SMP Global Facilities

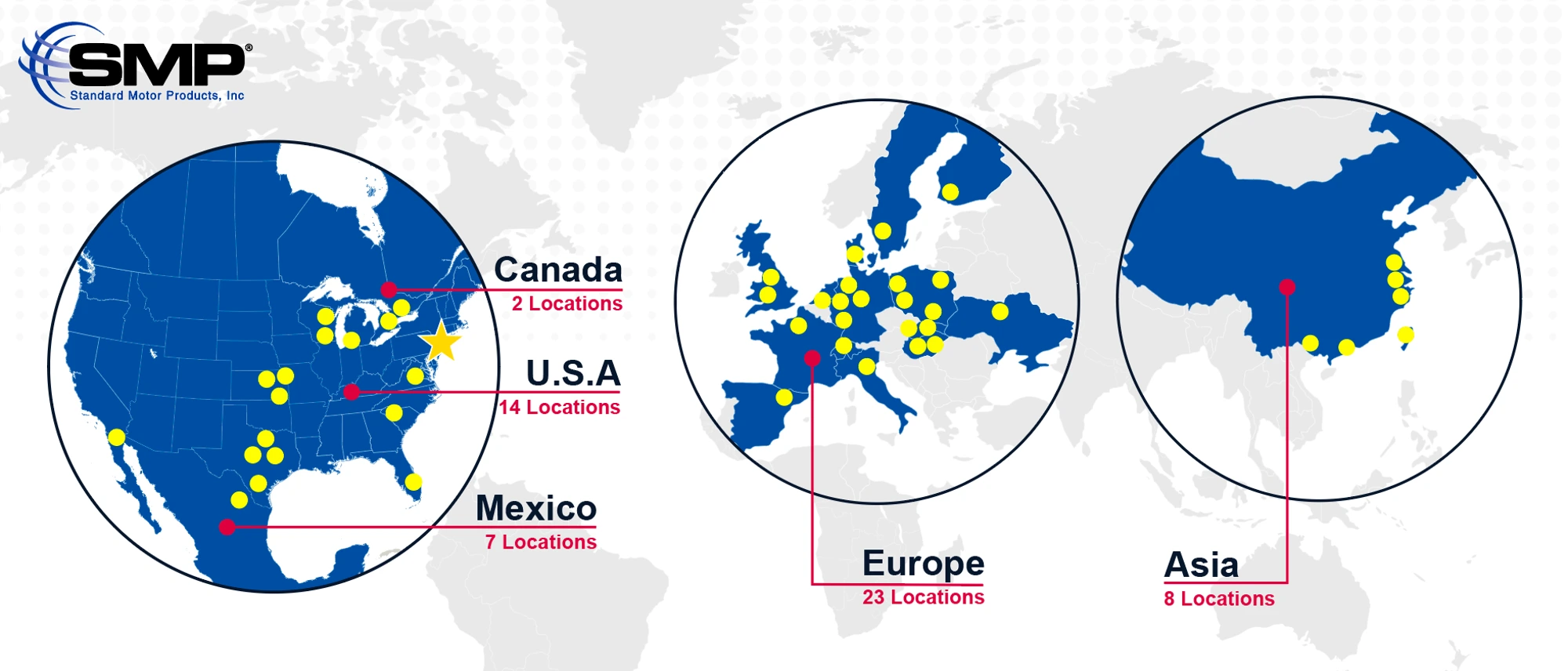

Headquartered in Long Island City, NY, SMP is a global manufacturer with over 6,500 employees across 54 manufacturing, distribution, engineering and office facilities located in North America, Europe and Asia.

Long Island City, NY

Corporate Vehicle Control

Long Island City, NY

Corporate and Vehicle Control HeadquartersThis location provides operation oversight for SMP and acts as a primary headquarters for the corporation, its divisions and its brands.

Our corporate headquarters in Long Island City, New York has housed SMP operations since 1936. It consists of 86,000 square feet of office space.

In addition to our Executive offices and Corporate Finance group, Long Island City is home to our Vehicle Control Division Marketing, Product Development, and Cataloging teams.

Our headquarters supports our offices across the globe, and houses a 20,000 square-foot engineering laboratory and test facility. Working alongside our International Sourcing staff, SMP engineers and engineering technicians ensure excellent quality control across all SMP products.

Bialystok, Poland

Vehicle Control Engineered Solutions

Bialystok, Poland

Manufacturing - Vehicle Control & Engineered SolutionsOur Bialystock, Poland facility is dedicated to engineering, manufacturing, and distributing the highest-quality vehicle control parts.

The 145,000 square-foot Bialystok, Poland facility is dedicated to engineering and manufacturing the highest-quality vehicle control parts for the traditional automotive aftermarket and non-Aftermarket end-market applications through our Engineered Solutions division (SMPEngineeredSolutions.com).

This facility’s unique capabilities also enable us to serve non-traditional markets like agricultural, industrial, commercial and heavy equipment, as well as the passenger vehicle markets.

The plant is IATF 16949, ISO 9001 and ISO 14001-certified and serves as a basic design and engineering center for advanced products. Featured are ignition coils including plug top coils and pencil coils, a variety of switches and sensors that include soot, speed and position, temperature and pressure, as well as a range of variable valve timing solenoids and cylinder deactivation solenoids. Multi-spindle winding, injection molding, potting, curing and welding are part of the vertically integrated manufacturing process.

All products manufactured at SMP® Poland go through a full spectrum of measurement and life testing in addition to a full range of environmental analysis that includes thermo shock, thermo cycling, salt spray, vibration, storage tests and more.

