January 26, 2024 / Training

A Closer Look: Emissions

The Check Engine Light (CEL) is arguably one of the most effective yet underappreciated advancements in reducing vehicle emissions. Following the introduction of On-Board Diagnostics II (OBD II), the CEL is illuminated continuously if an on-board system monitor has failed a specified number of times and is negatively affecting emissions. If a catalyst-damaging event, such as a misfire, occurs, the CEL will flash. In today’s world of electric vehicles, hybrids, and partial zero emission vehicles, many people forget that simply keeping their internal combustion engine (ICE)-powered vehicle operating as designed will help in reducing emissions.

Fuel Injection’s Effects on Emissions

With advancements in electronic fuel injection, the operation of the engine is so finely tuned that the powertrain control module (PCM) is optimally programmed to balance the air fuel ratio, ensuring maximum fuel economy and reducing tailpipe emissions. Various inputs, such as engine and air temperature (via ECT and IAT), the amount of air entering the engine (via MAF), and the throttle opening (via TPS) are all part of the equation. If any of these are out of range, the efficiency of the engine will be reduced and have a negative effect on the output controls from the PCM for devices such as fuel injectors and an electronically controlled transmission.

Fuel injection has contributed to reducing emissions by precisely controlling the amount of fuel mixed with the air coming into an engine. Port-style fuel injection finely tunes the amount of fuel that is supplied to each cylinder, and with Gasoline Direct Injection (GDI) on today’s vehicles, the amount of fuel that is directly fed into each cylinder is even more accurately controlled.

Exhaust Gas Recirculation

Exhaust gas recirculation (EGR) valves are more in line with what people envision when they think of vehicle emissions systems. One of the more harmful tailpipe emissions is nitrogen monoxide or NOx. NOx is produced when the internal combustion temperature gets too high. One way to cool the combustion temperature is to dilute the oxygen entering the cylinder with already-burnt air and choking out the flame. This is exactly what the EGR system does. By recirculating a small, metered amount of exhaust gas into the intake, the EGR system helps to cool the combustion chamber and reduce NOx. EGR systems come in many shapes and forms. Some have a digitally controlled EGR valve, while others are vacuum-controlled by a separate solenoid. Some are monitored by a change in MAF reading, some are monitored by temperature sensors, and some are monitored by a pressure differential sensor.

Standard® EGR Valves are a direct-fit replacement to the original and provide long-lasting durability.

In the late ‘90s, engineers discovered that they could achieve some level of EGR by phasing the exhaust valve to close later and overlapping with the intake stroke. This would draw in some exhaust gas and achieve the EGR result. Over the past 20+ years, Variable Valve Timing (VVT) has evolved from retarding the exhaust camshaft to advancing the intake camshaft, and in many cases doing both at the same time. VVT currently contributes to reducing tailpipe emissions while helping to increase engine performance. A faulty VVT system will certainly have a negative effect on the vehicle’s emissions.

