Bialystok, Poland

Manufacturing - Vehicle Control & Engineered Solutions

Our Bialystock, Poland facility is dedicated to engineering, manufacturing, and distributing the highest-quality vehicle control parts.

The 145,000 square-foot Bialystok, Poland facility is dedicated to engineering and manufacturing the highest-quality vehicle control parts for the traditional automotive aftermarket and non-Aftermarket end-market applications through our Engineered Solutions division (SMPEngineeredSolutions.com).

This facility’s unique capabilities also enable us to serve non-traditional markets like agricultural, industrial, commercial and heavy equipment, as well as the passenger vehicle markets.

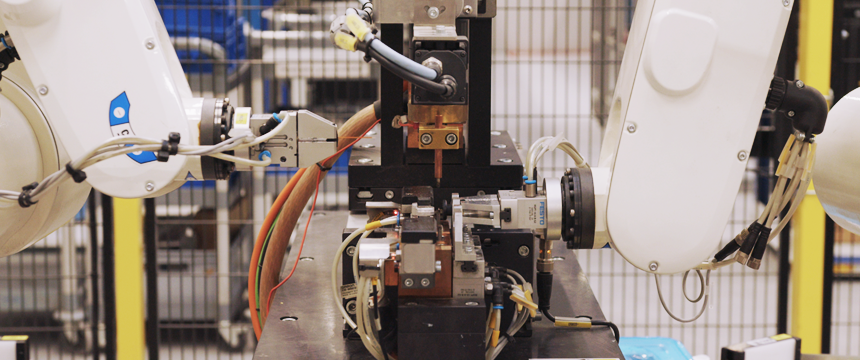

The plant is IATF 16949, ISO 9001 and ISO 14001-certified and serves as a basic design and engineering center for advanced products. Featured are ignition coils including plug top coils and pencil coils, a variety of switches and sensors that include soot, speed and position, temperature and pressure, as well as a range of variable valve timing solenoids and cylinder deactivation solenoids. Multi-spindle winding, injection molding, potting, curing and welding are part of the vertically integrated manufacturing process.

All products manufactured at SMP® Poland go through a full spectrum of measurement and life testing in addition to a full range of environmental analysis that includes thermo shock, thermo cycling, salt spray, vibration, storage tests and more.