September 19, 2022 / Training

A Closer Look: Turbocharger Operation and Installation

Turbocharger Overview

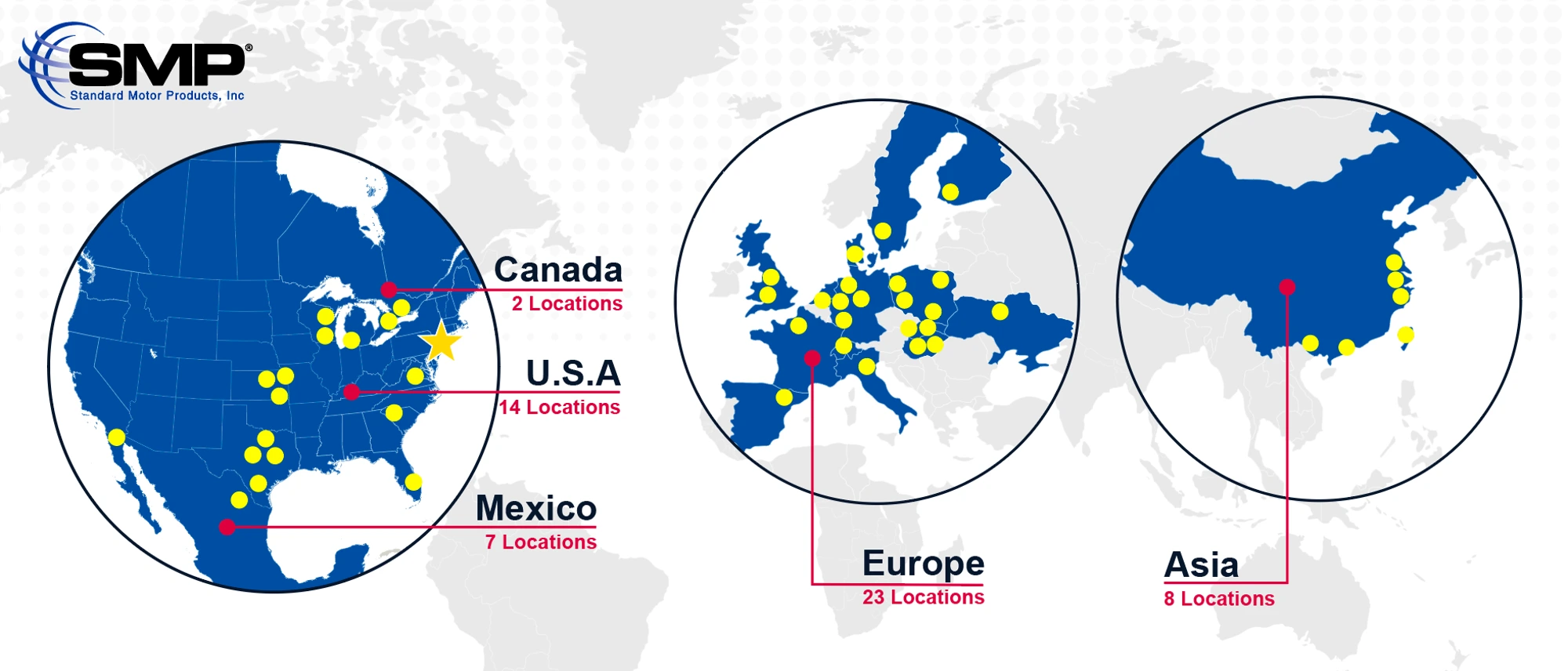

With an effort to increase fuel efficiency, maintain performance and reduce emissions, vehicle manufacturers are adding turbocharged engines to their lineups at a significant rate. Over the next five years, the turbo service market will continue to experience substantial growth.