Evaporative Emissions

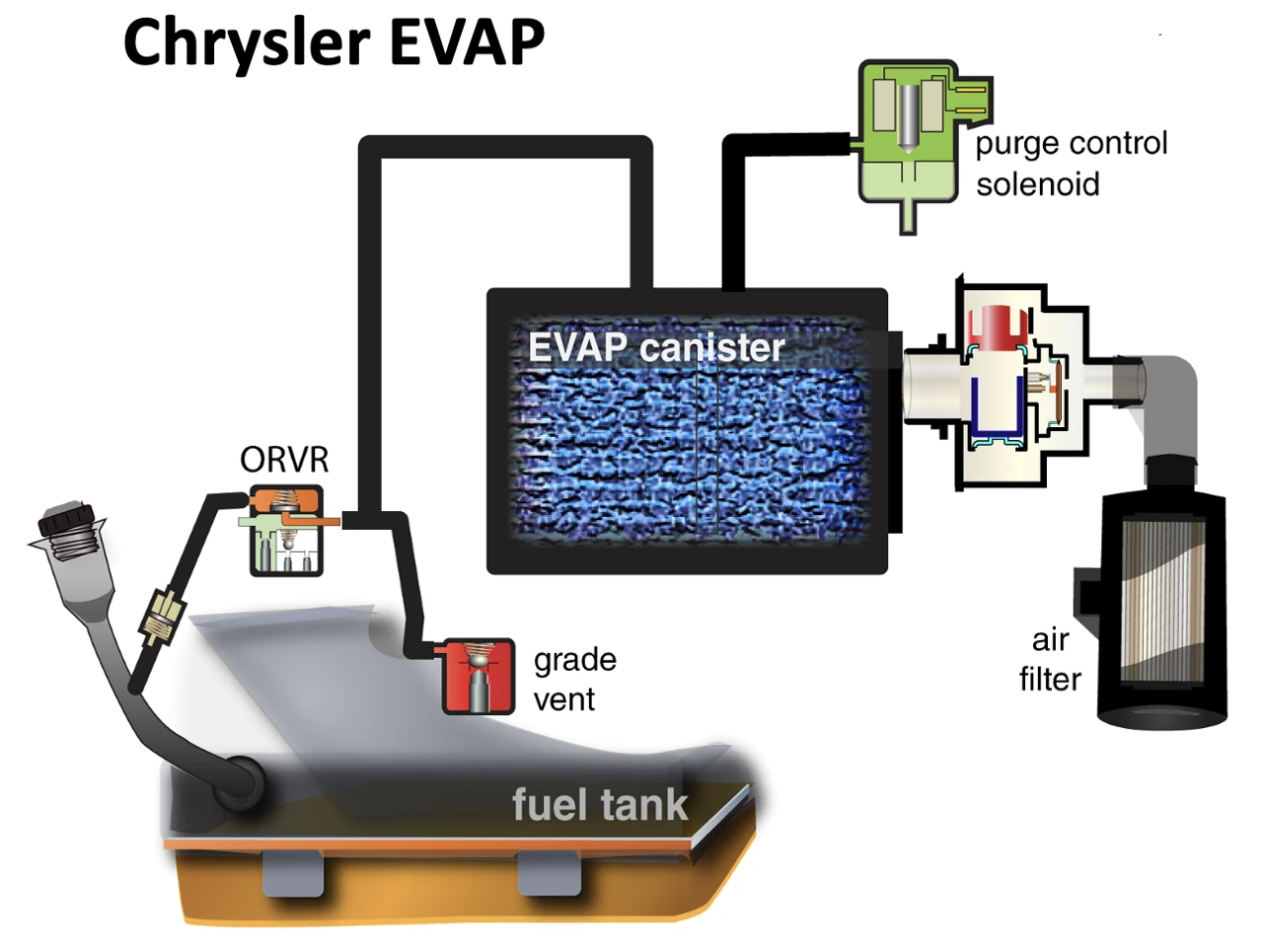

Evaporative emissions systems (EVAP) were introduced in the 1970s, and would eventually prove to be one of the most prominent advancements in vehicle emissions. While this system didn’t get a whole lot of attention until the ‘90s when it began being monitored and setting Diagnostic Trouble Codes, it has been reducing emissions for decades! The primary job of the EVAP system is to capture hydrocarbons (fuel vapors) in the fuel tank and redirect them to the engine where they can be consumed.

