January 08, 2024 / Training

A Closer Look: Ignition Coils

Engine misfires, rough idle, a decrease in power under acceleration, poor fuel economy, and a check engine light are all signs of an ignition coil that has failed. OE coils are known for their high failure rates. Read along for more information on ignition coils, how to diagnose a failed one, and why an original equipment manufacturer’s coil may not be the best replacement choice.

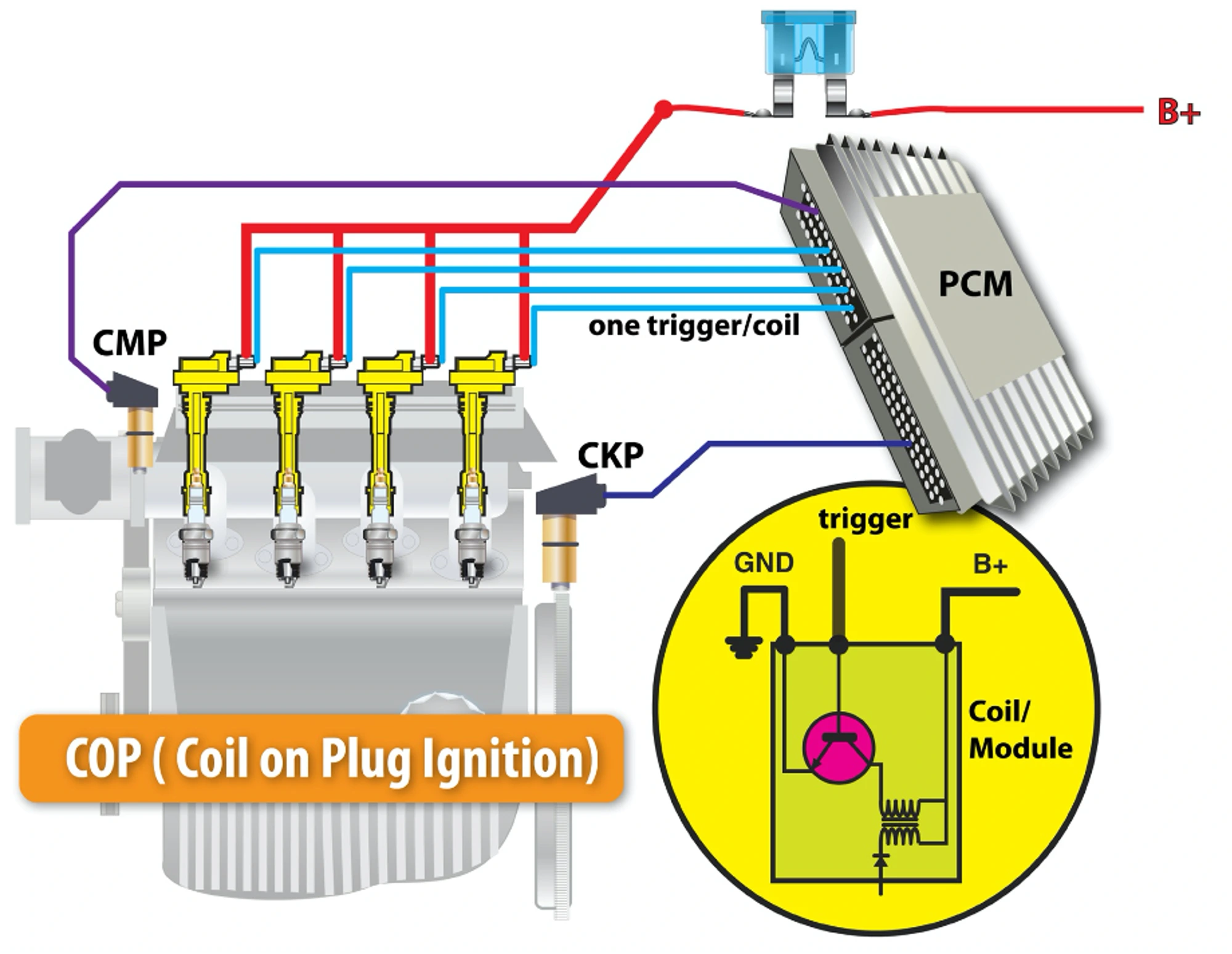

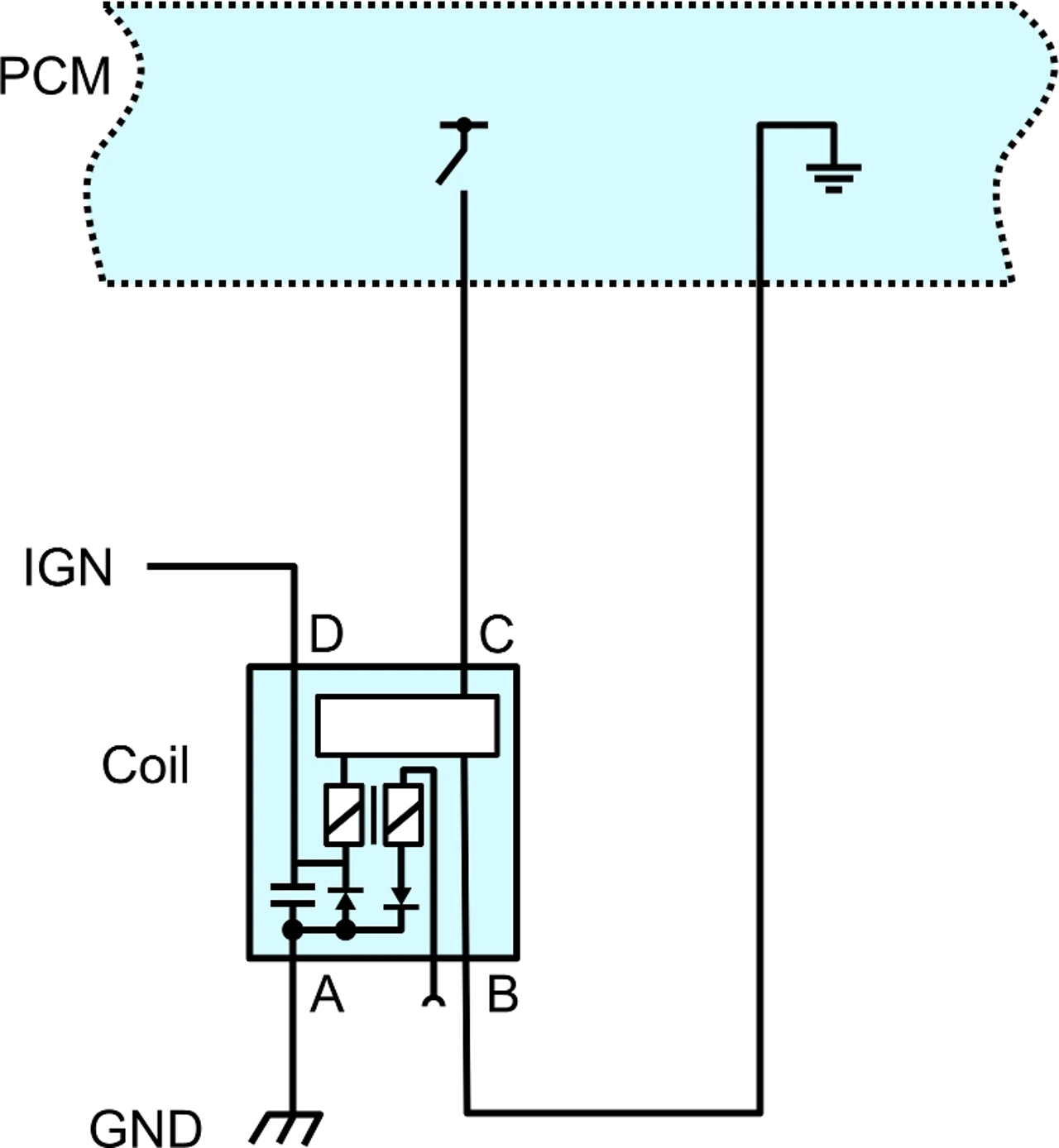

Is the coil driver in the powertrain control module (PCM), or is it in the coil itself? The answer to this may change the diagnostic process. The Coil-On-Plug (COP) system has gained popularity because of its universal application, control precision, and increased capabilities.

Let’s take a look at a typical Ford “driver-in-PCM” COP coil. The coil is provided a B+ source to one end of the primary winding, and the other end is connected to a low-side driver in the PCM. With this configuration, the PCM internally handles very high current, and also allows for technician access to the primary circuit for various tests.

PCM ignition coil driver circuits can fail due to the high current flowing through them, as well as damage by drivers that stay on too long, creating excessive heat. When replacing a PCM due to a driver failure, it is important to replace the coil as well. Be sure that the coils are disconnected, and do not turn the ignition on unless all damaged coils and the PCM have been replaced.

