What's in Your Box?™

Blower Motor Resistors

With our expertise and manufacturing processes in place, Standard® is able to offer the high-quality Blower Motor Resistors and Kits that professional technicians need for domestic and import vehicles.

3 Things To Know

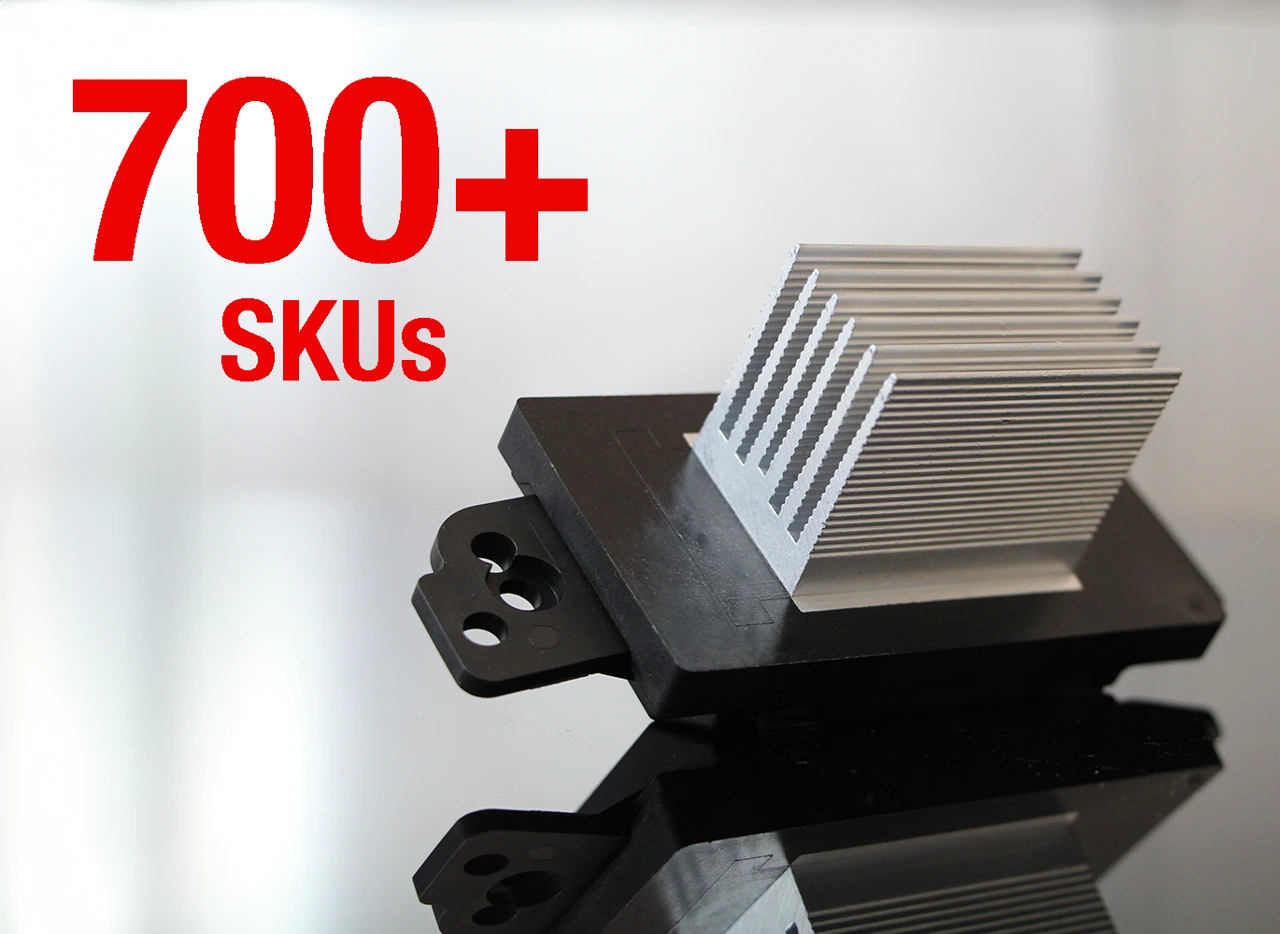

700+ Part Numbers

Standard® offers more than 700 Blower Motor Resistors and Kits for domestic and import applications.