Budapest, Hungary

Nissens

Budapest, Hungary

Data and Analytics - NissensOur Budapest, Hungary Nissens office operates as a global center for data and analytics.

Nissens Budapest offices supports multiple key functions of the aftermarket business including product cataloging, product research, data integrity, pricing, and Business Intelligence. This location is critical to Nissens data-driven approach used to better serve key customers.

Čachtice, Slovakia

Nissens

Čachtice, Slovakia

Manufacturing - NissensOur IATF and ISO certified Nissens location in Cachtice, Slovakia is dedicated to producing aluminum heat exchangers.

This 91,000 square foot, ISO 9001 and IATF 16949-certified manufacturing facility produces aluminum heat exchangers for multiple light vehicle and heavy-duty applications. The factory also produces aluminum heat exchangers and cores for a variety of industrial applications.

Nissens' manufacturing presence in Europe is central to its business strategy, enabling the company to deliver exceptional product quality while minimizing lead times. This commitment enhances operational efficiency and strengthens its position as a trusted partner in the global aftermarket.

Disputanta, VA

Vehicle Control

Disputanta, VA

Distribution Center - Vehicle ControlOur large and efficient Vehicle Control Distribution Center consistently delivers our high-quality products accurately and on time.

Most of our Vehicle Control supply is shipped from the SMP distribution facility in Disputanta, Virginia. The facility averages an impressive $3.2 million and 45,000 lines per day, providing significant distribution capabilities for SMP.

Our Virginia distribution facility occupies more than 400,000 square feet under one roof and includes our dedicated, on-site packaging department. The space allows the Vehicle Control Division to maintain finished goods and bulk inventory, featuring efficient Pack to Order (PTO) and Label to Order (LTO) systems for a multitude of brands. Orders are picked utilizing a state-of-the-art voice-directed hands-free technology. Picking efficiency is precisely monitored utilizing voice-directed and hands-free picking technology.

Taking advantage of the most modern inventory management systems and collaborative customer planning, the Virginia distribution center maintains a very accurate demand forecast providing consistently high fill-rates and rapid order turnaround which makes us the best full-line, full-service supplier of premium Vehicle Control products within the industry.

Edwardsville, KS

Vehicle Control Wire & Cable

Edwardsville, KS

Distribution Center - Vehicle Control (Wire & Cable)Our modern pack-to-order system in Edwardsville, Kansas efficiently serves many high-quality wire and cable brands.

Edwardsville, Kansas provides distribution to the Wire and Cable division as well as the ACI® Window Lift division. This 363,000 square-foot facility also houses research and development, design, and engineering for the wire and cable lines.

Our dedicated, on-site packaging department maintains a bulk inventory, so we can operate an efficient pack-to-order system that serves many brands. Knowledgeable engineering and marketing personnel assist our many traditional and retail customers. They are also available to review and quote special market needs, including farm and industrial applications.

The Edwardsville distribution center uses the most modern inventory management systems and collaborative customer planning. It maintains a very tight and accurate forecast-to-demand process providing consistently high fill-rates and rapid order turnaround. Orders are picked utilizing a state-of-the-art voice picking system, and picking efficiency is precisely monitored for accuracy.

Fort Lauderdale, FL

Vehicle Control

Fort Lauderdale, FL

Offices & Distribution Center - Vehicle ControlThe Fort Lauderdale facility uses the most modern inventory management systems and collaborative customer planning for complete inventory control.

Our Fort Lauderdale Vehicle Control Distribution Center is responsible for distributing and packaging Vehicle Control product. The facility is home to our Forecast Trading Corporation/Original Engine Management (OEM) division. It is our secondary Vehicle Control distribution center supporting our Disputanta, Virginia facility, enabling SMP to customize product stock for many smaller customers. Fort Lauderdale is also home to other product categories including filters, emissions, ignitions, switches and miscellaneous electrical products. We distribute brands under Master Pro, Import Direct, ValuCraft and about 20 other smaller private brands that are customer specific.

This dynamic facility occupies about 60,000 square feet in two side-by-side buildings, serving large and small customers. Approximately 80 employees provide customer service, product management, picking, packing and shipping. The vast space allows the Vehicle Control division to maintain a finished goods inventory and a bulk inventory, featuring efficient PTO and LTO (pack-to-order and label-to-order) systems for many brands.

We utilize a state-of-the-art electronic RF system. Picking efficiency is precisely monitored using voice-directed, hands-free picking technology. Our model involves stocking and packaging for many different brands which are shipped all over North America.

Foshan, China (CYJ)

Temperature Control Engineered Solutions

Foshan, China (CYJ)

Manufacturing – Temperature Control & Engineered SolutionsCYJ SMP specializes in the manufacturing of electric refrigerant compressors for the original equipment market.

In 2019, SMP acquired an interest in the Che Yijia New Energy Technology Co., Ltd. Founded in 2016, CYJ is a manufacturer of electric refrigerant compressors for mobile and stationary applications. Company operations include product design, development & validation and production processes including aluminum component machining, assembly, and final test. The annual compressor capacity is 500,000 units. Operations are IATF 16949 and ISO 14001 certified.

Foshan, China (FGD)

Temperature Control Engineered Solutions

Foshan, China (FGD)

Manufacturing – Temperature Control & Engineered SolutionsFGD SMP is a temperature control manufacturing facility that specializes in belt driven refrigerant compressors for the automotive aftermarket and the original equipment market

In 2017, SMP formed a joint venture with Foshan Guangdong Automotive Air Conditioning Co., Ltd, creating a new company called the Foshan FGD SMP Automotive Compressor Co., LTD. Company operations include product design, development & validation and production processes including aluminum component machining, assembly, and final test. The annual capacity is 750,000 units. Operations are IATF 16949 and ISO 14001 certified.

