motor Resistor Kits include a high-temp connector which withstands extreme temperatures to prevent melting and a direct-fit resistor to replace the damaged units, restoring A/C and heater blower motor variable speed control. These components are built in our IATF 16949 and ISO 9001-certified facilities to ensure that each part is designed to perform and last.

Precision Resistor Coils

For superior fan control

Kanthal D Resistor Wire

Provides longer life span for higher watt resistors

High-Quality Construction

High-quality ceramics made from copper electrical connectors ensure precise resistance values and tin-plated steel terminals guarantee maximum contact

Thermally Protected

With on-board fuse

High-temp Connector

Prevents melting under extreme temperatures

TXL Copper Wiring

Withstands high electric current to reduce heat-related failure

Tested and Proven

Undergoes thermal cycling to withstand temperatures ranging from -22°F to 257°F

BSD16 | Nissan Cars (2017-16)

Videos

Blower Motor Resistor Kit Videos

The StandardBrand YouTube Blower Motor Resistor Kit playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

A Closer Look: Blue Streak® Blower Motor Resistor Kits

Standard® and Blue Streak® BMR Overview

Successful Blower Motor & Resistor Diagnosis & Replacement | Pro Training PowerHour

Blower Motor Resistor Kits

Cam/Crank Sensor Kits

Cam Sensor Kits

Features & Benefits

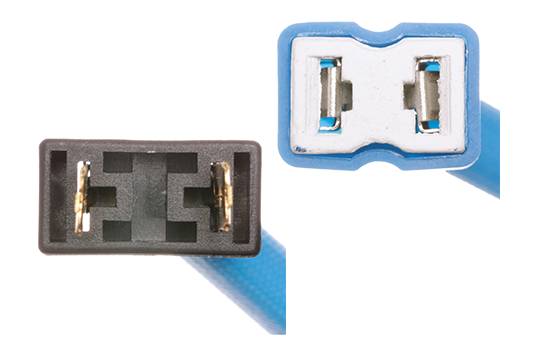

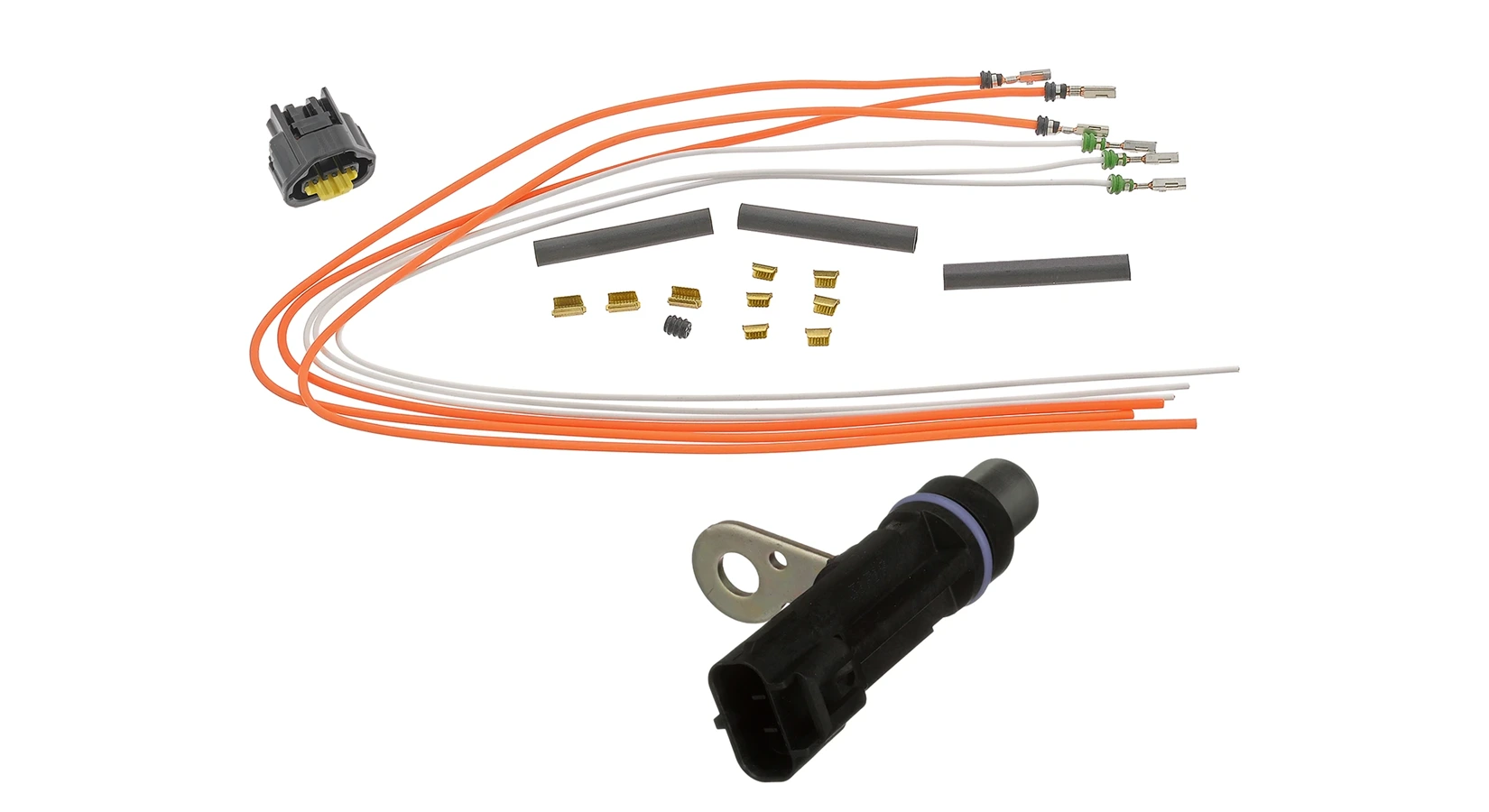

Blue Streak® developed high-quality Camshaft Sensor Kits to provide technicians with what they need to do the complete job. Our Kits include two Blue Streak® Camshaft Sensors along with the needed high-quality connectors to replace the melted or damaged originals.

Integrated Analog to Digital Converter

Sends a digital signal to the ECM for precise timing to optimize fuel economy and performance

Advanced Circuitry

Provides immunity from electromagnetic interference that meets ISO standards

Complete Kit

Includes two new precision sensors and high-temp connectors for a complete repair

Sealed Construction

Withstands extreme underhood conditions to ensure durability

Fluorocarbon Rubber Oil Seal

Ensures secure fit

PC460K | PC460K Nissan Cars & SUVs (2018-02)

Cam Sensor Kit Videos

The StandardBrand YouTube Cam Sensor Kit playlist features product and technical information and installation videos. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® Cam and Crank Sensors