High-Quality Components

Standard® Blower Motor Resistors use the highest-quality components that match the original for proper performance and ease of installation.

Blue Streak® Kits

Blue Streak® premium BMR Kits feature high-temp connectors that withstand excessive heat and prevent melting.

Standard® Has Blower Motor Resistors Covered

Coverage

Comprehensive Coverage

Standard® leads the industry in coverage with Blower Motor Resistors and complete Blower Motor Resistor Kits for domestic and import applications, including coverage for late-model applications.

- BMRs are powertrain-neutral, meaning that ICE, hybrid, electric, and fuel cell vehicles all feature HVAC systems with blowers that utilize them.

BMR Coverage 700+ Skus

Standard® offers more than 700 BMRs and Kits for domestic and import applications.

Market

Growing Market

Blower motor resistors are powertrain-neutral components, meaning that ICE, hybrid, electric, and fuel cell vehicles all feature HVAC systems with blowers that utilize resistors. In use since the 1960s, blower motor resistors are still used in every new vehicle built today, meaning this will remain an important category.

- By 1969, more than half of all American cars were outfitted with air conditioning.

Service Opportunities

Service Opportunities

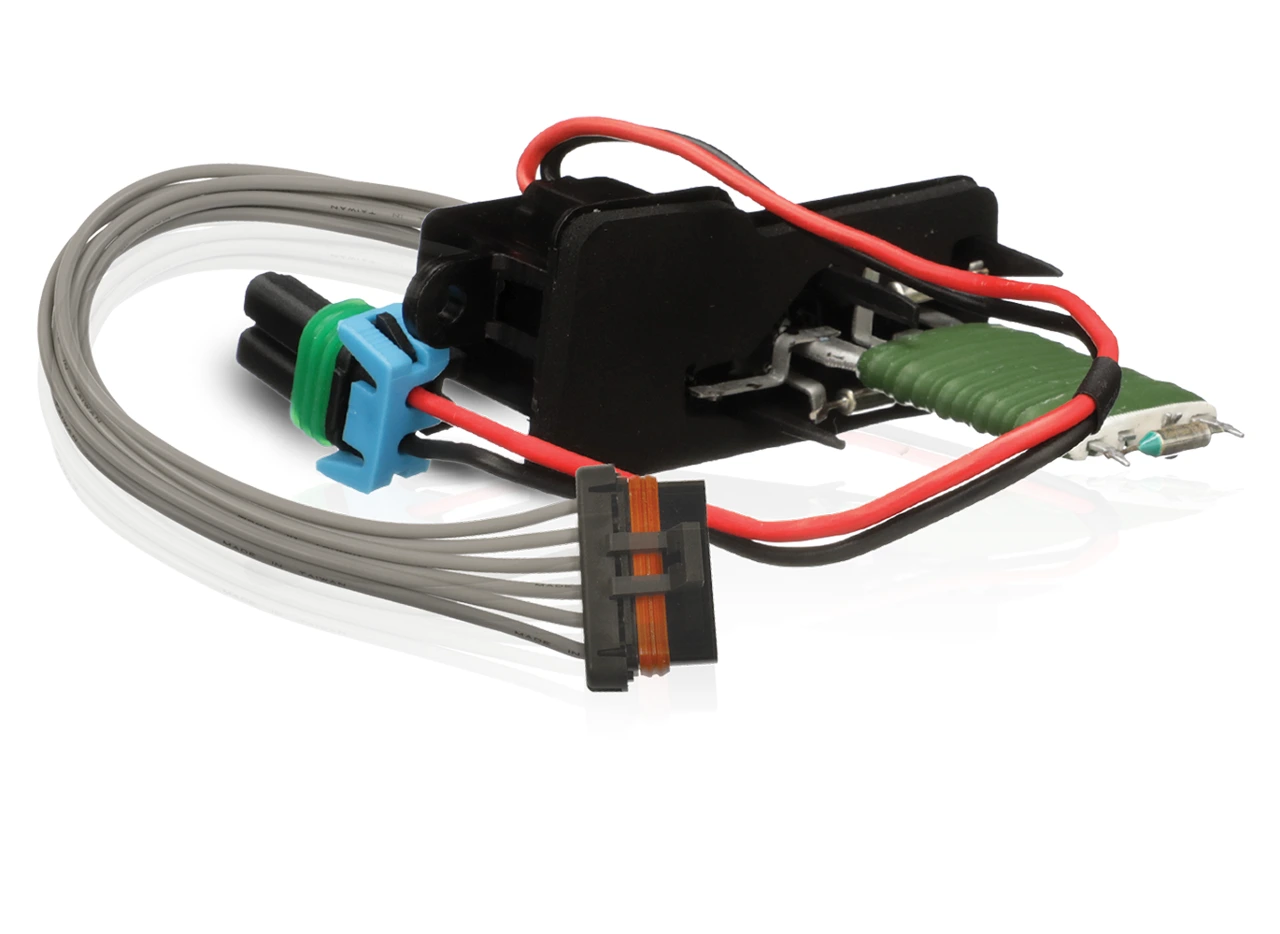

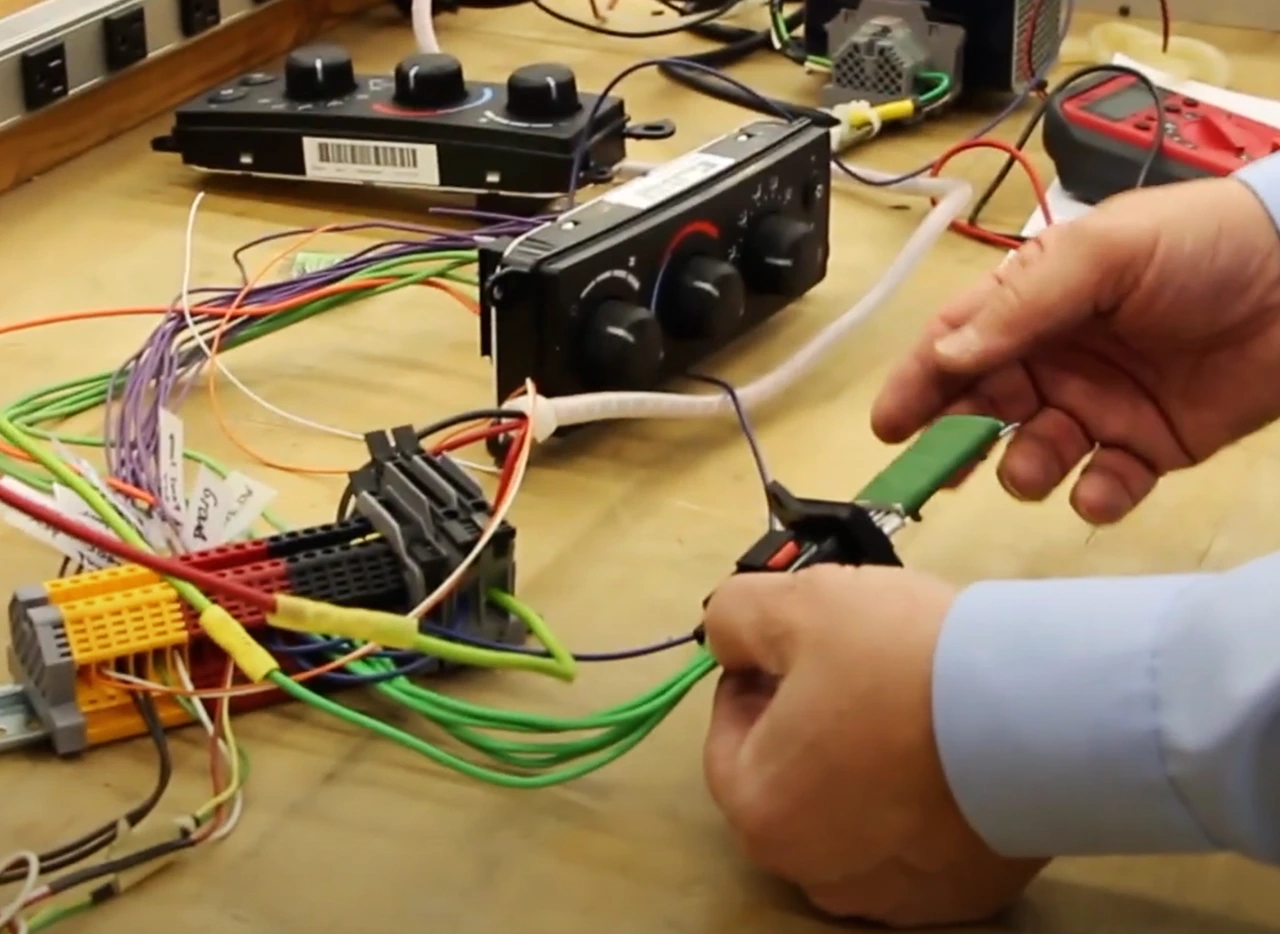

On most full-size GM trucks and SUVs from 2001 to 2007, the blower motor resistor encounters two common failures: water damage and excess heat. These designs are unable to manage condensation. Worn OE blower motors can create a demand for current that also damages the module. The excess current melts the wiring and plastic shroud, damaging the interface pins on the controller’s circuit board.