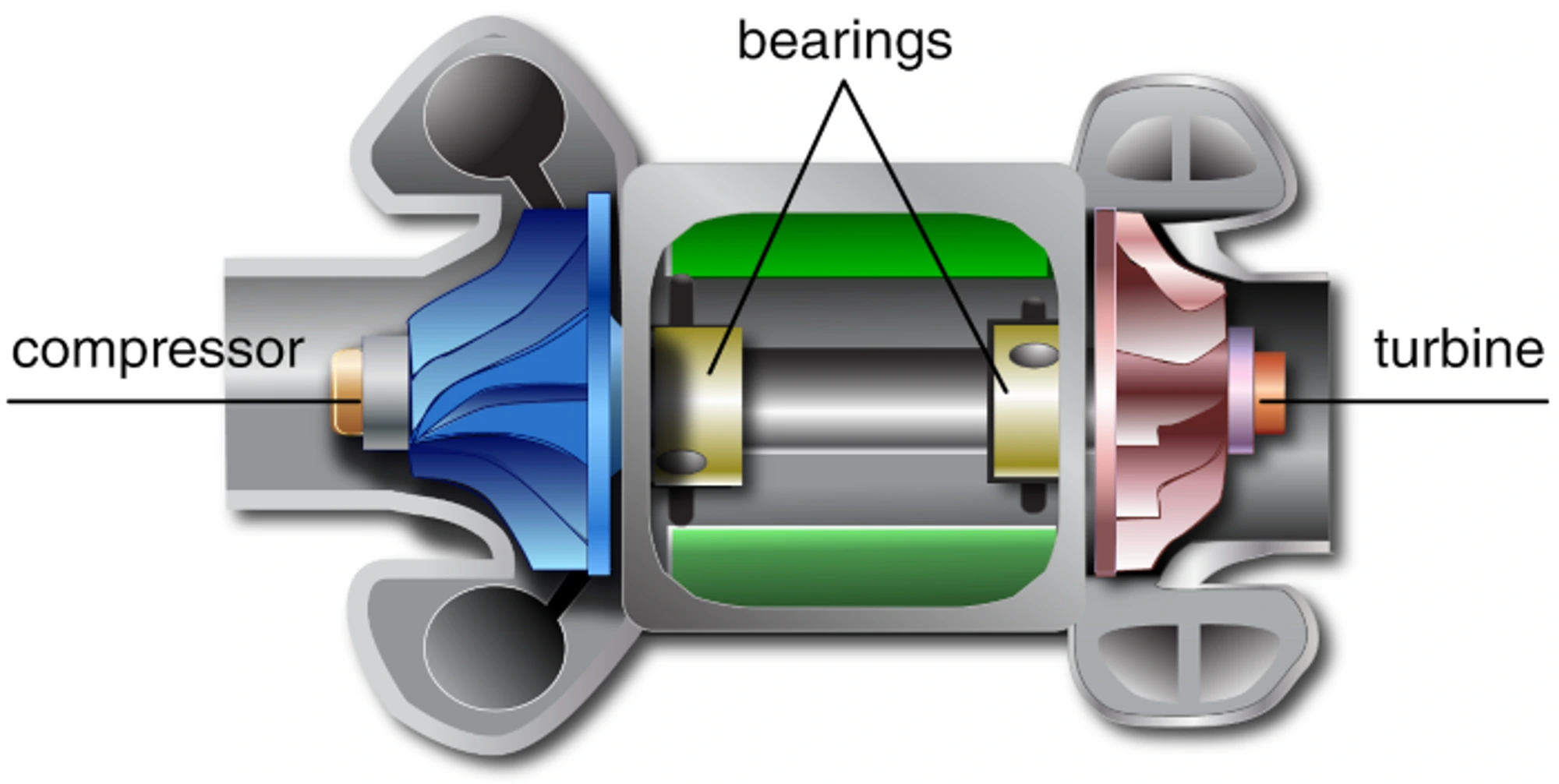

At a basic level, a turbocharger consists of just three major internal components: the turbine, the compressor and the bearing system that supports the turbine shaft. The compressor wheel, turbine wheel and shaft make up the Center Housing Rotating Assembly (CHRA), which is mounted inside of the turbocharger housing.