Cam and Crank Sensors | Standard® WIYB Training Series

A Closer Look: Standard Cam and Crank Sensors

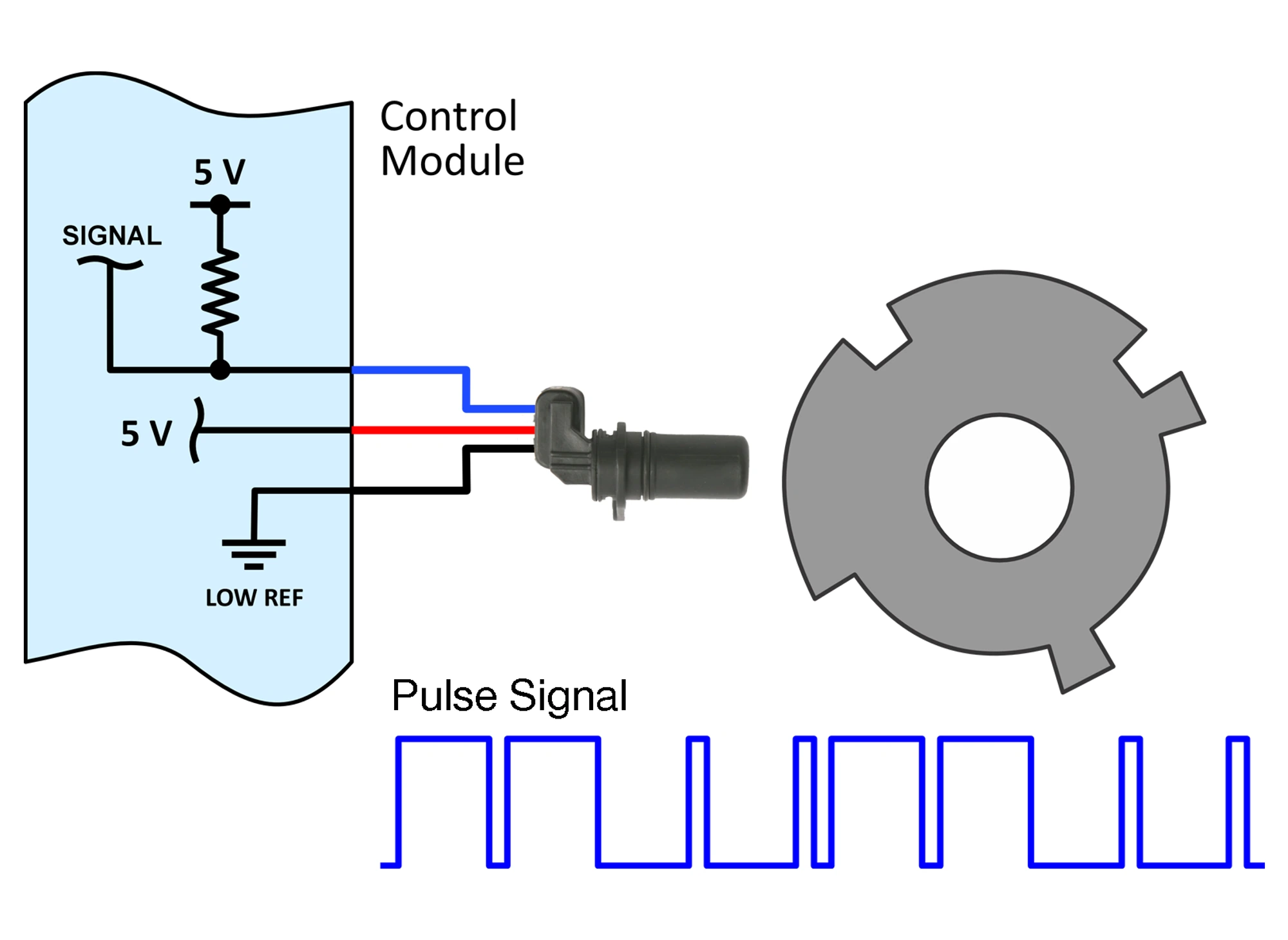

System Overview

Camshaft position sensors take readings off the camshaft and in real time send a signal to the vehicle’s control module. That information is used to adjust both fuel and timing for optimal fuel economy, performance and emissions. For the system to perform correctly, the camshaft position sensors much be accurate, fast and be durable enough to perform in high-heat conditions for thousands of miles.

Cam Sensor Kits

Crank Sensor Kits

Features & Benefits

Blue Streak® developed high-quality Crankshaft Sensor Kits to provide technicians with what they need to do the complete job. Blue Streak® Kits include a high-quality Crankshaft Sensor and a direct-replacement high-temp connector for a complete repair solution.

High-Grade Terminals

Copper alloy, brass, and phosphor bronze terminals for durability

Integrated Analog to Digital Converter

And digital signal processing with a dynamically adaptive switch point improves accuracy and operation

High-Quality Materials

Constructed with an insert-molded rare earth magnet and surface mount electronics in a sealed housing suitable for harsh underhood conditions

Complete Kit

Includes a crankshaft sensor and high-quality connector for a complete repair

PC284K | Chrysler / Dodge / Jeep / RAM (2013-99)

Crank Sensor Kit Videos

The StandardBrand YouTube Crank Sensor Kit playlist features product and technical information and installation videos. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® Cam and Crank Sensors

Cam and Crank Sensors | Standard® WIYB Training Series

A Closer Look: Standard Cam and Crank Sensors

Crank Sensor Kits

GDI Fuel Pump Kits

Features & Benefits

Features & Benefits

Our all-in-one Direct Injection High-Pressure Fuel Pump Kits simplify fuel pump replacements by including all of the components necessary to do the job right the first time. Each component is a direct-fit OE replacement for proper performance and ease of installation.

