September 16, 2022 / Training

A Closer Look: Tire Pressure Monitoring Systems (TPMS) Operation

TPMS System Overview: A Closer Look at this Important Safety System

Tire Pressure Monitoring Systems have been mandated for over 14 years but have been on vehicles for much longer. Yet they still seem to spark a love/hate relationship. Some motorists and techs find them a nuisance, while others recognize a valid safety device and prime service opportunity. TPMS brought a lot of new terminology – initiate, program, activate, clone, protocol and relearn. There have even been mixed messages sent from the industry. Ultimately, this is a safety system that warns drivers of issues with their tires and protects motorists from potential danger.

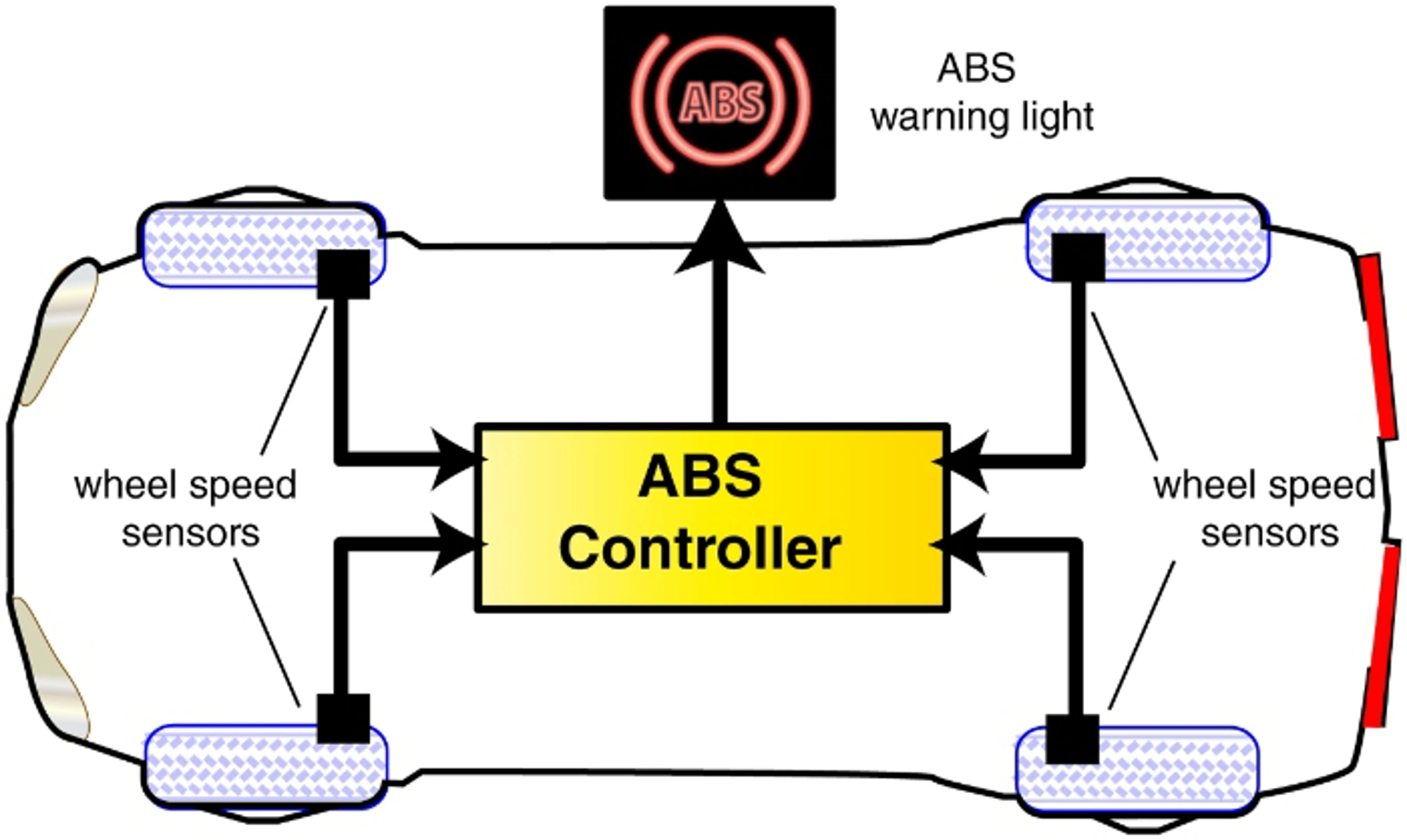

Indirect TPMS

Indirect systems rely on the ABS Brake system to monitor and compare wheel speeds to make sure they are all rotating in the same speed range. When a tire begins to lose air, it becomes smaller in diameter, which causes it to rotate faster than the others. The ABS speed sensor on the low tire’s wheel reports a frequency signal that increases when compared to the other tires – this activates a TPMS warning light. Rolling circumference of a tire may change due to:

- Insufficient tire pressure

- Structural damage on tires

- The vehicle is loaded heavily on one side

- One axle is heavily loaded (i.e. when pulling a trailer)

- When snow chains are used

- When a spare tire is installed

This TPMS system can detect under-inflation in up to three tires simultaneously but not all four. Since the indirect system compares wheel speeds, if all four tires lose the same amount of air the relative change will be zero.

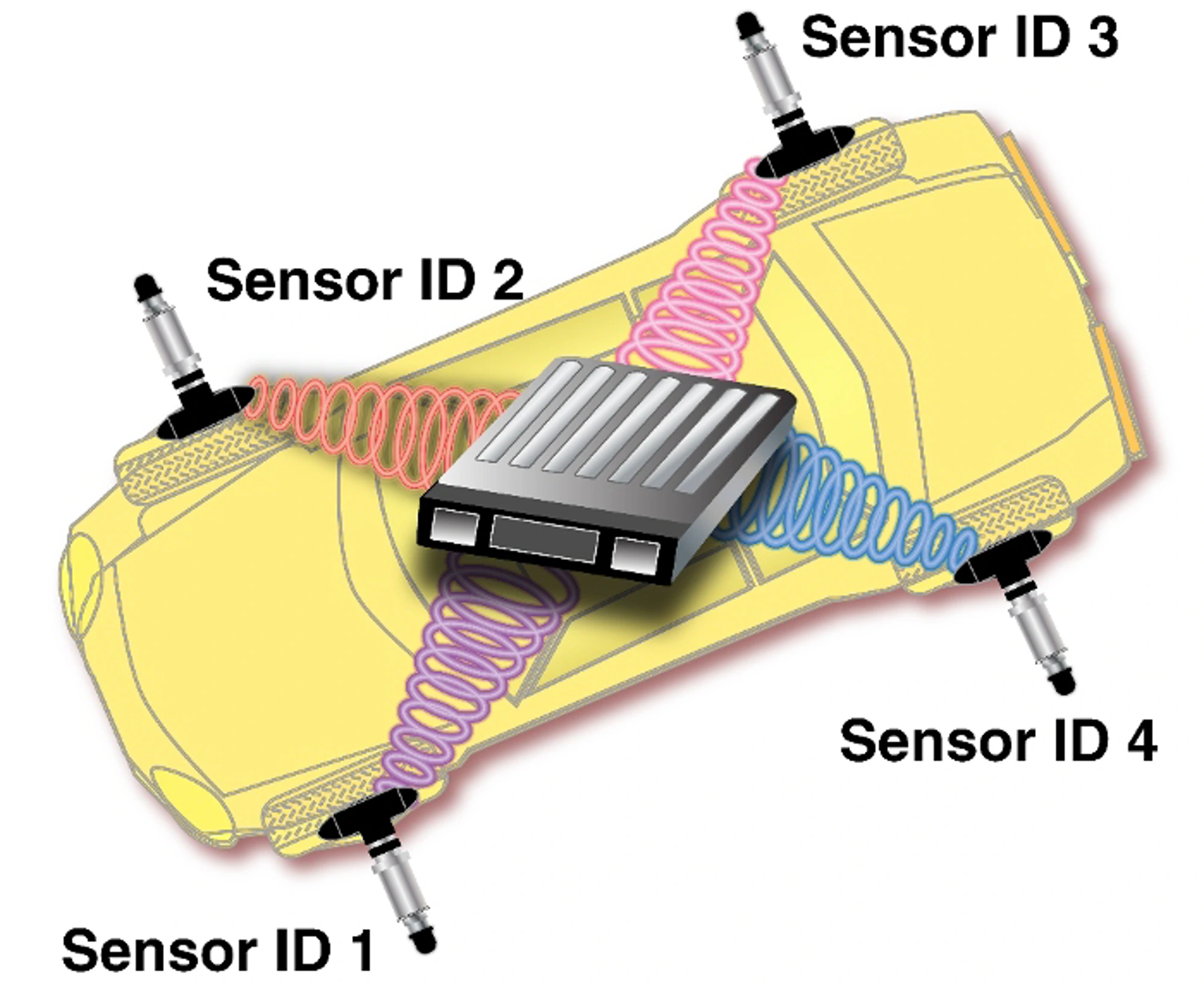

Direct TPMS

Direct TPMS systems consist of a control module (often it’s the same module as the Remote Control Door Lock Receiver, since they talk on the same frequency) and 4 or 5 sensors (one in each wheel, and sometimes the spare). The TPMS module receives real time data inputs from the sensors which transmit:

- Pressure

- Temperature

- Identification

- Accelerometer

The TPMS module then determines if the signal is below the manufacturer’s specified placard pressure threshold. If below the minimum, the module sends a request to the instrument cluster to illuminate the warning light. There are two main types of direct tire pressure monitoring systems – 'high line' and 'low line.’ High line systems will communicate specific information to the driver, and low line systems will communicate a generic message indicating that there is an issue.

TPMS Technology – Auto-Relearn

How Auto-Relearn Technology Works

Auto-Relearn automatically identifies each TPMS sensor, determines its position on the vehicle, and wirelessly transmits the information to the receiver for display on the dash – all without human intervention. For a better understanding, here are two popular Auto-Relearn technologies.