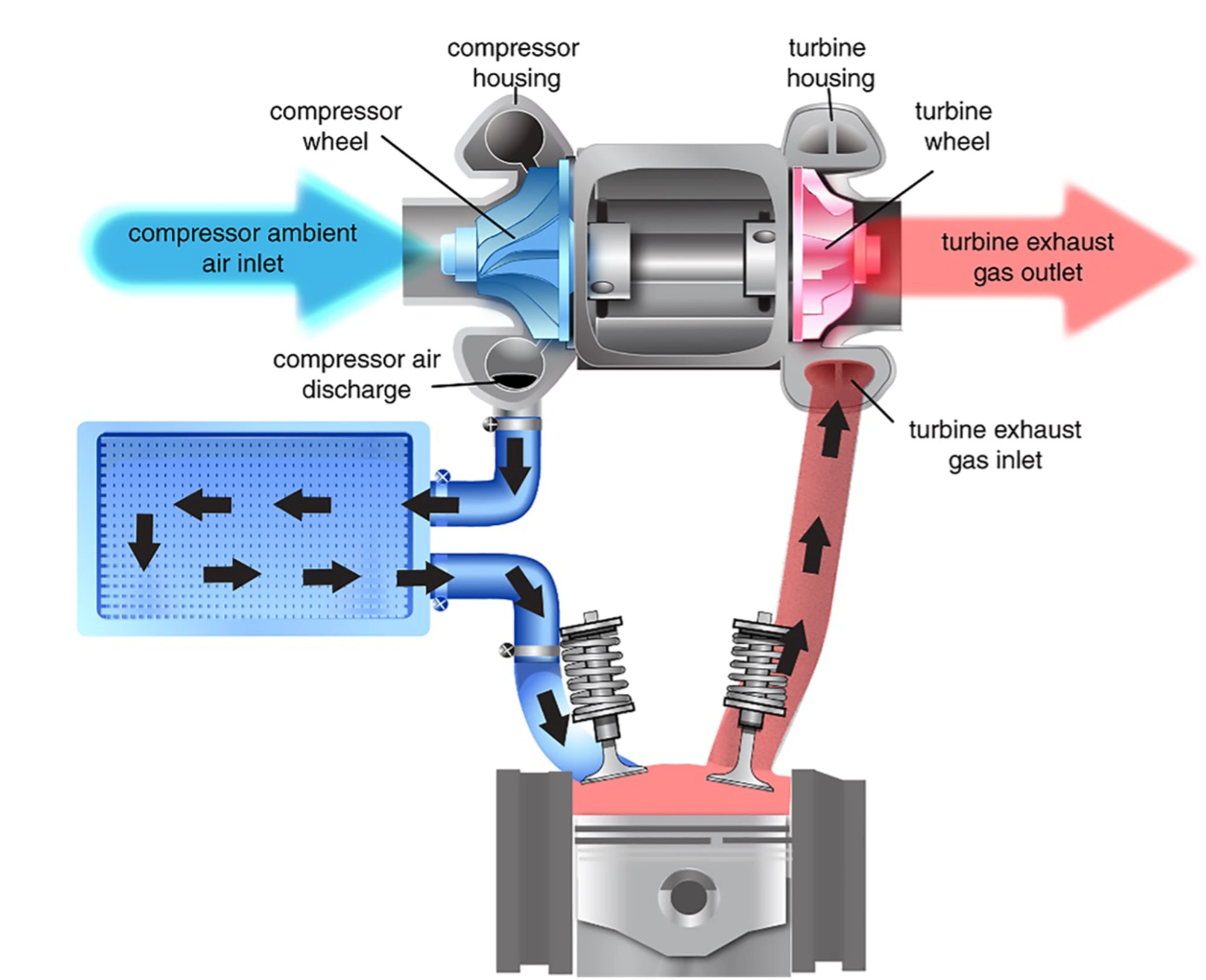

The turbocharger system converts exhaust gases into centrifugal force by flowing the exhaust through the turbine housing, forcing the turbine wheel into motion. As the turbine wheel spins, the compressor wheel on the opposite end of the common shaft draws fresh air into the turbocharger, where it is compressed and forced into the intake system. As the intake air is compressed, it builds heat that must be cooled. So the air flows through the intercooler before entering the combustion chamber. The result is significantly more air entering the combustion chamber. More fuel can be added, resulting in better efficiency and more power.