3- and 4-Wire Coils

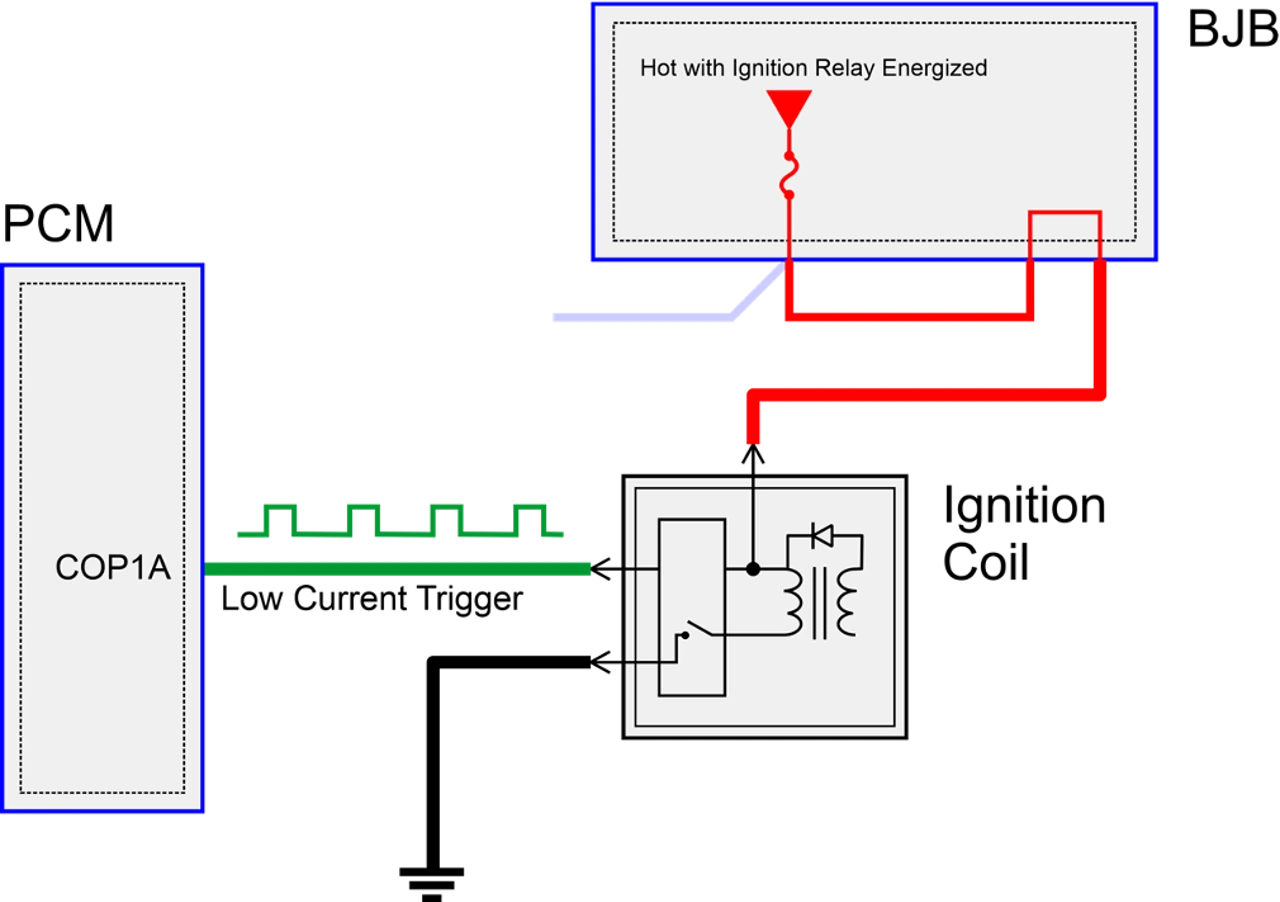

In the last decade, some Fords have been using a 3-wire coil with the driver located in the ignition coil (COP). The circuits are:

• Battery voltage

• Ground

• COPx

When the engine control module applies a voltage (~4-5V) to a coil’s COPx circuit, the internal driver will apply GND and B+ to the primary winding. When the voltage is removed, the internal driver will turn off the primary current. The collapsing magnetic field will induce a high voltage into the secondary winding, causing spark to occur across the spark plug.