Foshan, China (Gwo Yng)

Temperature Control Engineered Solutions

Foshan, China (Gwo Yng)

Manufacturing – Temperature Control & Engineered SolutionsGwo Yng SMP is a Temperature Control Manufacturing Facility that specializes in the manufacturing of refrigerant accumulators, receiver driers, hose assemblies, battery heat exchangers, and switches for the automotive aftermarket, original equipment, and original equipment service markets.

In 2014, SMP formed a joint venture with Gwo Yng Enterprise Co., Ltd. The company is vertically integrated and its operations include product design, development & validation and production processes including aluminum extruding, stamping, component machining, assembly, powder coating, and final test. The annual combined hose assembly and accumulator/receiver capacity is 4,000,000 units. Operations are IATF 16949 and ISO 14001 certified.

Glinde, Germany

Temperature Control Engineered Solutions

Glinde, Germany

Distribution & Sales – Temperature Control & Engineered Solutions (SMP KADE GmbH)Glinde, Germany is home to SMP KADE GmbH, our sales office and supply chain hub for SMP Temperature Control business in Europe.

To efficiently serve the European automotive temperature control market, SMP acquired Kade Trading GmbH. SMP KADE GmbH is responsible for OE and IAM sales to A/C system manufacturers and renowned vehicle manufacturers from HD trucks, buses, building and construction machinery, cranes and as well agricultural machinery.

Products include air conditioning accumulators, filter driers, hose assemblies, switches, belt drive and electric compressors for the automotive aftermarket, original equipment and original equipment service markets. Growing markets include electric compressors for electric vehicles.

SMP KADE GmbH services the customers from the early development stage, through prototypes, and into the serial production.

Greenville, SC

Vehicle Control Engineered Solutions

Greenville, SC

Manufacturing - Vehicle Control & Engineered SolutionsSMP's large, state-of-the-art Greenville facility engineers and manufactures an array of precision components for distribution to traditional aftermarket and specialty vehicle markets.

SMP's 181,000 square-foot Greenville, SC facility offers complete engineering and testing operations along with vertically integrated manufacturing that develops and builds the industry’s finest fuel injectors, diesel injectors and pumps, mechatronic engine control components, and emissions components.

Through these vertically integrated manufacturing initiatives and standardized production processes, our Greenville facility was the first SMP plant to attain its ISO 9001 quality certification.

The state-of-the-art Greenville facility manufactures fuel injectors, idle air control valves, evaporative system integrity modules (ESIM), diesel exhaust fluid (DEF) modules, and diesel pressure regulators, and remanufactures diesel fuel injectors. These products are manufactured for distribution to the traditional aftermarket, original equipment and original equipment service market channels, industrial, marine and heavy-duty markets.

This plant is also responsible for fuel system innovations such as developing and manufacturing both Liquefied Natural Gas (LNG) Injectors and Compressed Natural Gas (CNG), which allows an engine to run on compressed natural gas, decreases foreign oil dependency and reduces greenhouse gas emissions.

Throughout our Greenville facility, we make a strong effort to recycle fluids, metals and all other reusable materials with a commitment to recycling all unused scrap parts so they may find a new life elsewhere.

Hong Kong

Vehicle Control Temperature Control

Hong Kong

Sourcing and EngineeringOur SMP Hong Kong location allows access to fairly priced product while providing engineering and quality control to ensure low cost still means high quality.

Hong Kong serves as the sourcing hub for our Asian markets. Our 2,600 square-foot Asian Sourcing Offices include an expert Engineering and Sourcing team in Hong Kong, China and also in Taiwan.

Our Hong Kong office receives significant U.S. headquarters support that includes a dedicated Director of Resale and International Sourcing, a 20,000 square-foot engineering laboratory and test facility and a dedicated staff of engineers and engineering technicians to ensure excellent quality control.

Horsens, Denmark

Nissens

Horsens, Denmark

Nissens Headquarters and Development LaboratoryOur Horsens Demark facility serves as the global headquarters of Nissens Automotive performing multiple functions including sales administration, supply chain logistics and product development. This location features testing capabilities, warehousing and distribution as well as both manufacturing and remanufacturing.

Serving as the global headquarters for Nissens, this location houses multiple cross-functional teams responsible for the strategy and day-to-day operations of Nissens.

This ISO 14001:2015-certified facility includes a 16,000-square-foot testing lab used to qualify and validate the quality of new products and continuous production by testing performance and durability, as well as corrosion testing, electrical testing, material testing and more. This lab performs over 2,300 unique tests every year

Additionally, the facility includes Nissens' central warehouse with automated and semi-automated capabilities. A total of nearly 250,000 square feet is spread across two locations in the Horsens facility servicing the Nissens global supply network, and handling deliveries to customers and Nissens' subsidiaries with an operational capacity of 200,000 pieces distributed monthly.

Copper and brass heat exchangers are produced at this facility for all vehicle segments, including heavy-duty commercial, agriculture, and more. The facility is able to deliver customer-specific cores or coolers within 24 hours. The Nissens' factory workshop is also housed here and is capable of remanufacturing heat exchangers for a variety of heavy-duty, agricultural and construction applications.

Independence, KS

Vehicle Control Engineered Solutions

Independence, KS

Manufacturing - Vehicle Control and Engineered SolutionsOur Independence, Kansas facility is dedicated to manufacturing state-of-the-art vehicle components through vertically integrated and lean manufacturing techniques.