High-Pressure Fuel Pump

Camshaft Follower

Fuel Pump Mounting Gaskets

Fuel Pump O-Ring

GDP102K | General Motors Cars & SUVs (2017-08)

Videos

High-Pressure Fuel Pump Kits Videos

The StandardBrand Gasoline Direct Injection playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Blue Streak® GDI High-Pressure Fuel Pump Kits

GM 4 Cylinder GDI Pump and Injector Removal

Gasoline Direct Injection Diagnostics and Repair Tips | Pro Training PowerHour

GDI High-Pressure Fuel Pump Listings

Ignition Coils

Ignition Coils

Features & Benefits

Each Blue Streak® Ignition Coil is engineered with features to ensure that they perform under the most extreme conditions. Standard® engineers identify OE weak points and design Coils that last. Blue Streak® Coils are manufactured in Poland and tested in the lab and on vehicles to ensure precise performance.

Advanced Thermoplastic Coil Connector

Ensures proper connection and resists fractures caused by heat and thermal cycling

100% Pure Copper Windings

In the primary and secondary bobbins improve durability and provide higher resistance to prevent internal shorts and dielectric breakdown

High-Grade Copper Wires

Ensure heat resistance and prevent high voltage breakdown

Stainless Steel Spring

With internal ferrite noise suppressor prevents radio frequency interference (RFI)

High-Temp Boot

Prevents high-voltage leaks

UF303 | GM Cars, Trucks, and SUVs (2008-02)

Blue Streak Ignition Coil Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® and Blue Streak® Ignition Coil Overview

A Closer Look: Blue Streak Ignition Coils

Closer Look - Blue Streak Ignition Coils for Import Vehicles

Blue Streak® Ignition Coils

Ignition Coil Kits

Features & Benefits

Blue Streak® Ignition Coil Multipacks offer a complete replacement of old or worn ignition coils for a total repair. Each Blue Streak® Coil is engineered with features to ensure that they perform under the most extreme conditions. Blue Streak® Ignition Coils are manufactured in Poland and tested in the lab and on vehicles to ensure precise performance.

Updated Internal Design

Addresses OE flaws and helps to extend service life

100% Pure Copper Windings

In the primary and secondary bobbins improve durability and provide higher resistance to prevent internal shorts and dielectric breakdown

High-Temp Boot

Prevents high-voltage leaks

Advanced Thermoplastic Coil Connector

Ensures proper connection and resists fractures caused by heat and thermal cycling

UF349K6 | Nissan / Infiniti Cars, SUVs & Vans (2019-02)

Blue Streak Coil Multipack Videos

The StandardBrand YouTube Ignition Coils playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® and Blue Streak® Ignition Coil Overview

A Closer Look: Blue Streak Ignition Coils

Closer Look - Blue Streak Ignition Coils for Import Vehicles

Blue Streak® Ignition Coils

Knock Sensor Kits

Features & Benefits

Features & Benefits

Knock sensors create a voltage signal based on the vibrations caused by detonation. The computer uses this signal to retard timing when spark knock occurs. Blue Streak® Knock Sensor Kits are designed to respond to knock frequencies up to 1000 Hz, accommodating shifts in engine knock frequency and making it a more flexible sensor.

Double Sealed Connector Body

With an O-ring seal to provide a hermetic seal for the internal components, and a foam seal in the connector area provides a first line of protection, still allowing the housing to flex and achieve optimal sensor signal level

Made in the USA

Complete Kit

Includes two Knock Sensors and a high-quality harness for a complete repair

Updated Internal Design

Addresses OE flaws and helps to extend service life

KS116K | GM Cars, Trucks, SUVs & Vans (2007-99)

Videos

Knock Sensor Kit Videos

The StandardBrand YouTube Knock Sensor Kit playlist features product and technical information and installation videos. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