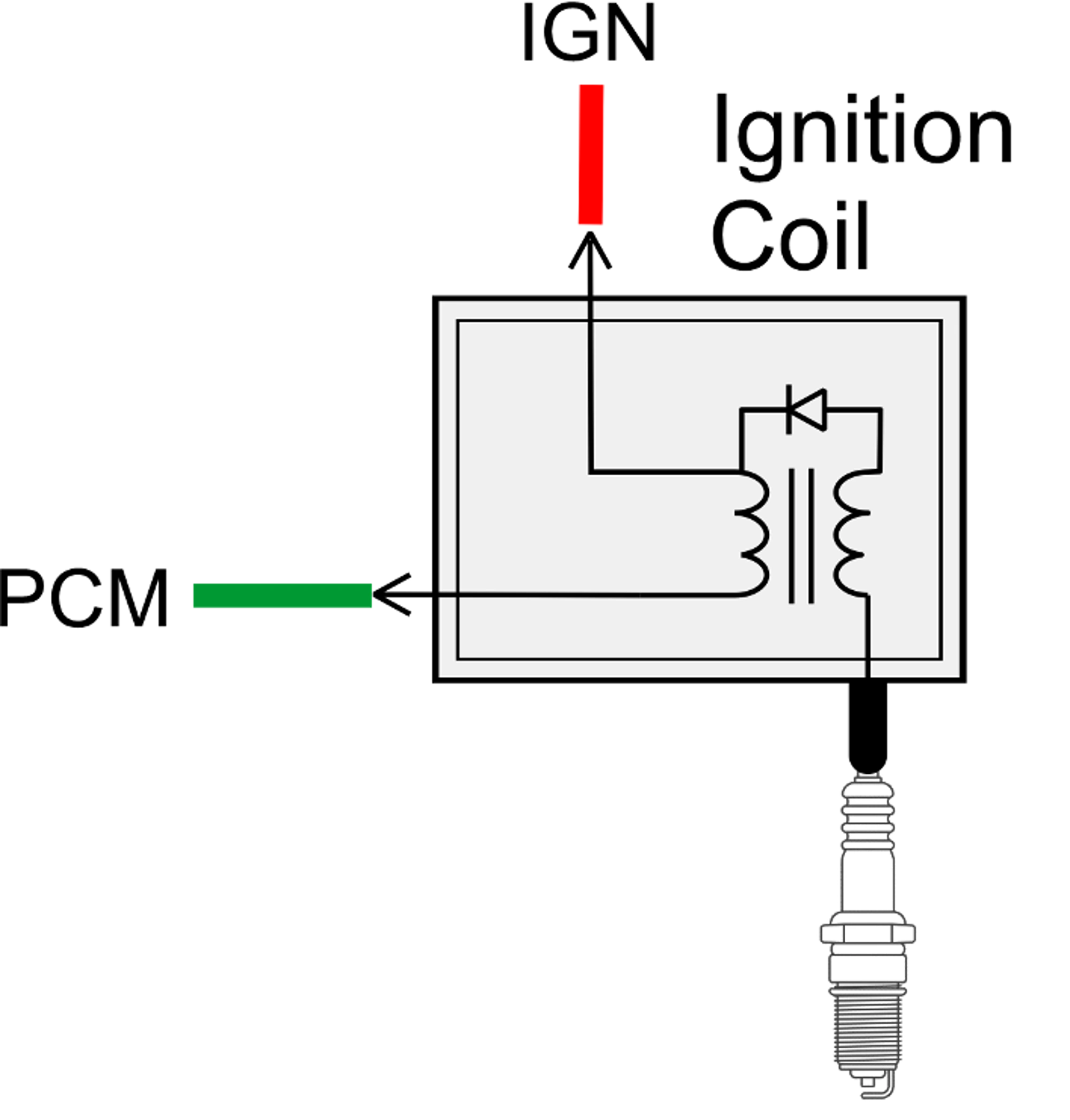

Many GM vehicles have been using 4-wire coils for over a decade. The circuits are:

• IGN B+

• Engine ground

• PCM ground

• Ignition Control (IC)

When the engine control module applies a voltage to a coil’s IC circuit, the internal driver will apply engine ground and B+ to the primary winding. Like the aforementioned Ford coil, when the voltage is removed, the primary current will turn off, collapsing the magnetic field and inducing a high voltage into the secondary winding. It is important to note that the PCM ground is necessary to the internal driver and that it is isolated from the engine ground.