Blue Streak® Blower Motor Resistor Kits include a new high-temp connector with high heat tolerances and a resistor with an improved seal to keep moisture out. Combined, these two improvements create a longer-lasting and better-performing Blower Motor Resistor.

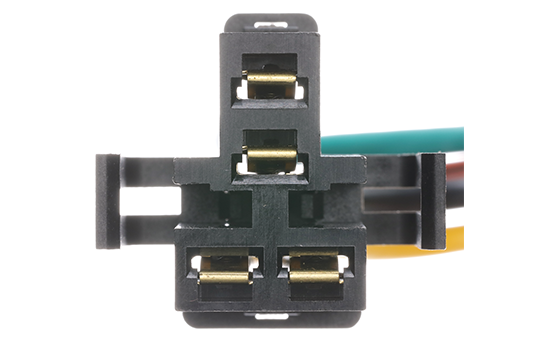

Current produces heat that can melt the OE connector.

Standard High-temp Blower Motor Resistor Connectors are designed to with withstand extreme temperatures to prevent melting.

Engineering & Design

Engineering

In addition to our full line of the highest-quality Standard® Blower Motor Resistors (BMR), we’ve engineered a line of Blue Streak® problem-solving high-temp connectors and kits. Each Blue Streak® BMR Kit includes an improved high-temperature connector for a longer service life.

