January 19, 2024 / Training

A Closer Look: Advanced Driver Assist Systems (ADAS)

Advanced Driver Assist Systems (ADAS) Overview

Advanced Driver Assist Systems have created quite a buzz over the last several years. New business opportunities continuously arise, including a new segment of mobile technicians focusing on ADAS calibrations. While ADAS may still seem relatively new, automotive service professionals have actually been servicing Driver Assist Systems for decades. Systems like power steering, power brakes, and cruise control have been

assisting motorists for many years. What is different with ADAS is that there are now input devices to understand what the driver’s intent is and alert the driver to potential dangers, rather than relying solely on the driver’s sight and sound.

Standard® Park Assist Sensor

Breaking Down ADAS Input Devices

ADAS input devices can be divided into four primary categories.

Ultrasonic

The “ultrasonic” category encompasses devices like park assist sensors and blind spot detection modules. Ultrasonic sensors are relatively simple and are great at measuring distance.

Radar

The next category is “radar”. Radar is more complicated than the ultrasonic category and is great at measuring distance and relative speed. We see radar used frequently in adaptive cruise control systems.

Standard® Cruise Control Distance Sensor

Optical

The third category is “optical,” and as you might imagine, this essentially encompasses cameras. These devices will identify objects and be used for things like lane keep assist or parking assistance.

LiDAR (Light Detection and Ranging)

Finally, the fourth category is “LiDAR.” LiDAR is the most complex, yet most accurate input available and produces 3D mapping. This is currently not the most popular ADAS input, but is gaining popularity as development costs reduce and technology advances.

How does ADAS work?

In addition to the input devices, ADAS relies on many of the vehicle’s other sensors to understand what the driver’s intent is. Sensors such as accelerator pedal position sensors and brake pedal position sensors tell the vehicle if the driver is intending to accelerate or slow down. Steering angle sensors and yaw rate sensors report the driver’s intended direction.

Tech Tip: ADAS Calibration

While many ADAS components are plug and play, others need to be calibrated to operate properly. For instance, steering angle sensors need to be recalibrated or “zeroed” after every alignment. These often-overlooked sensors are crucial to proper operation of the vehicle’s ADAS system.

Some vehicle manufacturers will require a static calibration on a component, others will require a dynamic calibration, and some will require no calibration at all. When recommending and installing ADAS parts, always remember that a calibration may be required after installation. Some ADAS parts like park assist cameras and sensors may not require any type of calibration, while others like cruise control distance sensors will almost always require calibration. It is also important to remember that it is the vehicle that determines if a part needs to be calibrated or not, not the part.

If you encounter an ADAS part that is not operating properly after installation, make sure that the correct steps have been taken to calibrate the part. It is possible that the part is not defective after all, and reviewing the calibration procedures can help you avoid having to return and replace the part a second time.

ADAS Opportunities

Many times, when ADAS is mentioned, the collision industry comes to mind due to the number of ADAS components that are susceptible to being damaged in a collision. However, as these systems age, there will be more and more repair and service opportunities.

Now that these systems are increasing in age and mileage, they are failing or coming out of calibration. For instance, the lenses of park assist cameras can become distorted over time. Cruise control distance sensors, lane departure cameras, and steering angle sensors are all critical safety features that can be damaged by daily wear and tear.

In northern regions, these systems are prone to corrosion from the harsh winter weather and salt on the roads. In every region, they are prone to water intrusion from rain, car washes, or flooding. While blind spot detection sensors are susceptible to accidents, they are also damaged by salt and road debris.

When these components fail, they will typically display a message on the dash and illuminate some sort of warning lamp. These are indicators that typically steer the vehicle toward the general repair facility where the customer takes their vehicle for similar errors like a TPMS warning or Check Engine light. These shops will then diagnose, replace the part, and calibrate the system as required.