With 390,000 square feet of space, SMP's Independence facility produces a wide variety of automotive electronics including sensors, controllers, switches, regulators and other ignition components. SMP’s Independence Plant is honored to produce parts under our Vehicle Control Division for our traditional aftermarket and in addition, excited to produce Engineered Solutions products to be distributed to the original equipment and original equipment service market channels as well, industrial, marine and heavy-duty markets. This expansive facility provides complete engineering and R&D support along with an exhaustive testing operation. The facility is proudly IATF 16949 and ISO 14001 (environmental) certified. Our Engineering group utilizes CAD/CAE/CASE tools to create and implement cutting-edge designs.

We make a vigilant effort throughout our plant to recycle fluids, metals and any other reusable materials. We recycle all oil, paper, steel, precious metals and corrugated materials. We also have a wastewater treatment area for our plate and paint departments.

Irving, TX

Vehicle Control Temperature Control Wire & Cable

Irving, TX

SMP Training CenterAt our award-winning SMP Training Center in Irving, Texas, we lead the way in advanced diagnostics and hands-on training for the professional automotive technician.

Located only 10 minutes from the Dallas-Fort Worth International Airport, SMP maintains a 14,000 square-foot facility that focuses on the design, development and delivery of Vehicle Control and Temperature Control training for aftermarket technicians and customer sales forces.

Developed by professionals focusing on the professional aftermarket technician, our training is customized to suit our technicians’ needs. We meet technicians face-to-face in the classroom, online and on social platforms to cover today’s hottest topics. There, we help them repair vehicles right the first time to be more successful and profitable. Equipped with the most current diagnostic equipment, this facility supports an 8,000 square-foot shop, two modern and comfortable classrooms, engineering testing, 360° catalog imaging, Temperature Control tech lines, and a virtual training studio. The space also houses the administrative and office space required to support all aspects of our salesperson and technician training.

With a staff of 20 professional trainers and developers, SMP presently provides five different technician and salesperson training programs. Standard® Pro-Training On-Site comes to technicians, delivering world-class training at a convenient location. Pro Training Live-Virtual offers interactive virtual sessions for ease of access, while Pro-Training On-Demand features a full library of training sessions to fit any busy schedule. Standard’s Masters Series is held in Texas, inviting technicians to train hands-on at our state-of-the-art training center. Finally, Power Hour offers technicians free training on their lunch breaks, to build on existing knowledge and train for success.

Kirchheim unter Teck, Germany

Engineered Solutions

Kirchheim unter Teck, Germany

Engineering, Sales, Distribution - Engineered SolutionsThe Stabil facility, located in Germany, brings expertise and proven abilities to deliver differentiated, high-quality products that complement SMP.

This 28,000 square-foot Kirchheim unter Teck facility, located in heart of the German automotive region around Stuttgart, became part of SMP with our 2021 acquisition of Stabil. This plant is dedicated to the highest-quality engineering, product development, sales and distribution of vehicle control and other auxiliary automotive parts. The majority of products manufactured at our Stabil Hungary plant are shipped from this location.

All parts at our Kirchheim unter Teck facility are engineered to the highest original equipment and original equipment service standards. Our unique capabilities allow us to also serve a variety of non-traditional markets like agricultural, industrial, commercial and heavy equipment, as well as passenger vehicles markets.

This IATF 16949, ISO 9001 and ISO 14001-certified facility provides basic product design for switches and sensors including speed, position, temperature and level — many of these being smart sensors. Additionally, the engineering center is responsible for various electronics, functional modules, high-technology plastic parts and connecting elements such as clamps.

Taking advantage of the most modern inventory management systems and collaborative customer planning, our Stabil distribution center maintains accurate demand forecasting to deliver consistently high fill-rates and rapid order turnaround to all locations throughout Europe.

The Kirchheim unter Teck facility supports SMP’s Engineered Solutions division (SMPEngineeredSolutions.com) that delivers custom-engineered solutions to vehicle and equipment manufacturers across diverse global end markets, including both on-highway and off-highway applications such as commercial vehicles, construction and agricultural equipment, power sports, and others.

View Supplier InformationLewisville, TX

Temperature Control

Lewisville, TX

Temperature Control Headquarters and Distribution CenterOur detailed forecast-to-demand process and collaborative customer planning allows our SMP Lewisville distribution center to consistently provide on-time shipping and high fill rates, even during the peak demand season.

The Temperature Control division facility covers 430,000 square feet and houses our Temperature Control corporate offices and warehouse distribution center. Utilizing advanced systems and technology, we create an accurate forecast of demand based on expectations presented by our expert in-house data analysts. The Lewisville distribution center is ISO 9001-certified. It maintains a firm grip on shipping and inventory control, efficiently processing and shipping more than $3 million in volume per day. When at capacity, during peak seasons, we regularly accommodate over 3,000 emergency orders per day.

A dedicated on-site packaging department allows the temperature control division to inventory in bulk and operate an efficient pack-to-order system serving many brands. Utilizing hands-free picking technology and RF system capabilities, orders are picked, consolidated, then audited for accuracy before getting shipped out on time.

Milwaukee, WI

Engineered Solutions

Milwaukee, WI

Manufacturing - Engineered SolutionsSMP's Trombetta facility, located in Milwaukee, WI, is an 84,000 square-foot fully equipped engineering, manufacturing and design center.

This 84,000 square-foot facility in Milwaukee, Wisconsin became part of SMP® with our 2021 acquisition of Trombetta. A worldwide leader in DC power switching and power management products for mobile equipment, this plant operates a full engineering and design center featuring engineering test labs and a manufacturing focus on contactors, solenoids and voltage regulators.