What Causes a Turbocharger to Malfunction?

Symptoms of a malfunctioning turbocharger include loss of power, excess smoke, high fuel consumption, overheating, increased exhaust temperature and oil leaks from the turbo. It’s important to note that defects in other components can produce the same symptoms. Before mistakenly attributing any of these issues to the turbocharger, remember that turbo performance can be impaired by mechanical damage or blockage caused by debris, or a leak in the turbo ductwork.

If whistling noises (other than normal turbo spooling) are heard coming from under the hood, it’s likely due to boost leaks. The first step is to check all of the joints in the turbo ductwork. Additional attention should be paid to the seams of the intercooler. If the noise persists, check the turbocharger clearances and wheels for housing contact.

If the turbocharger rotor assembly has seized up or is difficult to rotate, the problem is likely tied to the degradation of the oil. When the oil degrades, it can lead to carbon buildup in the bearing housing interior and can cause the rotor to seize. A turbocharger has specific axial and radial rotor clearances and sometimes, the clearances can be misdiagnosed as worn bearings. Clearances that are out of specification may be associated with a lubricating oil issue. When the turbo is replaced, the technician should always check for insufficient oil, dirt ingress and oil contamination with coolant.

To determine if the turbo has been damaged by foreign material, inspect the turbine wheel or impeller. If so, there will be clear evidence of foreign material that has entered through the turbine or compressor housings. If the blades are damaged, the turbo needs to be replaced. The technician should inspect for metal that has come off the turbo in the intake tubes. Metal particles in this area may indicate a damaged engine.

Common Trouble Codes

Two typical diagnostic trouble codes for turbos include P0299 (underboost) and P0234 (overboost). If you’re receiving an underboost code, the issue could be a wastegate that’s stuck in the open position or a leak between the compressor and throttle. Causes of overboost, on the other hand, include a wastegate that’s stuck in the closed position, a wastegate vent solenoid that’s stuck in the vent position, or leaking or disconnected control hoses.

Choose the Right Replacement Turbo

If the determination has been made that the turbo is faulty, there are a few things to keep in mind when installing a replacement turbo. First, ensure that the air ductwork is sealed and perfectly clean. Next, confirm there is proper lubrication and cooling at the turbo. The new turbo should have fresh engine oil bled through it before starting the engine. Finally, make certain that a new, quality air filter is installed on the vehicle, along with an oil change and replacement of any applicable breathers.