What's in Your Box? - Blue Streak® Kits

Blue Streak® Engineering

SMP Engineering Spotlight: Bialystok, Poland

Knock Sensor Kits

VVT Components

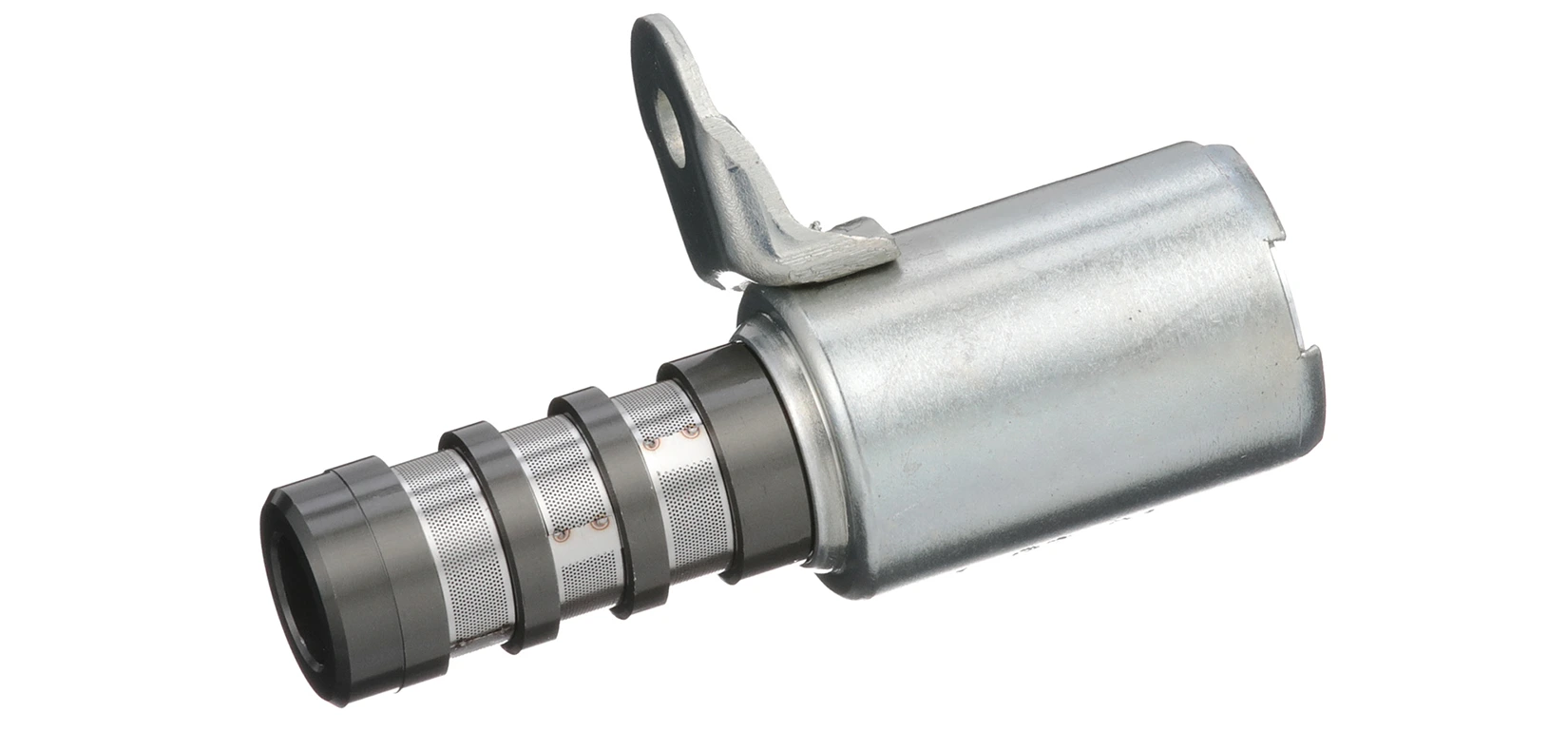

VVT Solenoids

Features & Benefits

Located on the camshaft, sprockets help maximize horsepower and torque curves, reducing emissions and improving vehicle efficiency. Standard® engineers have designed numerous improvements to our most popular VVT Sprocket for enhanced performance and long-lasting durability. Blue Streak® VVT Sprockets are direct-fit OE replacements and meet tight dimensional tolerances to improve internal sealing, minimize oil drain back, and reduce frequency of PCM correction.