All parts at our Milwaukee facility are engineered and tested to the highest-quality original equipment and original equipment service standards. Our unique, vertically integrated component machining capabilities allow us to serve a variety of market channels including heavy duty, construction, agriculture, motorcycle, powersports, hydraulics, lawn & garden and other non-traditional markets.

These products are engineered by our highly skilled team to withstand the harsh conditions associated with the rigors of these specialty markets. All products are subjected to a full spectrum of measurement and life testing including accelerated life, thermal cycling, thermal and mechanical shock, vibration and more.

The Milwaukee facility supports SMP’s Engineered Solutions division (SMPEngineeredSolutions.com) that delivers custom-engineered solutions to vehicle and equipment manufacturers across diverse global end markets, including both on-highway and off-highway applications such as commercial vehicles, construction and agricultural equipment, power sports, and others.

The SMP® Milwaukee facility is ISO 9001 Certified, RoHS Compliant and UL Authorized.

Mishawaka, IN

Vehicle Control Wire & Cable Engineered Solutions

Mishawaka, IN

Manufacturing - Vehicle Control (Wire & Cable) & Engineered SolutionsOur SMP Mishawaka, Indiana facility specializes in manufacturing bulk ignition cable and wire sets that are distributed to both traditional and non-traditional markets.

We take pride in our Mishawaka facility’s lean manufacturing practices. This 160,000 square-foot facility is IATF 16949 and ISO 14001 certified and features the most automated wire manufacturing equipment. It employs a vertically integrated production process including custom silicone compounding, multi-core fabrication, inner jacketing, braiding and continuous vulcanization outer jacketing.

Our Mishawaka facility engineers and manufactures wire products for the original equipment, original equipment service, traditional automotive, high performance, industrial, marine and appliance markets.

Product quality, with reduced production costs, is maintained in each step of our process thanks to vertical integration. To alleviate inventory, many just-in-time and lean manufacturing strategies are applied for manufacturing products. To even further improve process and manufacturing flow, the plant holds three to four Kaizen ("continuous improvement") activities a year. Special market needs, including farm and industrial applications, are reviewed through our experienced Engineering staff located in Mishawaka and in our Edwardsville, Kansas facility.

Extensive testing at the Mishawaka facility includes UL, SAE and ISO performance tests, customer specific tests, product performance verification, product benchmarking, and silicone compound testing for tensile, tear, hardness, gravity, durometer and color.

Mississauga, Ontario, Canada

Vehicle Control Temperature Control Wire & Cable

Mississauga, Ontario, Canada

Distribution Center, OfficesOur Mississauga, Ontario location is the office headquarters and distribution centre for the SMP/Blue Streak® Canadian operation.

As the Canadian head office for both our vehicle control and temperature control divisions, the Mississauga location is home to our product management, marketing, customer service and finance groups. In addition, SMP’s 83,000 sq. ft. facility distribution centre in Mississauga inventories a full-line of vehicle control and temperature control products and serves as a single-point distribution centre to all of Canada with regionalized accessibility.

Taking advantage of the most modern inventory management systems and collaborative customer planning with supply chain excellence, the Ontario distribution centre maintains a very efficient and accurate forecast-to-demand process by providing consistently high fill-rates and rapid order turnaround. Along with complete inventory control, this division utilizes an advanced pack-to-order system, as well as private label programs in both vehicle control and temperature control applications.

Niepołomice, Poland

Nissens

Niepołomice, Poland

Highway Automotive Headquarters - NissensOur Niepolomice, Poland, facility operates as the headquarters Highway Automotive, a Nissens’ brand focused on heavy duty trucks and off-road vehicles.

The Highway Automotive headquarters is located in Niepołomice, near Kraków, in southern Poland. The complete, standalone facility houses multiple cross-functional teams such as remanufacturing, sales, marketing, logistics, product management and procurement, administration, and includes a 75,000 square-foot distribution facility.

The Highway brand specializes in thermal control and emission control systems, providing customers with comprehensive solutions in the truck, bus, and off-road segments. Highway Automotive and its Poland facility became part of the SMP family in 2024 as part of SMP’s acquisition of Nissens Automotive Group.

Plewiska, Poland

Nissens

Plewiska, Poland

Distribution Center - NissensSMP’s Plewiska, Poland, facility operates as a distribution center for the global Nissens supply network, including European subsidiaries and customers.

Located in Plewiska, Poland, the Nissens European central warehouse is a distribution center strategically located in western Poland, a convenient distance from major transport connections. This 220,000-square-foot facility distributes 200,000 pieces each month monthly shipping to both Nissens’ local DCs and directly to Nissens’ European distribution partners.

Poznań, Poland

Nissens

Poznań, Poland

Global Marketing - NissensLocated in Poznań, Poland, this facility leads Nissens Global Marketing initiatives.

Nissens’ global marketing initiatives are driven by a team marketing professionals in our Poznań,office. Connected to the local Nissens sales office, all marketing and advertising programs are initially created here before being shared with local sales offices and local markets for adaption and implementation. This location shapes the strategic direction for all major marketing initiatives while providing the local offices with the assets required to facilitate effective promotions tailored to a specific country or market.

Pécel, Hungary

Engineered Solutions

Pécel, Hungary

Manufacturing - Engineered SolutionsOur Pécel, Hungary Stabil facility specializes in manufacturing high-quality vehicle control components.

This 34,000 square-foot facility in Pécel, Hungary joined SMP with our 2021 acquisition of Stabil. The plant is dedicated to the highest-quality manufacturing of vehicle control and other auxiliary automotive parts.