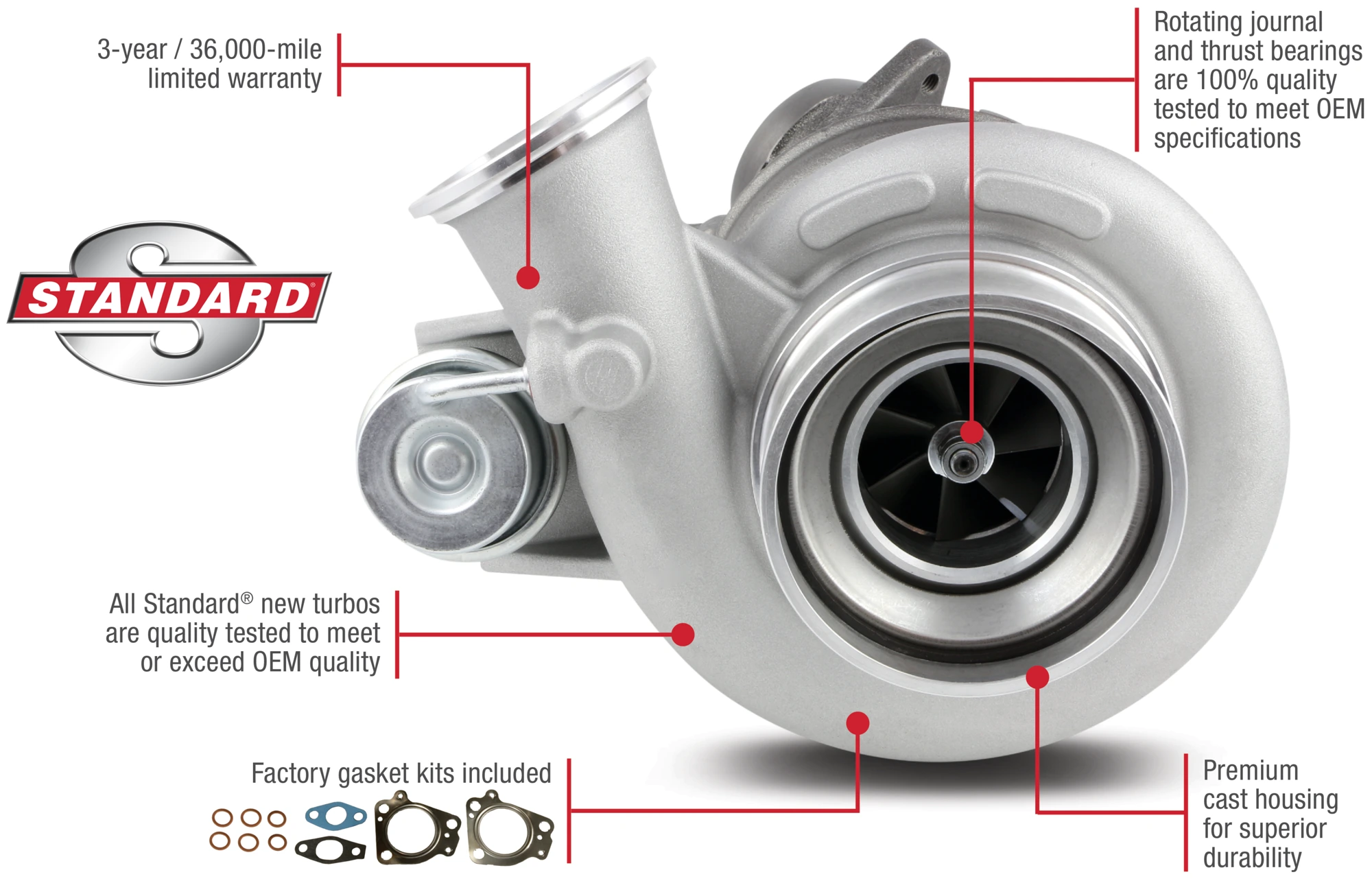

When selecting a replacement turbocharger, remember that quality matters. Standard® offers a complete line of 100% ALL-NEW (not remanufactured) premium turbochargers. This new, No-Core line provides coverage for gas and diesel, domestic and import applications.

Premium Replacements for a Growing Category

Standard® turbochargers are engineered to ensure each performs with precision for the application it is replacing. All Standard® turbos undergo a full spectrum of quality testing including burst test validation, on-vehicle performance and 100% end-of-line testing through the full RPM range.

As a quality-plus offering, Standard® new turbo units include factory gasket kits, a 3-year/36,000-mile limited warranty and carry no core charge – that means no core collection, no core inspection and no core returns. The Standard® line also includes an array of related components – turbo actuators, turbo oil drain tubes, wastegate solenoids, turbo boost, turbo speed sensors and more.

For more information on diagnosing and replacing Turbochargers and their components, visit the StandardBrand YouTube channel.

Previous News

September 16, 2022 / Training

A Closer Look: Tire Pressure Monitoring Systems (TPMS) Operation

March 01, 2024 / Training

Why Pentastar Oil Filter Housings Fail

In service since 2011, the Chrysler Pentastar 3.6L engine has powered more than 10 million of the most popular vehicles on the road. These Pentastar engines are equipped with oil filter housings, which contain the oil filter, sensors, and a heat exchanger to help cool the oil. The oil filter housings on the Pentastar V6 engine have become known for their high failure rates. These failures have mistakenly been attributed the idea that the housings can warp due to heat, but this has been proven false. So, why do these units typically leak?