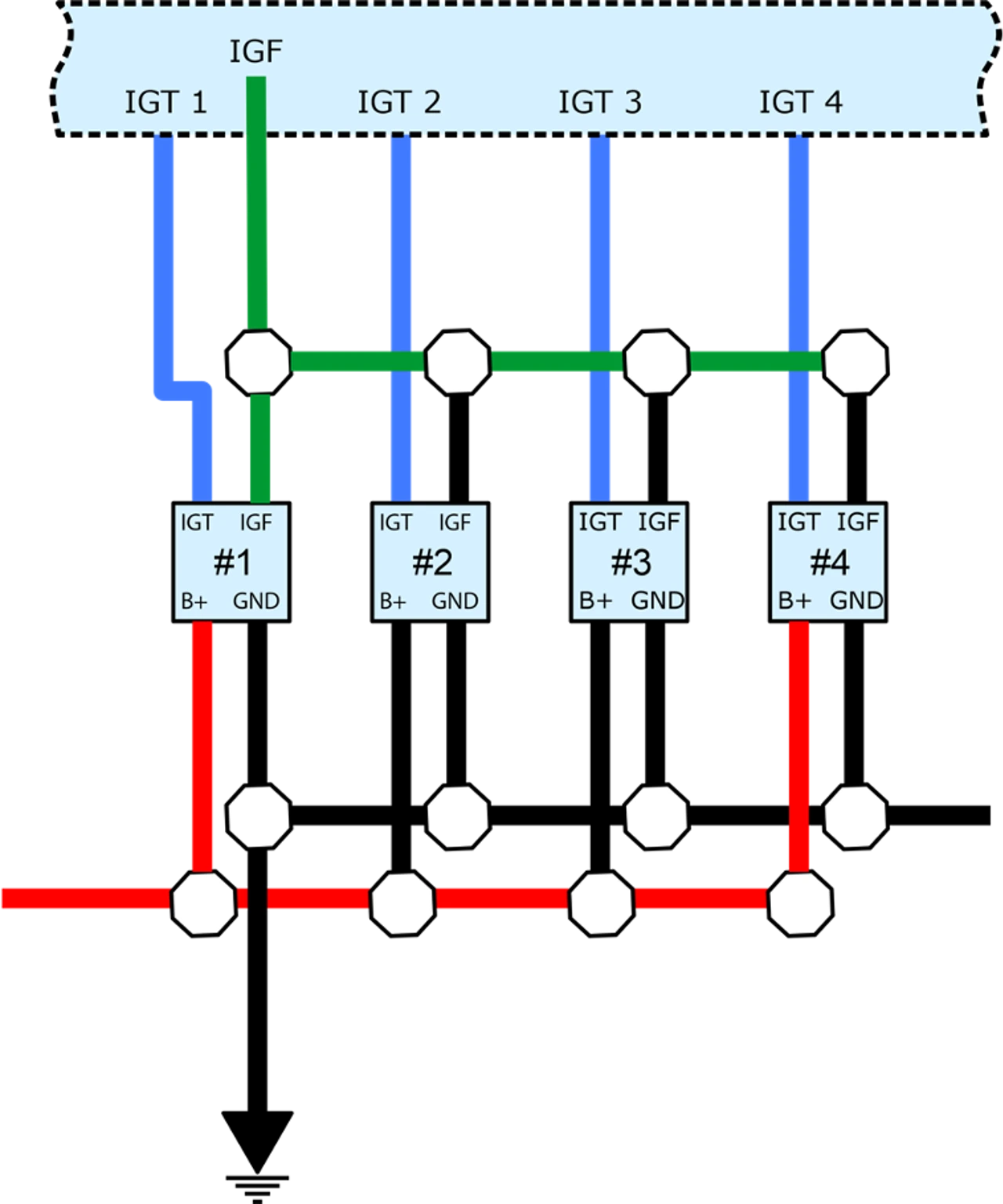

Toyota has been using a 4-wire COP system for a while. The circuits are:

• B+: Battery voltage

• GND: Ground

• IGT: Ignition timing signal

• IGF: Ignition confirmation signal

When the engine control module applies a voltage to a coils IGT circuit, the internal driver will apply GND and B+ to the primary winding. Again, removing the voltage to the IGT circuit causes the internal driver to turn off the primary current. The engine control module applies a 5V signal to the IGF circuits. If the coil driver has determined that the coil has or will fire successfully, the driver will pull the IGT signal low during that period.