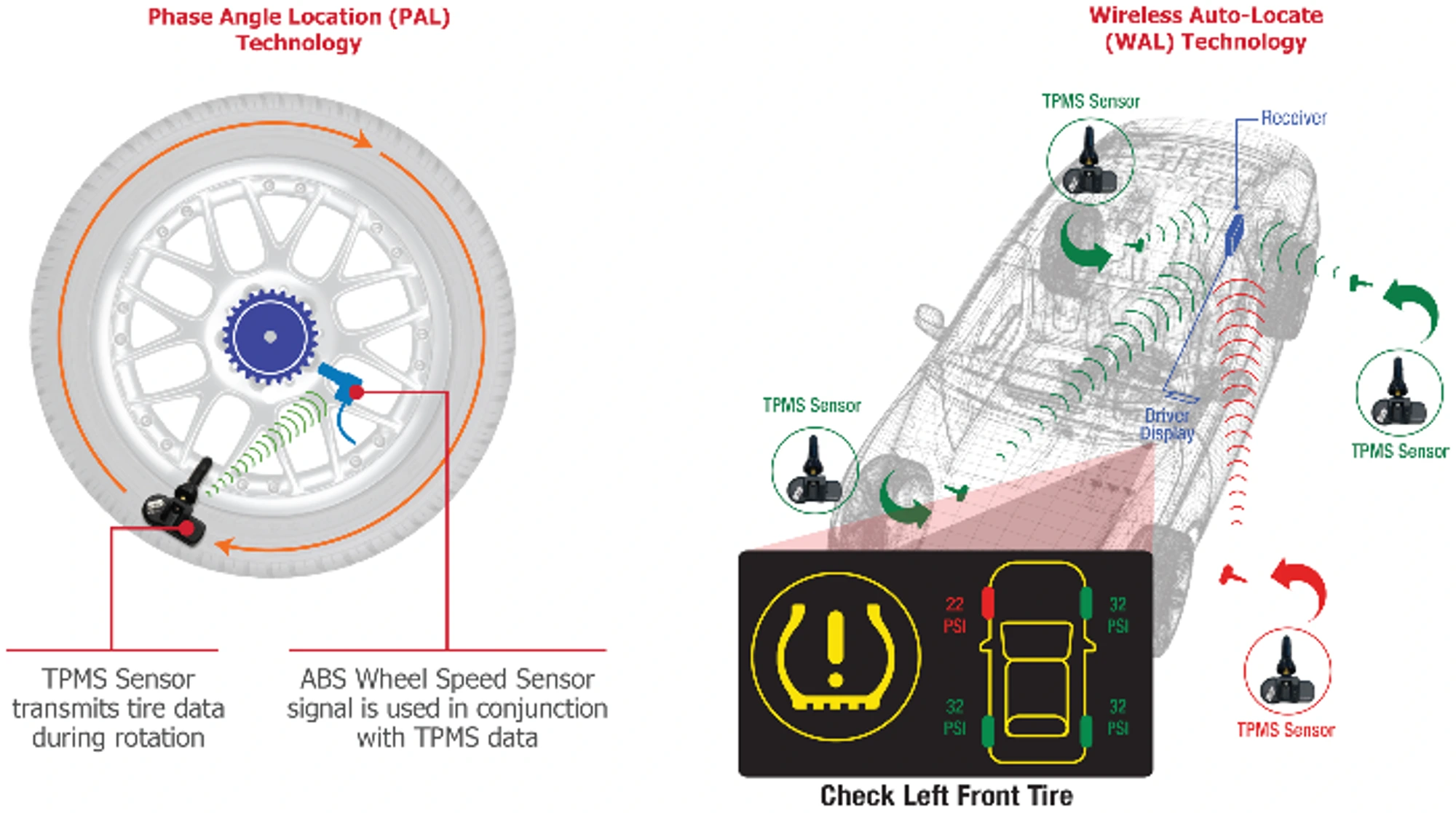

Phase Angle Location (PAL) Technology

Phase Angle Location uses ABS data along with TPMS sensor data to transmit tire pressure, temperature, position, and directional rotation while the vehicle is being driven. Vehicles equipped with PAL systems utilize the data to accurately identify the TPMS sensors’ location and pressure, which is shown on the driver display.

Wireless Auto-Locate (WAL) Technology

Wireless Auto-Locate systems use advanced TPMS technology along with RF signal strength to determine sensor location after installing a new sensor or tire rotation.

TPMS Sensors

When it comes to TPMS sensors, there are essentially two choices – OE-match or Universal. Each has its pros and cons.

The OE-match sensor is a direct-fit, 1-for-1 sensor. Each sensor has a specific protocol built in, and there’s one sensor for one application. The OE-match sensor line is typically long and requires an inventory investment.

Advantages

- No programming or selecting needed, technician simply installs and performs the vehicle relearn

Disadvantages

- Must stock numerous SKUs to ensure coverage

- New OE applications = additional SKUs

Universal TPMS sensors come in a variety of offerings. Some have multiple protocols in them and broadcast all at the same time to communicate with whichever vehicle they might be installed on. Others are selectable. And still others require the protocols to be downloaded, which allows the technician to choose the application for a specific repair. The right sensor is always available.

Advantages

- As few as one SKU required to stock

- Ability to add new applications without adding SKUs

- Ability to copy ID from the original sensor

Disadvantages

- A TPMS tool is required to program and relearn the sensor