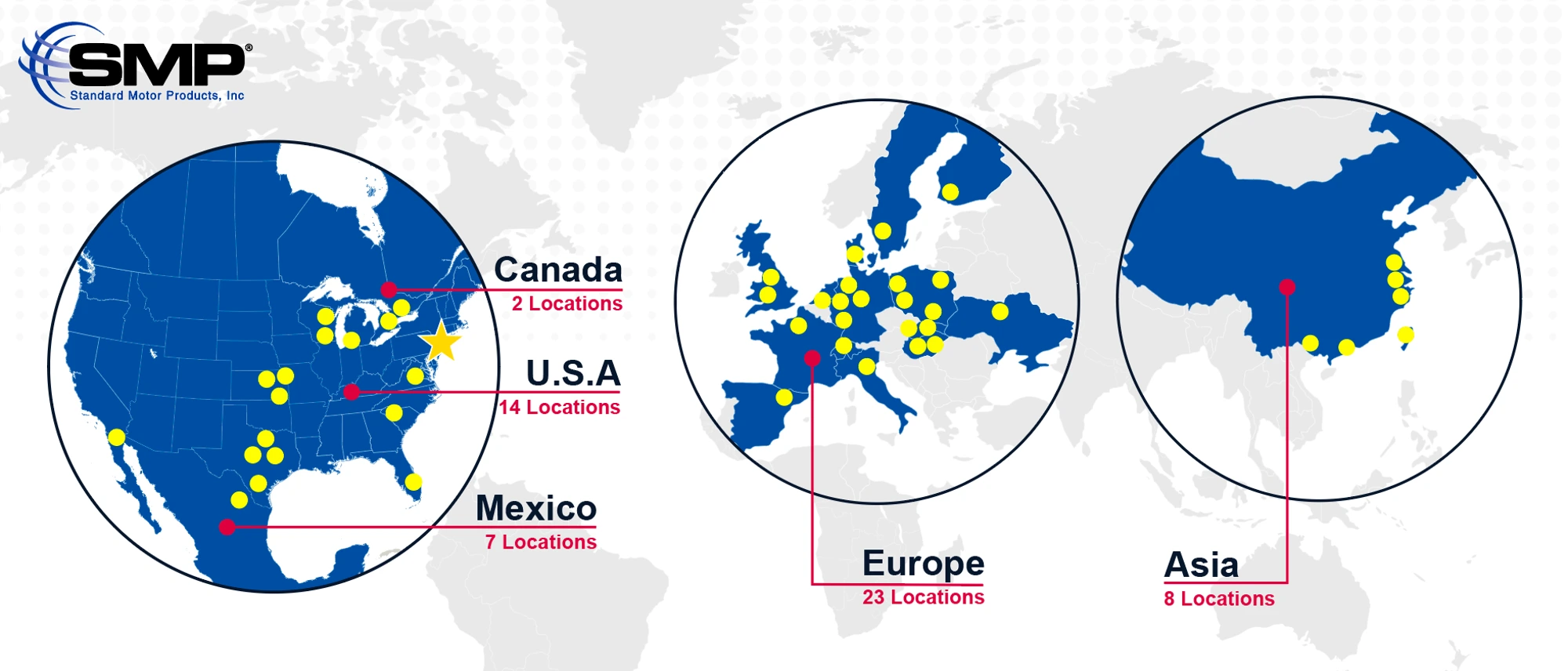

- Standard Motor Product facilities cover more than 3 million square feet in North America and all over the world.

Engineering BMRK

Blue Streak® Blower Motor ResistorKits include a new direct-fit replacement resistor and matching high-temp connector.

Manufacturing

Precision Manufacturing

Standard-manufactured Blower Motor Resistors and high-temp Blower Motor Resistor Kits are designed and built in our IAFT 16949-certified North American facilities.

- Blower motor resistors create a lot of heat due to the nature of the work that they do. That is why they are placed in a strategic location in the HVAC case, so airflow from the blower motor will help dissipate heat.

Testing & Validation

Testing & Validation

Our engineers sample-test every Blower Motor Resistor for draw, resistance, and RPM. Test samples are validated to precisely match the OE specs and meet or exceed the OE for durability. We examine performance at all speeds, and then conduct 48-hour load tests. It’s how we know our Blower Motor Resistors will operate at peak performance and deliver a long service life under all operating conditions.

- Blue Streak® Blower Motor Resistor Kits are covered by a limited lifetime warranty.

Blower Motor Resistors Categories

Technicians look to Standard® for the parts required to do the job right. From Blower Motor Resistors to complete Blower Motor Resistor Kits, Standard® has the parts needed to repair these systems correctly the first time.