All parts from our Pécel facility are engineered and manufactured to the highest-quality original equipment and original equipment service standards. Our advanced capabilities also allow us to serve a variety of non-traditional markets like agricultural, industrial, commercial and heavy equipment, as well as passenger vehicle markets.

The plant is IATF 16949 and ISO 9001 and ISO 14001 certified and serves as a basic design and engineering center for a variety of switches and sensors including speed, position, temperature and level — many of these being smart sensors. Additionally, this manufacturing center is responsible for a variety of electronics, functional modules and high-technology plastic parts. Injection molding, potting, curing, welding, hot-melt technology, PCB soldering, press fit and splicing are part of the vertically integrated manufacturing process.

All products manufactured at our Stabil Hungary facility go through a full spectrum of measurement and life testing in addition to a full range of environmental analysis that includes thermo shock, thermo cycling, salt spray, vibration and storage tests.

The Pécel facility supports SMP’s Engineered Solutions division (SMPEngineeredSolutions.com) that delivers custom-engineered solutions to vehicle and equipment manufacturers across diverse global end markets, including both on-highway and off-highway applications such as commercial vehicles, construction and agricultural equipment, power sports, and others.

Reynosa, Mexico (Temperature Control)

Temperature Control

Reynosa, Mexico (Temperature Control)

Temperature Control ManufacturingOur state-of-the-art facility allows for complete control of the manufacturing process from core inspection through packaged product.

A part of the Temperature Control division of SMP, our 100,000 square-foot Reynosa, Mexico facility manufactures and distributes a complete line of replacement climate control products specializing in the remanufacturing of import and domestic automotive air compressors. Lines manufactured in the Reynosa facility include Four Seasons, Hayden, ACI, Maxair and CompressorWorks. The Reynosa facility is ISO 9001 certified.

Undergoing strict quality control processes, all parts are factory-tested. Cores are inspected, pre-qualified and processed in a pre-wash. There are numerous wash and inspection stages before the core is re-qualified and moved to the assembly stage. After assembly, the unit must pass four quality tests in order to move forward — the function test, vacuum test, pressure test and the leak check tank. Only then can the product move forward to the final wash and pulley installation. Inspectors randomly sample and pull finished compressors from the paint line to run them on a durability test for at least 21 hours before the product can be shipped. This facility makes a concerted effort to recycle metals, fluids and all other reusable materials. Even coolant is reused after it has been filtered, and water is treated. As a result of these and other initiatives, Four Seasons holds the ISO 14001 certification of environmental management.

Reynosa, Mexico (Vehicle Control)

Vehicle Control

Reynosa, Mexico (Vehicle Control)

Vehicle Control ManufacturingEvery SMP product undergoes a comprehensive quality control regimen that includes extensive computer-controlled tests.

Our Vehicle Control division in Reynosa, Mexico, also known as Vehicle Control de Mexico, assembles switches, sensors, ignition components and many other components for our Engineered Solutions customers and Engineered Solutions service market channels as well as to the traditional aftermarket, industrial, marine and heavy-duty markets. In particular, the plant produces emission controls, EGR valves, IACs, transmission temperature senders, cam/crank sensors, caps and rotors, points and condensers, fuel pressure regulators, oil pressure sensors, throttle body regulators, accelerator pedals sensors, connectors, throttle position sensors, solenoid switches, PCV valves, filter housings, steering angle sensors, ignition switches, trailer connectors, ball precision switches, and canister vent valves. Our facility is ISO 9001-2015-certified and has received numerous awards and recognition for its quality delivery systems. In this 147,000 square-foot facility, SMP assembles a wide variety of automotive electronics, emission controls, electromechanical components, camshaft and crankshaft sensors, distributor caps and rotors, oil pressure senders and many other ignition components.

We make a concerted effort to recycle metals, plastics and any other reusable materials, such as copper, brass and other recyclable materials, for example our corrugated materials are separated and collected for recycling. Here at SMP Vehicle Control de Mexico, we are working towards receiving the coveted “Industria Limpia” federal certificate in the near future.

Reynosa, Mexico (Wire & Cable)

Wire & Cable

Reynosa, Mexico (Wire & Cable)

Manufacturing – Wire & CableThe SMP wire and cable facility in Reynosa, Mexico specializes in manufacturing and assembling ignition wires and battery cables for varied and extensive distribution.

In our 175,000 square-foot, IATF 16949 and ISO 9001-certified, high-volume facility, the entire operation, from raw material through custom packaging, is under strict quality control. In addition to producing the highest quality battery cables, our custom ignition wire sets undergo a rigorous design and manufacturing process. At the assembly stage, ignition wires are cut to length from reels of SMP’s own manufactured cable. Our cable is manufactured with automated wire manufacturing equipment that utilizes a vertically integrated production process that includes custom silicone compounding, multi-core fabrication, inner jacketing, braiding and continuous vulcanization outer jacketing. The assembly process includes all phases of production from cutting and stripping to terminating, booting and thorough testing.

We terminate and boot wires to desired specifications and package accordingly. Extensive testing includes: SAE and ISO 3808 performance tests, customer specific tests, product performance verification, product benchmarking, and a complete battery of silicone compound testing.

In our Reynosa plant and others like it across the globe, a strong effort is made to recycle fluids, metals and all other reusable materials. Nearly 95% of all byproduct is recycled and reclaimed for use in additional industrial applications.

Shanghai, China

Nissens

Shanghai, China

Distribution Center and Quality Control - NissensSMP’s Nissens location in Shanghai, China serves as an Asian hub for quality control and global logistics

The facility includes dedicated teams for both quality control and logistics and ships more than 300,000 pieces each month.