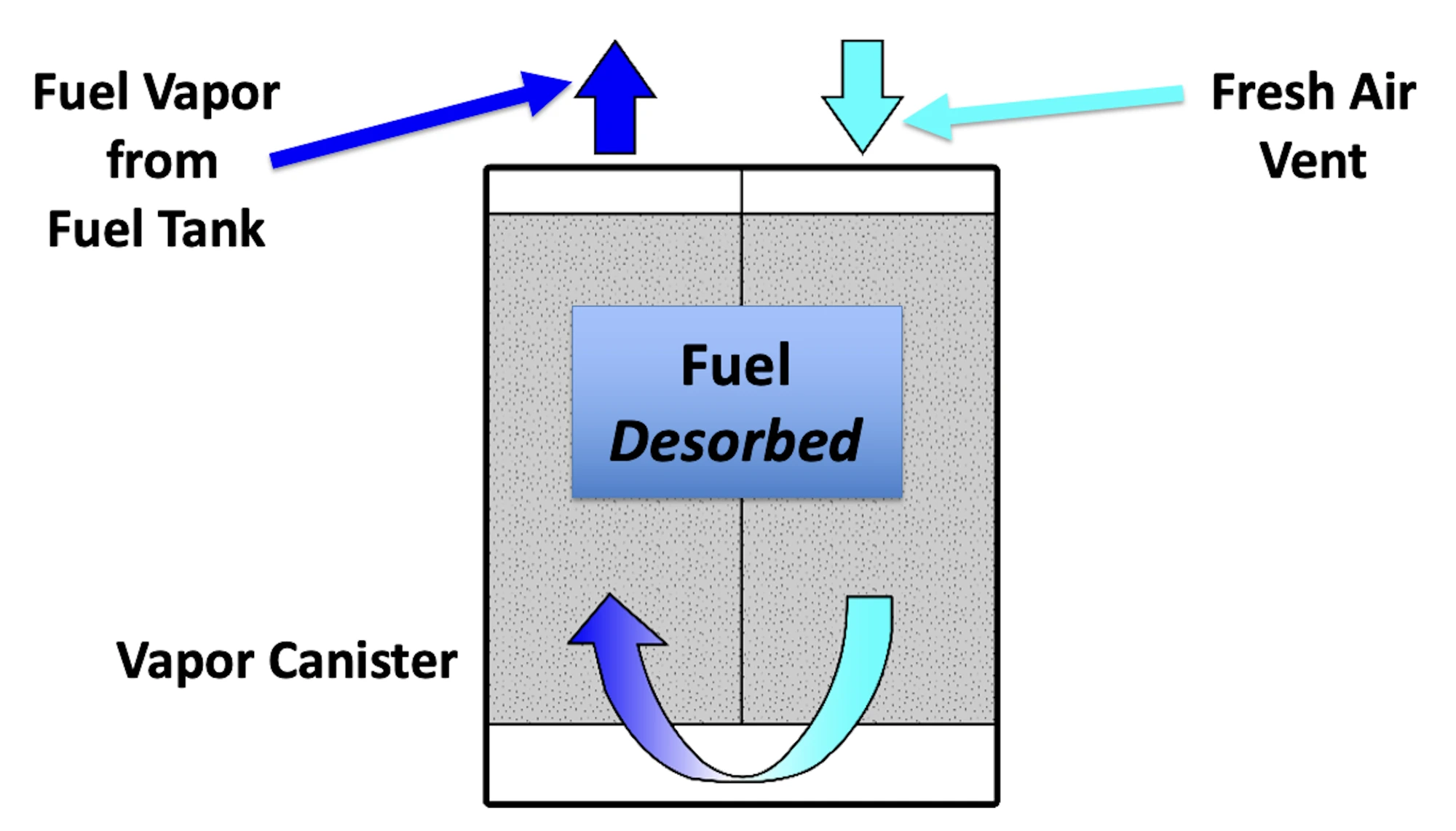

As fuel gets sloshed around in the fuel tank, the tank heats up, or as warm fuel is returned to the tank from the fuel rail, it will create vapors, which will be captured in the EVAP canister. Also, as fuel is added to the tank, it will displace the air in the tank, which will carry fuel vapors. The escaping air will be routed through the EVAP vent assembly, which contains a solenoid to open and close the vent. At this time, fuel vapors will also be adsorbed by the activated charcoal in the canister. Under certain driving conditions, the EVAP purge solenoid will be energized and apply vacuum to the canister, drawing fresh air in through the vent, and then through the canister, which will purge the fuel vapors from the canister, and eventually draw them into the engine to be consumed.