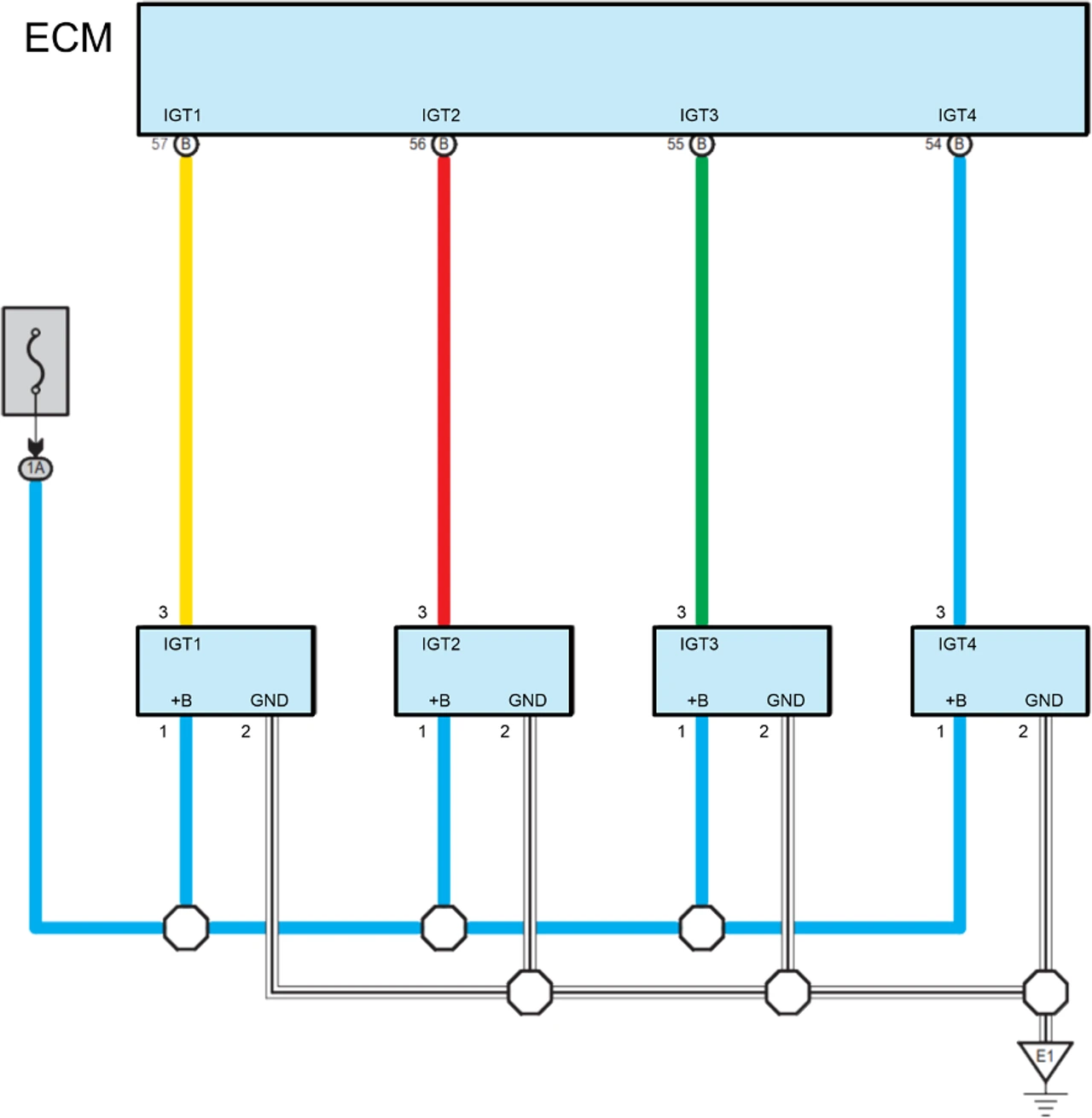

Newer Toyota engines (approximately 2019+) are equipped with a 3-wire coil. The circuits are:

• B+: Battery voltage

• GND: Ground

• IGT: Ignition timing signal

When the engine control module applies a voltage to a coils IGT circuit, the internal driver will apply GND and B+ to the primary winding. Like the others, removing the voltage will result in the primary current turning off.