August 15, 2022 / Training

Variable Valve Timing (VVT) Repair Tips

Variable Valve Timing (VVT) or Variable Cam Timing (VCT) is common on most newer engines. These systems are designed to reduce emissions and maximize engine performance and fuel economy. Here's some background on VVT and a few tips for dealing with issues that come up.

August 22, 2022 / Training

Variable Valve Timing (VVT) Operation

Variable Valve Timing (VVT) systems help reduce emissions and maximize engine performance and fuel economy. The VVT Solenoid (Oil Control Valve) meters the oil flow to control the actuation of the VVT Sprocket (Actuator or Phaser). The VVT Sprocket mechanically shifts the position of the camshaft. Here are a few tips for testing.

August 08, 2022 / Training

Turbocharger Diagnosis Tips

Turbocharged engines are becoming more popular, as vehicle manufacturers look to increase fuel efficiency, maintain performance and reduce emissions. Symptoms of a malfunctioning turbocharger include loss of power, excess smoke, high fuel consumption, overheating, high exhaust temperature and oil leaks from the turbo. Here are a few important diagnostic and repair tips to keep in mind.

August 12, 2022 / Training

Tire Pressure Monitoring System (TPMS) Repair Tips

The Tire Pressure Monitoring System (TPMS) is a safety device that measures, identifies and warns you when one or more of your tires is significantly under-inflated. Standard® and Intermotor® are committed to helping technicians with TPMS repairs, whether it’s offering OE-Match TPMS sensors or providing repair tips from our team of ASE-certified master technicians. Here are a few TPMS repair tips.

August 05, 2022 / Training

Mass Air Flow (MAF) Sensor FAQs

The Mass Air Flow (MAF) sensor is a key component of the engine’s fueling strategy. It is crucial that the MAF sensor reports with 100% accuracy to ensure peak performance, fuel economy and reduced emissions. Here are some helpful tips such as how and when to replace them and steps to extend their longevity.

August 19, 2022 / Training

Ignition Coil Operation

Coil-on-plug assemblies are designed to convert a low voltage (primary side) to a high voltage (secondary side) to fire the spark plugs. They perform the functions of both the ignition coil, which creates the spark energy, and the spark plug wire set, which delivers the high-voltage energy to the spark plug. Today's coil-on-plug assemblies come in a variety of physical and wiring configurations.

August 01, 2022 / Training

Diesel Engine Repair Tips

Diesel Engines have become more popular thanks to a steady string of advancements. New engine designs, noise and vibration-damping technologies, and improvements like electronic engine control have spawned a new generation of engines that are more powerful and fuel efficient than similar-size gasoline engines. Learn more about today's diesel engines with these repair tips from our team of ASE-certified master technicians.

January 05, 2024 / Training

A Closer Look: Turbochargers

Turbocharger Opportunities: In an effort to increase fuel efficiency, maintain performance, and reduce emissions, vehicle manufacturers are adding turbocharged engines to their lineups at a significant rate. Over the next five years, the turbo service market will continue to experience substantial growth.

January 15, 2024 / Training

A Closer Look: Servicing Electric and Hybrid Vehicles

Hybrid vehicles have been sold in the U.S. for over 20 years. As hybrids continue to grow in popularity, and as fully electric vehicles have entered the market in the past several years, they have brought with them numerous service opportunities for aftermarket repair facilities. Whether shops dive in and get involved with replacing batteries, inverters, or other high-voltage components, or they stick to light-duty servicing, there is plenty of work to go around.

January 08, 2024 / Training

A Closer Look: Ignition Coils

Engine misfires, rough idle, a decrease in power under acceleration, poor fuel economy, and a check engine light are all signs of an ignition coil that has failed. OE coils are known for their high failure rates. Read along for more information on ignition coils, how to diagnose a failed one, and why an original equipment manufacturer’s coil may not be the best replacement choice.

