What’s in Your Box?™

From advanced engineering and expert manufacturing to on-vehicle testing and extensive customer support, Standard® gives technicians more than just a part in a box.

When choosing automotive replacement parts, always ask these questions:

- Whose part is actually in the box?

- Does the brand have its own manufacturing facilities?

- How are the parts tested?

Here’s what’s in our box.

The Finest Brands in the Industry

Blue Streak®

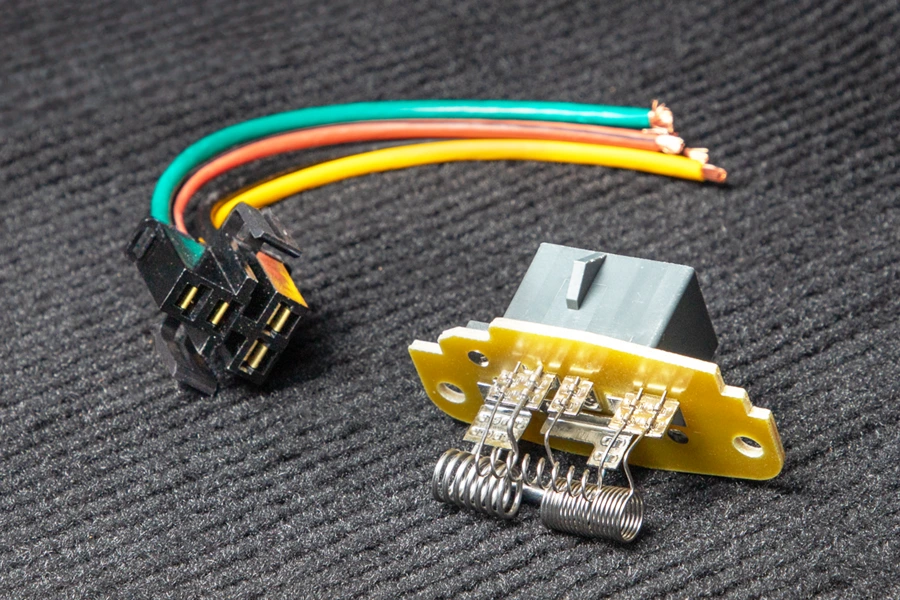

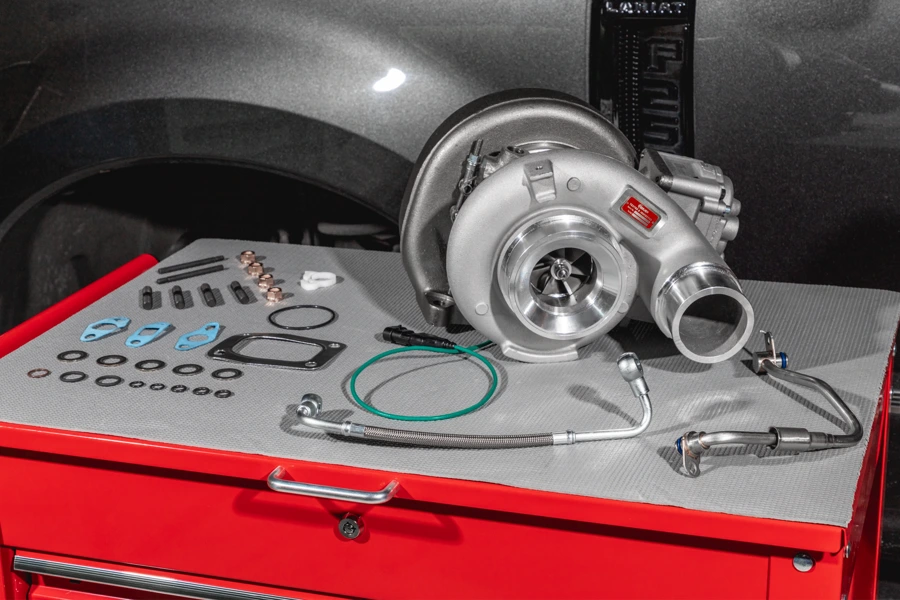

Blue Streak® is known for premium automotive quality, always giving technicians more. Engineered for superior performance and durability, Blue Streak® is the benchmark against which all other aftermarket brands are measured, delivering engineering improvements over the original design, and complete kits to make installation easier.