Best of Both Worlds – Standard® OE-Match and Standard® QWIK-SENSOR® Multi-Frequency TPMS Sensors

The Standard® TPMS program includes both options, delivering the best blended program in the industry. In addition to an extensive OE-Match direct-fit sensor line, Standard® has recently introduced QWIK-SENSOR® Multi-Frequency Single Sensor program.

This New Multi-Frequency TPMS sensor combines 314.9, 315 and 433/434 MHz applications into one single SKU, reducing inventory for distributors and shops, while making TPMS sensor replacement more efficient for professional technicians. The QS106 comes complete with a factory-installed valve stem.

Faster programming times, surface-mounted dual-band antenna and longer battery life are just a few of the enhancements engineered into the QWIK-SENSOR® QS106. This Multi-Frequency sensor has been independently tested to match OE protocols for precise form, fit and function – including LOCSYNC, PAL, POD and WAL advanced technologies. Now, required TPMS sensor programming can be completed before or after installation, and while under pressure.

Today’s advanced TPMS sensors utilize technology such as accelerometers, multi-axis positioning and a dedicated Application Specific Integrated Circuit (ASIC) to determine sensor location and rotational direction. That's why it’s more important than ever to choose premium replacements like the Standard® QWIK- SENSOR® Multi-Frequency TPMS Sensor.

Standard® – The Complete TPMS Program

Whether it’s an ABS sensor for an indirect system, an OE-Match sensor or a universal sensor for direct systems – Standard® has you covered! In addition to the QWIK-SENSOR® Single Sensor Program, Standard® offers a full line of premium OE-Match TPMS Sensors, service kits and tools – a unique blended TPMS program offering 99% coverage.