Blower Motor Resistors

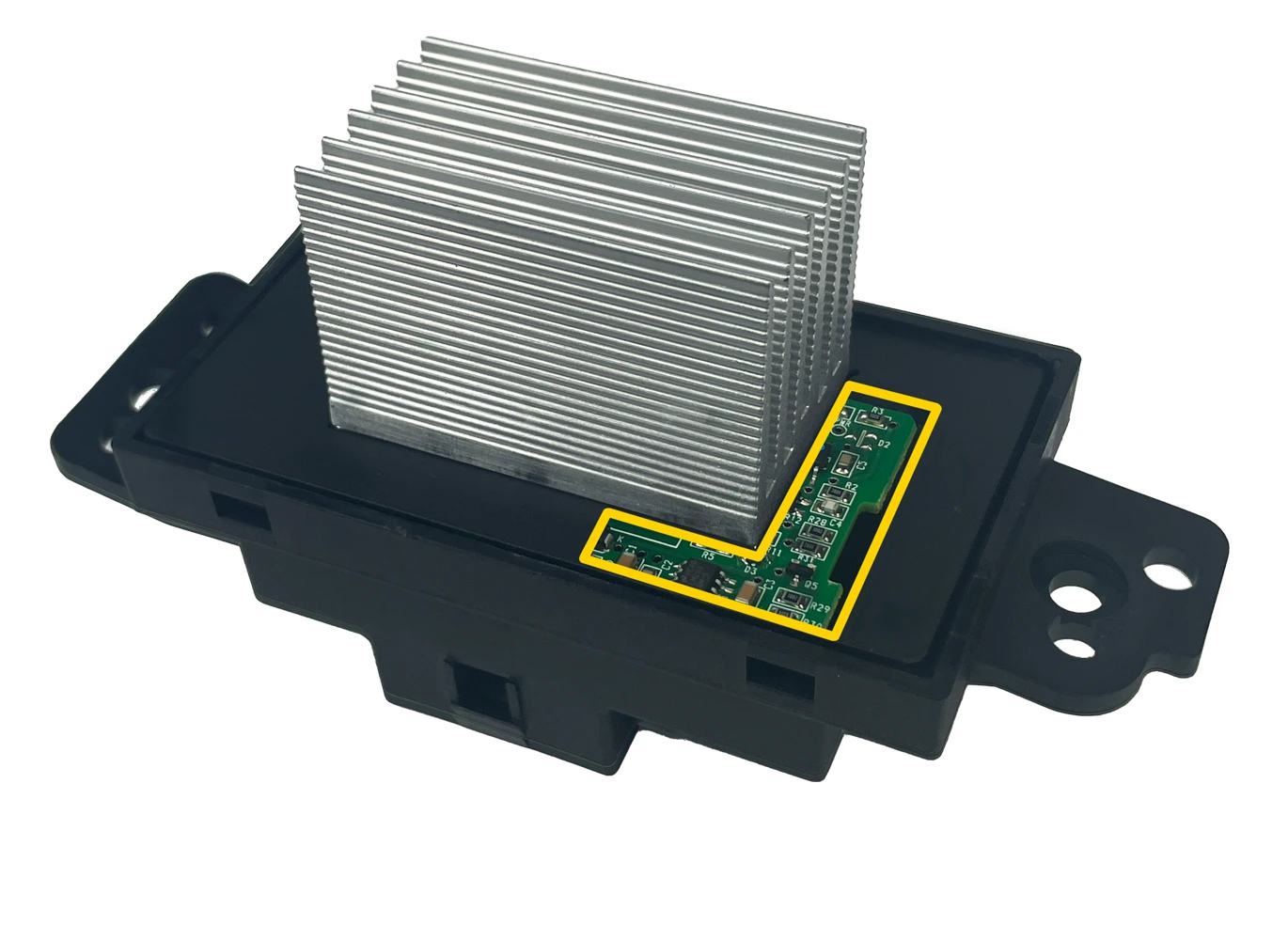

Features & Benefits

Features & Benefits

Blower motor resistors control the electrical current flowing from the fan switch to the blower fan, which allows the motorist to set the fan at different speeds. Standard® Blower Motor Resistors are built using the highest-quality materials available to ensure peak performance and reliability.

Improved Umbrella Cover Design

Prevents condensation from entering module

RTV Sealant

Around heat sink and cover perimeter prevents water intrusion

Upgraded 2 oz. Copper Board

Increases conductivity and power dissipation to prevent overheating

Manufactured in the USA

Larger Output Power Device

Mounted directly to heat sink improves heat dissipation

RU631 | GM Cars, Trucks, & SUVs (2009-00)

Videos

Blower Motor Resistor Videos

The StandardBrand YouTube Blower Motor Resistors (BMR) playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

Standard® and Blue Streak® BMR Overview

Blower Motor Resistor Replacement Tips

Successful Blower Motor & Resistor Diagnosis & Replacement | Pro Training PowerHour

Blower Motor Resistors

Blower Motor Resistor Kits

Features & Benefits

Features & Benefits

Blue Streak® Blower Motor Resistor Kits include a high-temp connector which withstands extreme temperatures to prevent melting and a direct-fit resistor to replace the damaged units, restoring A/C and heater blower motor variable speed control. These components are built in our IATF 16949 and ISO 9001-certified facilities to ensure that each part is designed to perform and last.