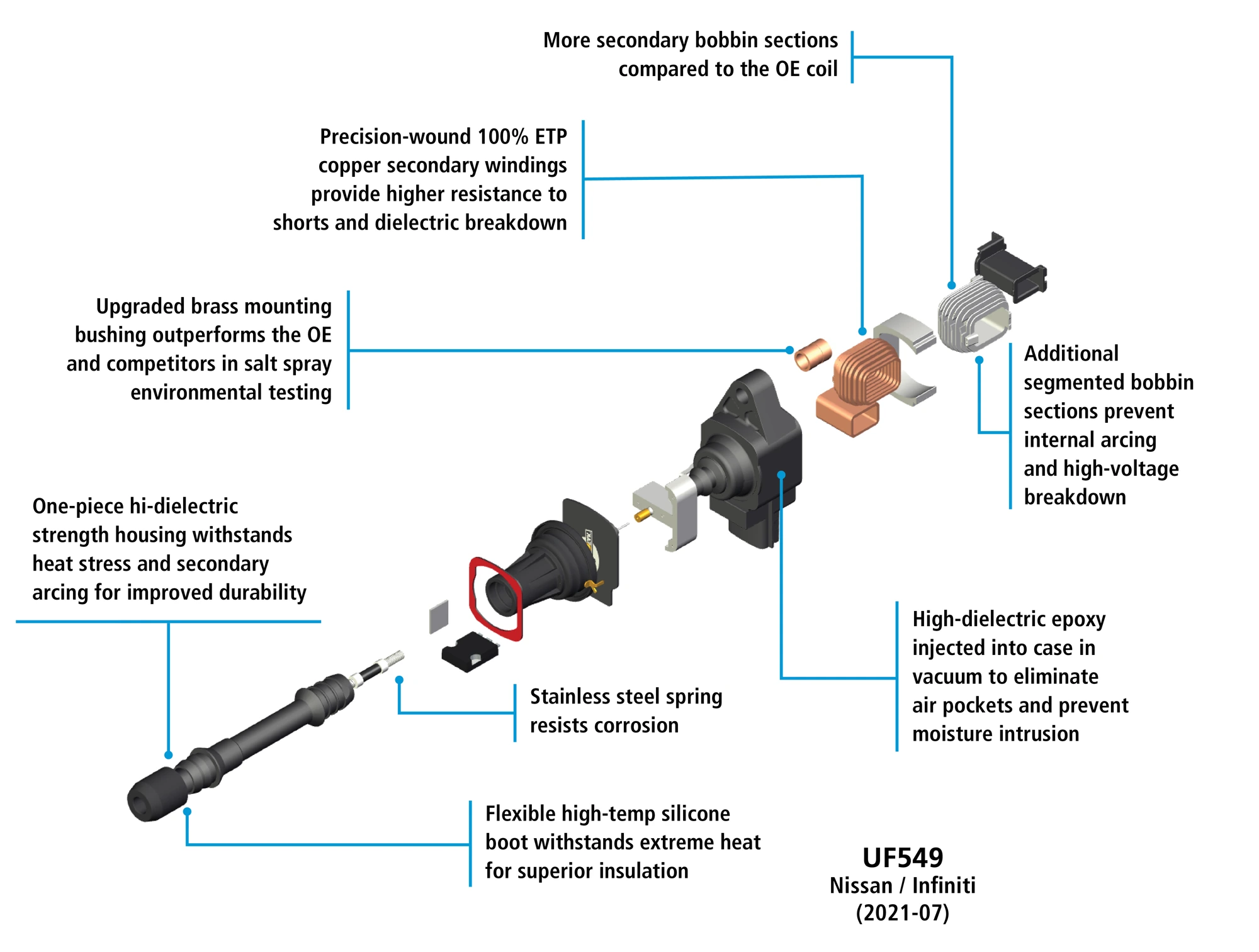

When OE Fails, Trust Standard®

Heat, moisture and corrosion are typical reasons that OE coils fail, and many OE designs can have weak points that lead to product failure. That’s why choosing a replacement coil that’s the same as the one that just failed doesn’t make sense. Blue Streak® engineers evaluate the original part, identify the OE issues, and correct those problems to deliver a better-performing and longer-lasting Coil. All Standard® and Blue Streak® Ignition Coils are subjected to extensive testing both in the lab and on vehicles to make sure parts perform in all conditions, at every RPM, and last.

No matter what type of ignition coil a vehicle has, it will likely fail at some point. With over 100 years of experience designing and manufacturing ignition components, Standard® has proven to be the brand technicians trust when the OE fails. Standard’s Ignition Coil Program features a variety of coil types to fit many applications. The Coils are expertly designed, engineered, and manufactured at SMP’s IATF 16949-certified Poland facility. Each one then undergoes rigorous examination and product validation, including extensive measurement and life testing, and a full range of environmental analysis to ensure 100% product reliability.

When OE Fails…Trust Standard®

March 01, 2024 / Training

Why Pentastar Oil Filter Housings Fail

In service since 2011, the Chrysler Pentastar 3.6L engine has powered more than 10 million of the most popular vehicles on the road. These Pentastar engines are equipped with oil filter housings, which contain the oil filter, sensors, and a heat exchanger to help cool the oil. The oil filter housings on the Pentastar V6 engine have become known for their high failure rates. These failures have mistakenly been attributed the idea that the housings can warp due to heat, but this has been proven false. So, why do these units typically leak?

August 15, 2022 / Training

Variable Valve Timing (VVT) Repair Tips

Variable Valve Timing (VVT) or Variable Cam Timing (VCT) is common on most newer engines. These systems are designed to reduce emissions and maximize engine performance and fuel economy. Here's some background on VVT and a few tips for dealing with issues that come up.

August 22, 2022 / Training

Variable Valve Timing (VVT) Operation

Variable Valve Timing (VVT) systems help reduce emissions and maximize engine performance and fuel economy. The VVT Solenoid (Oil Control Valve) meters the oil flow to control the actuation of the VVT Sprocket (Actuator or Phaser). The VVT Sprocket mechanically shifts the position of the camshaft. Here are a few tips for testing.

August 08, 2022 / Training

Turbocharger Diagnosis Tips

Turbocharged engines are becoming more popular, as vehicle manufacturers look to increase fuel efficiency, maintain performance and reduce emissions. Symptoms of a malfunctioning turbocharger include loss of power, excess smoke, high fuel consumption, overheating, high exhaust temperature and oil leaks from the turbo. Here are a few important diagnostic and repair tips to keep in mind.

August 12, 2022 / Training

Tire Pressure Monitoring System (TPMS) Repair Tips

The Tire Pressure Monitoring System (TPMS) is a safety device that measures, identifies and warns you when one or more of your tires is significantly under-inflated. Standard® and Intermotor® are committed to helping technicians with TPMS repairs, whether it’s offering OE-Match TPMS sensors or providing repair tips from our team of ASE-certified master technicians. Here are a few TPMS repair tips.

August 05, 2022 / Training

Mass Air Flow (MAF) Sensor FAQs

The Mass Air Flow (MAF) sensor is a key component of the engine’s fueling strategy. It is crucial that the MAF sensor reports with 100% accuracy to ensure peak performance, fuel economy and reduced emissions. Here are some helpful tips such as how and when to replace them and steps to extend their longevity.

August 19, 2022 / Training

Ignition Coil Operation

Coil-on-plug assemblies are designed to convert a low voltage (primary side) to a high voltage (secondary side) to fire the spark plugs. They perform the functions of both the ignition coil, which creates the spark energy, and the spark plug wire set, which delivers the high-voltage energy to the spark plug. Today's coil-on-plug assemblies come in a variety of physical and wiring configurations.

August 01, 2022 / Training

Diesel Engine Repair Tips

Diesel Engines have become more popular thanks to a steady string of advancements. New engine designs, noise and vibration-damping technologies, and improvements like electronic engine control have spawned a new generation of engines that are more powerful and fuel efficient than similar-size gasoline engines. Learn more about today's diesel engines with these repair tips from our team of ASE-certified master technicians.