January 12, 2024 / Training

A Closer Look: Gasoline Direct Injection (GDI)

Gasoline direct injection (GDI) is used on most new vehicles and requires a different approach to diagnosis and service. GDI technology has been an integral part of helping to improve fuel economy while reducing emissions and can be found in more than half of the U.S. fleet. In fact, the use of GDI engines has grown by over 600% since 2010. This means that in the next five years, 42 million more vehicles with GDI will enter the Aftermarket “Sweet Spot” of 6-12 years old, during which their injectors and related parts may need to be serviced or replaced. While GDI systems have proved effective, these systems encounter specific failures and require an understanding of how they work and how to test them when they set a code.

January 26, 2024 / Training

A Closer Look: Emissions

The Check Engine Light (CEL) is arguably one of the most effective yet underappreciated advancements in reducing vehicle emissions. Following the introduction of On-Board Diagnostics II (OBD II), the CEL is illuminated continuously if an on-board system monitor has failed a specified number of times and is negatively affecting emissions. If a catalyst-damaging event, such as a misfire, occurs, the CEL will flash. In today’s world of electric vehicles, hybrids, and partial zero-emission vehicles, many people forget that simply keeping their internal combustion engine (ICE)-powered vehicle operating as designed will help in reducing emissions.

September 12, 2022 / Training

A Closer Look: Electronic Throttle Bodies and Control Systems

Electronic Throttle Control (ETC) systems are responsible for improving fuel economy, reducing emissions, protecting powertrain components and providing an overall better driving experience. Most vehicles on the road today use ETC. It is important for technicians to understand the principles of the system before delving into system specifics.

January 29, 2024 / Training

A Closer Look: Electronic Throttle Bodies

A shop’s reputation is affected by things like accuracy of diagnosis, quality of the repair, and friendly service. Equally as important is the quality of the parts installed. If the shop does everything right, and the part fails, the customer will ultimately be upset with the shop. When a new part fails, the customer is inconvenienced again, and begins to lose faith with the shop that performed the work. This ultimately begs the question–why take a chance with inferior parts?

September 09, 2022 / Training

A Closer Look: Blower Motor Resistor Operation

Blower Motor Resistors (BMR) control the electrical current flowing from the fan switch to the blower fan, which allows the motorist to set the fan at different speeds. The fan speed can be changed by switching the blower resistor resistance mechanically, using a rotating lever, or electronically, by the air conditioning system.

September 05, 2022 / Training

A Closer Look: Anti-Lock Braking (ABS) System Operation

The Anti-Lock Braking System (ABS) is concerned with monitoring and controlling wheel slip, which helps maintain vehicle control. The major components of every ABS system are: wheel speed sensors, brake switch, brake master cylinder, EBCM and hydraulic assembly containing the pump motor, accumulator, valves and solenoids.

January 19, 2024 / Training

A Closer Look: Advanced Driver Assist Systems (ADAS)

Advanced Driver Assist Systems have created quite a buzz over the last several years. New business opportunities continuously arise, including a new segment of mobile technicians focusing on ADAS calibrations. While ADAS may still seem relatively new, automotive service professionals have actually been servicing Driver Assist Systems for decades. Systems like power steering, power brakes, and cruise control have been assisting motorists for many years. What is different with ADAS is that there are now input devices to understand what the driver’s intent is and alert the driver to potential dangers, rather than relying solely on the driver’s sight and sound.

January 22, 2024 / Training

A Closer Look: ABS Sensors

Anti-lock Braking Systems are intended to do exactly as the name portrays – prevent a vehicle’s wheels from locking up during a braking event. If any of the wheels lock up, the driver has less control of the vehicle and is more prone to an accident. By releasing some brake pressure to the locked-up wheel, the stopping distance will be increased, but the driver will be able to maintain control to hopefully avoid a collision. Prior to ABS, drivers were taught to pump the brake pedal when attempting to stop suddenly, or when stopping on gravel, ice, or loose pavement. Now, the ABS system does that for them.