Precision Resistor Coils

For superior fan control

Kanthal D Resistor Wire

Provides longer life span for higher watt resistors

High-Quality Construction

High-quality ceramics made from copper electrical connectors ensure precise resistance values and tin-plated steel terminals guarantee maximum contact

Thermally Protected

With on-board fuse

High-temp Connector

Prevents melting under extreme temperatures

TXL Copper Wiring

Withstands high electric current to reduce heat-related failure

Tested and Proven

Undergoes thermal cycling to withstand temperatures ranging from -22°F to 257°F

RU51HTK | Chevrolet / GMC Trucks (2018-96)

Videos

Blower Motor Resistor Kit Videos

The StandardBrand YouTube Blower Motor Resistor Kit playlist features product and technical information, installation videos, training videos and more. With more than 650 videos (and growing), the StandardBrand YouTube channel has proven to be a valuable resource for technicians and parts professionals alike.

A Closer Look: Blue Streak® Blower Motor Resistor Kits

Standard® and Blue Streak® BMR Overview

Successful Blower Motor & Resistor Diagnosis & Replacement | Pro Training PowerHour

Blower Motor Resistor Kits

System Overview

System Overview

Blower Motor Resistors control the electrical current flowing from the fan switch to the blower fan, which allows the motorist to set the fan at different speeds. The fan speed can be changed either by switching the blower resistor resistance mechanically, using a rotating lever, or electronically by the air conditioning system.

Blower Motor Resistors

Blower Motor Resistor Program

Tech Tips & Impact on Vehicle Systems

As experienced ASE-certified automotive technicians themselves, Standard® Pro Trainers are experts in blower motor resistors. Here’s what they say to look out for during a BMR service.

Due to technological advancements on today’s automotive heating and cooling systems, blower motor resistors have high amounts of current running through their connectors. As a result, the current produces heat that can melt the connector and resistor.

Worn OE blower motors can create a demand for current that also damages the resistor or module. The excess current melts the wiring and plastic shroud, damaging the interface pins on the controller’s circuit board.

Be sure to inspect the mating connector for signs of damage caused by excessive heat. If damaged, replace with a high-temp replacement.

For repairs, use an inductive amp clamp to check that the blower motor current draw is less than 80% of the fuse rating on high. If the current is too high, replace the blower motor. Otherwise, the new resistor will fail too. You should also inspect the mating connector for signs of damage caused by excess heat.

Verify that the HVAC drain is free of debris and able to drain properly. As condensation builds up on the evaporator core, it needs to exit the HVAC box through the drain. If the drain is restricted, water will build up in the HVAC case and damage the blower motor resistor.

Ensure that there are no airflow restrictions in the HVAC case. A dirty cabin air filter or other debris like a mouse nest in the HVAC case will have an effect on the amount of current drawn by the blower motor, and damage the blower motor resistor.

Due to technological advancements on today’s automotive heating and cooling systems, blower motor resistors have high amounts of current running through their connectors. As a result, the current produces heat that can melt the connector and resistor.

Worn OE blower motors can create a demand for current that also damages the resistor or module. The excess current melts the wiring and plastic shroud, damaging the interface pins on the controller’s circuit board.

Be sure to inspect the mating connector for signs of damage caused by excessive heat. If damaged, replace with a high-temp replacement.

For repairs, use an inductive amp clamp to check that the blower motor current draw is less than 80% of the fuse rating on high. If the current is too high, replace the blower motor. Otherwise, the new resistor will fail too. You should also inspect the mating connector for signs of damage caused by excess heat.

Verify that the HVAC drain is free of debris and able to drain properly. As condensation builds up on the evaporator core, it needs to exit the HVAC box through the drain. If the drain is restricted, water will build up in the HVAC case and damage the blower motor resistor.

Ensure that there are no airflow restrictions in the HVAC case. A dirty cabin air filter or other debris like a mouse nest in the HVAC case will have an effect on the amount of current drawn by the blower motor, and damage the blower motor resistor.

Check Out Our Available Pro Training Classes

Training, Installation & Product Videos

Viewing video(s) 1-4 of 4

No results found