Standard®

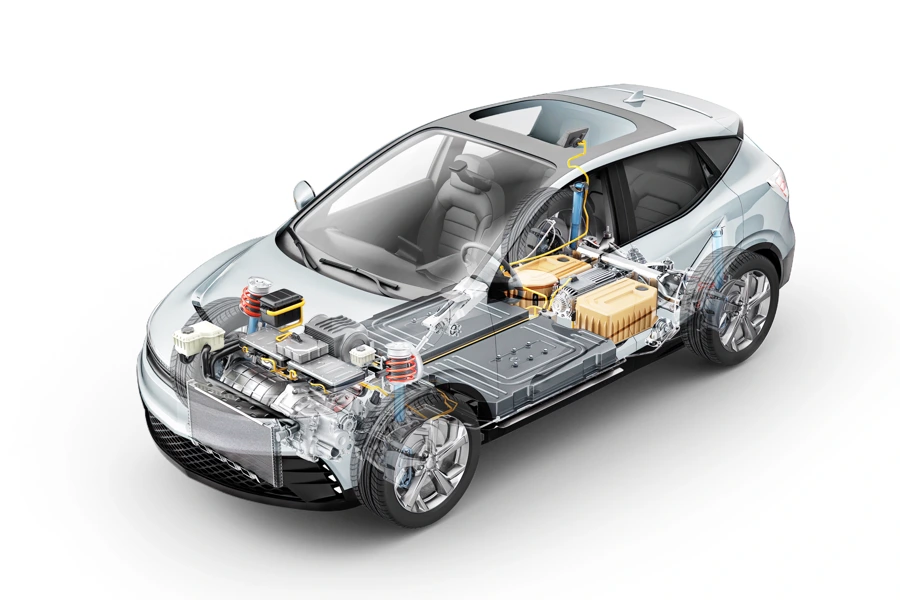

Standard® is the most recognized and awarded vehicle control and engine management brand in the industry, engineering, manufacturing and distributing more than 50,000 automotive replacement parts in some of the most advanced categories covering gasoline, diesel, hybrid, electric, and powertrain-neutral applications.

Digital Resources

Digital Product Portfolios, Product Brochures, New Item Spotlights and more, view our latest sales support materials.

2024 Best Problem-Solver Award presented by The Import Vehicle Community

Explore Standard® Products

A Commitment to Integrity

At the heart of every Standard® part is a set of core values that have been consistent from day one: expert manufacturing, extensive product testing, precise catalog data, award-winning training and support, and a time-tested ability to adapt to the latest automotive technologies.