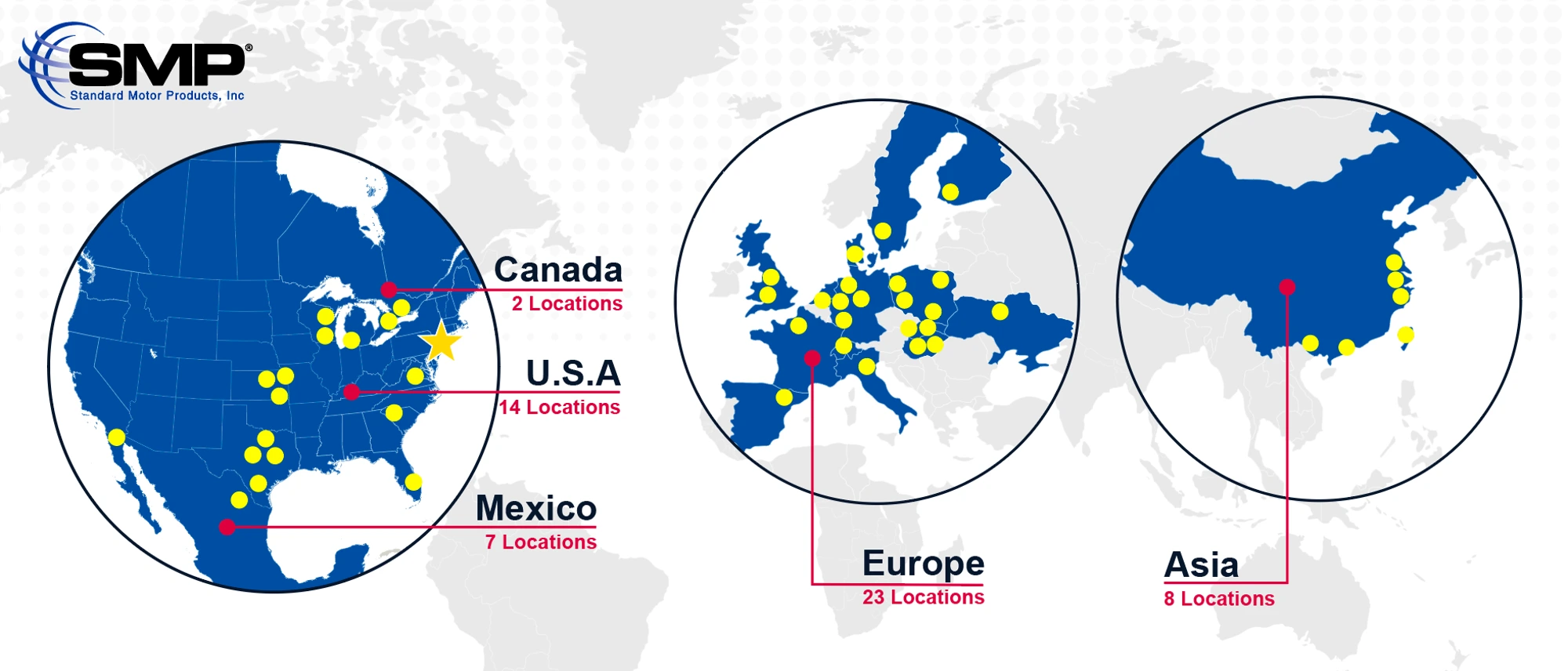

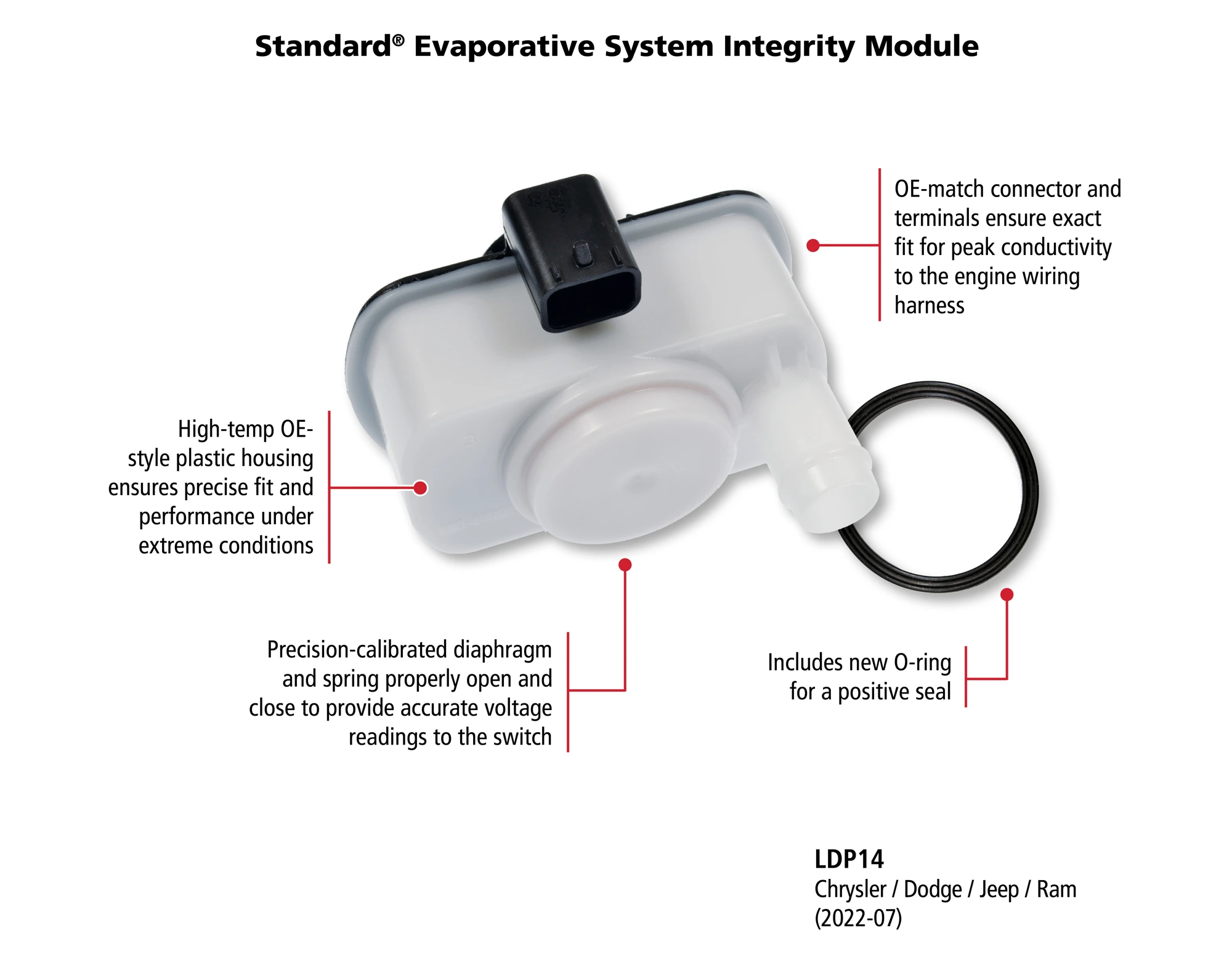

All of these systems work together to reduce emissions, and keep the Check Engine Light off! Any fault with any of these components could have a negative effect on the emissions. When a fault is detected, it is important to choose a quality replacement part that matches the performance of the original design in all conditions. Standard’s Emissions program includes more than 3,400 products for import and domestic vehicles. Standard® also offers complete VVT and Fuel Injection programs. The Standard® Emissions program includes Canister Purge Solenoids, EGR Valves, Fuel Vapor Canisters, Canister Vent Solenoids, Canister Purge Valves, EVAP System Integrity Modules (ESIM), EGR Control Solenoids, Crankcase Breather Hoses, Crankcase Filters and much more. Standard’s emissions components are precision-engineered and tested for durability and OE-matching performance. Standard® engineers develop more durable, longer-lasting components to help keep vehicles running clean.