January 01, 2023 / Training

A Closer Look: Variable Valve Timing

In an effort to increase fuel efficiency and elevate performance across today’s vehicles, nearly every manufacturer has equipped new vehicles with Variable Valve Timing (VVT) technology, also known as Variable Cam Timing (VCT).

September 19, 2022 / Training

A Closer Look: Turbocharger Operation and Installation

Turbochargers consist of just three major internal components: the turbine, the compressor and the bearing system that supports the turbine shaft. In an effort to increase fuel efficiency, maintain performance and reduce emissions, vehicle manufacturers are adding turbocharged engines to their lineups at a significant rate.

September 16, 2022 / Training

A Closer Look: Tire Pressure Monitoring Systems (TPMS) Operation

The Tire Pressure Monitoring Systems (TPMS) is a valid safety device that has been mandated for years. TPMS introduced a lot of new terminology – initiate, program, activate, clone, protocol and relearn. This safety system, a prime service opportunity, warns drivers of issues with their tires and protects motorists from potential danger.

January 15, 2024 / Training

A Closer Look: Servicing Electric and Hybrid Vehicles

Hybrid vehicles have been sold in the U.S. for over 20 years. As hybrids continue to grow in popularity, and as fully electric vehicles have entered the market in the past several years, they have brought with them numerous service opportunities for aftermarket repair facilities. Whether shops dive in and get involved with replacing batteries, inverters, or other high-voltage components, or they stick to light-duty servicing, there is plenty of work to go around.

January 26, 2024 / Training

A Closer Look: Emissions

The Check Engine Light (CEL) is arguably one of the most effective yet underappreciated advancements in reducing vehicle emissions. Following the introduction of On-Board Diagnostics II (OBD II), the CEL is illuminated continuously if an on-board system monitor has failed a specified number of times and is negatively affecting emissions. If a catalyst-damaging event, such as a misfire, occurs, the CEL will flash. In today’s world of electric vehicles, hybrids, and partial zero-emission vehicles, many people forget that simply keeping their internal combustion engine (ICE)-powered vehicle operating as designed will help in reducing emissions.

September 12, 2022 / Training

A Closer Look: Electronic Throttle Bodies and Control Systems

Electronic Throttle Control (ETC) systems are responsible for improving fuel economy, reducing emissions, protecting powertrain components and providing an overall better driving experience. Most vehicles on the road today use ETC. It is important for technicians to understand the principles of the system before delving into system specifics.

January 29, 2024 / Training

A Closer Look: Electronic Throttle Bodies

A shop’s reputation is affected by things like accuracy of diagnosis, quality of the repair, and friendly service. Equally as important is the quality of the parts installed. If the shop does everything right, and the part fails, the customer will ultimately be upset with the shop. When a new part fails, the customer is inconvenienced again, and begins to lose faith with the shop that performed the work. This ultimately begs the question–why take a chance with inferior parts?

September 09, 2022 / Training

A Closer Look: Blower Motor Resistor Operation

Blower Motor Resistors (BMR) control the electrical current flowing from the fan switch to the blower fan, which allows the motorist to set the fan at different speeds. The fan speed can be changed by switching the blower resistor resistance mechanically, using a rotating lever, or electronically, by the air conditioning system.

September 05, 2022 / Training

A Closer Look: Anti-Lock Braking (ABS) System Operation

The Anti-Lock Braking System (ABS) is concerned with monitoring and controlling wheel slip, which helps maintain vehicle control. The major components of every ABS system are: wheel speed sensors, brake switch, brake master cylinder, EBCM and hydraulic assembly containing the pump motor, accumulator, valves and solenoids.

January 19, 2024 / Training

A Closer Look: Advanced Driver Assist Systems (ADAS)

Advanced Driver Assist Systems have created quite a buzz over the last several years. New business opportunities continuously arise, including a new segment of mobile technicians focusing on ADAS calibrations. While ADAS may still seem relatively new, automotive service professionals have actually been servicing Driver Assist Systems for decades. Systems like power steering, power brakes, and cruise control have been assisting motorists for many years. What is different with ADAS is that there are now input devices to understand what the driver’s intent is and alert the driver to potential dangers, rather than relying solely on the driver’s sight and sound.

January 22, 2024 / Training

A Closer Look: ABS Sensors

Anti-lock Braking Systems are intended to do exactly as the name portrays – prevent a vehicle’s wheels from locking up during a braking event. If any of the wheels lock up, the driver has less control of the vehicle and is more prone to an accident. By releasing some brake pressure to the locked-up wheel, the stopping distance will be increased, but the driver will be able to maintain control to hopefully avoid a collision. Prior to ABS, drivers were taught to pump the brake pedal when attempting to stop suddenly, or when stopping on gravel, ice, or loose pavement. Now, the ABS system does that for them.