Explore the Standard® advantage at QWIKSENSOR.com and StandardTPMS.com.

Check out TPMS videos on the Standard Brand YouTube channel.

Previous News

September 12, 2022 / Training

A Closer Look: Electronic Throttle Bodies and Control Systems

March 01, 2024 / Training

Why Pentastar Oil Filter Housings Fail

In service since 2011, the Chrysler Pentastar 3.6L engine has powered more than 10 million of the most popular vehicles on the road. These Pentastar engines are equipped with oil filter housings, which contain the oil filter, sensors, and a heat exchanger to help cool the oil. The oil filter housings on the Pentastar V6 engine have become known for their high failure rates. These failures have mistakenly been attributed the idea that the housings can warp due to heat, but this has been proven false. So, why do these units typically leak?

August 15, 2022 / Training

Variable Valve Timing (VVT) Repair Tips

Variable Valve Timing (VVT) or Variable Cam Timing (VCT) is common on most newer engines. These systems are designed to reduce emissions and maximize engine performance and fuel economy. Here's some background on VVT and a few tips for dealing with issues that come up.

August 22, 2022 / Training

Variable Valve Timing (VVT) Operation

Variable Valve Timing (VVT) systems help reduce emissions and maximize engine performance and fuel economy. The VVT Solenoid (Oil Control Valve) meters the oil flow to control the actuation of the VVT Sprocket (Actuator or Phaser). The VVT Sprocket mechanically shifts the position of the camshaft. Here are a few tips for testing.

August 08, 2022 / Training

Turbocharger Diagnosis Tips

Turbocharged engines are becoming more popular, as vehicle manufacturers look to increase fuel efficiency, maintain performance and reduce emissions. Symptoms of a malfunctioning turbocharger include loss of power, excess smoke, high fuel consumption, overheating, high exhaust temperature and oil leaks from the turbo. Here are a few important diagnostic and repair tips to keep in mind.

August 12, 2022 / Training

Tire Pressure Monitoring System (TPMS) Repair Tips

The Tire Pressure Monitoring System (TPMS) is a safety device that measures, identifies and warns you when one or more of your tires is significantly under-inflated. Standard® and Intermotor® are committed to helping technicians with TPMS repairs, whether it’s offering OE-Match TPMS sensors or providing repair tips from our team of ASE-certified master technicians. Here are a few TPMS repair tips.

August 05, 2022 / Training

Mass Air Flow (MAF) Sensor FAQs

The Mass Air Flow (MAF) sensor is a key component of the engine’s fueling strategy. It is crucial that the MAF sensor reports with 100% accuracy to ensure peak performance, fuel economy and reduced emissions. Here are some helpful tips such as how and when to replace them and steps to extend their longevity.

August 19, 2022 / Training

Ignition Coil Operation

Coil-on-plug assemblies are designed to convert a low voltage (primary side) to a high voltage (secondary side) to fire the spark plugs. They perform the functions of both the ignition coil, which creates the spark energy, and the spark plug wire set, which delivers the high-voltage energy to the spark plug. Today's coil-on-plug assemblies come in a variety of physical and wiring configurations.

August 01, 2022 / Training

Diesel Engine Repair Tips

Diesel Engines have become more popular thanks to a steady string of advancements. New engine designs, noise and vibration-damping technologies, and improvements like electronic engine control have spawned a new generation of engines that are more powerful and fuel efficient than similar-size gasoline engines. Learn more about today's diesel engines with these repair tips from our team of ASE-certified master technicians.

January 01, 2023 / Training

A Closer Look: Variable Valve Timing

In an effort to increase fuel efficiency and elevate performance across today’s vehicles, nearly every manufacturer has equipped new vehicles with Variable Valve Timing (VVT) technology, also known as Variable Cam Timing (VCT).

January 05, 2024 / Training

A Closer Look: Turbochargers

Turbocharger Opportunities: In an effort to increase fuel efficiency, maintain performance, and reduce emissions, vehicle manufacturers are adding turbocharged engines to their lineups at a significant rate. Over the next five years, the turbo service market will continue to experience substantial growth.