Every Standard® emissions component is calibrated for precise performance. To ensure trouble-free operation, each one must pass comprehensive quality testing, including computer-controlled bench testing for resistance, leakage, and response and flow rates.

For more information on Standard® emissions components, visit StandardBrand.com, and for help diagnosing and replacing these components, search “emissions” on the StandardBrand YouTube channel.

March 01, 2024 / Training

Why Pentastar Oil Filter Housings Fail

In service since 2011, the Chrysler Pentastar 3.6L engine has powered more than 10 million of the most popular vehicles on the road. These Pentastar engines are equipped with oil filter housings, which contain the oil filter, sensors, and a heat exchanger to help cool the oil. The oil filter housings on the Pentastar V6 engine have become known for their high failure rates. These failures have mistakenly been attributed the idea that the housings can warp due to heat, but this has been proven false. So, why do these units typically leak?

August 15, 2022 / Training

Variable Valve Timing (VVT) Repair Tips

Variable Valve Timing (VVT) or Variable Cam Timing (VCT) is common on most newer engines. These systems are designed to reduce emissions and maximize engine performance and fuel economy. Here's some background on VVT and a few tips for dealing with issues that come up.

August 22, 2022 / Training

Variable Valve Timing (VVT) Operation

Variable Valve Timing (VVT) systems help reduce emissions and maximize engine performance and fuel economy. The VVT Solenoid (Oil Control Valve) meters the oil flow to control the actuation of the VVT Sprocket (Actuator or Phaser). The VVT Sprocket mechanically shifts the position of the camshaft. Here are a few tips for testing.

August 08, 2022 / Training

Turbocharger Diagnosis Tips

Turbocharged engines are becoming more popular, as vehicle manufacturers look to increase fuel efficiency, maintain performance and reduce emissions. Symptoms of a malfunctioning turbocharger include loss of power, excess smoke, high fuel consumption, overheating, high exhaust temperature and oil leaks from the turbo. Here are a few important diagnostic and repair tips to keep in mind.

August 12, 2022 / Training

Tire Pressure Monitoring System (TPMS) Repair Tips

The Tire Pressure Monitoring System (TPMS) is a safety device that measures, identifies and warns you when one or more of your tires is significantly under-inflated. Standard® and Intermotor® are committed to helping technicians with TPMS repairs, whether it’s offering OE-Match TPMS sensors or providing repair tips from our team of ASE-certified master technicians. Here are a few TPMS repair tips.

August 05, 2022 / Training

Mass Air Flow (MAF) Sensor FAQs

The Mass Air Flow (MAF) sensor is a key component of the engine’s fueling strategy. It is crucial that the MAF sensor reports with 100% accuracy to ensure peak performance, fuel economy and reduced emissions. Here are some helpful tips such as how and when to replace them and steps to extend their longevity.

August 19, 2022 / Training

Ignition Coil Operation

Coil-on-plug assemblies are designed to convert a low voltage (primary side) to a high voltage (secondary side) to fire the spark plugs. They perform the functions of both the ignition coil, which creates the spark energy, and the spark plug wire set, which delivers the high-voltage energy to the spark plug. Today's coil-on-plug assemblies come in a variety of physical and wiring configurations.

August 01, 2022 / Training

Diesel Engine Repair Tips

Diesel Engines have become more popular thanks to a steady string of advancements. New engine designs, noise and vibration-damping technologies, and improvements like electronic engine control have spawned a new generation of engines that are more powerful and fuel efficient than similar-size gasoline engines. Learn more about today's diesel engines with these repair tips from our team of ASE-certified master technicians.

January 01, 2023 / Training

A Closer Look: Variable Valve Timing

In an effort to increase fuel efficiency and elevate performance across today’s vehicles, nearly every manufacturer has equipped new vehicles with Variable Valve Timing (VVT) technology, also known as Variable Cam Timing (VCT).

January 05, 2024 / Training

A Closer Look: Turbochargers

Turbocharger Opportunities: In an effort to increase fuel efficiency, maintain performance, and reduce emissions, vehicle manufacturers are adding turbocharged engines to their lineups at a significant rate. Over the next five years, the turbo service market will continue to experience substantial growth.