Expert Manufacturing

Award Winning Training & Install Videos

Customer Care

World Class Catalog Data

There is more than just a part inside every Standard® and Blue Streak® box

Research & Development

Design Centers

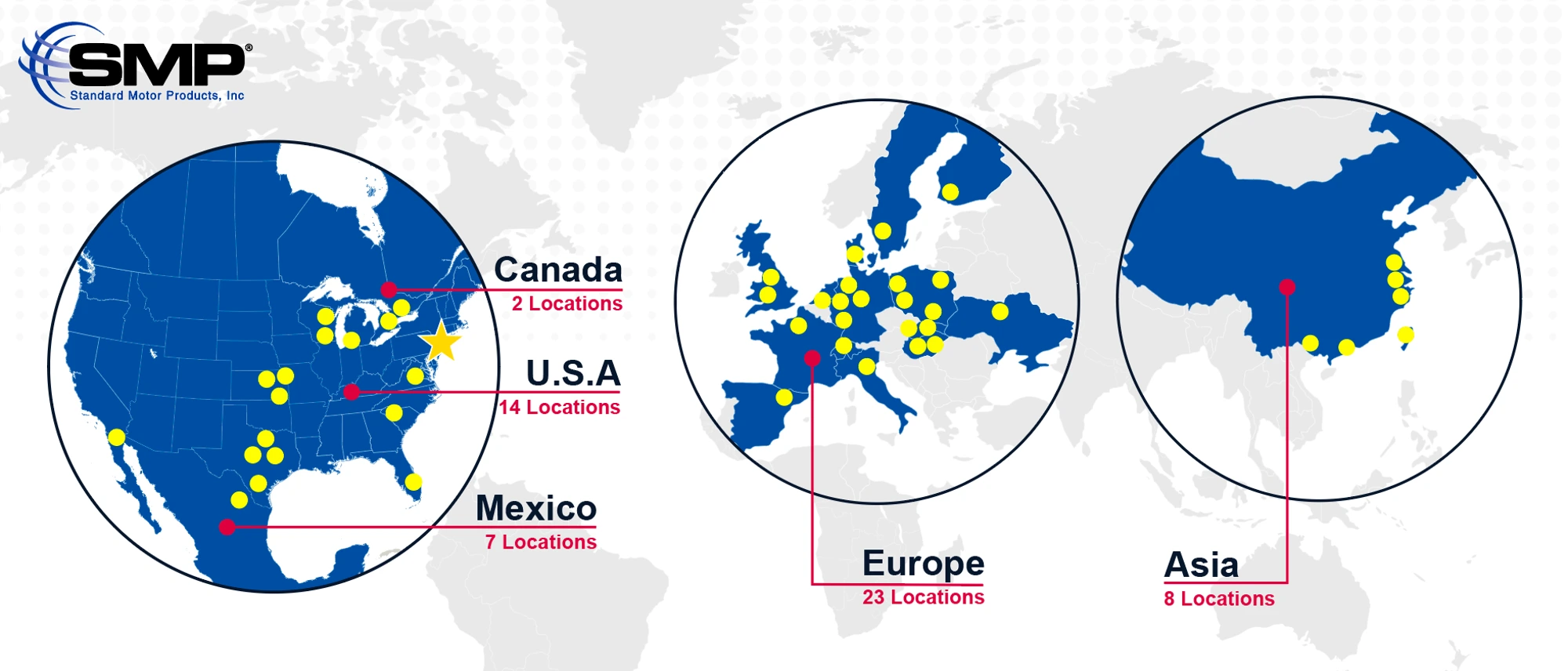

We have thirteen fully equipped design and development centers around the world, including multiple North American locations, and advanced facilities in Poland and Germany. This global footprint allows us to effectively engineer and deliver the best-performing automotive replacement parts.

Engineering Improvements

Our engineering teams continually evaluate the performance and durability of original equipment parts. When a weak point is identified, we engineer design improvements to give technicians more durable, longer-lasting components.

Long Island City, NY

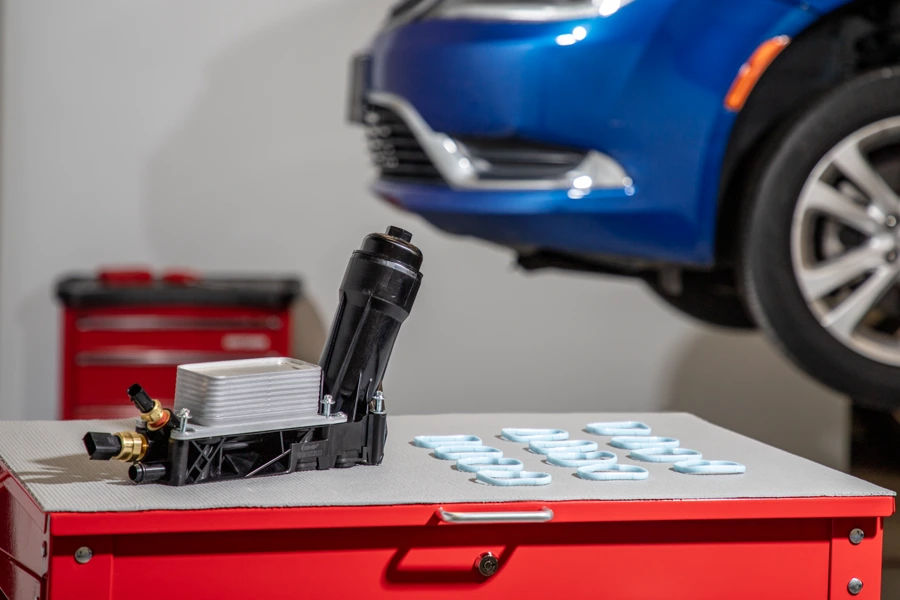

Our advanced center at SMP® headquarters in Long Island City designs and engineers a wide variety of vehicle control components including Sensors, Actuators, Electronic Throttle Bodies and Oil Filter Housings.