Welded Reinforcement

Ensures a stronger connection between screen and body

Welded Filters

Have equal overlapping diameters with no gaps to maintain structural integrity

Stainless Steel Shaft

Stronger, stainless steel shaft for consistent performance and durability

Lubrication Groove

Keeps armature lubricated for a longer service life

Hardened Steel Componentry

Limits sludge buildup

VVT109 | Ford Cars, Trucks & SUVs (2020-11)

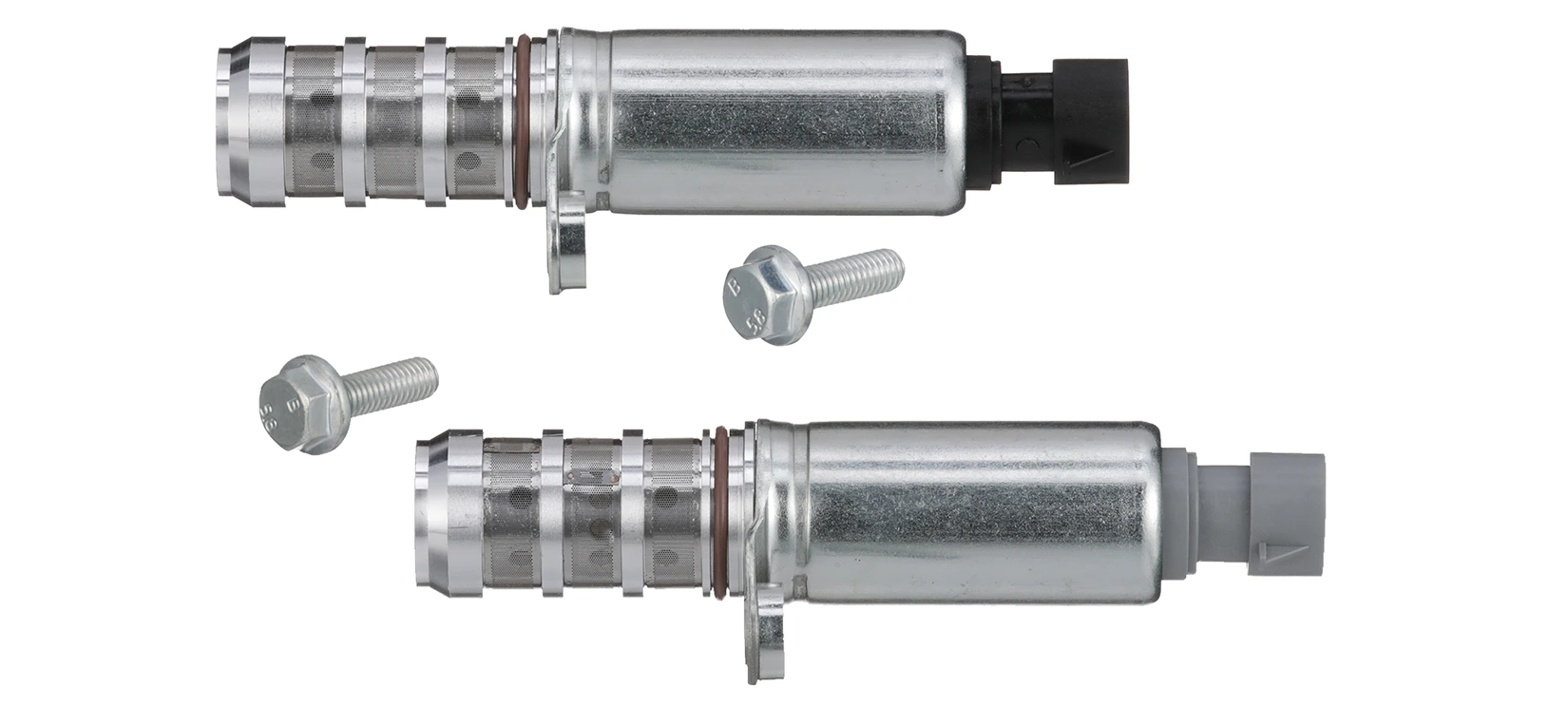

Features & Benefits

The GM 2.4L and Toyota 3.0L / 3.3L applications are known to have high failure rates for VVT solenoids. We have these covered with kits that include improvements over the OE design. Blue Streak® VVT Solenoid Kits include two new premium Solenoids with quality O-rings and gaskets to help prevent oil leaks.