Standard® Park Assist Camera

Helping You Help Them

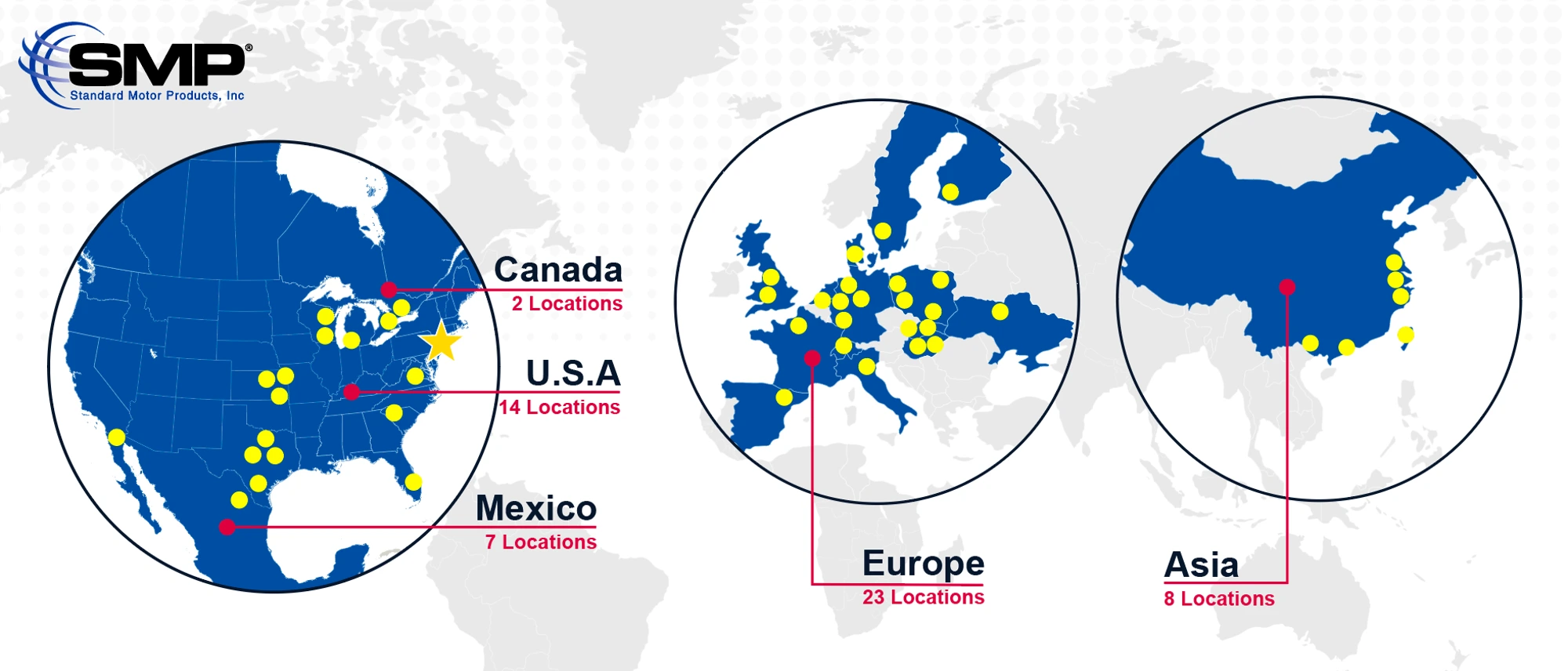

Seeing as ADAS is a newer category, you might think the dealership is your best bet when ordering replacement parts for customer vehicles. Skip the dealership and check out Standard’s ADAS program.

The Standard® ADAS program includes over 900 part numbers, providing all of the aforementioned parts, from Blind Spot Detection Sensors to Cruise Control Distance Sensors, as well as Lane Departure System Cameras and Park Assist Sensors and Cameras. These components are designed to integrate correctly with electronic crash avoidance systems, and are manufactured to stringent quality standards, matching the original for easy installation and delivering precise performance. In total, the

Standard® line of ADAS parts provides coverage for more than 280 million vehicles on the road. Gas, diesel, hybrid, or electric, import or domestic, Standard® has you covered.