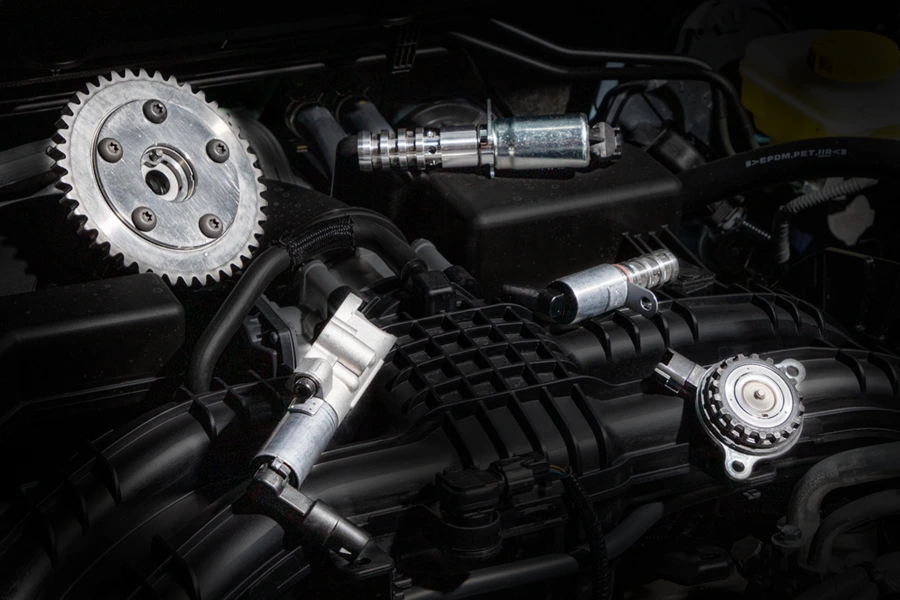

Precision Manufacturing

Expert Manufacturer

Standard® is an expert manufacturer, controlling the entire process from raw material to end-of-line testing. Our manufacturing facilities are IATF 16949, ISO 9001 and ISO 14001 certified.

Bialystok, Poland

Our advanced 145,000 square-foot facility in Poland manufactures the highest-quality aftermarket parts – VVT Solenoids, ABS Sensors, and Ignition Coils – as well as a broad range of vehicle control components including switches and sensors in the following categories: soot, speed and position, temperature, and pressure.

Greenville, South Carolina

Our 181,000 square-foot Greenville facility offers complete engineering and testing operations, along with vertically integrated manufacturing that develops and builds the industry’s finest gasoline and diesel fuel injectors and pumps, and a variety of emission control components.

Testing & Validation

In-Lab Testing

New Standard® and Blue Streak® parts are subjected to precision examination, product validation, and environmental analysis. Testing includes thermal shock, vibration, salt spray, extreme temperature chamber testing and more, to ensure that each component will perform under the harshest conditions.

On-Vehicle Validation

To ensure that every Standard® component correctly integrates within the complex electronic systems on today’s vehicles, our extensive quality control process is supported by live on-vehicle testing at the Standard® Vehicle Testing Center in Texas.

End-of-Line Testing

Before a part can be placed in the Standard® box, it must pass a strict and comprehensive end-of-line test. For example, all Standard® Cam and Crank Position Sensors are tested for timing, pulse-width and signal amplitude.

Sales Support

Sales Support & Customer Insights

We strongly believe in providing industry professionals with the tools they need to be successful. Our experienced field sales team collaborates with an expanded category management group to provide world-class sales support. The Standard® Field Category Management Team was a recent winner of the MEMA Aftermarket Channel Excellence Award.

Marketing & Data Support

We regularly produce new marketing pieces for distributors, technicians and parts professionals. These include product information, technical features, and new item spotlights. The Standard® eCatalog and SMP® Parts App deliver the most current catalog data with robust, rich content – 360° and multi-view images, installation videos, instruction sheets, part specs and more.

Technician Training

Standard® Training educates technicians in the latest automotive repair technologies with in-person, live-virtual, and on-demand online classes. Each year, our professional trainers, who are also experienced ASE-certified automotive technicians themselves, train more than 60,000 technicians.