Welded Reinforcement

Ensures a stronger connection between screen and body

Two premium VVT Solenoids

Blue Streak® VVT Solenoid Kits include two new premium Solenoids with quality O-rings and gaskets to help prevent oil leaks

Stainless Steel Shaft

Stronger, stainless steel shaft for consistent performance and durability

Welded Filters

Have equal overlapping diameters with no gaps to maintain structural integrity

Stainless Steel Shaft

Stronger, stainless steel shaft for consistent performance and durability

Hardened Steel Componentry

Limits sludge buildup

VVT2000K | GM 4 Cyl. (2017-06)

VVT Solenoid Videos

The StandardBrand YouTube Variable Valve Timing (VVT) playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Variable Valve Timing (VVT) Overview

Standard® VVT Components

Diagnosing Variable Valve Timing (VVT) Systems

VVT Solenoids

VVT Sprockets

Features & Benefits

Located on the camshaft, sprockets help maximize horsepower and torque curves, reducing emissions and improving vehicle efficiency. Standard® engineers have designed numerous improvements to our most popular VVT Sprocket for enhanced performance and long-lasting durability. Standard® and Blue Streak® VVT Sprockets are direct-fit OE replacements and meet tight dimensional tolerances to improve internal sealing, minimize oil drain back, and reduce frequency of PCM correction.

Bolt Included

OE-style installation bolt included for ease of installation

Larger Contact Area

Means no friction between the sprocket and rotor

Advanced Componentry

Advanced coil spring and locking pin for durability

Enhanced Performance

In timing phase response

Design Improvements

Virtually eliminate component wear for less oil loss

VVT500 | Ford Cars, Trucks & SUVs (2014-04)

VVT Sprocket Videos

The StandardBrand YouTube Variable Valve Timing (VVT) playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Variable Valve Timing (VVT) Overview

Standard® VVT Components

Ford 5.4L Cam Phaser and VVT Control Solenoid Replacement

VVT Sprockets

VVT Service Kits

Features & Benefits

Ford 5.4L engines feature highly technical VVT systems which are susceptible to failure. They typically fail due to low engine oil levels, poor oil circulation, or oil and filter change irregularities. Blue Streak® offers a Complete Timing Repair Kit to solve this OE problem. Everything for a complete repair – solenoids, sprockets, timing chain, guide, tensioner, arm, seals, crankshaft wheel, and gaskets.

VVT Sprockets

Timing Chains

VVT Solenoids

Crankshaft Seal

Crankshaft Position Wheel

Gaskets

Drive Gear Sprocket

Timing Chain Tensioners

Timing Chain Guides & Tensioner Arms

VVT420K | Ford 5.4L (2014-04)

VVT Service Kit Videos

The StandardBrand YouTube Variable Valve Timing (VVT) playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Variable Valve Timing (VVT) Overview

Standard® VVT Components

Diagnosing Variable Valve Timing (VVT) Systems

VVT Service Kits

Blue Streak®

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in advanced vehicle systems. Here’s what they say to look out for during a service or installation.

An ignition-related misfire can damage the catalytic converter in a few miles or several minutes of driving if a vehicle doesn’t register the faulty coil and continues to feed fuel to the cylinder.

Rough idle, stalling, lack of power, decreased fuel economy, engine noise or a check engine light may be signs of an issue with the VVT system.

Using the correct oil weight is critical to the health of any variable valve timing system.

Many times, the cam sensor and connector will become saturated with engine oil. If this is the case, the leak should be repaired and the connector replaced at the same time as the sensor(s).

Blower motor resistors typically burn out due to excessive electrical draw. Replace the blower motor, electrical connector, and cabin air filter along with the new resistor.

Engine oil is the lifeblood of the VVT system. Ensure that properly spec’d oil is used when replacing VVT components.

An ignition-related misfire can damage the catalytic converter in a few miles or several minutes of driving if a vehicle doesn’t register the faulty coil and continues to feed fuel to the cylinder.

Rough idle, stalling, lack of power, decreased fuel economy, engine noise or a check engine light may be signs of an issue with the VVT system.

Using the correct oil weight is critical to the health of any variable valve timing system.

Many times, the cam sensor and connector will become saturated with engine oil. If this is the case, the leak should be repaired and the connector replaced at the same time as the sensor(s).

Blower motor resistors typically burn out due to excessive electrical draw. Replace the blower motor, electrical connector, and cabin air filter along with the new resistor.

Engine oil is the lifeblood of the VVT system. Ensure that properly spec’d oil is used when replacing VVT components.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-19 of 19

No results found