For more information on diagnosing and replacing these components, search “ADAS” on the StandardBrand YouTube channel.

March 01, 2024 / Training

Why Pentastar Oil Filter Housings Fail

In service since 2011, the Chrysler Pentastar 3.6L engine has powered more than 10 million of the most popular vehicles on the road. These Pentastar engines are equipped with oil filter housings, which contain the oil filter, sensors, and a heat exchanger to help cool the oil. The oil filter housings on the Pentastar V6 engine have become known for their high failure rates. These failures have mistakenly been attributed the idea that the housings can warp due to heat, but this has been proven false. So, why do these units typically leak?

August 15, 2022 / Training

Variable Valve Timing (VVT) Repair Tips

Variable Valve Timing (VVT) or Variable Cam Timing (VCT) is common on most newer engines. These systems are designed to reduce emissions and maximize engine performance and fuel economy. Here's some background on VVT and a few tips for dealing with issues that come up.

August 22, 2022 / Training

Variable Valve Timing (VVT) Operation

Variable Valve Timing (VVT) systems help reduce emissions and maximize engine performance and fuel economy. The VVT Solenoid (Oil Control Valve) meters the oil flow to control the actuation of the VVT Sprocket (Actuator or Phaser). The VVT Sprocket mechanically shifts the position of the camshaft. Here are a few tips for testing.

August 08, 2022 / Training

Turbocharger Diagnosis Tips

Turbocharged engines are becoming more popular, as vehicle manufacturers look to increase fuel efficiency, maintain performance and reduce emissions. Symptoms of a malfunctioning turbocharger include loss of power, excess smoke, high fuel consumption, overheating, high exhaust temperature and oil leaks from the turbo. Here are a few important diagnostic and repair tips to keep in mind.

August 12, 2022 / Training

Tire Pressure Monitoring System (TPMS) Repair Tips

The Tire Pressure Monitoring System (TPMS) is a safety device that measures, identifies and warns you when one or more of your tires is significantly under-inflated. Standard® and Intermotor® are committed to helping technicians with TPMS repairs, whether it’s offering OE-Match TPMS sensors or providing repair tips from our team of ASE-certified master technicians. Here are a few TPMS repair tips.

August 05, 2022 / Training

Mass Air Flow (MAF) Sensor FAQs

The Mass Air Flow (MAF) sensor is a key component of the engine’s fueling strategy. It is crucial that the MAF sensor reports with 100% accuracy to ensure peak performance, fuel economy and reduced emissions. Here are some helpful tips such as how and when to replace them and steps to extend their longevity.

August 19, 2022 / Training

Ignition Coil Operation

Coil-on-plug assemblies are designed to convert a low voltage (primary side) to a high voltage (secondary side) to fire the spark plugs. They perform the functions of both the ignition coil, which creates the spark energy, and the spark plug wire set, which delivers the high-voltage energy to the spark plug. Today's coil-on-plug assemblies come in a variety of physical and wiring configurations.

August 01, 2022 / Training

Diesel Engine Repair Tips

Diesel Engines have become more popular thanks to a steady string of advancements. New engine designs, noise and vibration-damping technologies, and improvements like electronic engine control have spawned a new generation of engines that are more powerful and fuel efficient than similar-size gasoline engines. Learn more about today's diesel engines with these repair tips from our team of ASE-certified master technicians.

January 01, 2023 / Training

A Closer Look: Variable Valve Timing

In an effort to increase fuel efficiency and elevate performance across today’s vehicles, nearly every manufacturer has equipped new vehicles with Variable Valve Timing (VVT) technology, also known as Variable Cam Timing (VCT).

January 05, 2024 / Training

A Closer Look: Turbochargers

Turbocharger Opportunities: In an effort to increase fuel efficiency, maintain performance, and reduce emissions, vehicle manufacturers are adding turbocharged engines to their lineups at a significant rate. Over the next five years, the turbo service market will continue to experience substantial growth.