Our 86,000-square-foot Shanghai facility’s logistical center supplies others Nissens facilities around the world and is also capable of delivering products directly to major distribution partners.

Sheboygan Falls, WI

Engineered Solutions

Sheboygan Falls, WI

Manufacturing - Engineered SolutionsThe Sheboygan, Wisconsin facility specializes in advanced electronic technology and CAN bus expertise.

Our 22,000 square-foot facility in Sheboygan Falls, WI joined SMP as part of our 2021 acquisition of Trombetta, a leader in DC power switching and power management products for mobile equipment. This location specializes in CAN bus-enabled technology with a full engineering, design and new product development center.

The focus at this advanced facility is engineering, production and assembly of circuit boards and high-integrity Controller Area Network (CAN) devices used in intelligent device networking. Our circuit board assembly lines are both flexible and dynamic, able to quickly adjust production levels to meet low, medium or high-volume demand.

Devices ranging from I/O modules to sensors, our CAN products are rugged and dependable and made for use on J1939, CANopen, and NMEA2000 CAN systems. All parts produced at our Sheboygan Falls facility undergo extensive functional testing, including the use of automated optical inspection equipment.

The Sheboygan Falls facility supports SMP’s Engineered Solutions division (SMPEngineeredSolutions.com) that delivers custom-engineered solutions to vehicle and equipment manufacturers across diverse global end markets, including both on-highway and off-highway applications such as commercial vehicles, construction and agricultural equipment, power sports, and others.

The SMP Sheboygan Falls facility is ISO 9001 Certified and RoHS Compliant.

St. Thomas, Ontario, Canada

Temperature Control Engineered Solutions

St. Thomas, Ontario, Canada

Manufacturing - Temperature Control & Engineered SolutionsOur Unimotor facility in Ontario, Canada specializes in manufacturing high-quality automotive temperature control motors.

As part of the SMP Temperature Control division, Unimotor, located in Ontario, Canada, specializes in manufacturing high-quality blower motors, cooling fan motors, brushless motors and condenser fan motors for the automotive aftermarket and as part of the SMP Engineered Solutions division manufactures products for Original Equipment, Original Equipment Service, Marine, RV, Military and Heavy Equipment Markets.

This modern 40,000 square-foot facility allows for numerous design capabilities including advanced 3D modeling, airflow performance and electrical magnetic interference. Our extensive testing and engineering allows development of new-model designs and allows us to solve unique application problems.

All of the products produced at our facility are 100% tested for functional performance and operational noise (in a sound booth) before they are permitted to leave our facility. Every stage of product development and manufacturing is subject to extensive quality control inspections to ensure all engineering and quality requirements are met. The facility is registered to ISO 9001 standard and has implemented a QOS (Quality Operating System) committed to the continuous improvement of all business processes.

Throughout the Unimotor facility, a conscientious effort is made to recycle fluids, metals and all other reusable materials. We recycle more than 80% of all waste generated throughout the facility. Waste and energy reduction plans are an important part of Unimotor's continuous improvement. The facility is registered to the ISO 14001 standard and is committed to meeting customer and regulatory requirements.

Taichung City, Taiwan

Vehicle Control

Taichung City, Taiwan

Manufacturing - TPMS SensorsOur Taichung City, Taiwan facility specializes in designing and manufacturing high-grade, high-tech TPMS (Tire Pressure Monitoring System) sensors.

SMP acquired an equity position in Orange Electronic Co. Ltd., located in Taichung City, Taiwan in early 2013. Averaging production of over a million sensors annually, the advanced and socially responsible facility in Taiwan has earned many international and national certifications including U.S. FCC, European E-Mark, Canada IC, Taiwan NCC and meets FMVSS138, SAE J2657, ISO9001, and IATF 16949 quality standards.

The engineers at the Taichung City, Taiwan facility specialize in market analysis and development for OE replacement sensors and TPMS. They continue to lead the way in engineering initiatives for some of our most highly sought-after products.

Tijuana, Mexico

Engineered Solutions

Tijuana, Mexico

Manufacturing - Engineered SolutionsOur Trombetta location in Tijuana, Mexico is dedicated to expert assembly and demanding quality control.

Our 30,000 square-foot Tijuana, Mexico Trombetta facility specializes in high-volume production assembly and distribution of regulators, electronic controls, solenoids and contactors. SMP Trombetta is a leading manufacturer of DC power switching and power management products for mobile applications.

Our expert team is dedicated to delivering the highest-quality product. Every part undergoes rigorous product validation through an extensive regimen of on-site laboratory testing.

The Tijuana facility supports SMP’s Engineered Solutions division (SMPEngineeredSolutions.com) that delivers custom-engineered solutions to vehicle and equipment manufacturers across diverse global end markets, including both on-highway and off-highway applications such as commercial vehicles, construction and agricultural equipment, power sports, and others.

The SMP Tijuana facility is ISO 9001 certified, RoHS Compliant, and UL Authorized.

Tilburg, Netherlands

Nissens

Tilburg, Netherlands

AVA Headquarters - NissensOur Netherlands facility operates as the headquarters of AVA, a Nissens Brand which delivers competitive cooling solutions to aftermarket customers.

Strategically located in one of the Netherlands’ key logistics centers, our 27,000 square-foot facility serves as a central hub for operations in the Benelux region, and as headquarters for the AVA brand. The 6,000 square-foot office space is utilized for product development, management, purchasing, warranty, customer service and marketing teams, working across regions to deliver quality products and services tailored to meet the needs of AVA’s distribution partners.