January 15, 2024 / Training

A Closer Look: Servicing Electric and Hybrid Vehicles

Hybrid vehicles have been sold in the U.S. for over 20 years. As hybrids continue to grow in popularity, and as fully electric vehicles have entered the market in the past several years, they have brought with them numerous service opportunities for aftermarket repair facilities. Whether shops dive in and get involved with replacing batteries, inverters, or other high-voltage components, or they stick to light-duty servicing, there is plenty of work to go around.

January 08, 2024 / Training

A Closer Look: Ignition Coils

Engine misfires, rough idle, a decrease in power under acceleration, poor fuel economy, and a check engine light are all signs of an ignition coil that has failed. OE coils are known for their high failure rates. Read along for more information on ignition coils, how to diagnose a failed one, and why an original equipment manufacturer’s coil may not be the best replacement choice.

January 12, 2024 / Training

A Closer Look: Gasoline Direct Injection (GDI)

Gasoline direct injection (GDI) is used on most new vehicles and requires a different approach to diagnosis and service. GDI technology has been an integral part of helping to improve fuel economy while reducing emissions and can be found in more than half of the U.S. fleet. In fact, the use of GDI engines has grown by over 600% since 2010. This means that in the next five years, 42 million more vehicles with GDI will enter the Aftermarket “Sweet Spot” of 6-12 years old, during which their injectors and related parts may need to be serviced or replaced. While GDI systems have proved effective, these systems encounter specific failures and require an understanding of how they work and how to test them when they set a code.

January 26, 2024 / Training

A Closer Look: Emissions

The Check Engine Light (CEL) is arguably one of the most effective yet underappreciated advancements in reducing vehicle emissions. Following the introduction of On-Board Diagnostics II (OBD II), the CEL is illuminated continuously if an on-board system monitor has failed a specified number of times and is negatively affecting emissions. If a catalyst-damaging event, such as a misfire, occurs, the CEL will flash. In today’s world of electric vehicles, hybrids, and partial zero-emission vehicles, many people forget that simply keeping their internal combustion engine (ICE)-powered vehicle operating as designed will help in reducing emissions.

January 29, 2024 / Training

A Closer Look: Electronic Throttle Bodies

A shop’s reputation is affected by things like accuracy of diagnosis, quality of the repair, and friendly service. Equally as important is the quality of the parts installed. If the shop does everything right, and the part fails, the customer will ultimately be upset with the shop. When a new part fails, the customer is inconvenienced again, and begins to lose faith with the shop that performed the work. This ultimately begs the question–why take a chance with inferior parts?

September 09, 2022 / Training

A Closer Look: Blower Motor Resistor Operation

Blower Motor Resistors (BMR) control the electrical current flowing from the fan switch to the blower fan, which allows the motorist to set the fan at different speeds. The fan speed can be changed by switching the blower resistor resistance mechanically, using a rotating lever, or electronically, by the air conditioning system.

September 05, 2022 / Training

A Closer Look: Anti-Lock Braking (ABS) System Operation

The Anti-Lock Braking System (ABS) is concerned with monitoring and controlling wheel slip, which helps maintain vehicle control. The major components of every ABS system are: wheel speed sensors, brake switch, brake master cylinder, EBCM and hydraulic assembly containing the pump motor, accumulator, valves and solenoids.

January 19, 2024 / Training

A Closer Look: Advanced Driver Assist Systems (ADAS)

Advanced Driver Assist Systems have created quite a buzz over the last several years. New business opportunities continuously arise, including a new segment of mobile technicians focusing on ADAS calibrations. While ADAS may still seem relatively new, automotive service professionals have actually been servicing Driver Assist Systems for decades. Systems like power steering, power brakes, and cruise control have been assisting motorists for many years. What is different with ADAS is that there are now input devices to understand what the driver’s intent is and alert the driver to potential dangers, rather than relying solely on the driver’s sight and sound.

January 22, 2024 / Training

A Closer Look: ABS Sensors

Anti-lock Braking Systems are intended to do exactly as the name portrays – prevent a vehicle’s wheels from locking up during a braking event. If any of the wheels lock up, the driver has less control of the vehicle and is more prone to an accident. By releasing some brake pressure to the locked-up wheel, the stopping distance will be increased, but the driver will be able to maintain control to hopefully avoid a collision. Prior to ABS, drivers were taught to pump the brake pedal when attempting to stop suddenly, or when stopping on gravel, ice, or loose pavement. Now, the ABS system does that for them.