September 19, 2022 / Training

A Closer Look: Turbocharger Operation and Installation

Turbochargers consist of just three major internal components: the turbine, the compressor and the bearing system that supports the turbine shaft. In an effort to increase fuel efficiency, maintain performance and reduce emissions, vehicle manufacturers are adding turbocharged engines to their lineups at a significant rate.

September 16, 2022 / Training

A Closer Look: Tire Pressure Monitoring Systems (TPMS) Operation

The Tire Pressure Monitoring Systems (TPMS) is a valid safety device that has been mandated for years. TPMS introduced a lot of new terminology – initiate, program, activate, clone, protocol and relearn. This safety system, a prime service opportunity, warns drivers of issues with their tires and protects motorists from potential danger.

January 08, 2024 / Training

A Closer Look: Ignition Coils

Engine misfires, rough idle, a decrease in power under acceleration, poor fuel economy, and a check engine light are all signs of an ignition coil that has failed. OE coils are known for their high failure rates. Read along for more information on ignition coils, how to diagnose a failed one, and why an original equipment manufacturer’s coil may not be the best replacement choice.

January 12, 2024 / Training

A Closer Look: Gasoline Direct Injection (GDI)

Gasoline direct injection (GDI) is used on most new vehicles and requires a different approach to diagnosis and service. GDI technology has been an integral part of helping to improve fuel economy while reducing emissions and can be found in more than half of the U.S. fleet. In fact, the use of GDI engines has grown by over 600% since 2010. This means that in the next five years, 42 million more vehicles with GDI will enter the Aftermarket “Sweet Spot” of 6-12 years old, during which their injectors and related parts may need to be serviced or replaced. While GDI systems have proved effective, these systems encounter specific failures and require an understanding of how they work and how to test them when they set a code.

January 26, 2024 / Training

A Closer Look: Emissions

The Check Engine Light (CEL) is arguably one of the most effective yet underappreciated advancements in reducing vehicle emissions. Following the introduction of On-Board Diagnostics II (OBD II), the CEL is illuminated continuously if an on-board system monitor has failed a specified number of times and is negatively affecting emissions. If a catalyst-damaging event, such as a misfire, occurs, the CEL will flash. In today’s world of electric vehicles, hybrids, and partial zero-emission vehicles, many people forget that simply keeping their internal combustion engine (ICE)-powered vehicle operating as designed will help in reducing emissions.

September 12, 2022 / Training

A Closer Look: Electronic Throttle Bodies and Control Systems

Electronic Throttle Control (ETC) systems are responsible for improving fuel economy, reducing emissions, protecting powertrain components and providing an overall better driving experience. Most vehicles on the road today use ETC. It is important for technicians to understand the principles of the system before delving into system specifics.

January 29, 2024 / Training

A Closer Look: Electronic Throttle Bodies

A shop’s reputation is affected by things like accuracy of diagnosis, quality of the repair, and friendly service. Equally as important is the quality of the parts installed. If the shop does everything right, and the part fails, the customer will ultimately be upset with the shop. When a new part fails, the customer is inconvenienced again, and begins to lose faith with the shop that performed the work. This ultimately begs the question–why take a chance with inferior parts?

September 09, 2022 / Training

A Closer Look: Blower Motor Resistor Operation

Blower Motor Resistors (BMR) control the electrical current flowing from the fan switch to the blower fan, which allows the motorist to set the fan at different speeds. The fan speed can be changed by switching the blower resistor resistance mechanically, using a rotating lever, or electronically, by the air conditioning system.

September 05, 2022 / Training

A Closer Look: Anti-Lock Braking (ABS) System Operation

The Anti-Lock Braking System (ABS) is concerned with monitoring and controlling wheel slip, which helps maintain vehicle control. The major components of every ABS system are: wheel speed sensors, brake switch, brake master cylinder, EBCM and hydraulic assembly containing the pump motor, accumulator, valves and solenoids.