The facility also includes a 21,000 square-foot warehouse and has been part of the SMP portfolio since 2024.

Wuxi, China

Engineered Solutions

Wuxi, China

Manufacturing - Engineered SolutionsSMP's Trombetta location in Wuxi, China increases our global footprint with expert contactor manufacturing.

Our 39,000 square-foot Wuxi, China facility is dedicated to stringent quality control and focused on high-volume contactor assembly. This plant employs extensive on-site end-of-line and quality testing. SMP Trombetta is a leading manufacturer of DC power switching and power management products for mobile applications.

This strategic location provides SMP Trombetta with an expanded global manufacturing footprint, deep engineering talent and an experienced local Sales division with additional sales support in Shanghai.

The Wuxi facility supports SMP’s Engineered Solutions division (SMPEngineeredSolutions.com) that delivers custom-engineered solutions to vehicle and equipment manufacturers across diverse global end markets, including both on-highway and off-highway applications such as commercial vehicles, construction and agricultural equipment, power sports, and others.

The SMP Wuxi facility is ISO 9001 Certified and RoHS Compliant and UL Authorized.

Corporate Vehicle Control

Long Island City, NY

Corporate and Vehicle Control HeadquartersVehicle Control Engineered Solutions

Bialystok, Poland

Manufacturing - Vehicle Control & Engineered SolutionsNissens

Budapest, Hungary

Data and Analytics - NissensNissens

Čachtice, Slovakia

Manufacturing - NissensVehicle Control

Disputanta, VA

Distribution Center - Vehicle ControlVehicle Control Wire & Cable

Edwardsville, KS

Distribution Center - Vehicle Control (Wire & Cable)Vehicle Control

Fort Lauderdale, FL

Offices & Distribution Center - Vehicle ControlTemperature Control Engineered Solutions

Foshan, China (CYJ)

Manufacturing – Temperature Control & Engineered SolutionsTemperature Control Engineered Solutions

Foshan, China (FGD)

Manufacturing – Temperature Control & Engineered SolutionsTemperature Control Engineered Solutions

Foshan, China (Gwo Yng)

Manufacturing – Temperature Control & Engineered SolutionsTemperature Control Engineered Solutions

Glinde, Germany

Distribution & Sales – Temperature Control & Engineered Solutions (SMP KADE GmbH)Vehicle Control Engineered Solutions

Greenville, SC

Manufacturing - Vehicle Control & Engineered SolutionsVehicle Control Temperature Control

Hong Kong

Sourcing and EngineeringNissens

Horsens, Denmark

Nissens Headquarters and Development LaboratoryVehicle Control Engineered Solutions

Independence, KS

Manufacturing - Vehicle Control and Engineered SolutionsVehicle Control Temperature Control Wire & Cable

Irving, TX

SMP Training CenterEngineered Solutions

Kirchheim unter Teck, Germany

Engineering, Sales, Distribution - Engineered SolutionsTemperature Control

Lewisville, TX

Temperature Control Headquarters and Distribution CenterEngineered Solutions

Milwaukee, WI

Manufacturing - Engineered SolutionsVehicle Control Wire & Cable Engineered Solutions

Mishawaka, IN

Manufacturing - Vehicle Control (Wire & Cable) & Engineered SolutionsVehicle Control Temperature Control Wire & Cable

Mississauga, Ontario, Canada

Distribution Center, OfficesNissens

Niepołomice, Poland

Highway Automotive Headquarters - NissensNissens

Plewiska, Poland

Distribution Center - NissensNissens

Poznań, Poland

Global Marketing - NissensEngineered Solutions

Pécel, Hungary

Manufacturing - Engineered SolutionsTemperature Control

Reynosa, Mexico (Temperature Control)

Temperature Control ManufacturingVehicle Control

Reynosa, Mexico (Vehicle Control)

Vehicle Control ManufacturingWire & Cable

Reynosa, Mexico (Wire & Cable)

Manufacturing – Wire & CableNissens

Shanghai, China

Distribution Center and Quality Control - NissensEngineered Solutions

Sheboygan Falls, WI

Manufacturing - Engineered SolutionsTemperature Control Engineered Solutions

St. Thomas, Ontario, Canada

Manufacturing - Temperature Control & Engineered SolutionsVehicle Control

Taichung City, Taiwan

Manufacturing - TPMS SensorsEngineered Solutions

Tijuana, Mexico

Manufacturing - Engineered SolutionsNissens

Tilburg, Netherlands

AVA Headquarters - NissensEngineered Solutions

Wuxi, China

Manufacturing - Engineered SolutionsNissens

Alfajarín, Spain

Sales Office, Distribution Center - NissensNissens

Backa, Sweden

Sales Office, Distribution Center - NissensNissens

Balsall Common, Great Britain

Sales Office, Distribution Center - NissensNissens

Dell'Emilia, Italy

Sales Office, Distribution Center - NissensNissens

Dortmund, Germany

Sales Office, Distribution Center - NissensNissens

Grapevine, TX

Sales Office - NissensNissens

Kyiv, Ukraine

Sales Office, Distribution Center - NissensNissens

Lisses, France

Sales Office, Distribution Center - NissensNissens

Nagytarcsa, Hungary

Sales Office, Distribution Center - NissensNissens

Olive Branch, Mississippi

Distribution Center - NissensNissens

Poznań, Poland

Sales Office, Distribution Center - NissensNissens

Turku, Finland

Sales Office, Distribution Center - NissensNissens

Unterentfelden, Switzerland

Sales Office, Distribution Center - NissensNo locations found