September 19, 2022 / Training

A Closer Look: Turbocharger Operation and Installation

Turbochargers consist of just three major internal components: the turbine, the compressor and the bearing system that supports the turbine shaft. In an effort to increase fuel efficiency, maintain performance and reduce emissions, vehicle manufacturers are adding turbocharged engines to their lineups at a significant rate.

September 16, 2022 / Training

A Closer Look: Tire Pressure Monitoring Systems (TPMS) Operation

The Tire Pressure Monitoring Systems (TPMS) is a valid safety device that has been mandated for years. TPMS introduced a lot of new terminology – initiate, program, activate, clone, protocol and relearn. This safety system, a prime service opportunity, warns drivers of issues with their tires and protects motorists from potential danger.

January 15, 2024 / Training

A Closer Look: Servicing Electric and Hybrid Vehicles

Hybrid vehicles have been sold in the U.S. for over 20 years. As hybrids continue to grow in popularity, and as fully electric vehicles have entered the market in the past several years, they have brought with them numerous service opportunities for aftermarket repair facilities. Whether shops dive in and get involved with replacing batteries, inverters, or other high-voltage components, or they stick to light-duty servicing, there is plenty of work to go around.

January 08, 2024 / Training

A Closer Look: Ignition Coils

Engine misfires, rough idle, a decrease in power under acceleration, poor fuel economy, and a check engine light are all signs of an ignition coil that has failed. OE coils are known for their high failure rates. Read along for more information on ignition coils, how to diagnose a failed one, and why an original equipment manufacturer’s coil may not be the best replacement choice.

January 12, 2024 / Training

A Closer Look: Gasoline Direct Injection (GDI)

Gasoline direct injection (GDI) is used on most new vehicles and requires a different approach to diagnosis and service. GDI technology has been an integral part of helping to improve fuel economy while reducing emissions and can be found in more than half of the U.S. fleet. In fact, the use of GDI engines has grown by over 600% since 2010. This means that in the next five years, 42 million more vehicles with GDI will enter the Aftermarket “Sweet Spot” of 6-12 years old, during which their injectors and related parts may need to be serviced or replaced. While GDI systems have proved effective, these systems encounter specific failures and require an understanding of how they work and how to test them when they set a code.

September 12, 2022 / Training

A Closer Look: Electronic Throttle Bodies and Control Systems

Electronic Throttle Control (ETC) systems are responsible for improving fuel economy, reducing emissions, protecting powertrain components and providing an overall better driving experience. Most vehicles on the road today use ETC. It is important for technicians to understand the principles of the system before delving into system specifics.

September 09, 2022 / Training

A Closer Look: Blower Motor Resistor Operation

Blower Motor Resistors (BMR) control the electrical current flowing from the fan switch to the blower fan, which allows the motorist to set the fan at different speeds. The fan speed can be changed by switching the blower resistor resistance mechanically, using a rotating lever, or electronically, by the air conditioning system.

September 05, 2022 / Training

A Closer Look: Anti-Lock Braking (ABS) System Operation

The Anti-Lock Braking System (ABS) is concerned with monitoring and controlling wheel slip, which helps maintain vehicle control. The major components of every ABS system are: wheel speed sensors, brake switch, brake master cylinder, EBCM and hydraulic assembly containing the pump motor, accumulator, valves and solenoids.

January 19, 2024 / Training

A Closer Look: Advanced Driver Assist Systems (ADAS)

Advanced Driver Assist Systems have created quite a buzz over the last several years. New business opportunities continuously arise, including a new segment of mobile technicians focusing on ADAS calibrations. While ADAS may still seem relatively new, automotive service professionals have actually been servicing Driver Assist Systems for decades. Systems like power steering, power brakes, and cruise control have been assisting motorists for many years. What is different with ADAS is that there are now input devices to understand what the driver’s intent is and alert the driver to potential dangers, rather than relying solely on the driver’s sight and sound.